Sustainable Exam 2

1/138

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

139 Terms

bakelite

first fully synthetic plastic

Created to respond to the need of growing electrical industry for insulating wires and other high voltage devices

Combination of phenol and formaldehyde…a type of “resin”

resin

pure polymeric material without any additives

inert

polymers themselves are typically ______

Polyurethanes

Polyacrylonitrile (used in carbon fiber composites) (PAN)

Polyvinyl chloride

Epoxy resins

AcrylonitrileButadiene-styrene(ABS)

rank the toxicity of polymers by synthetic pathway (5)

polyurethanes

which polymer?

ethylene oxide

sterilizes food, sterilizes medical equipment, chemical synthesis

toluene diisocyanate

polyacrylonitrile

which polymer?

used in carbon fiber composites

composite stronger and lighter than steel

common in airplanes

acrylonitrile

polyvinyl chloride

which polymer?

vinyl chloride

used in piping

epoxy resins

endocrine disruptor

bisphenol A, epichlorohydrin

acrylonitrile butadiene-styrene

acrylonitrile, styrene

used in automotive industry

strong plastic

additives

polymer

a material is only called a plastic when it has ______?

otherwise, just a ________.

plasticizers

make plastics more pliable and impact resistant

phthalates

widespread human exposure

bisphenol-A

Used in food packaging as can liners, water tank liners, polycarbonate bottles

Contains (mimics) estrogenic effects in men and women

Studies found lower total testosterone levels in subjects with higher BPA levels and greater frequency of cancers

polybrominated diphenyl ethers

•Fire retardants added to many different resins

•Many plastics can exist as a fuel source

•Limited data on human effects but considered an endocrine disruptor

dioxin

•Considered the world’s most toxic chemical

•Emitted when polybromonated fire retardants are made, mixed with plastics, or during plastic recycling process

•Affects brain development, immune function, cancer risk

alkylphenols

•UV Stabilizers

•Reduce testosterone and estrogen levels, reproductive toxin

•Ex: lignin

anthropocene era

era of earth’s geological history where almost everything is shaped by human activity: forests, lakes, land mass, oceans, atmosphere etc.

When geologists study our age in the future, the presence of plastics may be the greatest indicator of the human activity

30

60

10

____% of all plastic ever produced still in use

____% discarded in landfills or mismanaged environmental leakage

____% recycled or incinerated

asia

n. america

europe

middle east/africa

latin america

highest plastic contributors by country

how plastics degrade

physical/mechanical forces that shear, pulverize, and splinter

chemical: thermal or UV breakdown

biological: biodegradation by microorganisms

1 mm -0 .1 mm

what measurement qualifies as a microplastic?

microplastics

any small particles entering the environment

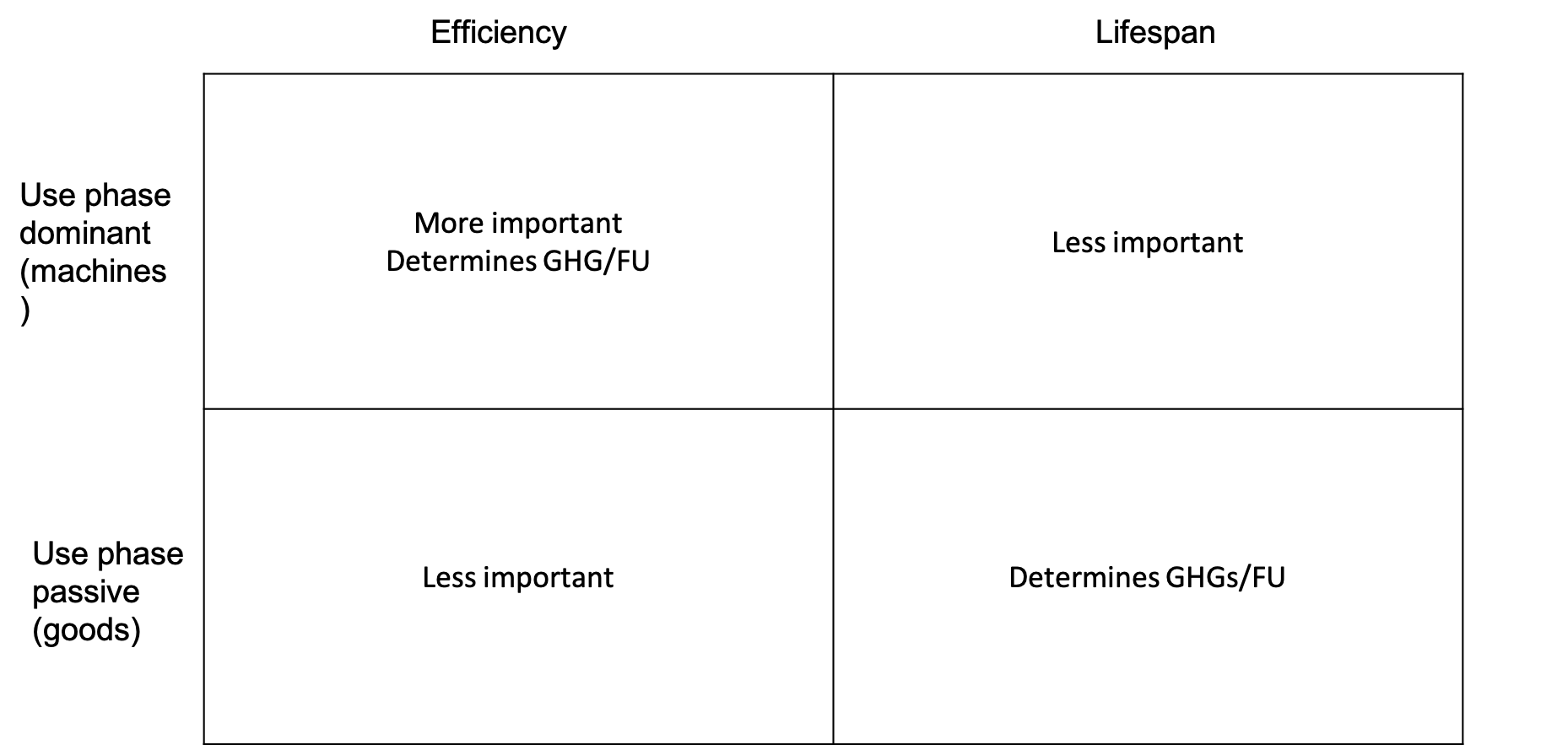

worst scenario (passive)

short lifespan, high manufacturing emissions

worst scenario (dominant)

short lifespan, low efficiency

•because the worst thing you could have is dividing your GHGs by one use

•Best scenario is to have endless uses

•Ex: aluminum

why single use plastics are so bad?

manufacturing

transportation

plastic GHGs come from? (2)

takes more work to convert a natural product like corn into plastic

reason less steps and GHGs with oil to plastic?

issues from plastic waste in waterways

•Blockage / damming of natural water flows

•Become breeding ground for pests / mosquitos

•Source for leaching of toxic chemicals

•Disturbing natural biocycles, nutrient cycles

•MP ingestion and disruption of food chain

•Economic losses to tourism and fishing, economic development

PE

most common polymer type found in fish?

issue of MP pollution on land

disrupts ability of soil to store carbon

nitrogen and phosphorus nutrient cycles disrupted

more GHGs emitted from soil

disrupt natural microbial diversity and affect soil temps

they have increased SA

how are MPs able to absorb nutrients and toxins from the environment?

polymer

large molecule made of repeating units

monomer

individual units that react

dimer

two monomers bonded together

oligomer

several monomers bonded together

polyolefin

what class of polymer?

polypropylene

polyethylene

polystyrene

polyvinyl chloride

polyolefin

•Saturated C-C and C-H bonds with other

functionalization

•Very efficient processing conditions

•Very cheap feedstocks

•Highest produced plastics worldwide

condensation polymers

what class of polymer?

polyethylene terephthalate

polyamide

polycarbonate

polyurethane

condensation polymers

•Higher oxygen and nitrogen content

•Contain reactive bonds that can be used for

biodegradation or chemical recycling

•Many are considered “engineering resins” due to strength, ductility, heat resistance

•More expensive than polyolefins

polyester

reaction of diol and dicarboxylic acid

condensation polymerization

by-products often produced

ex: water

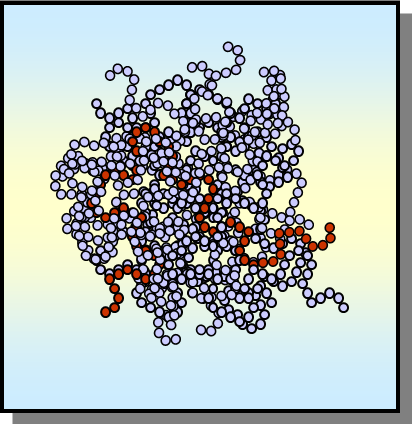

network or gel polymers

crosslinked polymers that contain short side chains (cross links) that connect different polymer chains into a “network”

crosslinked polymers

________ __________ don’t melt, but simply degrade under heat and don’t dissolve into solvents

used as adhesives and binding agents

forming a network from a trifunctional molecule is the reaction of phenol with formaldehyde

bakelite

example of network formation:

thermoplastic

•melts as a response to heat, solidifies upon

cooling

•Heat is able to increase motion of polymer chains until they begin to flow (melt)

•Allows for ease of processing

thermoset

•After the material is cured / synthesized, it will not melt again

•Additional heating results in polymer degradation

•Typically crosslinked polymer systems

thermoplastic

thermoset or thermoplastic?

thermoset

thermoset or thermoplastic?

melt processing

•one of the cheapest and most efficient way to use plastics

•Includes mechanical recycling techniques

•Does not often contain by-products

•Includes injection molding, blow molding, thermoforming, and others

•Is largely responsible for the proliferation of plastic containers used in everyday applications

has the lowest melting point of the main polymers, less energy required

why is PE the largest produced polymer from an energy perspective?

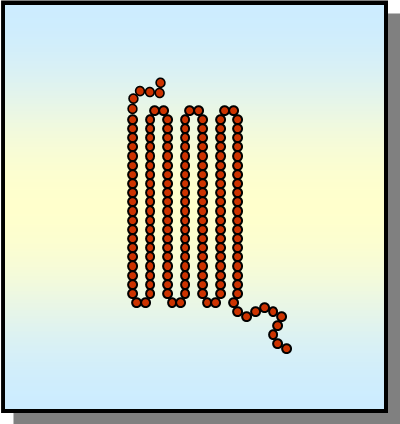

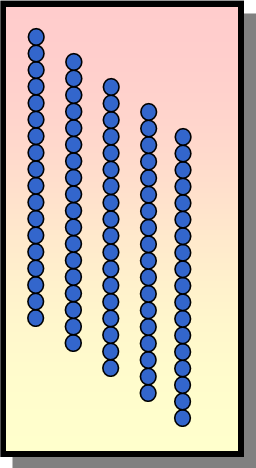

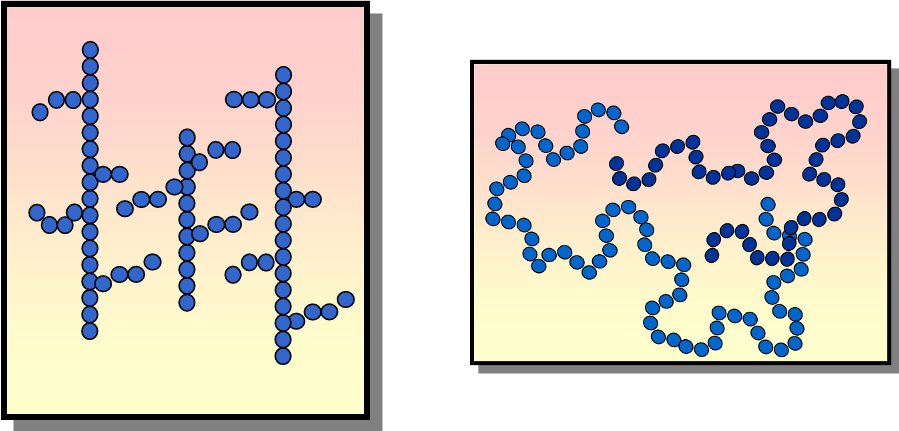

crystallinity

Refers to how polymer chains line up on the molecular level and determines many of usable properties of commodity plastics

random- amorphous

Does not contain a definite melting

point but undergoes continual softening

as polymer chains gain more movement

ordered- crystalline

Contains a definite melting point where polymer flow occurs

high

high or low crystallinity desired?

high barrier

high

high or low crystallinity desired?

high strength/stiffness

low

high or low crystallinity desired?

toughness (ability to take impact)

low

high or low crystallinity desired?

translucent material

HDPE

which material?

Linear chains pack tightly together and therefore create more dense materials

LDPE

which material?

Chains that are branched cannot crystalize do not pack as tightly together and therefore contain more space between the polymer chains

HDPE

HDPE or LDPE?

Stronger and more opaque

LDPE: low crystallinity

LLDPE: varying crystallinity

HDPE: high crystallinity

UHMWPE: high strength cases

4 types of PE

increases

effect with increasing degree of crystallinity:

strength

increases

effect with increasing degree of crystallinity:

stiffness

decreases

effect with increasing degree of crystallinity:

toughness

generally decreases

effect with increasing degree of crystallinity:

optical clarity

Small molecules usually cannot penetrate or diffuse through the crystalline domains, hence “barrier properties”, which make a polymer useful for things like food wrap, increase with degree of crystallinity

effect with increasing degree of crystallinity:

barrier properties

Similarly, solvent molecules cannot penetrate the crystalline domains, which must be overcome before the polymer will dissolve. Solvent resistance increases with degree of crystallinity

effect with increasing degree of crystallinity:

solubility

chemical feedstocks

polyolefin energy demand comes primarily from _______ __________

electrical requirements

polyolefin GHG emissions come mainly from _______ ________

polyester

which material?

has a more even split for energy demand and chemical feedstocks

less efficient polymer synthesis

higher GHGs than polyolefin

true

T/F: the use phase for polyolefin is insignificant

condensation polymers

•They have other active groups, no longer just a hydrocarbon

•Because of the added groups we get better barrier and mechanical properties

•They have byproducts (even if it’s water)

•Has energy impacts

polyolefins

•long chain hydrocarbon

•Simplest polymer

•Very cheap to produce

•Produced in gas phase

•Use phase not significant

bioplastics

biodegradable plastics

recycled plastics

3 kinds of sustainable plastics

bioplastics

•Made from natural materials

•Some are compostable

•Ex. PLA, PHA, Soy PU, Bio- Polyethylene, Bio-Polyamide, Bio-Polycarbonate

biodegradable plastics

•Engineered to break down faster, but not necessarily into harmless substances

•Ester bonds (biodegrade)

•Can still be made from fossil fuels

•Ex. Starch, Cellulose Acetate, PBAT, PBS, PLA, PHA

recycled plastics

•Starting from processed materials instead of raw materials

•Generally achieves a reduction in energy requirement for second generation materials

Bio-PET

which material?

•Replaces one component in PET synthesis with sugarcane-based ethylene glycol

•No difference in biodegradability from PET

Bio-PE

which material?

•Another product of sugarcane

•Not biodegradable, but recyclable

•Drop-in replacement (chemically identical) to traditional PE

•Applications in HDPE, LDPE, LLDPE packaging

•First made from Brazilian Sugarcane

bc it has a high yield

why is sugarcane used as an alternative?

Bio-PA (nylons)

which material?

•Produced from Castor oil – an industrially produced vegetable oil

•Non-edible oil

•Drop-in replacement to PA 6,10, PA 10,10

•Typically have higher impacts than polyesters

•Require solvents and high temperature for synthesis

non-edible sources for biopolymers

castor bean

jatropha seed

mahua seed

Karanja seed

perilla seed

animal fats

starch

cellulose/lignin

chitosan

tannins/wood resins

polyhydroxyalkanoates (bacteria)

Biobased polycarbonate

which material?

•typically used in clear plastic applications: plexiglass/water bottles, headlights

•Often uses BPA, a biobased version uses glucose-based monomer

•Not biodegradable, similar properties as traditional PC

Bio-PHA?

which material?

•Produced by bacteria and harvested from

intracellular deposits

•Expensive to produce

•Blended with starch and cellulose to improve properties and decrease cost

•About 2 months to decompose in the backyard:

one of very few home compostable plastics

•Uses: food wraps, cups, plates, medical uses (sutures, gauze), coatings

polylactic acid (PLA)

which material?

•Thermoplastic produced through bacterial fermentation

•Less expensive processing than PHA

•First industrially produced bioplastic at scale

•Most widely produced bioplastic

•Brittle and more restrictive in applications

•Degrades 1-6 months in commercial

facilities

•Uses: grocery bags, food packaging, bottles, medical sutures, 3D printing

FALSE

T/F: PLA is industrially compostable and recyclable

over-engineering

a problem brought up by the sustainability community that argues we don’t need our plastics to last 100s of year

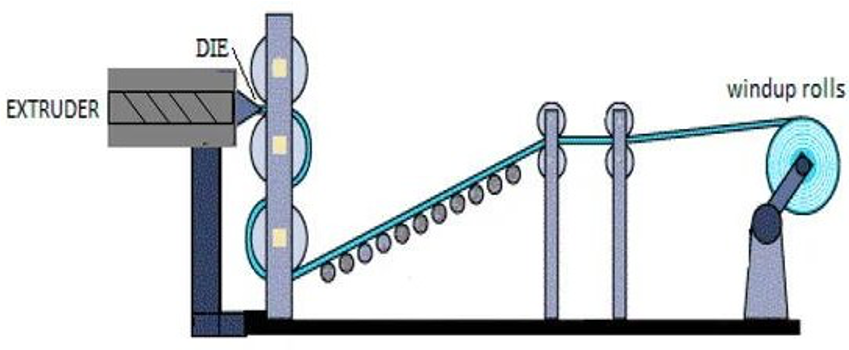

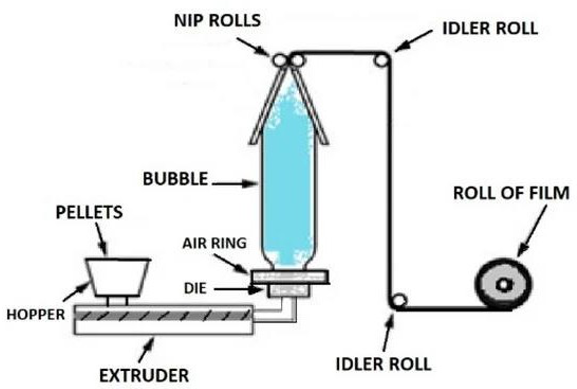

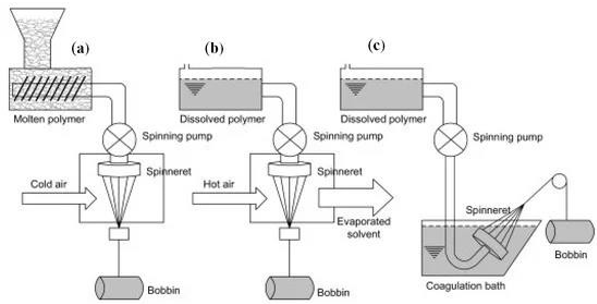

extrusion

blow molding

flexible packaging most often produced through what two processes?

too low a melt-viscosity

why can’t PLA undergo blow molding?

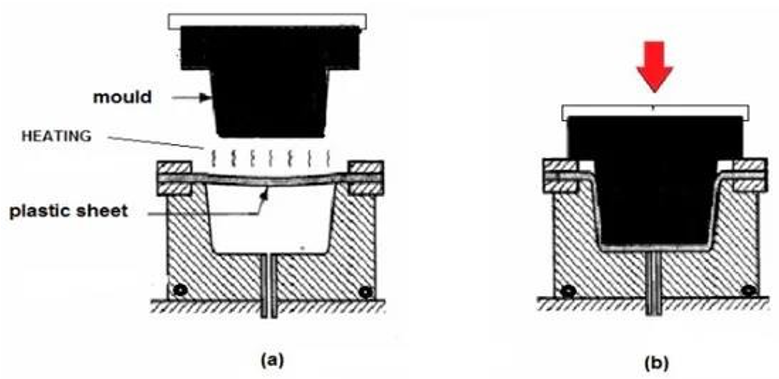

die extrusion

blow molding

thermoforming

fiber spinning

yes

can PLA and PHA both undergo thermoforming?

crystallinity

creating textiles requires high ________

PHA

which material has shown highest promise with fiber spinning?

benefits of using biobased feedstocks

•The same additives are normally needed

•Energy and GHG emissions are normally similar

soy PU foam

•Developed by Ford for automotive seating ~ 30% biomass

•Most toxic component still remains in synthesis: Diisocyanates

•Soy oil replaces petroleum-based polyol

•Can be synthesized at room temperature by mixing a Part A and Part B component

•Can be used in “Foam-in-place” applications

plasticized starch

Can be sourced from corn, wheat, rice, barely, potato, cassava etc.

Blend of amylose and amylopectin: 25/75% respectively

Native starch must be plasticized (is too brittle naturally) to be used in packaging applications

Typically involves heating with water, glycerol, or sorbitol

Then blended with other resins to increase the bio-content, decrease cost, increase biodegradability

for greater insulation properties

why you want a closed cell foam?