Vapor-Liquid and Gas-Liquid Separation Processes

1/50

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

51 Terms

More volatile component is…

the one with the lower boiling point

Volatility equation

generally considered CONSTANT

Raoult’s Law

pi=xipi,sat

the partial vapor pressure of a solvent in a solution is equal to the vapor pressure of the pure solvent multiplied by its mole fraction in the solution

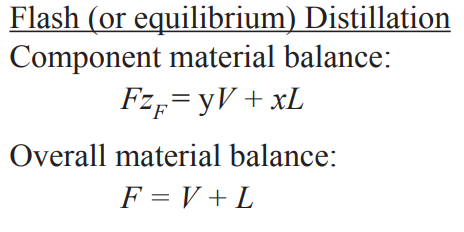

Binary flash (equilibrium) distillation (e.g. flash vessel, flash drum, etc.)

→ 6 DOF

energy balance: FHF + Qflash = VHV + LHL

Operating line for binary flash distillation

Fraction of feed vaporized (f)

f = V/F

Feed quality (q)

q = L/F

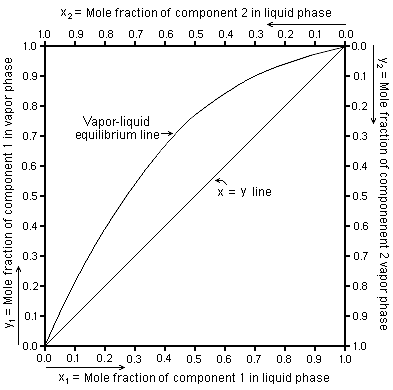

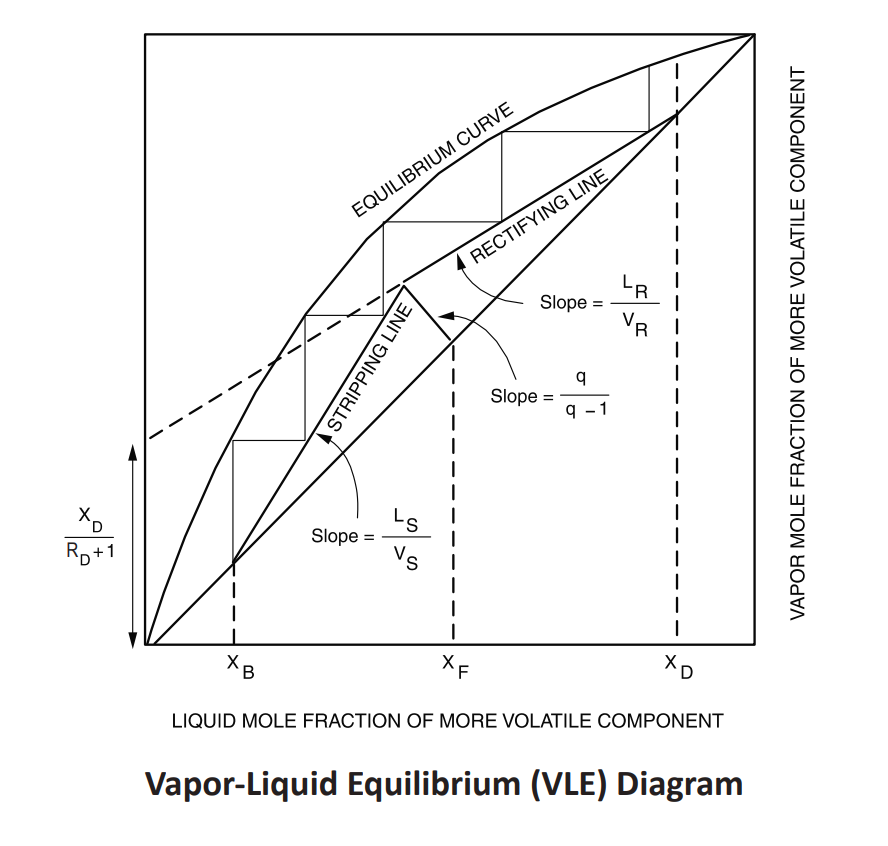

Vapor liquid equilibrium curve (sketch it!!!)

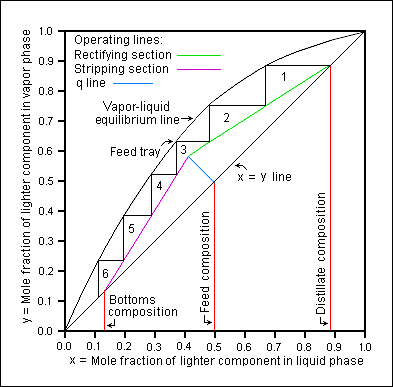

McCabe-Thiele diagram for binary flash distillation (sketch it!!!) → what assumption is required?

relies on the assumption of CONSTANT MOLAR OVERFLOW:

molar heats of vaporization of feed components are EQUAL

every mole condensed → a mole of vapor is condensed

heat & energy effects are negligible (processes adiabatic)

this can be expressed as:

Ln=Ln+1=…=LR

Vn=Vn+1=…=VR

Lm=Lm+1=…=LS

Vm=Vm+1=…=VS

→ w/ assumption, only need 1 operating line

Batch distillation (e.g. still of still pot)

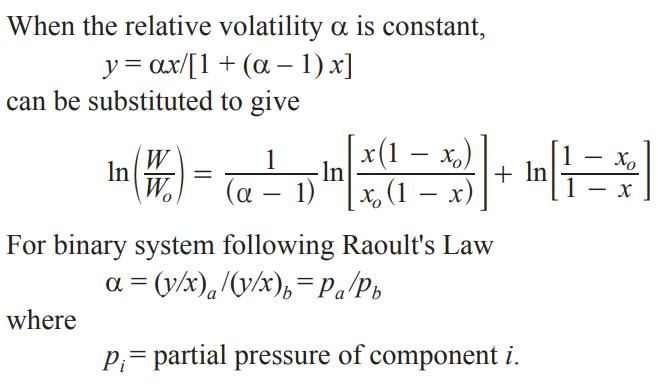

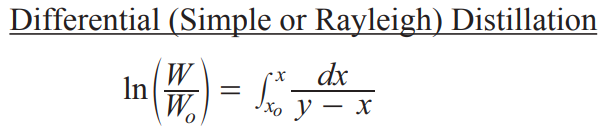

Differential (Simple/Rayleigh) distillation

simplest form of batch distillation → vapor is continuously removed from a liquid, and the composition of the vapor and the remaining liquid (residue) are calculated using the Rayleigh equation

Wo is initial charge

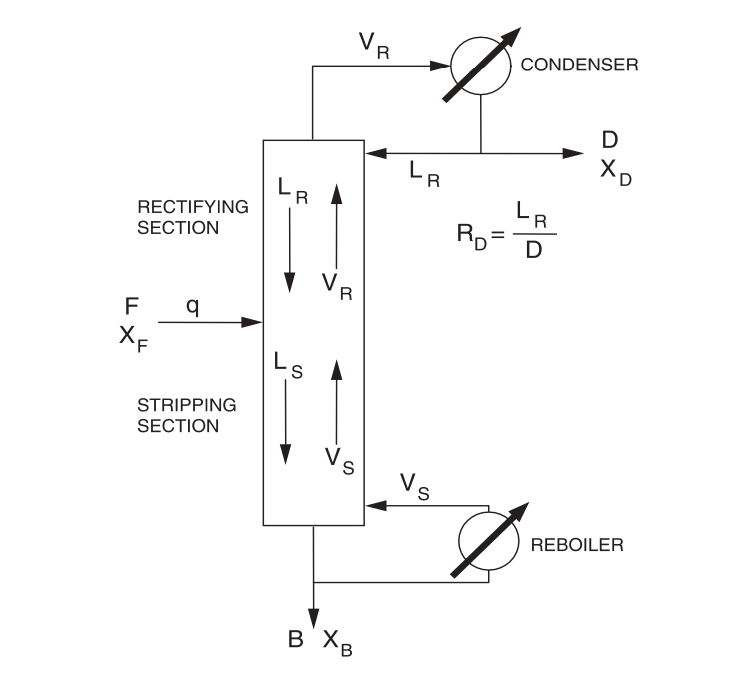

Continuous distillation (e.g. column distillation) → sketch it!!!

→ assumes vapor/liquid leaving each stage is in equilibrium

→ pressure drop between stages is negligible

→ stages operate at different temperatures

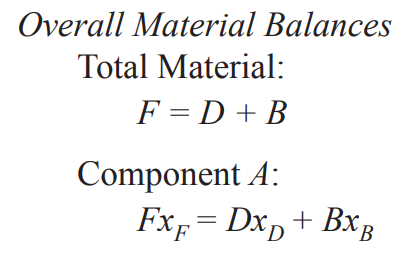

Distillate (D)

Overhead stream → contains a greater concentration of the volatile component

Bottoms (B)

Stream from bottom of column → contains greater concentration of the less volatile component

Partial condensor

operating equation is the same as total condenser

→ ALSO counts as a equilibrium stage at the top of the column (total condenser does not)

Partial reboiler

returns a portion of the bottoms to the column

→ counts as an equilibrium stage

Total reflux

hypothetical condition where all vapor is condensed and all bottoms are returned to column

→ maximum reflux ratio

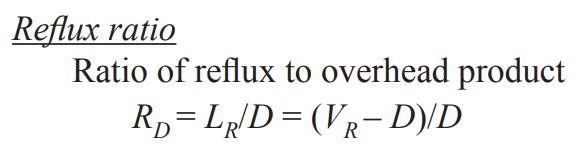

External reflux ratio (RD)

liquid reflux entering the first stage of distillation (LR) divided by distillate flow rate (D)

Internal reflux ratio (LR/VR)

liquid reflux entering the first stage of distillation (LR) divided by rectifying flow rate (VR)

= RD/(1+RD)

Minimum reflux ratio (Rmin)

reflux ratio that will result in an infinite number of stages

(graphically, this is where the top operating line touches the equilibrium curve → called pinch point)

Overall (molar) material balance for continuous distillation

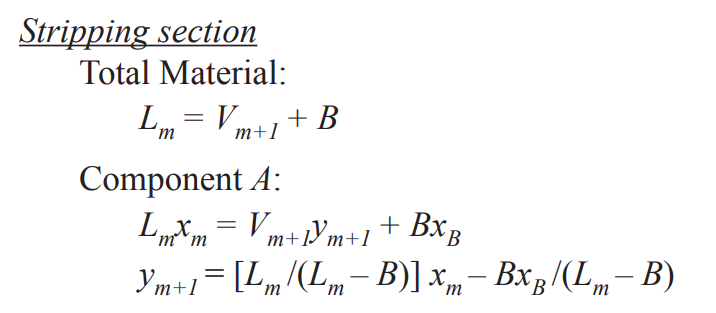

How are trays numbered? (n vs m?)

from to TOP → down

n : rectifying section

m : stripping section

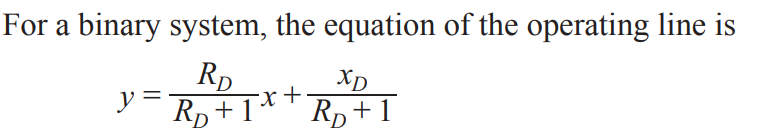

Rectifying (top) section material balance

Stripping section material balance

Operating lines

represents the mass balance relationship between liquid and vapor phases in a column, defined by a linear equation. In the common McCabe-Thiele method, there are two operating lines: one for the rectifying (top) section and one for the stripping (bottom) section

Equilibrium ratio (Kn)

= yn/xn

a function of composition, temperature, and pressure

Where does operating line intersect y = x line?

at y = x = xB

Stepping off stages

draw lines between equilibrium curve and the operating line

rectifying: start at xD and step DOWN

stripping: start at xB and step UP

feed stage location should be placed where operating lines intersect

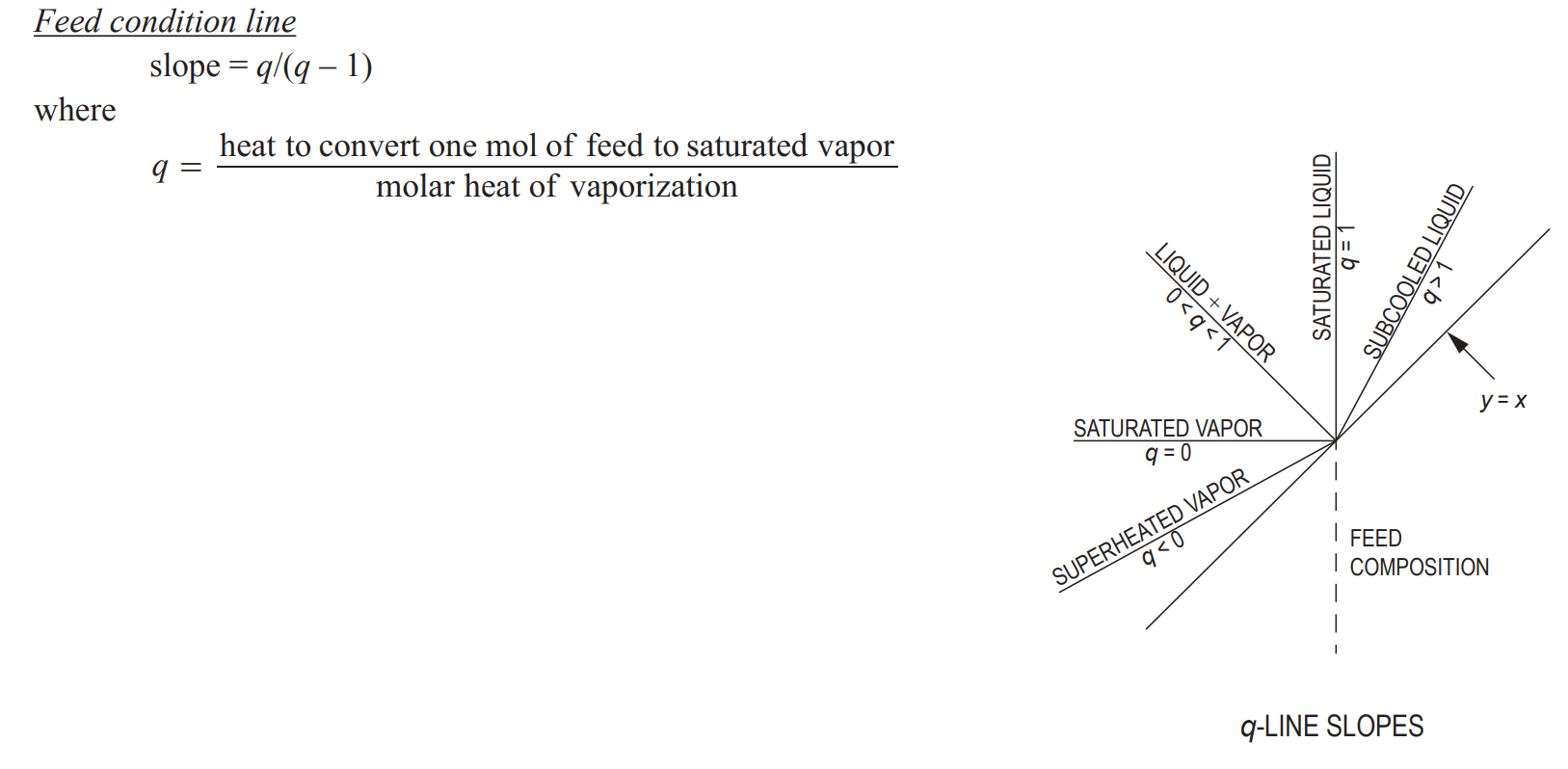

Feed quality (q)

fraction of the feed that remains LIQUID

Feed equation (q)

straight line

q = (hg - h)/hfg

where hfg is latent heat

Fraction of the feed vaporized (f)

complement of the feed quality

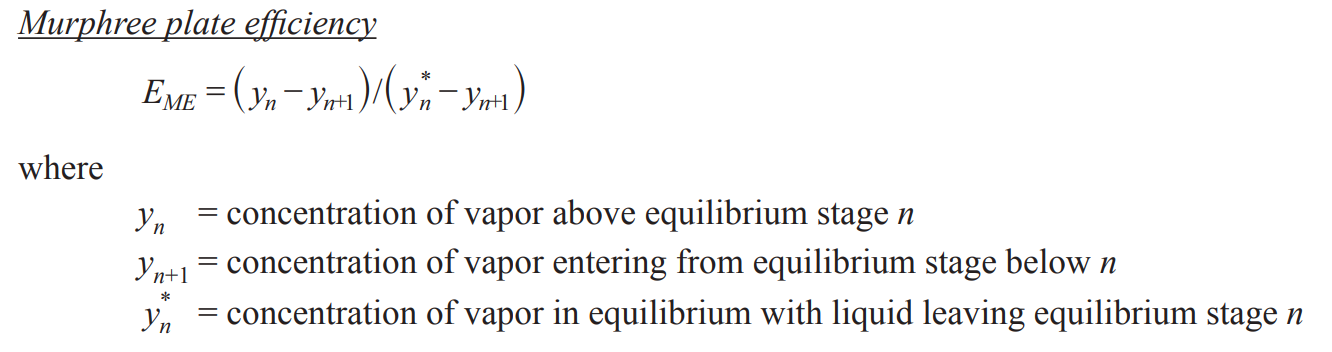

Murphree plate efficiency, EME

measure of deviation from actual liquid/vapor composition from ideal (equilibrium on every stage)

→ NOT the same as overall efficiency

Absorption (general)

component in gas stream (solute) is transferred into a stream of a nonvolatile liquid (solvent, separating agent)

→ purified gas is product

Physical absorption

a gas component has greater solubility in the solvent than in its original stream

Chemical (reactive) absorption

the gas component to be removed reacts with and stays with the solvent

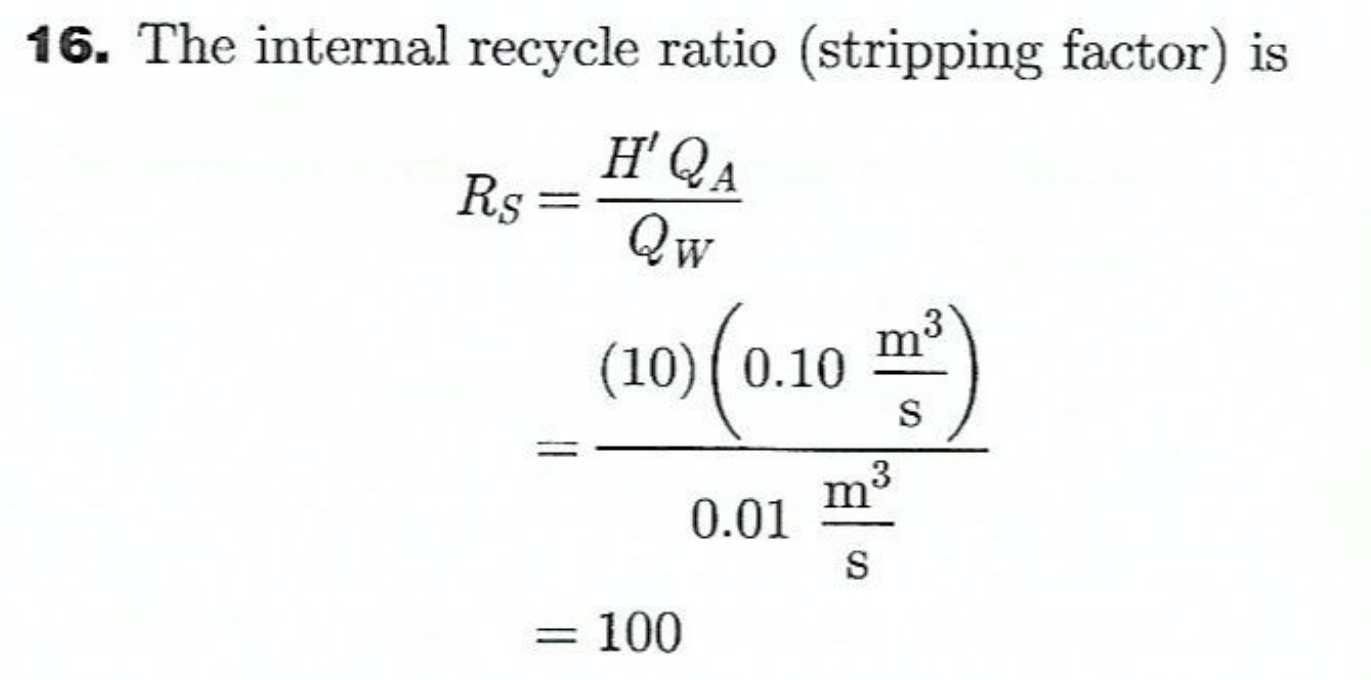

Stripping (desorption)

solute from liquid stream is transferred to an insoluble gas stream

→ purified liquid is product

absorption drives mass transfer here too!

Raffinate

purified flow

Extract

dirtied flow

Absorption/stripping in trayed columns: main assumptions

carrier gas is insoluble in the liquid phase

solvent is nonvolatile

the system is isothermal and isobaric

Benefits of trayed columns

can handle wider range of liquid and gas flows

performance and efficiencies predictions are better

easier to install cooling

easier to clean → can be used with liquids that cause fouling or contains solids

Henry’s law

the amount of a gas that dissolves in a liquid is directly proportional to the partial pressure of that gas above the liquid, at a constant temperature

→ valid for LOW solute concentrations and solute partial pressures (< 1 atm)

pA = H’xA

Benefits of packed columns

lower liquid residual (better for flammable or toxic liquids)

better with foaming fluids

less expensive

lower pressure drop

better suited for vacuum operations

What can we assume about pack column flow rates

solvent flow (Ls) and pure gas flow (Gs) are ~constant (NOT total liquid flow, L, or total gas flow, G)

Packing is characterized by what?

surface-to-volume ratio (a)

intrinsic volume drop

which is characterized by packing factor (Cf)

inversely proportional to packing size

HETP?

NEQ?

Height equivalent of a theoretical plate (common measure of efficiency)

Number of equivalent theoretical plates

Porosity (ε)

void fraction of packed bed

ε = (V of voids in bed)/(total V of bed)

Interstitial velocity (vi)

average velocity of fluid through the pores of the column → calculated from superficial velocity, vo

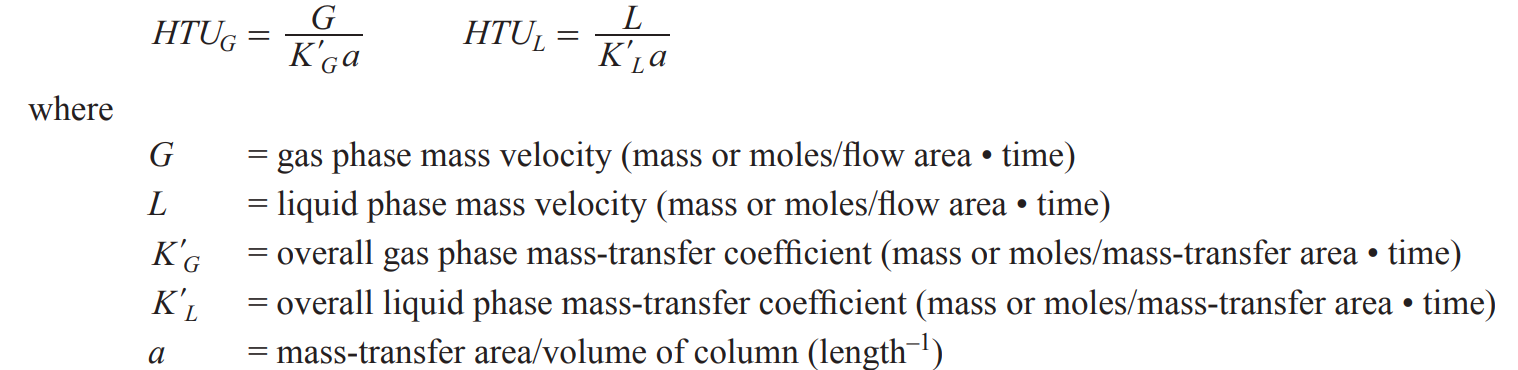

HTU

Height of transfer unit (the smaller, the more efficient the unit) → phase dependent

NTU

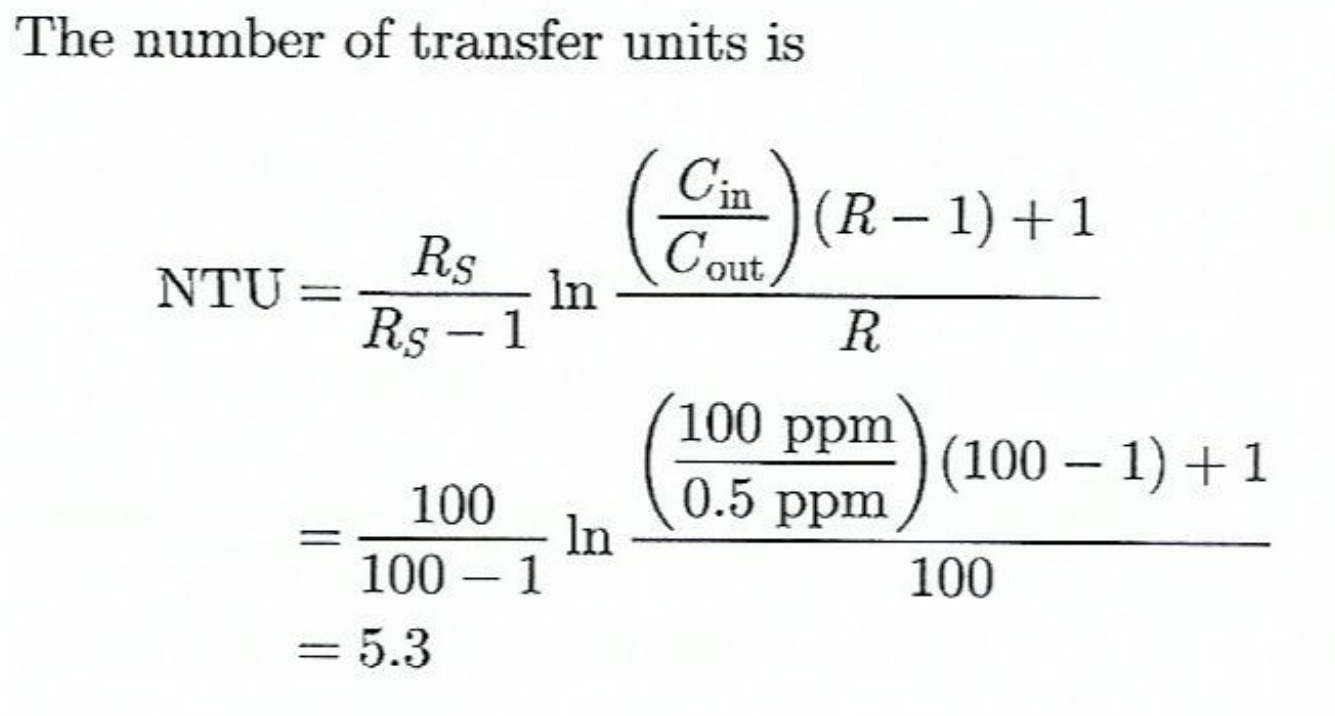

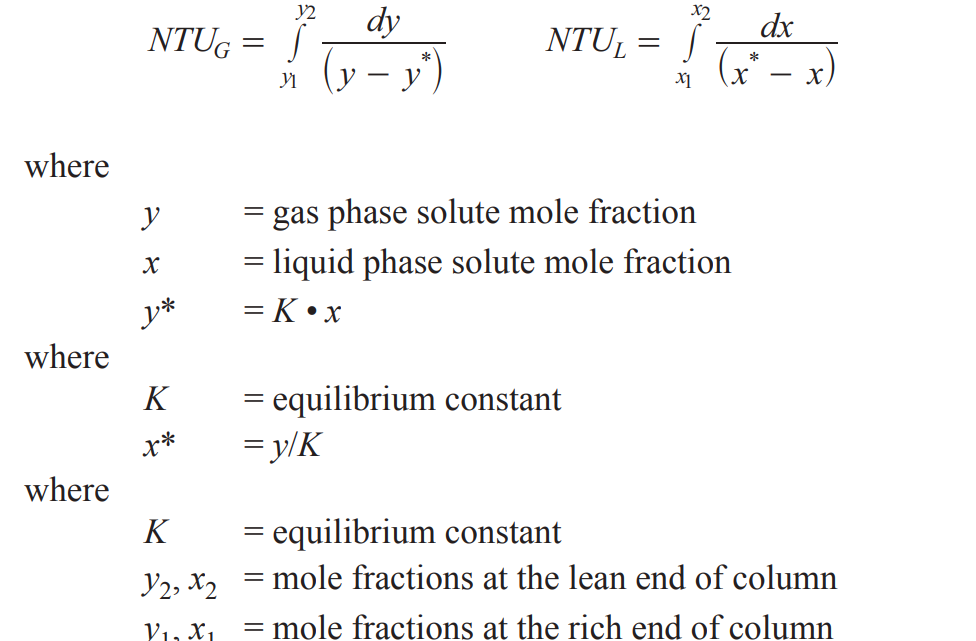

Number of mass transfer units → phase dependent

Ergun equation use

used to calculate pressure drop through a layer of packing

NTU equation from practice questions