Chapter 9 - Polymers

1/53

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

54 Terms

Polymers

Termed as plastics

cheap

easy to manufacture

versatile

Polymer structure

Made up of many monomers, covalently bonded

Plastic

Ability to be molded into different shapes readily

Addition Polymerisation

C=C double bonds break and go to the side, to attach with other molecules

Naming For Polymer (In addtion reaction)

poly + name (e.g. polyethene)

Empirical formula of monomer

same as polymer

Properties Of Polymers

dispersion forces increase as molecule increases in size

lightweight

non-conductors of electricity

durable

versatile

acid-resistant

flammable

Low Density Polyethene (LDPE)

polymer is formed too fast for neat and symmetrical formation - goes off in branches

branches caused distance between chains, and cannot pack closely together

dispersion force becomes weaker

made in high temp (300 degrees), high pressure

Properties Of LDPE

non crystalline

more branching

low density

transparent

low dispersion forces

low melting point (e.g. cling wrap)

soft

non-conductor of electricity

High Density Polyethene

plastics made in:

low pressure, low temp

has fewer branches - molecules pack closer

more crystalline and ordered

allowed to form well, warm slowly and cool slowly - therefore stronger

Properties Of HDPE

high density

hard

relatively high melting point

crystalline sections

non-conductor of electricity

opaque (not clear) (e.g. milk bottles)

Vinyl Group

Inclusion of more electronegative atoms to increase the melting point (inclusion of chlorine instead of hydrogen)

PVC (Polyvinyl Chloride)

Inclusion of Chlorine so it is more durable

used in:

floors

pipes, plumbing

electrical wire insulation

medical tubing and blood bags

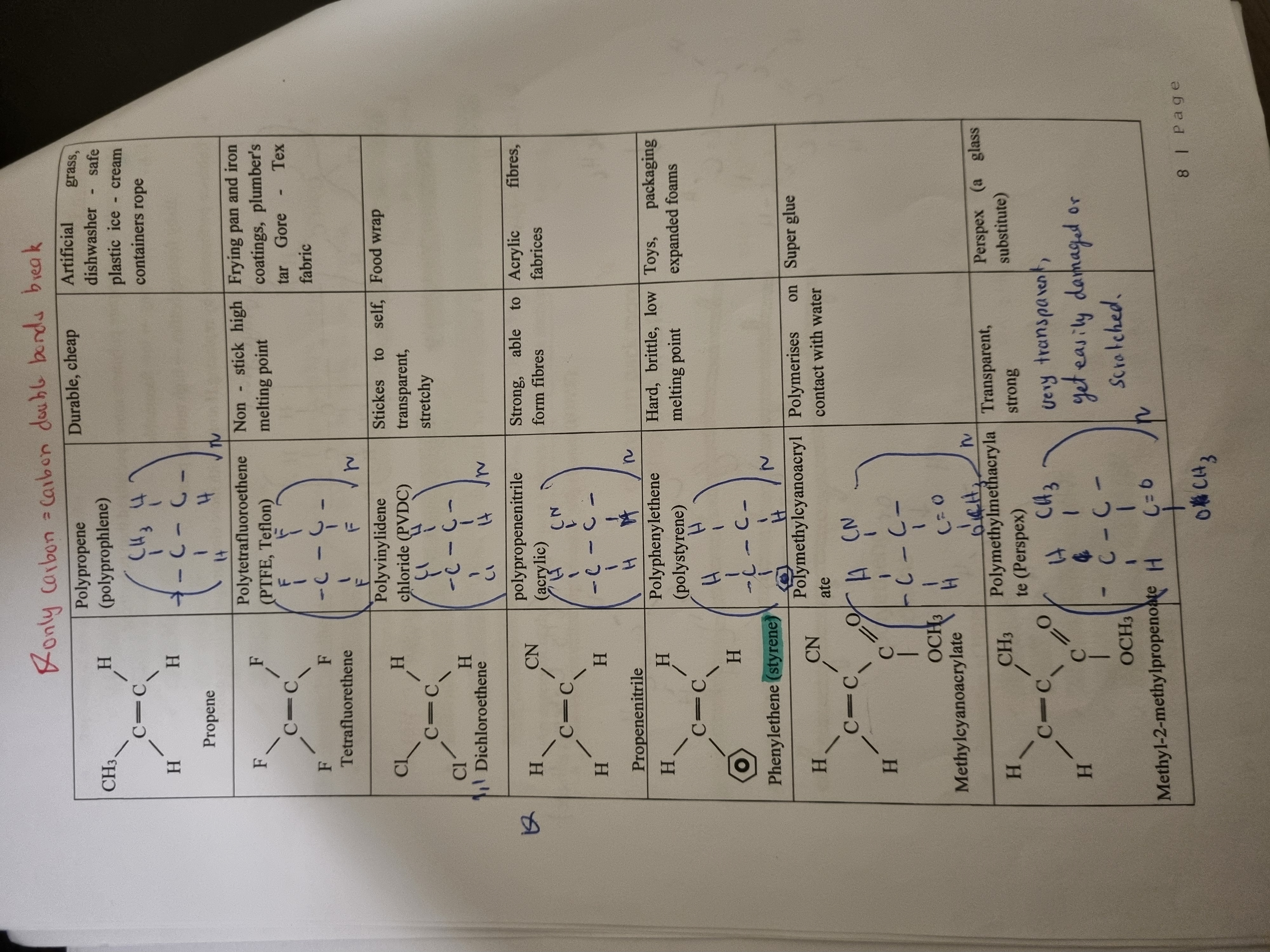

Common Polymers

Polypropene - artificial grass, dishwasher (durable and cheap)

Polytetrafluoroethylene (Teflon) - frying pan, iron coatings (non-stick high melting point)

Polyvinylidene (2 chlorines) - sticks to self, stretchy (food wrap)

polypropenenitrile - fabrics (strong, able to form fibres)

polyphenylethene (has benzene) - toys, packaging (hard, brittle, low melting point)

Polymethylcyanoacrylate - super glue - polymerises on contact with water

Perspex - glass substitute - transparent and strong

Three types of thermosetting polymers are

thermoplastic polymers - (i.e. PVC)

thermosetting polymers

elastomers

Thermosetting polymers (hard)

very hard and rigid (cannot be remoulded or reshaped once hardened)

have covalent cross links that form a rigid structure

are so strong that when tried to heat, monomer-monomer covalent bonds will also break

Char

used to make shatterproof crockery and saucepans

Thermoplastic Polymer (soft)

weak bonds between chains

can easily be remolded or reshaped

easily melts

has low melting point

Elastomers (In-between)

have occasional cross links, but are also soft

can “stretch” and elongate but return to original position.

e.g. tires, rubber bands

Condensation Polymerisation

When Two molecules with functional groups form, emitting water.

Forms Of Polyethene

UHMWPE - Ultra high Moleculecular Weight Polyethene (bullet proof vest, safety helmets)

LDPE

HDPE

Teflon

Tetraflurorethene

Teflon uses

Frying pans

medical implants

gear

gore-tex clothing (water proof, breatheable fabric)

Properties Of Teflon

Non-stick

Heat resistant

Good mechanical properties

Flame resistant

Chemical resistant

Polar Vs Non-polar Polymers

Polar : strong dipole-dipole forces and weak dispersion forces (stronger)

Non-polar: weak dispersion forces only

Co-polymers

combing two or more different monomers into one polymer

light weight, thermal insulator

allows light and heat to penetrate the glass

allows to get properties of both monomers

ABS

Used to make LEGO blocks

Rigid and strong

Can be melted

popular for 3D printing

Molten ABS is used to build solid objects

Conductive Polymers

Polymer-based circuits that allow electricity to flow as well as being insulative.

Photoconductive Polymers

Create electricity from light

light sensitive monomer - vinyl carbazole

Photoconductive polymer - polyvinyl carabazole

Side Group Of Monomers

Prevent the sliding of chains and stacking closely.

Prevent formation of crystalline structures

Polystyrene

has bulky side group “benzene”

is hard, brittle, but low density

used to make food containers, refrigerator parts and dvd cases

PMMA

large side groups

more malleable, less brittle

Plasticizers

Forcing polymers to form distanced, so that the plastic intentionally is made flexible and soft

Plasticizer in PVC

made more flexible

polymer made softer

normally is room temp

Foamed polymer

Blowing gas through melted polymer

used for “shock absorbing” lightweight, insularity

e.g. takeaway containers or foam

Reasons for Synthetic polymers

easier degradation

fater process

better for environment

Ways to produce biodegradable plastic

make condensation polymer

addign additives (e.g. transaition metals for food wrapping or shopping bags)

Enzyme

biological catalyst

breaks down covalent bonds (hydrolysis)

increases rate of reaction

Bio based

material partly derived from biomass

biodegradable

Organisms in the natural substance, actively breaking it down

compostable

process that distintegrates material leaving no poison in the soil (under 90 days)

PVA (how is it dissolvable)

adding OH group - making it dissolve in water

PETase

Adding of enzyme to PET, and breaks down the covalent bonds for faster degradation

attacks C-O bond.

Mechanical Recycling

Only for thermoplastics (soft)

Polymer structure is unchanged

molded into different products

only physical reshaping

Organic Reaction

Microbial (bacteria) breaks down polymer (hydrolysis)

condensation reaction forms polymers

hydrolysis breaks down polymers into monomers

natural decomposition

Chemical recycling

polymer structure is broken

“cracking” - polr bonds break and changes into smaller molecules

Turned into oils or basic molecules

Used for complex/contaminated plastics

Non compostable bio-polymer

ethene 1,2 diol

to make bioethanol from carbohydrates fermented with yeast

Bio based and compostable

are formed with starch

PLA - polylactic acid

Polyethene

sugar-glucose (ferments) - bioetehanol - biopolyethene

Sugar - bioethanol

sugar (hydrolysis) - glucose (fermentation) - bioethanol

Starch - bioethanol

Starch - sugar - glucose - bioethanol

Common uses of polymers

Why Is Gold Easy To Recycle

Maintains its purity over time

Doesn’t vigorously react with water or other compounds

preserves the energy from mining, and continuous mining for the resource.

What Is Nylon

A thermoplastic - can easily be remolded - covalent bonds are intact, but intermolecualr bonds break