3.4.5 Making operational decisions to improve performance: managing inventory and supply chains

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

32 Terms

Define Outsourcing (also known as subcontracting)

The use of an external organisation to complete part of or all of an activity in the production process/used to deal with unexpected increase in demand

Outsourcing pros (x2)

Allows business to focus on areas of core competence

Allows a business to increase production levels to beyond there capacity

Outsourcing cons (x2)

Issues with quality

Supplier may charge a higher price

Define part time staff

Permeant members of staff that work fewer then 30 hours a week

Define Temporary staff

Staff employed on a short term-basis often at specific times during the year

Part time/temporary staff pros (x2)

Give business flexibility

May incur lower costs

Part time/temporary staff cons (x2)

Introduction and training costs

The skill of the part time/temporary staff

Define Producing to order

Where products are manufactured only after an order has been placed by a customer e.g. new cars/sandwiches

Producing to order pros (x2)

Lower level of wastage

High level of customer satisfaction

Producing to order cons (x2)

Difficult to deal with unexpected changes in demand

Customer need to wait for the product

Define inventory control

The management of organisations level of stock to enable it to match the supply to the demand

Stock includes e.g. (x2)

Raw materials

Finished goods

Pro high level of inventory (x2)

Meet unexpected changes in demand

Able to benefit from bulk buying of raw materials (economies of scale)

Pro low level of inventory (x2)

Low costs incurred in storing and securing raw materials

Less money tied up in working capital

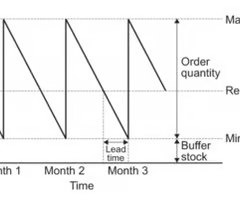

Define inventory control charts

A diagram used to represent an organisation's stock levels over a period of time

Inventory control charts: Re- order level

The stock level that triggers the purchase of new inventory

Inventory control charts: Lead time

The time taken for a supplier to deliver an order once it has been placed

Inventory control charts: Buffer level at inventory

The target minimum level of inventory to be held by a business

Inventory control charts: Re- order quantity

The amount of stock a business orders

Influences on the levels of inventory held (x4)

Production techniques (i.e. use of mass production/JIT)

Reliability of suppliers

Anticipated levels of demand

Finance

Stock managment techniques (x3)

Stock rotation

Reduction in security

Production techniques

Influences on choice of supplier (x3)

Quality: The experience of the customer when receiving the goods

Price: How much the business will pay for supplies which will directly affect costs

Capacity: The ability to meet demand at a constant quantity and on time

Define Suppliers

Organisations in the supply chain who provide goods and services used in the production process

Businesses rely on supplies to

Supply the necessary good: At the time they are needed/in the required quantity

Impact on operational performance measured via (x4)

Unit cost

capacity utilisation

flexibility

quality

Define Inventory

Refers to the stock a business has

Define supply chain

System of people, organisations , and information involved in the process of producing products and satisfying consumer demand

Managing a supply chain: specialisation

Where each organisation focuses on its core competence within the supply chain

Managing a supply chain pro (x2)

Increase focus on core competence

Increase efficiency

Define vertical integration

Where an organisation manages the whole supply chain

Vertical integration pro (x2)

Reduce raw material price

Increase security of suppliers

Value of managing supply chain

Impact on: unit cost , capacity utilisation , flexibility and quantity