MTE2201 Module 10 - Mechanical properties of polymers

1/18

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

19 Terms

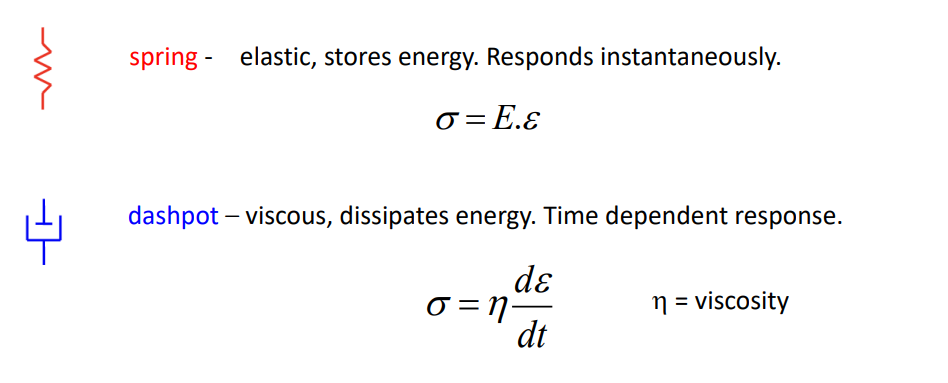

Behaviour of thermoplastic polymers and how they can be modelled

They are viscoelastic. So they have:

Elastic behaviour - instantaneous response to stress/strain

Viscous behaviour - Time dependent response to stress/strain

Mechanical behaviour of viscoelastic polymers can be modelled by connecting springs and dashpots in different ways

Characteristic behaviour of viscoelastic polymers:

-Stress relaxation (decay of stress with time after fixed deformation)

-Creep (increase in strain with time after application of a constant load)

Both are curved

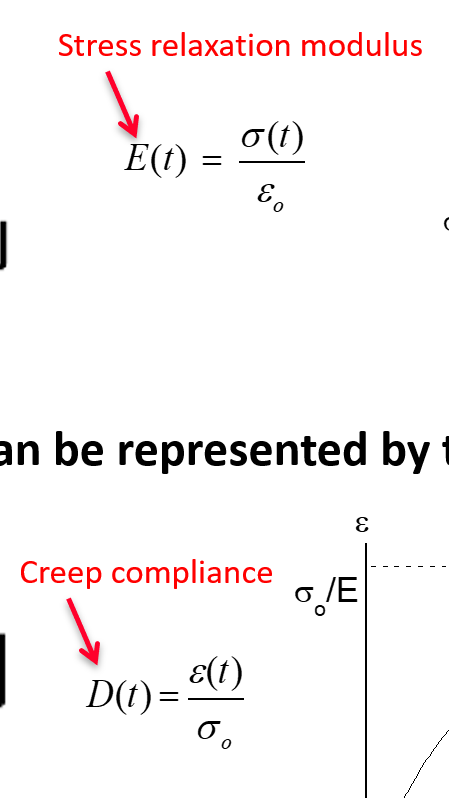

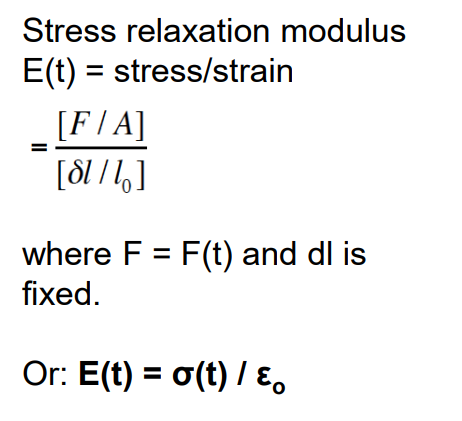

Stress relaxation

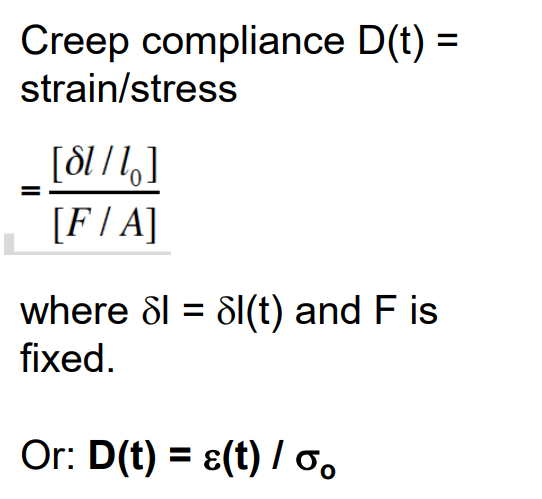

Creep compliance

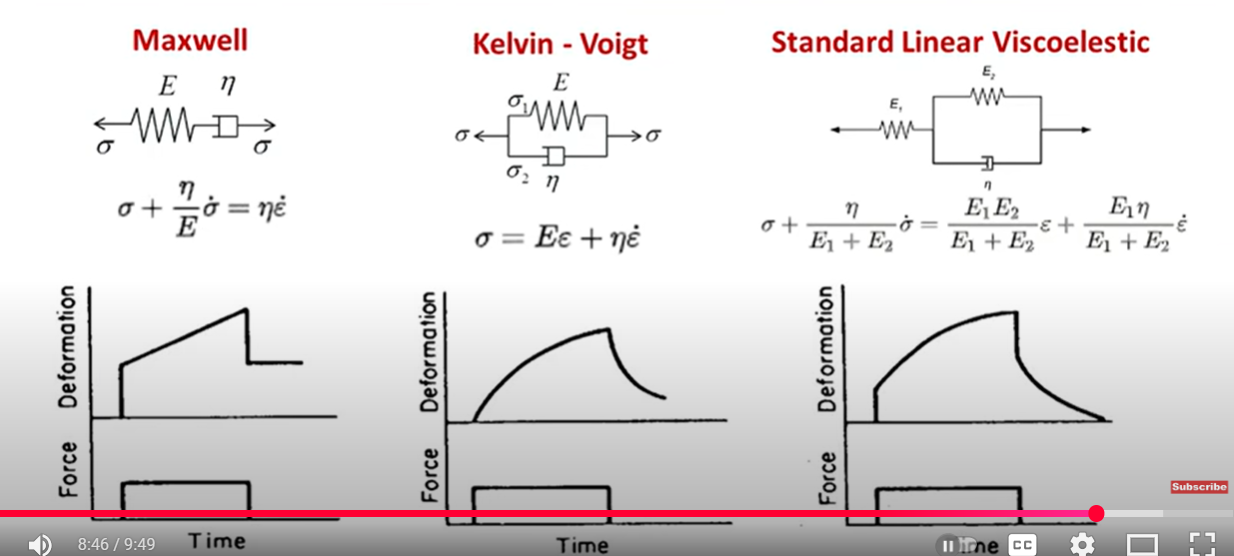

Maxwell model

Connecting a spring and dashpot in series. Can model stress relaxation, but predicts creep to be linear when it is really nonlinear.

Kevin Voigt Model

Spring n dashpot in parallel. Can model creep and creep recovery. Predicts hookean spring behaviour, so not good for modelling stress relaxation.

Standard linear viscoelastic model

Can model both creep and viscoelastic behaviour

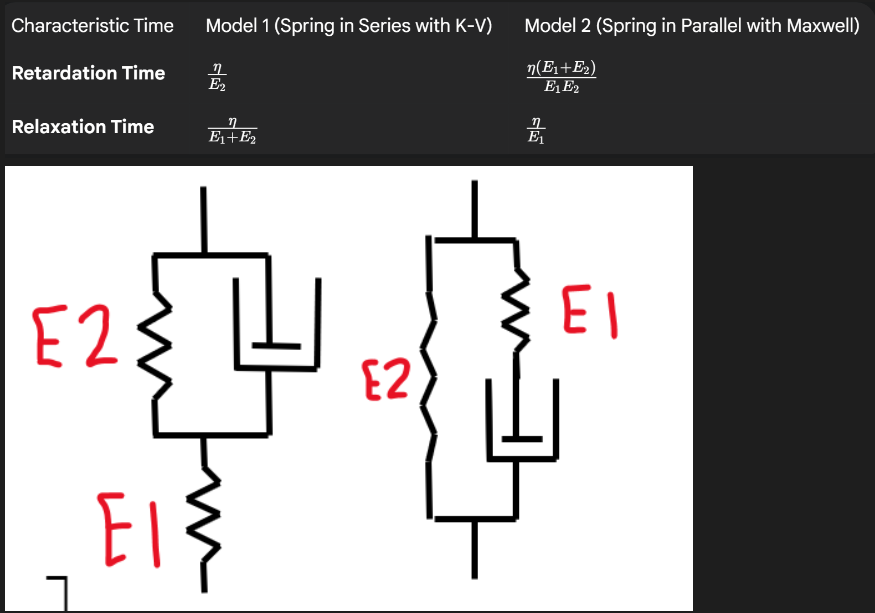

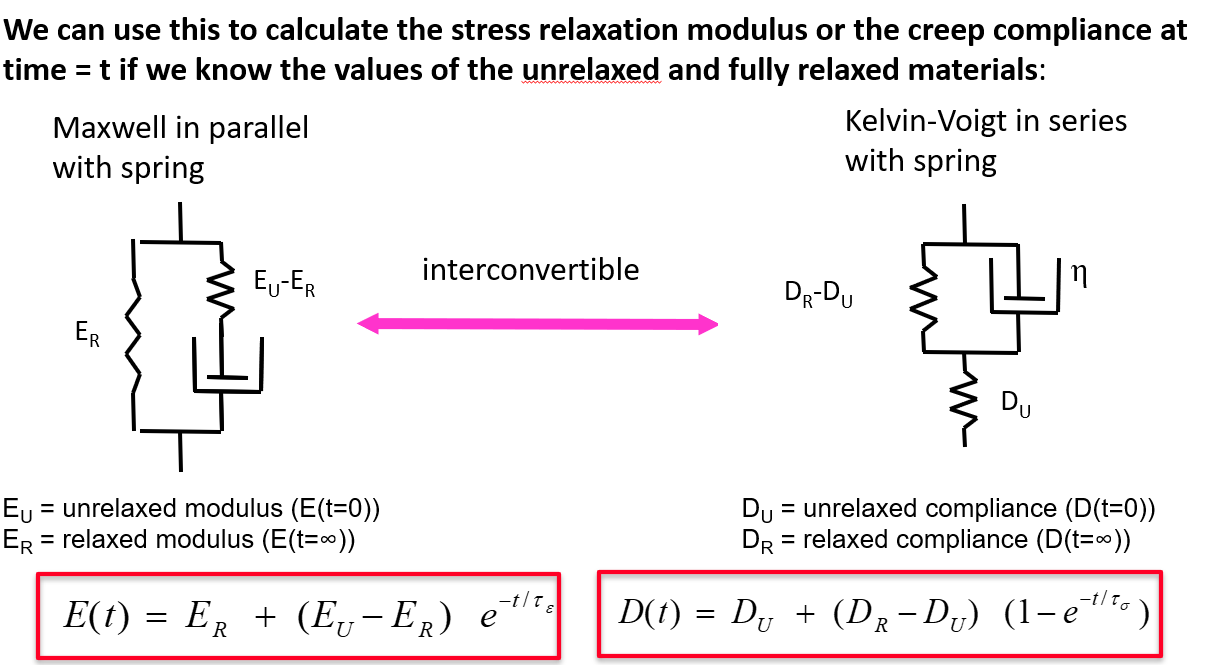

Retardation and relaxation time equations for standard linear model

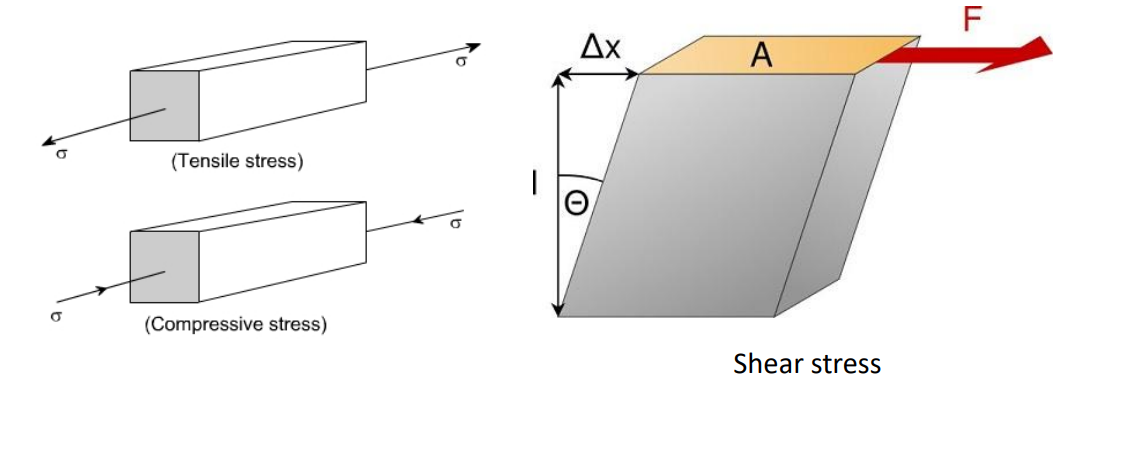

The 3 main modes of deformation

Tensile, compression, shear

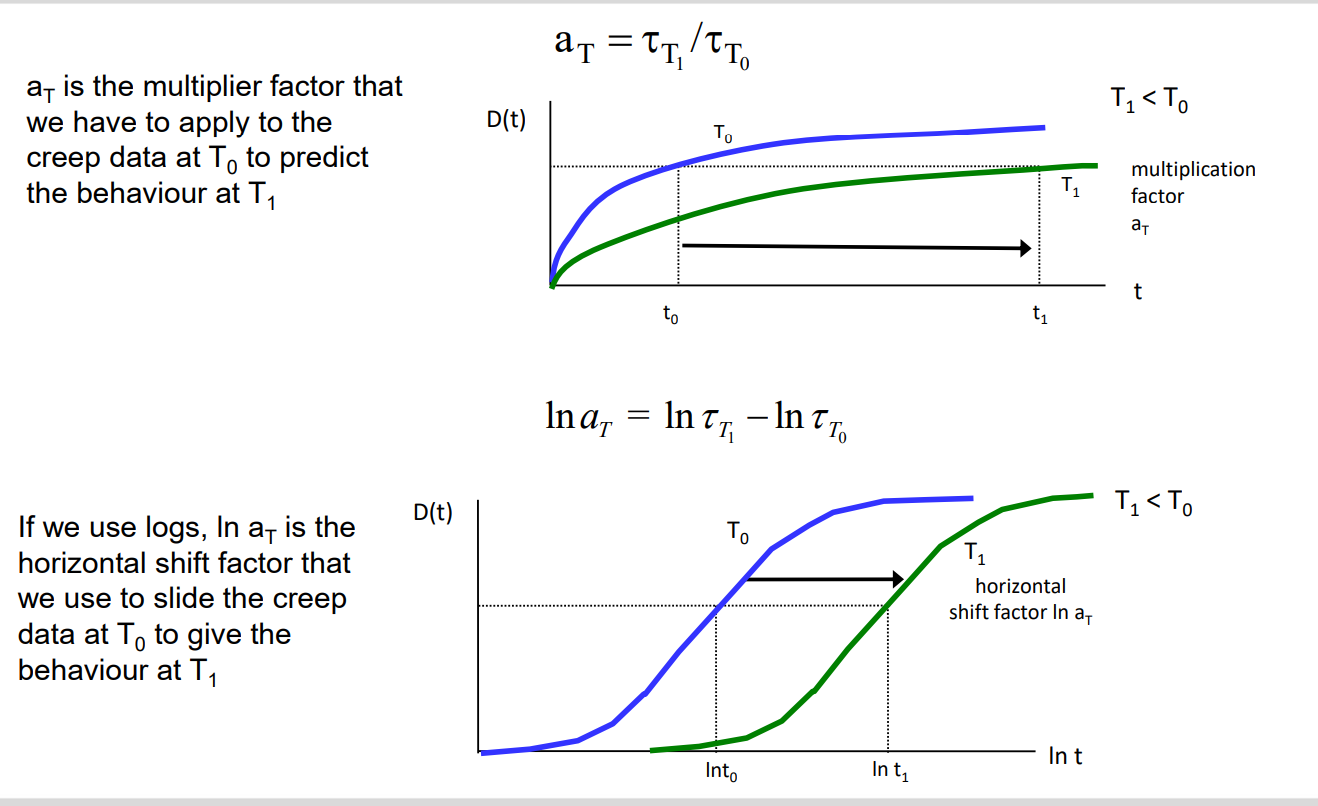

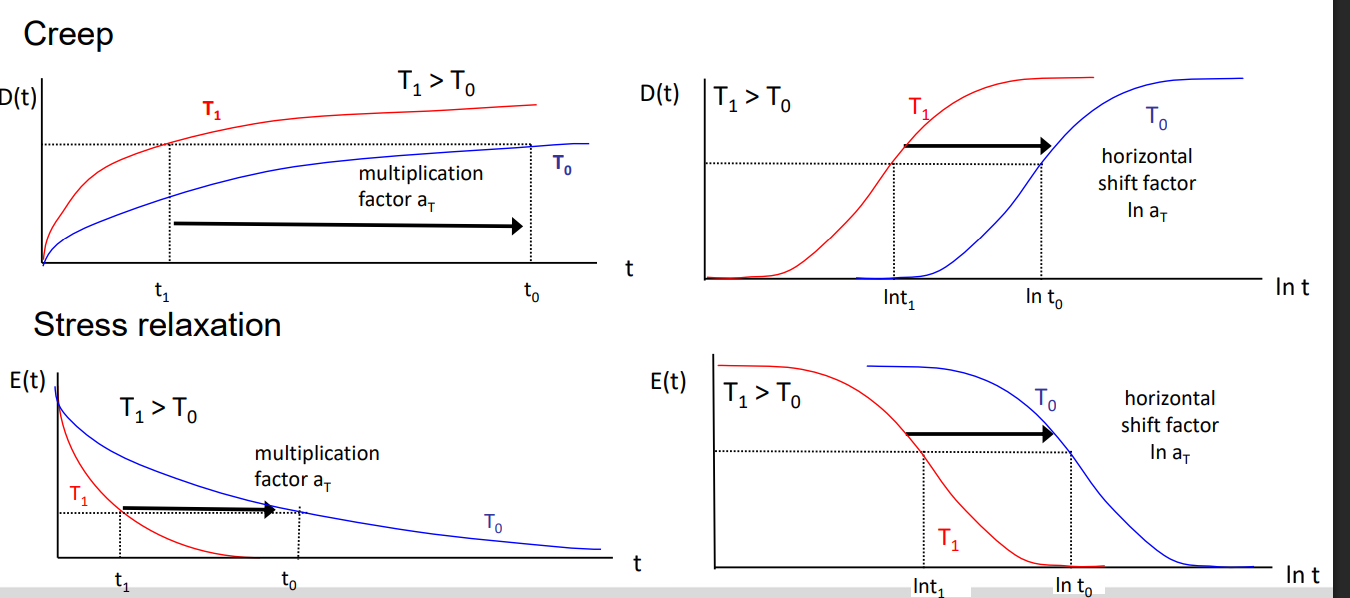

Time temperature superposition with time and log time

Time temp superposition of creep and stress relaxation

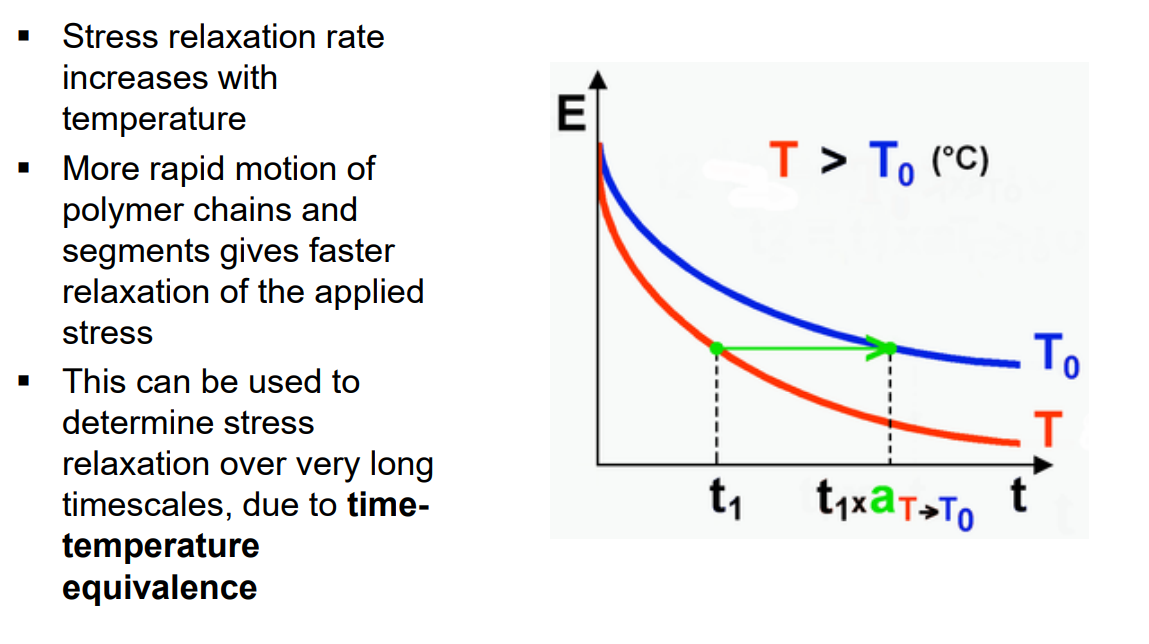

Stress relaxation rate vs temperature

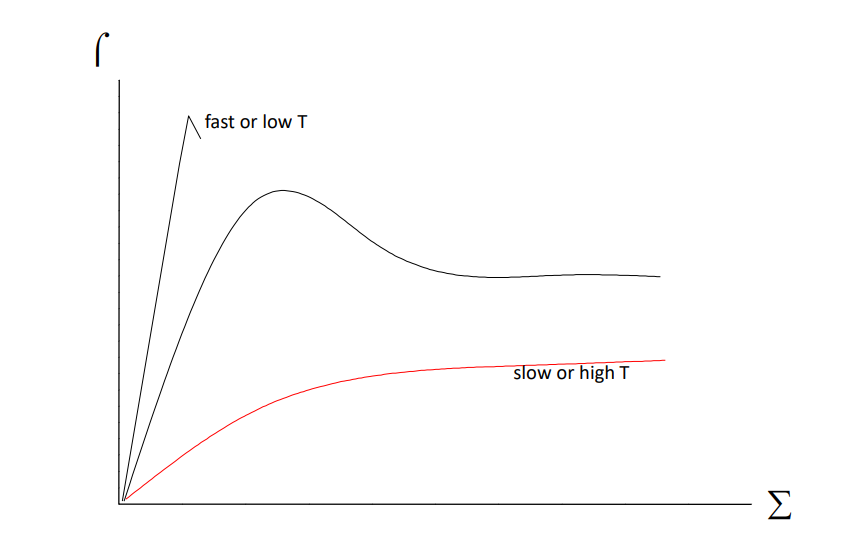

slow rate/ high temp effect on applied stress

At slow rates or high temperatures, the molecular segments have time to rearrange and so reduce the applied stress.

Drawing of an amorphous thermoplastic polymer beyond the yield point causes:

Uncoiling and orientation of polymer chains, causing increased strength and stiffness as intermolecular forces can act more effectively along parallel chains.

Time temp principle

For viscoelastic materials, time and temperature have an equivalent effect on the movement of polymer chains.

Retardation and relaxation time

3 flaws of 2 element models

1.Each model cannot describe all viscoelastic properties, like either creep or SR but not both

2. Neither one alone can describe all materials types

3. The models involve only a single relaxation time with a width of 1.2 decades of time. Polymers relax over much longer timescales eg 10 decades of time!

Stress relaxation modulus and creep compliance in 3 element model

compliance is not strain. Compliance is strain / stress.

Same with stress relaxation. stress relaxation modulus is stress/strain.

Stress relaxation modulus and creep compliance in 2 element model