Dosage Forms: Exam 3- Solids (Oral)

1/122

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

123 Terms

Discuss the advantages of powdered dosage forms

POWDERS

Advantages

Absorbed more rapidly than tablets or capsules

Easy to give large doses

As compared to a tablet with 1 g of active ingredient plus excipients

Easier to swallow than tablets or capsules

More chemically stable than liquids or preparations

Discuss the disadvantages of powdered dosage forms

POWDERS

Disadvantages

Can’t mask unpleasant taste or odors

Inconvenient to handle

Can be expensive to manufacture

Powders have explosion risk—> may need special handling equipment

Dose inaccuracy (bulk powders)

Problematic if drugs is hygroscopic or deliquescent

Methods of blending powders: Spatulation

BLENDING POWDERS

Spatulation

Mixing 2 or more powders together with a spatula

Not suitable for large quantities

Why?

Very little compaction or compression results from this method

Homogenous blending is not as certain

Especially good for eutectic mixtures

Methods of blending powders: Trituration

BLENDING POWDERS

Trituration

Powders are mixed using mortar and pestle

Results in:

Blending

Particle size reduction

Reduced powder bulkiness (with heavy trituration)

Choice of mortar

Blending only: glass

Blending and size reduction: porcelain or Wedgwood

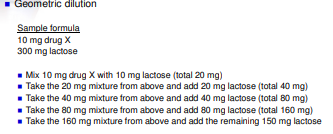

Methods of blending powders: Geometric dilution

BLENDING POWDERS

Geometric dilution

Very useful for achieving a uniform distribution of potent drugs

Start with the ingredient present in the smallest amount

Add additional ingredients in order of quantity required by approximately doubling the portion being mixed with each addition

Methods of blending powders: Sifting

BLENDING POWDERS

Sifting

Mixing by passing through a sifter (sieve)

Useful when powders are in the same particle size range

Otherwise, stratification will result

Methods of blending powders: Tumbling

BLENDING POWDERS

Tumbling

Mixing by placing powders in a large container that rotates

Describe methods of granule preparation discussed in class.

GRANULE PREPARATION

Two types of granulation

Wet

Dry

For both types, first steps are:

Weigh all materials

Blend powders to make a uniform mixture

Identify the steps involved in: Wet granulation

Weigh all materials

Blend powders to make a uniform mixture

Moisten the desired powder or blended powder mixture

Mix

Pass dough through screen of appropriate mesh size to produce the desired particle size range

Air dry or use heat

Identify the steps involved in: Dry granulation

Weigh all materials

Blend powders to make a uniform mixture

Compact

Roller compaction: form ribbons of compressed material

Slugging: form oversized tablets

Size by grinding compacted material (ribbons or slugs)

Describe methods of granule preparation discussed in class: Wet granulation

WET GRANULATION

Water is most frequently used solvent

Relatively inexpensive

Limited ecological impact

Non-flammable

Disadvantages:

Takes longer to dry:

Potential problems with heat-sensitive drugs

Causes hydrolysis in susceptible products

Organic solvents sometimes used

During processing of water-sensitive drugs

When short drying time is needed

Disadvantages

Flammable—> expensive safety precautions are needed

Solvents/solvent potentially harmful to workers, environment

Expensive

Describe methods of granule preparation discussed in class: Dry graunulation

DRY GRANULATION

Powder particles are aggregated under high-pressure

Used primarily with drugs that:

Are moisture sensitive

Do not compress well after wet granulation

Done by

Slugging

Roller compaction

Explain how granules differ from powders

GRANULES

Prepared agglomerates of smaller particles

In general, irregular in shape

Behave as single particles

Size ranges 2-4 mm (sieve #4-12)

Uses:

As a dosage form in itself

As intermediate step in the process of tableting

Explain why granules are preferred to powders in pharmaceutical processing. (e.g. density is increased, dust is reduced or eliminated)

ADVANTAGES OF GRANULATION

Granules flow better than powders

More stable than powders

More easily wetted by solvent

Higher density

Occupy less volume per weight—> more convenient storage and shipping

Larger particle size

Prevents individual powder ingredients from segregating

lead to elimination of dust

With toxic materials, leads to decreased risk of toxic dust

Less powder explosion risk

Improves compression properties of powder blend

Discuss the advantages of capsules as a dosage form

CAPSULES AS A DOSAGE FORM

Advantages

Dose accuracy

Easy to administer

Dosage flexibility

Ability to include combinations of drugs

Ability to mask unpleasant tastes and odors

Moore chemically stable than liquid preparations

Drugs with poor compressibility can be filled into a capsule

Discuss the disadvantages of capsules as a dosage form

CAPSULES AS A DOSAGE FORM

Disadvantages

Sensitive to moisture

Loss of moisture to environment or hygroscopic capsule contents can make the capsule brittle

Absorption of moisture from environment can make the capsule sticky

Cross-linking of reactive aldehyde groups with gelatin

Not suitable for aqueous and alcoholic preparations

These solvents can dissolve the capsule shell unless the formulation is extensively revised

List and describe the purpose of the components of a capsule shell

CAPSULES

An edible package made from gelatin or other suitable material which is filled with drug and excipients

Produces a unit dosage, mainly for oral use

From the Latin capsula, meaning a small box

Identify what types of ingredients can be incorporated into hard capsules

HARD GELATIN CAPSULES

Composition of capsule shell:

Gelatin

Source of collage

Plasticizers: increase flexibility of the shell

Water

Coloring agents

Opaquants

Sometimes include:

Flavoring agents

Sweeteners

Composition of powder content mixture:

Active ingredients

Diluent

Lubricants or glidants

Wetting agents

HGC can also be filled with:

Granules

Pellets

Non-aqueous liquids

Semi-solids

Describe situations when an alternative to gelatin would be useful in a hard capsule shell.

NON-GELATIN CAPSULES

Reasons for alternative shells

Gelatin is unsuitable for certain populations

Strict vegetarians

Those with religious or cultural restrictions

Why?

Those with food allergies (alternatively shells typically dairy, corn, and wheat free)

Some drugs react with gelatin

HPMC is inert

HPMC has lower moisture content than gelatin

Prevents hydrolysis of extremely moisture-sensitive drugs from the moisture in the capsule shell

LICAPS

2-piece hard capsules

Specially designed for secure containment of liquids and semi-solids

Uses Fusion Technology for sealing

Vegetarian: Kosher and Halal certified

HPMC based

Free of gluten and other allergens

At this point, appear to be used only in the vitamin or supplement industry

Advantages

No plasticizers or preservatives

Reduced changes for drug oxidation

Dual release is possible:

Capsule in capsule

Pellets dispersed in an immediate-release liquid formulation

Allows for isolation of incompatible actives until delivery

Describe situations in which a soft gelatin capsule would be useful

SOFT GELATIN CAPSULES

Available in different shapes

Useful when:

Active ingredient is liquid

Active ingredient is suspended or dissolved in liquid vehicle

Active ingredient or formulation is semisolid

Identify what types of ingredients can be incorporated into soft gelatin capsules

SOFT GELATIN CAPSULES

Liquids that may be contained in soft gelatin capsules:

Oil

Non-aqueous, water-miscible liquids such as PEG 400

Liquids that may NOT be contained in soft gelatin capsules without extensive reformulation

Water

Alcohol

Composition of capsule shell:

Gelatin or other suitable material

Plant cellulose

HPMC

Glycerin of polyhydric alcohols (such as sorbitol)

Identify what excipient functions may be included in capsule formulations

SOFT GELATIN CAPSULES

One-step manufacturing process

Liquid would escape from shell if done in multiple steps

Discuss the advantages of tablets as a dosage form

TABLETS

Advantages

Dose accuracy

Easy to administer

Rapid and reasonably inexpensive production

More chemically stable than liquid dosage forms

Easy to mask unpleasant tastes and odors

May be colored, flavored, imprinted

Discuss the disadvantages of tablets as a dosage form

TABLETS

Disadvantages

Some drugs are not compressible—> can’t formulate

If coating is required, processing is more expensive

Some patients may have difficulty in swallowing

Recognize and describe the unique properties of the various types of tablets discussed in class: Immediate release tablets

IMMEDIATE RELEASE TABLETS

Regular tablets that, when administered orally, disintegrate in the stomach and release drug for absorption

Can be prepared using different technologies

Single compression

Multi compression

Recognize and describe the unique properties of the various types of tablets discussed in class: Compressed tablets

COMPRESSED TABLETS

Requires only a single compression step

Wide variety of shapes possible

Recognize and describe the unique properties of the various types of tablets discussed in class: Multi-compressed tablets

MULTI COMPRESSED TABLETS

Require more than one compression step

Require special machinery

Can be used to prepare modified release products

Allows incompatible layers of drug to be separated

Types of multi-compressed tablets

Multiple-layer tablets:

Compress additional granulation onto a previously compressed layer

Layer

Immediate release or sustained release

Drug A or drug

Recognize and describe the unique properties of the various types of tablets discussed in class: Types of multi-compressed tablets

TYPES OF MULTI COMPRESSED TABLETS

Multiple-layer tablets:

compress additional granulation onto a previously compressed layer

Layers

Immediate release or sustained release

Drug A or drug B

Press-coated tablets:

Compress another granulation layer around the entire compressed table

Tablet within tablet

Recognize and describe the unique properties of the various types of tablets discussed in class: Sugar-coated tablets

SUGAR-COATED TABLETS

Coating is water-soluble

Coating:

Protects from humidity

Improves taste

Taste masking

Sweet taste of coating istelf

Enhances appearance

Coating is usually thick, adds size

Premarin (conjugated estrogens): thin coating

Recognize and describe the unique properties of the various types of tablets discussed in class: Film coated tablets

FILM-COATED TABLETS

Coated with polymeric film

May be water-soluble or water-insoluble

Thin

Provides taste masking

Improve stability of the drug

Recognize and describe the unique properties of the various types of tablets discussed in class: Enteric-coated tablets

ENTERIC-COATED TABLETS

Coated with polymeric film that resists disruption in the stomach

Drug is released in the intestine

Example

Enteric-coated aspirin

Recognize and describe the unique properties of the various types of tablets discussed in class: Sublingual tablets

SUBLINGUAL TABLETS

Flat, oval tablets

Dissolve under the tongue

Absorbed through the oral mucosa

Erode quickly

Rapid drug absorption

Recognize and describe the unique properties of the various types of tablets discussed in class: Buccal tablets

BUCCAL TABLETS

Flat, oval tablets

Placed in buccal cavity (between the cheek and gum)

Dissolves in the buccal region

Absorbed through oral mucosa

Typically erode and release drug more slowly than sublingual

Example:

Fentora (fentanyl citrate buccal tablet)

Recognize and describe the unique properties of the various types of tablets discussed in class: Mucoadhesive buccal tablets

MUCOADHESIVE BUCCAL TABLETS

Formulated from materials that adhere to mucous membranes

Allows product to remain in place for an extended period

Example:

Oravig (miconazole buccal tablet)

Instructions: tablet should be placed against the upper gum just about the incisor tooth and held in place with slight pressure over the upper lip for 30 seconds to ensure adhesion

Dissolves in buccal region

Locally treats oropharyngeal candidiasis

erodes and release drug slowly

Recognize and describe the unique properties of the various types of tablets discussed in class: Effervescent tablets

EFFERVESCENT TABLETS

Compressed granular effervescent salts

Contain drug which dissolves rapidly after adding water

Formulation has both dry acid and base components

Dissolve and react to produce effervescence (CO2)

Helps in taste making

Rapid action is possible

Example

Alka Seltzer products

Recognize and describe the unique properties of the various types of tablets discussed in class: Chewable tablets

CHEWABLE TABLETS

Disintegrate rapidly when chewed

Creamy, flavored base

Usually mannitol

Useful for:

Children

Adults who have difficulty swallowing

Recognize and describe the unique properties of the various types of tablets discussed in class: Rapid-dissolve tablets

RAPID-DISSOLVE TABLETS

Formulated to have pleasant taste and mouth feel

Do not require chewing

Disintegrate within 45 seconds when placed in mouth

Dissolved tablet than swallowed

Oral, not sublingual or buccal product

Useful for:

Children

Adults who have difficulty swallowing

Situations in which water is not readily available

Ensuring medication compliance (psychiatric patients)

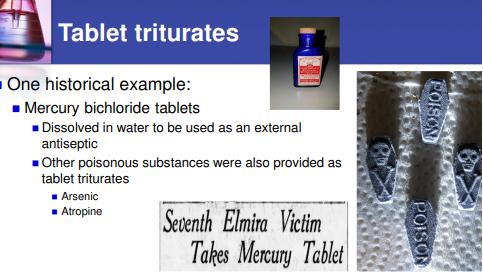

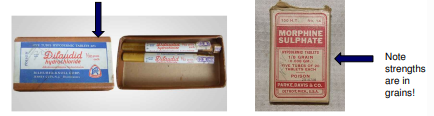

Recognize and describe the unique properties of the various types of tablets discussed in class: Tablet triturates

TABLET TRITURATES

One historical example

Mercury bichloride tablets

Dissolved in water to be used as an external antiseptic

Other poisonous substances were also provided as tablet triturates

Arsenic

Atropine

Hypodermic tablets

Subset of tablet triturates

Physicians used during house calls if needed an injectable solution

Resulting solutions were not sterile

Recognize and describe the unique properties of the various types of tablets discussed in class: Modified release tablets

MODIFIED RELEASE TABLETS

Any tablet in which drug release is modified as compared to an immediate-release product

Categorized into

Delayed release

Sustained release

Controlled or extended release

List and describe the function of the components present in a tablet (active ingredient, diluent, etc) given an ingredient list.

TABLET COMPOSITION

May or may not have all of the following excipients

Depends on:

Properties of active ingredients

Intended use

These excipients may be found in capsule formulations also

Common Tablet Components

Active ingredient

Diluent

Granulating agent

Disintegrant

Lubricant

Glidant

Coloring agents

Flavors

Opacifying agents

Coating agents

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Diluent (tablet or capsule)

DILLUENT (TABLET OR CAPSULE)

Inert filler used to create

Desired bulk

Flow properties

Compression characteristics needed for tablet or capsule manufacture

Must be compatible with the drug

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Direct compression diluents

DIRECT COMPRESSION DILUENTS

Special case excipient

Used in direct compression formulations to allow proper compression characteristics without adding a granulation step

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Chewable tablet diluents

CHEWABLE TABLET DILUENTS

Special case excipient

Must have good mouth feel and taste

Mannitol

Powdered sugar (sucrose)

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Granulating agents or binders

GRANULATING AGENTS OR BINDERS

Used to cause adhesion of powder particles in tablet granulations

Impart cohesive properties to powder

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Tablet disintegrants

TABLET DISINTEGRANTS

Allow tablet to break apart

Absorb water, and either swell or dissolve

Usually between 5-15% (w/w) of formulation

Super-disintegrants

Effective @ low levels

2-4% (w;w)

Cross-linked, so swell more effectively

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Lubricants

LUBRICANTS

Three roles identified with lubricants- understand the differences:

True lubricant role

Anti-adherent role

Glidant role

Substantial overlap between these roles; one excipient might serve more than one of the functions

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Lubricants- true lubricant role

LUBRICANTS: TRUE LUBRICANT ROLE

Decrease friction at the interface between a tablet’s surface and the die wall during ejection

Reduce wear on punches and dies

Too much can “water-proof” the tablet→ poor disintegration; dissolution

What effect will this have on drug absorption?

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Lubricants- antiadherent role

LUBRICANTS: ANTIADHERENT ROLE

Prevent powders or granules sticking to tablet punch faces, or capsule machine dosators, tamping pins, etc.

Similar and overlapping functions with true lubricants

Define the following excipient functions in tablets. Identify which of these excipient functions are also found in capsules: Lubricants- glidant role

LUBRICANTS: GLIDANT ROLE

Improves flow properties of powder mixtures during capsule and tablet processing

Reduces friction between the particles

Pure glidants do not reduce die-wall friction

What might happen if too much lubricant is included in a capsule or tablet formulation? Too much granulating agent? Too much binder?

Too much can “water-proof” the tablet→ poor disintegration; dissolution

List the steps in manufacturing tablets.

TABLET MANUFACTURING

3 Methods

Direct compression

Wet granulation

Dry granulation

List the steps in manufacturing tablets: Direct compression

DIRECT COMPRESSION

Make tablets without making granules first

Ingredient must be compressible

If drug itself isn’t very compressible, large amounts of diluent must be used

Steps:

Weigh raw materials

Mix raw materials

Compress mixture

List the steps in manufacturing tablets: Wet and dry granulations

WET AND DRY GRANULATIONS

Granule formation discussed earlier in lecture packet

Granules for tableting can be produced via wet or dry granulation

Wet granulation: granules sized by screening wet dough before drying

Dry granulation: granules sized by grinding compacted ribbons or slugs

Once granules of the correct size have been produced

Add lubricant

Mix Compress

List the steps in manufacturing tablets: Compression

COMPRESSION

Occurs in a tableting machine

Single punch:

Not particularly large-scale production

Slow

Only produces one tablet per revolution

Multi-station

Method used in industry

Rapidly produces large volumes of tablets

Describe the reasons for tablet coating

COATING AGENTS

Protect the tablet from decomposition

ALL coatings mask unpleasant taste, odor, or appearance

Provide easier swallowing

In some cases:

Control the site of drug release

Protect the drug from the gastric environment

Protect the gastric environment from the drug

Prolong drug release

Prevent interaction of incompatible ingredients

Examples

Sugar coating

Liquid glucose

Film coating

Hydroxyethyl cellulose

Hypromellose

Enteric coating

Cellulose acetate phthalate

List the types of tablet coatings available and identify an appropriate type of coating for a specific problem or situation: Sugar coating

SUGAR COATING

Tablet is coated with layers of sugar, color, and flavor

Can double the size of a tablet

Positives

Masks unpleasant tastes and odors

Produces a very attractive product

Problems

Time consuming

Requires skilled personnel

Coating varies from batch to batch and sometimes within the batch

List the types of tablet coatings available and identify an appropriate type of coating for a specific problem or situation: Tablet polishing agent

TABLET POLISHING AGENT

Used to impart an attractive sheen to sugar-coated tablets

Example

Carnauba wax

White wax

List the types of tablet coatings available and identify an appropriate type of coating for a specific problem or situation: Film coating

FILM COATING

Tablet is coated with a thin layer or membrane of a plastic-like material

Forms a skin-tight coating of the material over the tablet

Coating solution can be aqueous or non-aqueous

Polymer=film former

Mask unpleasant tastes and odors

List and describe the function of the components present in a tablet coating: Alloying substance

ALLOYING SUBSTANCE

Component in film coatings

Provides water solubility or permeability to the film to ensure penetration by body fluids and therapeutic availability to the drug

List and describe the function of the components present in a tablet coating: Plasticizer

PLASTICIZER

Component of film-coating solutions used to make fil more pliable, enhancing the spread of coating over tablets, beads, and granules

Adds flexibility and durability to the film

Example:

Diethyl phthalate

Glycerin

Triethyl citrate

List and describe the function of the components present in a tablet coating: Opaquant

OPAQUANT

Used to render a coating opaque

May be used alone or with a colorant

Example:

Titanium dioxide

List and describe the function of the components present in a tablet coating: Film coating- additional components

FILM COATING: ADDITIONAL COMPONENTS

Surfactants

Enhances spreadability of the film during application

Sweeteners; flavors; aromas

Enhance patient acceptability

Glossants

Provide luster

Do not require an additional polishing step

List and describe the function of the components present in a tablet coating: Enteric coating

ENTERIC COATING

Type of film coating that permits a tablet (or capsule) to pass from the stomach to the intestine before it begins to integrate and dissolve

Resists breakdown in gastric fluid

Masks unpleasant tastes and odors (though not primary purpose)

Material used:

Polyvinyl alcohol (PVA) phthalate

Hydroxypropyl methylcellulose (HPMC) phthalate

Cellulose acid phthalate (CAP)

List and describe the function of the components present in a tablet coating: Sustained release coating

SUSTAINED RELEASE COATING

Coating alters the release profiles of the active ingredient from the tablet

Release of drug is slow, but prolonged

Different types of polymers are used

Types depend on:

Release profile desired

Type of drug

List and describe the function of the components present in a tablet coating: Gelatin coated tablet

GELATIN COATED TABLET

Gelatin used as a coating agent

Makes tablet appear like a capsule

Primarily used for aesthetic appeal

List and describe the function of the components present in a tablet coating: Tablet coatings- Given the same base tablet, would film coating or sugar coating lead to a larger final product? Why?

Compare and contrast soluble and lake dyes: Compare

COLORING AGENTS

Improves aesthetic appeal

Assists in product identification

Makes the appearance distinctive

Masks color variation in ingredients (especially capsules and tablets)

Examples:

Soluble dyes

Lake dyes

Compare and contrast soluble and lake dyes: Soluble dyes

SOLUBLE DYES

Chemical compounds that exhibit their coloring power when dissolved in a solvent

Synthetics are available in a wide range of shades or hues with higher coloring power than natural pigments

Natural dyes less frequently used pharmaceutically, but are frequently seen in foods

Can lead to problems during wet granulation

Soluble colors may migrate during drying step

If multiple colors are used, they might migrate at different rates

Uneven coloring (or mottling) results

Can be diminished by absorbing onto additives such as starch or talc

Compare and contrast soluble and lake dyes: Lake dyes

LAKE DYES

Aluminum salts of FD&C water soluble dyes absorbed to alumina substrate

Available in 6 basic colors

Yellow, orange, pink-red, orange-red, green-blue, royal blue

Blends are available to provide more colors

Insoluble and color by dispersion

Particle size is very critical to coloring capacity

Smaller particle size leads to increased surface area for reflected light

Advantages

Because they are insoluble, the drying stages of processing may be performed more quickly

Opaque

Mottling is reduced

Overcoloring is not a problem; only 1 shade of color will result

Color is more reproducible

Full-color development requires fewer applications

Time savings

Lower raw material costs

Define the various tablet and film coating defects discussed in class

TABLET DEFECTS

Capping

AKA splitting

Top of tablet separates from bottom

Lamination

Separates into layers

Picking

Small fragments of film flake from the tablet surface

Peeling

Larger sections of film flake or peel from the tablet surface

Define the various tablet and film coating defects discussed in class: Orange peel effect

COATING DEFECTS

Orange peel effect

Roughness of tablet surface

Contributing factors:

High atomization pressure and extended spray time

Coating droplets drying before they spread completely over the tablet surface

Define the various tablet and film coating defects discussed in class: Twinning and mottling

COATING DEFECTS

Twinning

2 or more tablets sticking together

Most common with capsule-shaped tablets

Due to slow pan speed or high spray rate

Mottling

Uneven color distribution on tablet surface

Define the various tablet and film coating defects discussed in class: Bridging and infilling

COATING DEFECTS

Bridging

Coating film contracts and lifts off the tablet surface, suspending across the score line or tablet logo

Infilling

Score line or tablet logo is filled with coating

Define the various tablet and film coating defects discussed in class: Chipping and erosion

COATING DEFFECTS

Chipping

Portion of coating and sometimes tablet chips off

Due to high pan speed, friable tablet core, or poor choice of plasticizer

Erosion

Disfiguration of the core tablet when subjected to the coating solution for too long at at time

Define the various tablet and film coating defects discussed in class:

TABLET AND COATING DEFFECTS

May require

Changes in excipients (in tablet or coating)

Different punch design

More robust tablet

Change in pan speed

Change in coating application speed

Explain why tablet hardness, friability, disintegration, and dissolution testing are used to assess quality in tablet manufacturing: Tablet hardness (breaking force)

TABLET HARDNESS (BREAKING FORCE)

Force required to crush a tablet

Resistance to chipping, abrasion or breakage under conditions of coating, storage, transport and handling depends on this

Too hard —>

Tablet may not disintegrate or dissolve in specified time

Too soft —>

Tablet wont’ withstand handling

Load before fracture of common tablet types:

Oral: 4-10 kg

Chewable: 3 kg

Some sustained release: 10-20 kg

Explain why tablet hardness, friability, disintegration, and dissolution testing are used to assess quality in tablet manufacturing: Table friability

TABLET FRIABILITY

Related to hardness

Evaluates durability

Ability to withstand abrasion in handling, packaging and shipping

Tablets are weighed and placed in tumbling device

Weighed before and after a specified # of rotations

Weight loss should not exceed 1%

Explain why tablet hardness, friability, disintegration, and dissolution testing are used to assess quality in tablet manufacturing: Disintegration time

DISINTEGRATION TIME

A measure of the time required under a given set of circumstances for a group of tablets to disintegrate into particles

Placed into baskets with mesh at bottom

Agitated in a bath of suitable liquid

Particles must become small enough to go through the mesh

Many USP monographs specify disintegration time

Less than 30 minutes for most tablets

Usually not required for capsules unless enteric coated

Why?

Explain why tablet hardness, friability, disintegration, and dissolution testing are used to assess quality in tablet manufacturing: Dissolution time

DISSOLUTION TIME

Conducted to determine the amount of drug dissolved from the dosage form at certain time intervals

A drug must be present in solution to be fully absorbed

Disintegration DOES NOT imply dissolution

The dissolution of a drug from a dosage form is indicative of the availability of the drug for absorption in vivo

Vessel contains dissolution medium

Usually simulated gastric or intestinal fluid

Stirred at a predetermined rate

Dosage unit must be submerged completely in the dissolution medium

Different methods (most common*)

USP type 1 apparatus: basket*

Stainless steel cylindrical basket of 40-mesh cloth attached to shaft

Dosage unit is placed in the dry basket and submerged

Can be used with dosage units that float

More common with capsules

USP type 2 apparatus: paddle*

Paddle attached to shaft is used as stirring element

Dosage unit is allowed to sink to the bottom of the vessel before blade rotation begins

Dosage unit must not float

USP type 3 apparatus (FYI): reciprocating cylinder

USP type 4 apparatus (FYI): flow-through cell

Define rapid dissolve tablets

RAPID DISSOLVE TABLETS

Frequently referred to as Oral Disintegrating Tablets (ODT)

Disintegrate in the mouth within 30 seconds

More convenient to carry and take than oral liquids

FDA considers to be a new dosage form

Must get approval even if product is already on the market as a conventional release tablet

Advantages of rapid dissolve tablets

ADVANTAGES

Good for patients that have issues with oral dosage forms

Elderly—> hand tremors, difficulty in swallowing

Very young—> difficulty in swallowing

Mentally challenged patients

Developmentally disabled patients

Uncooperative patients

Patients required reduced liquid intake

Patients experiencing “sudden attacks” that prevent easy swallowing

Animals

Disadvantages of rapid dissolve tablets

DISADVANTAGES

Taste masking can be challenging for some drugs

Why?

Friability

Manufacturing costs

Stability of the product

Define rapid dissolve films

RAPID DISSOLVE FILMS

Thin film that incorporates the drug

Disintegrates within seconds in contact with water or saliva

Drug then swallowed or absorbed by buccal mucosa

Contains:

Drug (1-25%)

Water-soluble polymers (40-50%)

Softener (0-20%)

Fillers (0-40%)

Flavors or sweeteners

Potential uses:

Good for drugs requiring fast onset of action

Antiemetics

Migraine medication

Sleep medication

Opioid dependence (Suboxone)

Good for local treatment of oral cavity

Dissolves before sick child or uncooperative patient can spit out

Rapid dissolve films: Advantages

ADVANTAGES

Very rapid dissolution

Inexpensive to make

Can theoretically be compounded

How do you think this would compare to the molded ODT compounds?

Rapid dissolve films: Disadvantages

DISADVANTAGES

Poor taste masking, even for rapid dissolve products

Low drug loading capacity

List and compare the methods of manufacturing rapid-dissolve products

RAPID DISSOLVE TECHNOLOGY

Most products use one or more of the following processing technologies

Lyophilized foam

Compression

Sublimation

Candy-floss method

Spray-drying

Tablet molding

List and compare the methods of manufacturing rapid-dissolve products: Lyophilized form

LYOPHILIZED FORM

Tablets are prepared by foaming a mixture of drug and excipients

Foam is poured into a mold

Product is then freeze-dried

Mold serves as a unit dose dispensing package

Resulting tablets have amorphous, porous structure

Similar in texture to meringue (but foamed texture of meringue set by heating, rather than by freeze-drying)

Advantages

Extremely rapid dissolution

Within a few seconds of being placed on the tongue

Disadvantages

Very soft

Packaging material must be peeled away, exposing the tablet

Relatively expensive

Time-consuming

May not be stable under enviornmental stresses (heat or humidity)

Matrices used:

Usually gelatin or sugar-based excipients such as mannitol

May have improved stability if use:

At least 50% mannitol

0.07-3.2% natural gum (acacia, guar, xanthan)

Examples

Claritin, Reditabs (loratadine)

Seasonal allergies

Zofran ODT (ondansetron)

Brand name has been discontinued; generics available

Nausea and vomitting

List and compare the methods of manufacturing rapid-dissolve products: Compression

COMPRESSION

Formulations contain

Super-disintegrant

Small amount of effervescent material

MOA

Super-disintegrant pulls moisture into tablet

Effervescent material starts dissolving

Facilitates tablet breakup

Tablets are a little thinner than standard tablets

Larger surface area exposed to saliva

Packaged in firm molded plastic package to prevent breakage

Tablets are thin and fragile

Advantages

Rapid dissolution

30-45 seconds

Not as fast as some methods

Disadvantages

Water-insoluble disintegrants

Mouthfeel and swallowability issues

Effervescent materials are sensitive to moisture

Need protective packaging

Examples

Triaminic soft chew- cough and cold

No longer available

Zomig-ZMT (zolmitriptan)- migraine

Brand names ODT has been discontinued; generics available

List and compare the methods of manufacturing rapid-dissolve products: Sublimination

SUBLIMINATION

Volatile excipients are added to other tablet ingredients

Urethane

Urea

Ammonium carbonate

Ammonium bicarbonate

Benzoic acid

Phthalic acid

Naphthalene

Camphor

Mixture is compressed into tablets

Volatile materials are removed during the manufacturing process via sublimation

Porous structure results

Advantages

Exhibit good mechanical strength

makes porous tablet that allows quick water penetration

Quick disintegration

10-20 seconds

Disadvantages

Fragile formulation; needs proper packaging

List and compare the methods of manufacturing rapid-dissolve products: Candy floss method

CANDY FLOSS METHOD

Not all sugar-based excipients have ideal characteristics for rapid-dissolve

Dissolution rates

Compressibility

Compactibility

Use spinning machine to convert sorbitol or sucrose into candy floss

Improves above characteristics

Mill, blend, and compress

Advantages

Can hold large amount of drug

EZ chew: 1000 mg

Flash dose: 600 mg

Potentially good taste masking ability

Very product-dependent

Disadvantages

High processing temperature

Drug must be heat-stable

List and compare the methods of manufacturing rapid-dissolve products: Spray drying

SPRAY DRYING

Solvent is evaporated rapidly

Can produce highly porous, fine powders

Disintegrate within 20 seconds

Formulations contain:

Support agents: gelatin

Bulking agents: mannitol

Super-disintegrants: sodium starch glycolate or croscarmellose sodium

pH adjusters to enhance disintegration or dissolution: citric acid or sodium bicarbonate

Advantages

Forms highly porous powder

Dissolves rapidly

Disadvantages

Use of solvent

Expensive technology

List and compare the methods of manufacturing rapid-dissolve products: Tablet molding

TABLET MOLDING

Prepared using water-soluble ingredients

Tablet dissolves rapidly and quickly

Less compact than compressed tablets

Porous structure enhances dissolution

Advantages

Rapid dissolution

Can be compounded

Do you forsee any problems with this?

Disadvantages

Binding agent must be added to increase mechanical strength

Sucrose

Acacia

PVP

Poor taste masking abilities, even compared to other ODT types

Can Actiq (or generic equivalent) and Fentora be used interchangeably? Why or why not?

FENTANYL ACTIQ

Brand name has been discontinued, but similar generics remain

Appearance

Off-white lollipop

Large Rx symbol on stick

Requires special packaging

Open with scissors

Reduces risk of accidental overdose by child (looks like candy)

Absorbed via the buccal mucosa

Provides almost instant relief

Effects last only about 15 minutes

Typically long enough to relieve breakthrough pain

Patient can control rate of drug delivery

Remove and dispose of when pain relief is felt

FENTORA

Fentanyl buccal tablet

Onset in 15 minutes

Provides pain relief for ~60 minutes

Higher bioavailability than Actiq

F=0.65 (vs F=0.47)

Do NOT use interchangeably

Explain the mechanism by which Fentora has enhanced rate and extent of absorption.

FENTORA

Uses OraVescent drug delivery technology

Effervescent reaction

Is thought to enhance rate and extent of buccal absorption

Define troches / lozenges / pastilles

TROCHES; LOZENGES; PASTILLES

Solids containing the medicinal agent in a suitably flavored base

Intended to be slowly dissolved in the mouth

Usually for localized effect

Some may be chewable

Often made in the pharmacy

Melt the ingredients

Mix

Pout into molds

Define troches

TROCHES

Technically only refers to compressed lozenges

In practice, “troche” and “lozenge” are used interchangeably

Define pastilles

PASTILLES

Softer texture

Contain high percentage of sugar or a combination of gelatin and sugar

Molded

Slowly dissolved in mouth or chewed

Advantages of troches; lozenges; pastilles

ADVANTAGES

Easy to give to patients who have difficulty swallowing

Pleasant to taste

Extends time drug is in contact with oral cavity

Can prepare in pharmacy with minimal equipment

Disadvantages of troches; lozenges; pastilles

DISADVANTAGES

Children may mistake for candy

Ingredients must be heat stable

Describe what products troches; lozenges; pastilles are used for

USES

Especially good for relief of minor sore throat pain and irritation

Cough drops

Drug categories

Local anesthetics

Antibiotics; antibacterials

Analgesics