06 Metals and Ceramics 3

1/57

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

58 Terms

Characterise Aluminium (7)

Third more common material on Earth

Low density

Good strength (70 - 100 MPa) (Good tensile strength to density ratio: Al > Fe (200 MPa))

High resistance to weather (corrosion resistance due to Al2O3)

Good formability and machinability

High electrical conductivity (Good electrical conductivity to density ratio: Al > Cu)

High thermal conductivity

Characterise Al wrt its alloys (2)

Wrought alloys: Mn, Mg, Cu

Cast alloys: Si, Cu, Mg

Characterise Copper (7)

Available as Cu ore

Very high electrical conductivity (only after Ag)

High thermal conductivity

Strength increased through cold deformation (but still low tensile strength (less than 440 MPa))

Formable

Weldable and solderable

High corrosion resistant (patina)

Applications of Copper (5)

Electrical applications

Mechanical engineering

Chemical engineering

Civil engineering

Coins

Which metals is copper usually alloyed with? (4)

Zinc (Brass, more than 50 wt % Cu): higher strength, higher corrosion

Tin (Bronze more than 60 wt % Cu): higher strength, hardness, corrosion resistance

Nickel: weldable, high restance against erosion, corrosion, cavitation, high stength (more brittle)

Al

Mn

Si

Characterise Magnesium (12)

High availability

Lowest density among metals (1.74 g cm-3)

Low strength

Low E

Medium cost

Excellent machinability

Good mechanical damping

Good castability

Low corrosion resistance

High reactivity

Not used for construction

Hexagonal Centered Packed: poor formability, low toughness, high notch-sensitivity

Where is Mg used? (3)

Gearboxes, housings, etc

Helicopters

Airplanes

Which metals is magnesium usually alloyed with? (4)

Aluminium, zinc: increase toughness, decrease notch-sensitivity

Manganese: increase corrosion resistance

Cerium, thorium: increase strength at high temperature (up to 300°C)

Zirconium: grain refinement, formability and strength

Characterise Titanium (9)

Fourth most common material in Earth’s crust

Cost effective obtainment since mid 20th century

Pure and with up to 20 wt % of other elements

High stength (up to 1400 MPa)

Low density

High cost

HIgh working temperatures

High corrosion resistance (oxide layer)

Ductile and forgeable

Varying lattice structure

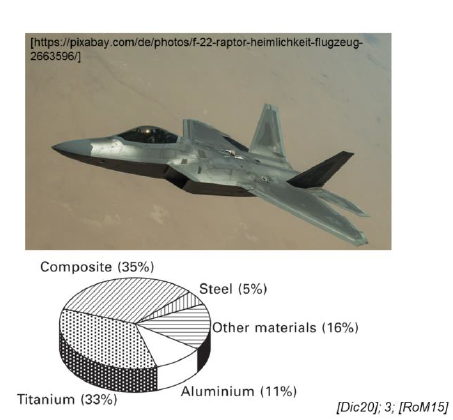

Use in Aerospace of Ti (5)

High performance engines

Landing gear components

Airframe structure

Spacecraft and rocket structures

Helicopter structures

Discuss inclusion of oxygen in Ti alloys (3)

Dobled tensile strength

Reduced formability

Reduced corrosion resistance

Which additives is α-titanium normally alloyed with? (4)

Aluminium

Oxygen

Nitrogen

Carbon

Characterise α-titanium (4)

Low to medium strength

Low density

Good weldability

High warm and cold stability of mechanical properties

Characterise β-titanium (4)

Higher strength

High vibrational resistance

Higher cold-formability

Higher density

Characterise α + β-titanium (4)

Two phase alloy (two different unit cells)

High specific strength

Hardenable

Lower strength than β-titanium but better specific strength

Characterise Nickel (7)

0.02% of Earth’s outer silicate crust

FCC (high formability)

High strength

Very high density

High cost

Very high working (service) temperatures

Ferromagnetic

Uses of Nickel (4)

Stable properties at high service temperatures

HP compressor blades

Combustion chamber

Turbine blades

Which materials is Nickel most alloyed with? (5)

Copper

Chromium

Cobalt

Iron

Molybdenum

What are Nickel-based superalloys? (7)

Alloys with extremely high temperature stability

At least 50 wt % Ni

Inconel

Used for turbine engines

High strength

Long fatigue life

High creep, stress rupture and corrosion resistance at high temperatures

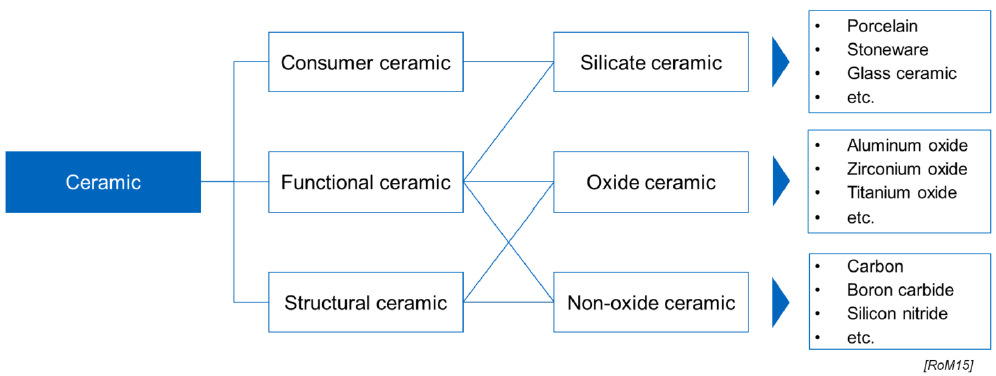

How are ceramics classified? (3)

Consumer ceramics (Silicate + Oxide)

Functional ceramics (Silicate + Oxide + Non-oxide )

Structural ceramics (Oxide + Non-oxide)

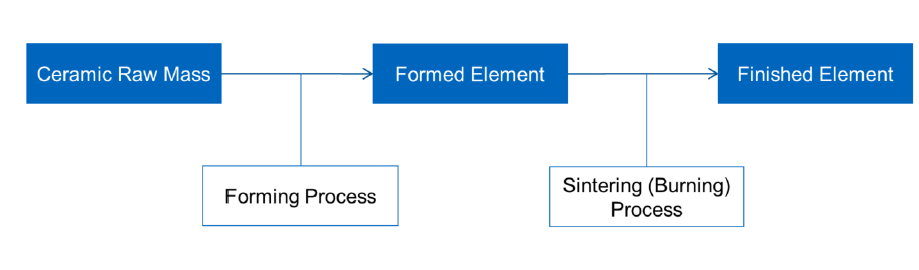

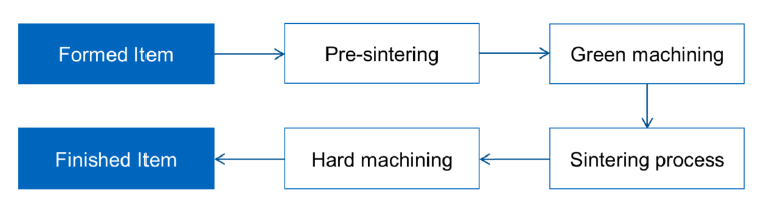

How are ceramic materials created?

Formed out of Ceramic Raw Mass

Formed element sintered to reach finished element

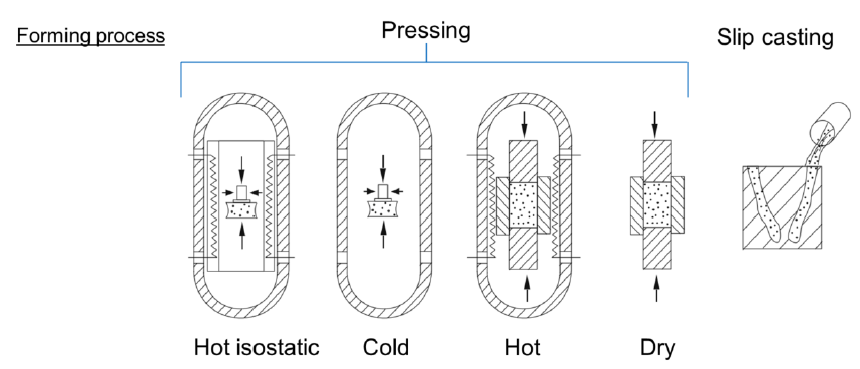

What forming processes are there for ceramics? (5)

Hot isostatic

Cold

Hot

Dry

Slip casting (non-oxide ceramics)

Plasticizing (often addition of thermoplastics) → extrusion/injection molding

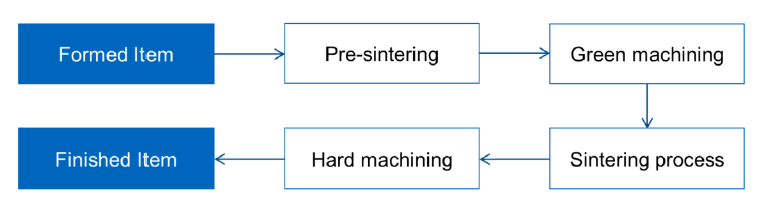

What is pre-sintering?

“Heat treatment“ to a lower temperatures than final sintering

What is green machining?

Process that increases manufcaturing precision

Allows complex modifications of geometry without influencing forming process

What is sintering?

Heating the material up up to a temperature dependant of the material

What is hard machining?

Post-processing machining to achieve higher dimensional precission and surface quality

How is the structure of silicate ceramics after sintering?

Glassy and crystalline

How is the structure of oxide and non-oxide ceramics after sintering?

Polycrystalline

What happens after sintering wrt the overall structure? (2)

Pores and inclusions limit grain growth in the atomic structure

Pores, inclusions and manufacturing defects dominate properties of ceramics

Which kind of bonds is displayed by the atoms of a cermaic material?

Fully covalent

Partial ionic

Fully ionic

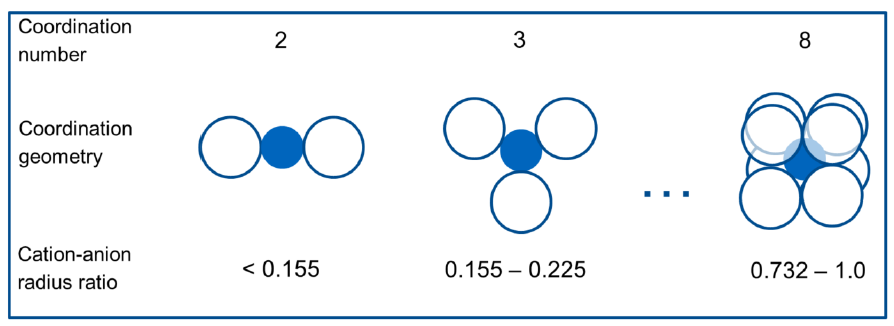

What is a coordination number?

Number of anions surrounding one cation

What are the usual coordination numbers for ceramics?

4

6

8

What is the ralation between the ratio of radii and the coordination number?

The higher the ration of radii, the higher the number of possible cation-anion connections (coordination number)

General Disadvantages of Ceramics (7)

Mechanical properties inferior to metals

Disposition to brittle fracture with low energy absorption

High scatter of mechanical strength

Strength depedant of item volume and surface

Decrease of strength at static load (static fatigue)

Very low thermal conductivity

Low thermal expansion

What is the reason for the mechanical and physical disadvantages of ceramics? (4)

Inhomegenities

Pores

Inclusions

Micro cracks

Physical and mechanical properties of ceramics (3)

High hardness

Low electric conductivity

Ofter high corrosion resistance

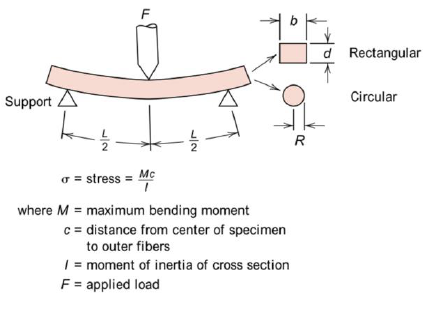

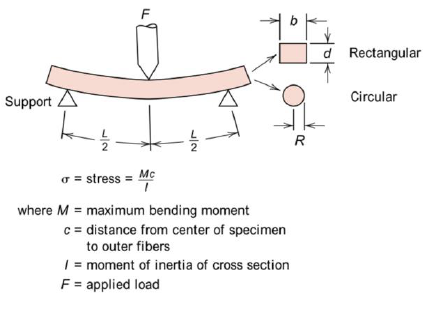

How is a ceramic charaterized?

With a flexural strength test (actually measures the maximum shear but whatever)

Formulae in Cheat Sheet

Why is it difficult to apply a regular tensile test to a ceramic material? (3)

Difficult specimen preparation (complicated geometry)

Brittle materials difficult to grip

High precission required

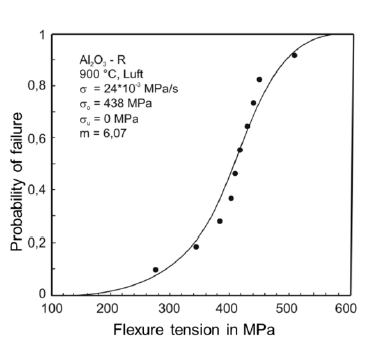

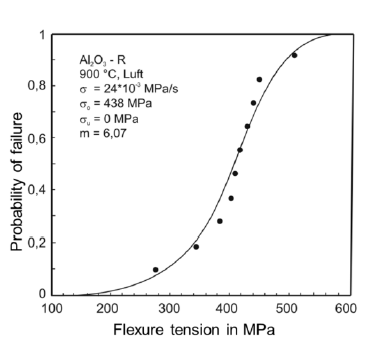

How is the probability of failure of a ceramic material modeled?

Via the Weibull distribution and using a flexure tension test

Formula in Cheat Cheet

Which rules are to be followed for constructions with ceramics? (5)

Avoid sharp edges

Avoid abrupt cahnges of cross section

Pressure load prefered over tensile load

Avoid high edge pressure

Consider different thermal expansion coefficients

Characterise Al2O3 (6)

Common

Good mechanical and chemical properties

High hardness

Disposition to creeping at high temperatures

High thermal expansion

Medium thermal conductivity

Characterise Si3N4 (5)

Group of ceramics: dense silicon nitrides

Suitable for high temperature applications up to 1400 °C

Polyphase material with amorphous or semi-crystalline proportions up to 30%

Tailorable

Los resistance against aggresiva chemical solutions

Characterise B4C (8)

Boron Carbide

Third hardest material in the world

Extreme high hardness at high temps (stable up to 1500 °C)

Non-oxide and non-metallic

Only machinable with diamond tools

Thermal conductivity decreases with increasing temperature

Los oxidation ressitance

High chemical resistance

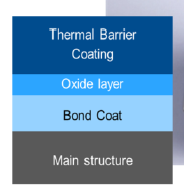

What does TBC stand for?

Thermal Barrier Coating

What is TBC used for? (5)

Thermal isulation via ceramic coating

Metallic bond coat

Wear and corrosion resistant due to high proportion of Al

Applied by plasma sprying or electron beam vapor deposition

Normally used for gas turbines

SQ: For which applciations are nickel-based superalloys typically used in aerospace engineering?

Turbine engines

Wherever thermo stability is needed

Higher stability of material leads to higher operation temperature of engine and thus to higher thrust

SQ:What is the main advantage of α-titanium over β-titanium?

Low density

Good weldability

High warm and cold stability of mechanical properties

SQ: Why is Al often preferred over Mg for lightweight design, even though it has higher density?

Al displays better mechanical properties, specially tensile strength

Mg is more reactive than Al

SQ: Why is copper not commonly used for aerospace structure? In which engineering discipline is copper used pedominantly instead?

High denisty

Inferior strength to weight ratio

Cost

Electrical engineering

SQ: How are ceramic materials classified?

Silicate ceramics

Oxide ceramics

Non-oxide ceramics

SQ: Name the differences between silicate ceercamic, oxide and non-oxide ceramics according to their crystal structure after sintering

Silicate: glassy and crystal phases

Oxide and non-oxide: polycrystalline structure

SQ: What should be considered in the design process of ceramic products?

Ceramics raw material

Final geometry

Quantity of pieces

SQ: What characteristic of ceramic materials is of special interest for aerspace applications?

Thermal insulation

SQ: Why is the mean value of strength insufficient for characterization of ceramic materials?

Due to considerable deviations due to pores, inclusions, inhomogenities, micro cracks, brittleness

Failure at 0.1% strain

SQ: Describe the setup of a thermal barrier coating

Main structure

Bond Coat (high Al proportions)

Oxide Layer (Al)

TBC (Zircon or Yridium ceramics)

SQ: Why are turbine engine parts with high temperature requirements typically not made form massive ceramic materials?

Due to inferior mechanical properties of ceramics, like brittleness or poor eleongation to failure

SQ:Describe the crystal structure of predominantly ionic ceramics

Oppositely charged ions to achieve neutral crystall over the whole material body

Accomodation within lattice structure driven by and radii ration (cation to anion radii ratio) and coordination numbers

SQ: What is the difference between green machining and hard machining of ceramics?

Green machining: presintered material

Hard machining: sintered material