RPD - Metal Alloys & Metal Framework Fabrication (Quiz 5)

1/117

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

118 Terms

What type of metal alloys are used in the fabrication of RPD framework?

- Noble metal

- Base metal

noble metal consist of metals from ___________ and ___________ group, which are highly resistant to oxidation and dissolution in inorganic acids

gold and platinum

What type of metal are the following?

- Ruthenium (Ru)

- Rhodium (Rh)

- Palladium (Pd)

- Silver (Ag)

- Osmium (Os)

- Iridium (Ir)

- Platinum (Pt)

- Gold (Au)

Noble metals

Define the following:

A metal that readily oxidizes or dissolves to release ions

base metal

What type of metal are the following?

- Chromium (Cr)

- Manganese (Mn)

- Cobalt (Co)

- Nickel (Ni)

- Copper (Cu)

- Aluminum (Al)

- Carbon (C)

- Silicon (Si)

- Gallium (Ga)

- Molybdenum (Mo)

- Tantalum (Ta)

Base metals

What are 4 common base metal casting alloys used in RPD?

- Cobalt-chromium

- Cobalt-chromium nickel

- Nickel-chromium

- Titanium

In base metal casting alloys for removable partial dentures nickel-chromium alloys can be prepared with or without what element?

Beryllium

All of the following are important characteristics of ideal RPD metals EXCEPT:

a. corrosion resistant

b. light weight

c. high strength

d. high modulus of elasticity

e. high density

f. low cost

E - should say LOW density

What is the principle material used in fabrication of RPD?

chromium type alloys

All alloys contain ________ to prevent corrosion and tarnish

Chromium (Cr)

Define the following:

The ability of a metal to prevent corrosion and tarnish

passivation

What is Vitallium composed of?

cobalt chromium

Chromium (Cr) alloys have an elongation of only 2–3% and are quite brittle. Which alloy allows greater elongation and is less brittle?

Vitalium (a cobalt-chromium alloy - exhibits higher ductility and improved toughness compared to pure chromium alloys)

for the cobalt chromium alloys, it contains about ___% cobalt

60%

for the cobalt chromium alloys, it contains about ___-___% chromium

25-30%

What metal contributes to the hardness of the alloy?

cobalt

What metal contributes to the corrosion resistance of the alloy?

chromium

Molybdenum, tungsten, and carbon contributes to the ________ and ________ of the alloy

hardening and strengthening

Manganese and silicon contribute to the _______ of the alloy

fluidity

What percent of the cobalt-chromium-nickel is cobalt?

50%

What percent of the cobalt-chromium-nickel is chromium?

25%

What percent of the cobalt-chromium-nickel is nickel?

19%

what metals does Nickel-Chromium comprise? (4)

- nickel

- chromium

- aluminum

- beryllium

In Nickel-Chromium, this metal contributes the following:

- Lowers the melting temperature

- Enhances fluidity

- Improves grain structure

beryllium

What metal is lighter than chromium and just as strong?

titanium

what type of gold has been used in RPDs?

Type IV gold alloy

the melting temperature of the base metal RPD alloys are significantly _________ than those of the gold alloys

higher

What are two characteristics of polished Co-Cr and Ni-Cr?

- Lustrous

- Silvery white

t/f: chromium alloys are heavier than gold alloys

False (Cr alloys are lighter than gold alloys)

T/F: Linear casting shrinkage is relatively high for chromium-based alloys

True

___________ weight materials are especially useful for the construction of large and bulky maxillary removable appliances

Lighter

Chromium-based alloys are _____% harder than type IV gold alloys and they require special equipments for finishing and polishing

30%

What property of metals makes it fracture resistant?

tensile strength (ultimate tensile strength: 621-828 MPa)

What property of metals makes it resistant to permanent deformation?

yield strength (414-621 MPa)

The modulus of elasticity of base based metal alloy is ___x that of gold alloys

2x

Co-Cr alloys exhibit elongation of ___-___%

2-3%

Co-Cr-Ni alloys elongate ___%

10%

Why do Co-Cr-Ni alloys elongate more than Co-Cr alloys?

less amount of molybdenum and carbon

Can Co-Cr alloys be improved or controlled by heat treatment?

No

Can Ni-Cr alloys strength and ductility be altered by high temperature heat treatment?

Yes

alloys containing greater than 85% Cr, Co and Ni exhibit a reasonable degree of intraoral _______

corrosion resistance

Chromium-containing alloys resist corrosion through ___________, where a Cr₂O₃ film forms spontaneously in air, creating a protective barrier against oxidation and corrosion.

Passivation

Chemical coating with ________ reduces Cr release levels in artificial saliva = better corrosion resistance

zirconium oxide (ZrO2)

Repair or modification of a Co-Cr-Mo RPD framework should be done with the same alloy to avoid ________

galvanic corrosion

________ type alloys are attacked by chlorine. Therefore house bleach should not be used for cleaning

chromium

What is the most common investment materials used in RPD?

phosphate bonded or ethyl silicate (ethyl silicate is preferred)

What materials compensate for the high linear casting shrinkage of Co-Cr alloys?

phosphate bonded or ethyl silicate

What problem can occur during the casting of cobalt-chromium (Co-Cr) alloys if gases become trapped in the molten metal?

Can produce voids in large casting

ID the type of investment material:

- 80% refractory fillers (silica in the form of cristoballite or quartz)

phosphate bonded investments

ID the type of investment material:

- Contains binder (magnesium oxide and phosphate)

phosphate bonded investments

ID the type of investment material:

- Carbon is added to produce clean casting and facilitate easy removal of castings

phosphate bonded investments

ID the type of investment material based on the following advantages:

- High strength

- Easily withstand temps that reach 1650 F

- Used with high-fusing ceramometal alloys

phosphate bonded investments

ID the type of investment material:

- Binder is silica gel that reverts to silica

ethyl silicate bonded investment

ID the type of investment material:

- Can be heated from 2000-2150 F

ethyl silicate bonded investment

ID the type of investment material based on advantages:

- Ability to cast high temp alloys (base metal alloys)

- Good finish

- Low distortion

- High thermal expansion

ethyl silicate bonded investment

___________ affects the microstructure and mechanical properties of Cr-Co alloys

casting temp

What is used to adjust the alloy due to hardness and strength?

high speed lab equipment

ID the type of investment material based on disadvantages:

- Cast clasps can break in service even in short period of time, due to fatigue

- Difficult to adjust due to hardness, strength & low elongation

- High hardness can cause excessive wear of restorations or natural teeth that contact the cast framework

Cobalt-chromium (Co-Cr) base metal alloys used in RPD frameworks

What is the most known metal allergy, with 10-20% incidence?

nickel

nickel allergies are more common in _______ and can be caused from chronic exposure through jewelry and can be quite severe

women

t/f: individuals that are allergic to Ni will always react to intraoral nickel

false, will not always react (immunological tolerance/possible genetic component)

t/f: nickel ions are documented as mutagens in humans, but no evidence that they are carcinogenic intraorally

true

t/f: Various nickel compounds may contribute to the development of nasal and lung cancers

true

What metal has been associated with the following?

- Occupational hazards as an increase risk of lung cancer and tumors in men

- Revealed a very high leakage which may pose a health risk

- Acidic environment enhances release

beryllium

Define the following:

- Chronic allergic type lung response and chronic lung disease caused by exposure to beryllium and its compounds

- Condition is incurable, but symptoms can be treated

Berylloisis

___________ occurs only in individuals with a hypersensitivity to beryllium

occupational lung disease

What are the ten steps of fabrication of metal framework?

1. Survey by retripoding the master cast and outline the partial design on the cast

2. Beading 0.5 mm deep and wide

3. Block out and relief (parallel block out, shaped, arbitrary, relief)

4. Duplication (reversible hydrocolloid)

5. Refractory cast (trimmed, treated with model spray or bees wax)

6. Waxing

7. Major connector and denture base minor connectors

8. Burn out and casting

9. Recovering the casting

10. Finishing and polishing

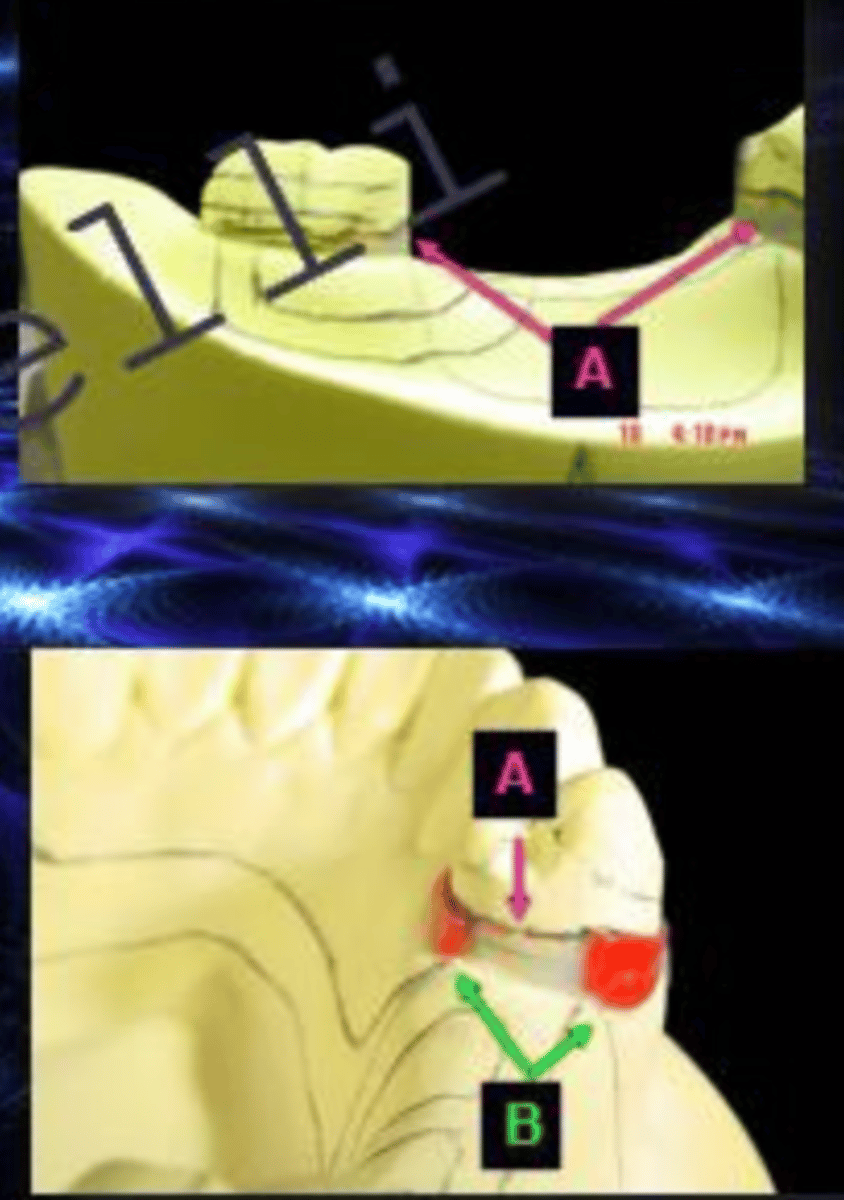

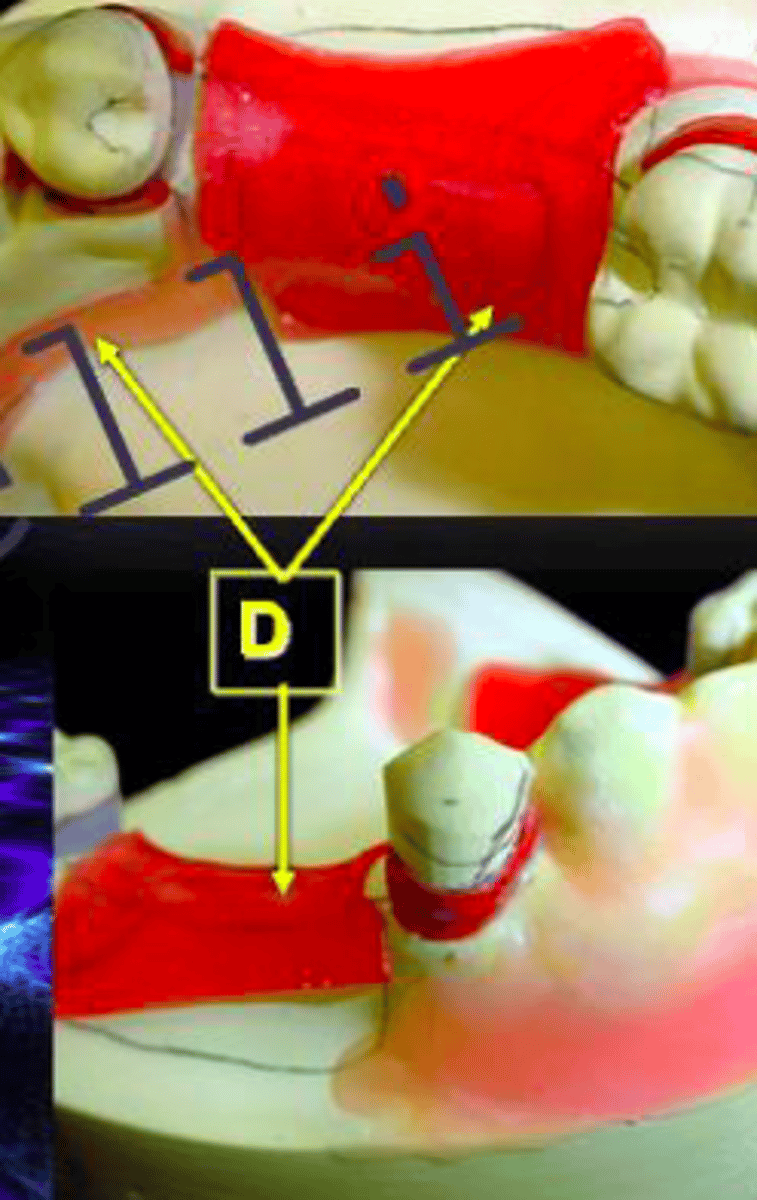

ID the type of block out at A:

parallel

ID the type of block out at B

shaped

ID the type of block out at C:

arbitrary

ID the type of block out at D:

relief

ID the type of block out at D:

Relief

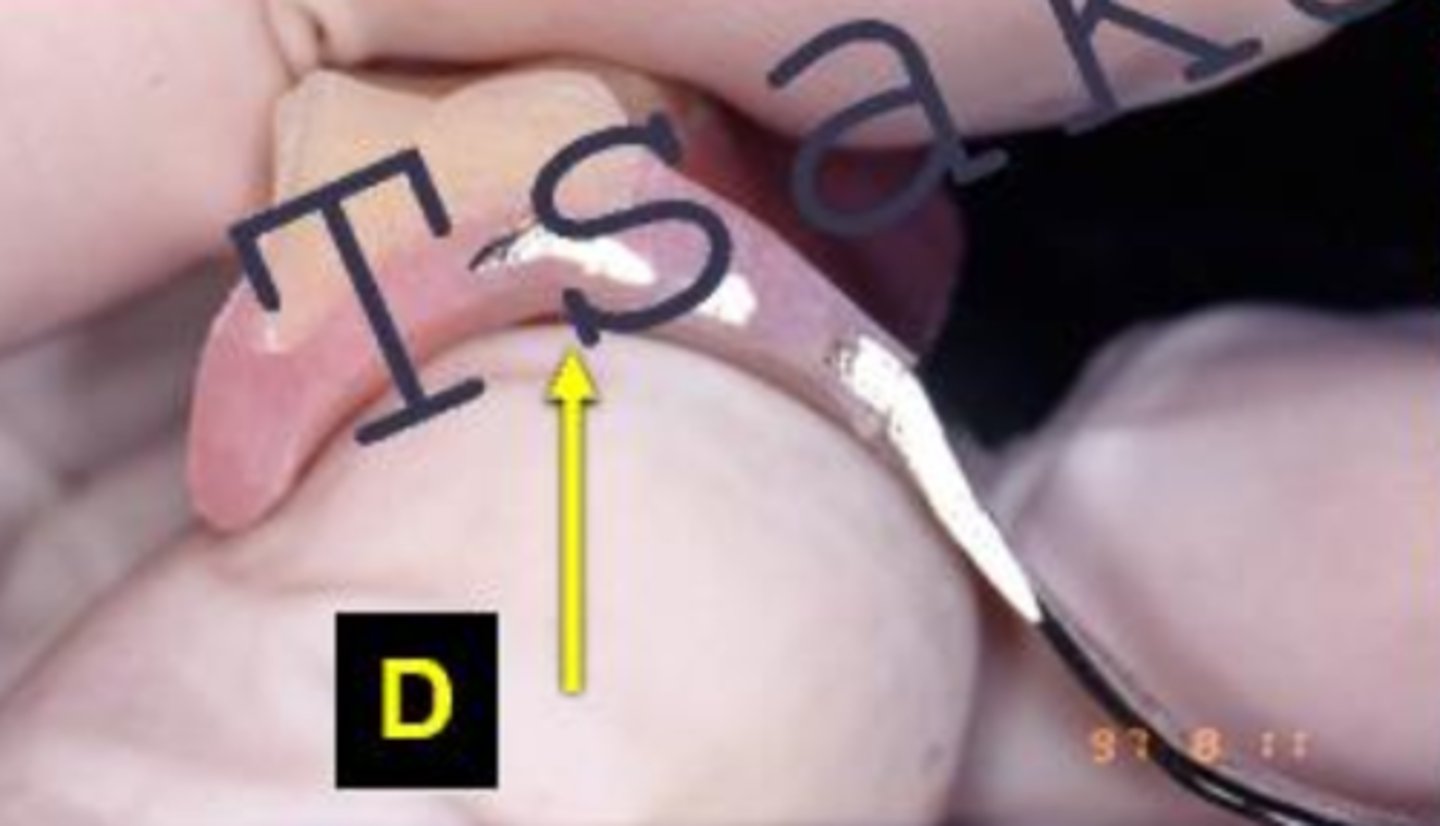

What is the arrow pointing to?

Tissue stops

Which type of block out is used to eliminate undercuts along the path of insertion before duplicating the master cast?

A. Arbitrary block out

B. Shaped block out

C. Parallel block out

D. Relief block out

C. Parallel block out

Which type of block out is used to prevent metal impingement on soft tissue or to relieve undercuts not used for retention?

A. Arbitrary block out

B. Shaped block out

C. Parallel block out

D. Relief block out

A. Arbitrary block out

Which type of block out is used to provide relief around soft tissue contours like gingival margins?

A. Arbitrary block out

B. Shaped block out

C. Parallel block out

D. Relief block out

B. Shaped block out

Which type of block out is most commonly used on the mandible only?

A. Arbitrary block out

B. Shaped block out

C. Parallel block out

D. Relief block out

D. Relief block out

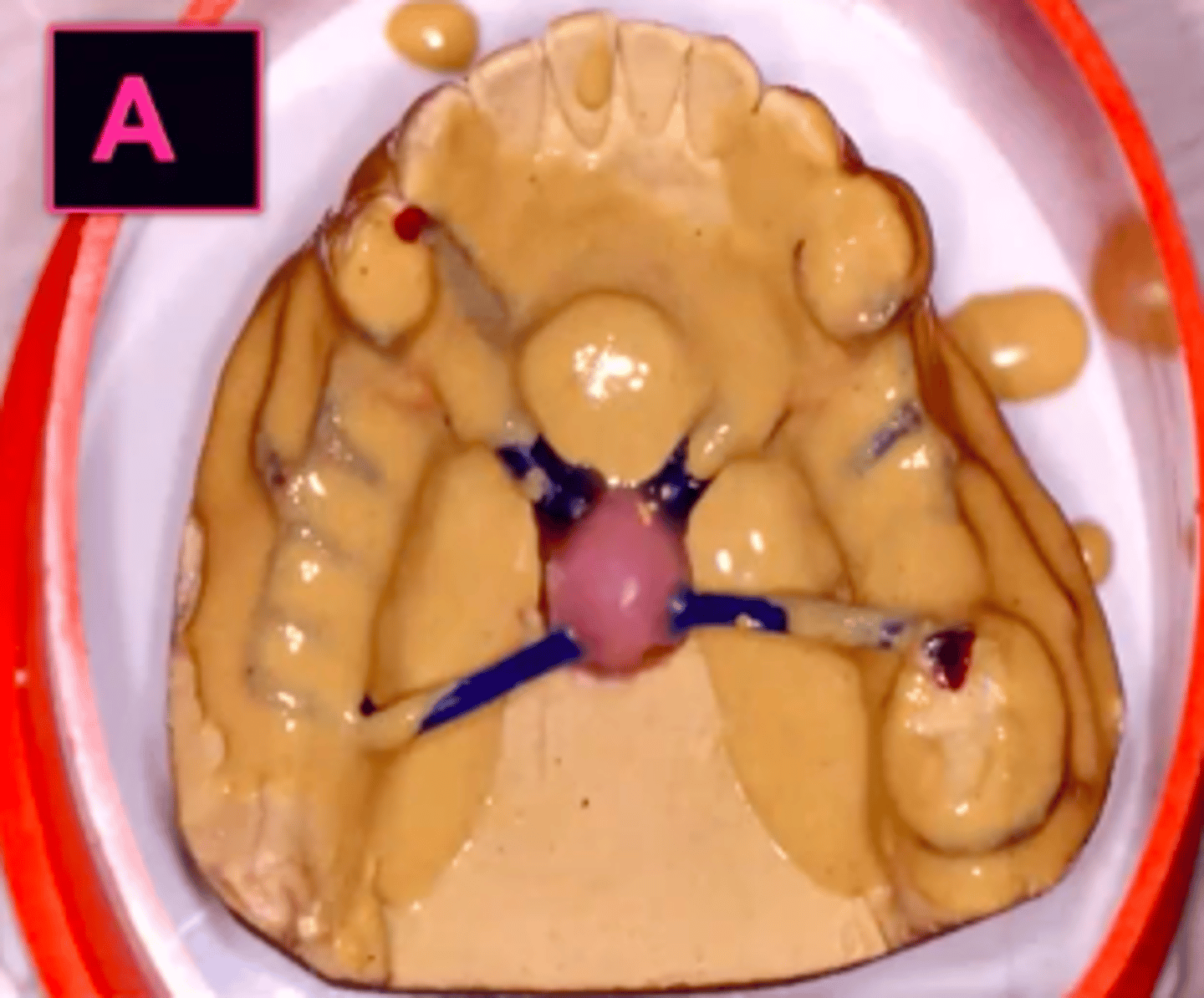

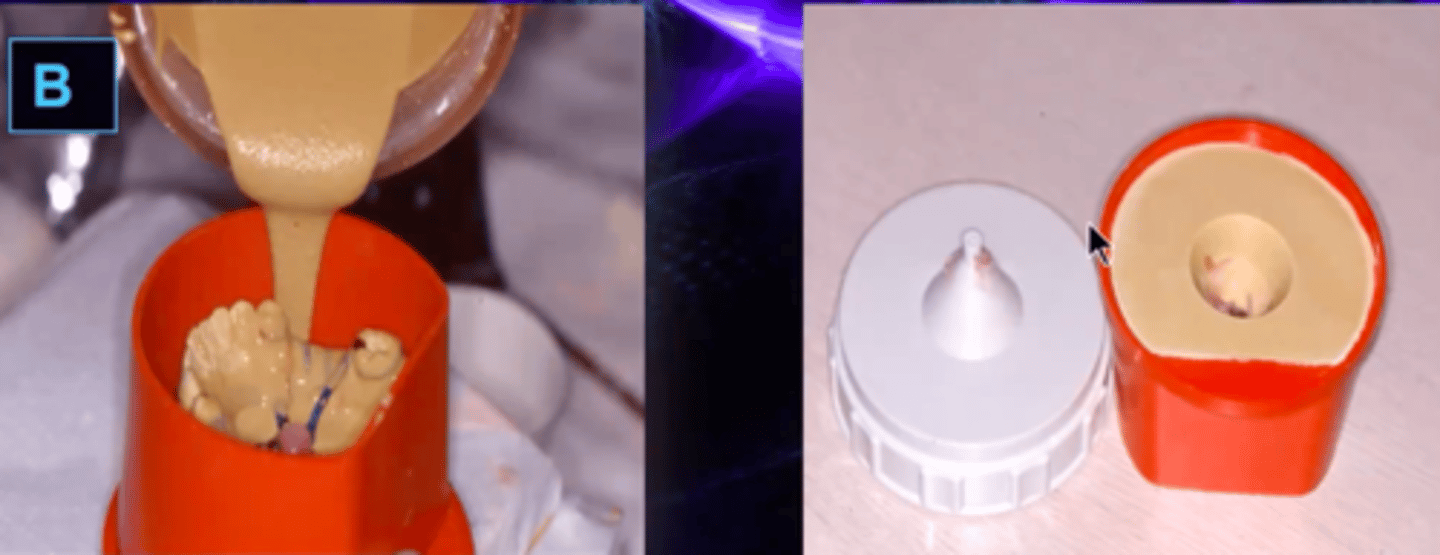

During the duplication step in metal framework fabrication for an RPD, which material is most commonly used?

Reversible hydrocolloid (agar)

What cast is made to withstand high temperatures?

refractory cast

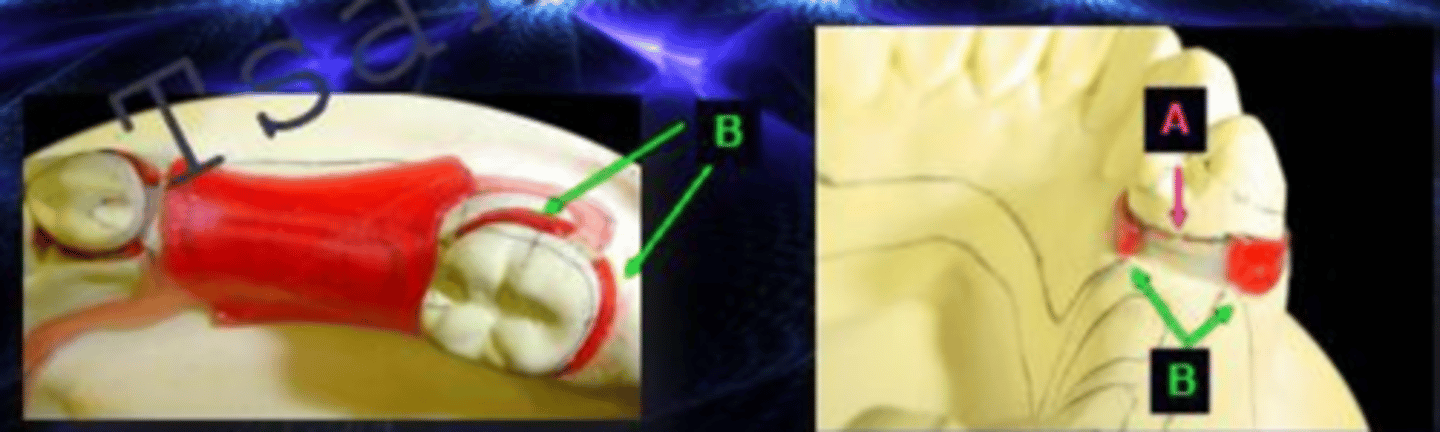

ID the type of investment:

paint on investment

ID the type of investment:

outer investment

What type of clasp is a part of the framework?

casts alloy clasps

What type of clasp should be soldered to the framework?

WW clasps

Excessive heating of the WW clasp should be avoided during casting or soldering because it will cause ________, compromising the wires mechanical properties

recrystallization

If a WW clasp is overheated, it will ________ the flexibility

decrease

WW should be _________ to the framework at some distance from the retentive terminal reducing the likelihood of overheating during soldering procedure

soldered

WW retentive clasps are available in ___-___ guage thickness

18-20 gauge

All of the following are advantages of what?

- Flexible in any direction

- Used for greater undercuts (0.02")

- More esthetic

- Minimal tooth contact

- Less fatigue failure

Using a WW retentive clasp

All of the following are disadvantages of what?

- Extra steps in fabrication

- Distortion by patient carelessness

- Distort with function

Using a WW retentive clasp

When checking an RPD returned from the lab, what defects do you look out for?

- Positive bubbles or nodules

- Voids or porosities

When checking an RPD returned from the lab, what are two characteristics of continuity to look for?

- Reproduction of anatomy

- Smooth and round transition

When checking an RPD returned from the lab, the major connector should be what?

Rigid and strong

When checking an RPD returned from the lab, the rest should be a minimum of ___mm at the junction

1.5mm

When checking an RPD returned from the lab, the clasp should be what?

uniformly tapered

When checking an RPD returned from the lab, finish lines should have what two characteristics?

- Staggered finish line

- Less than 90 degrees

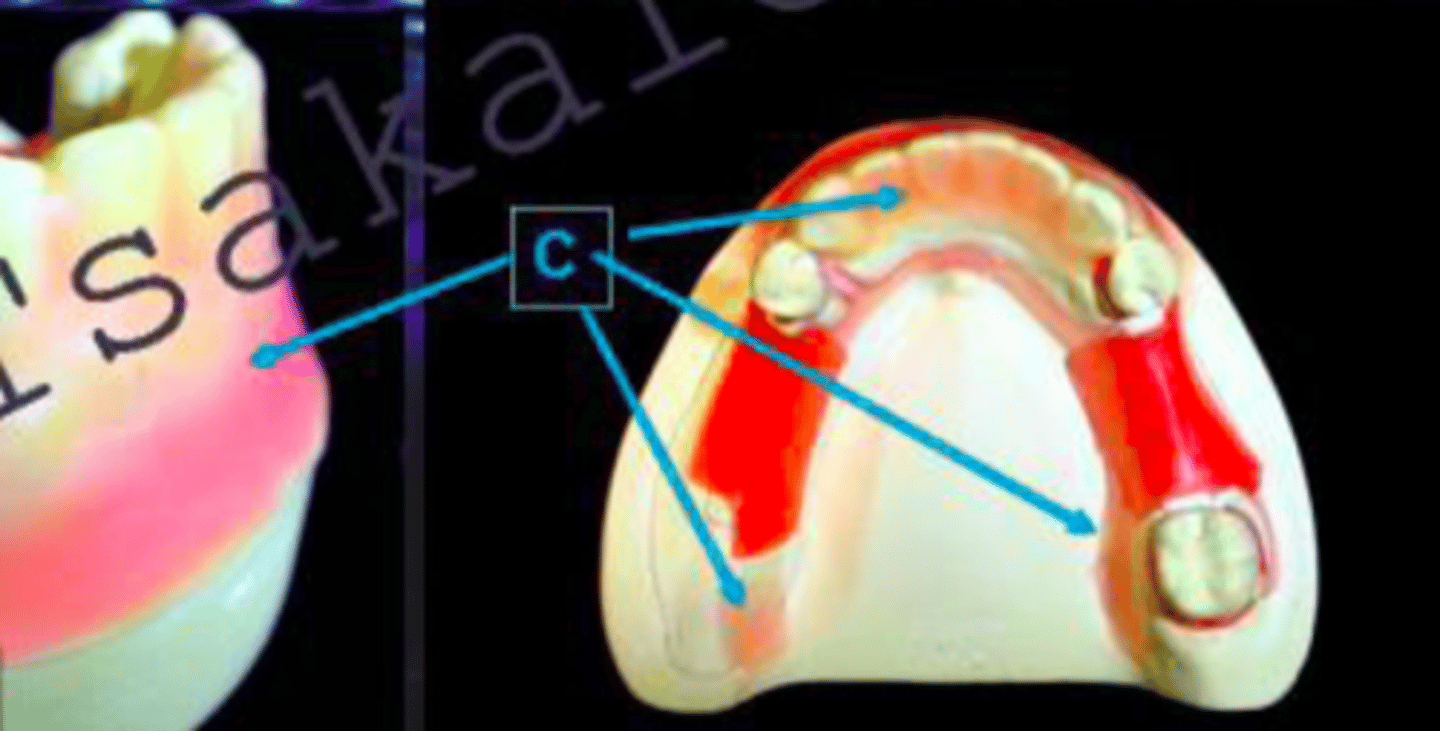

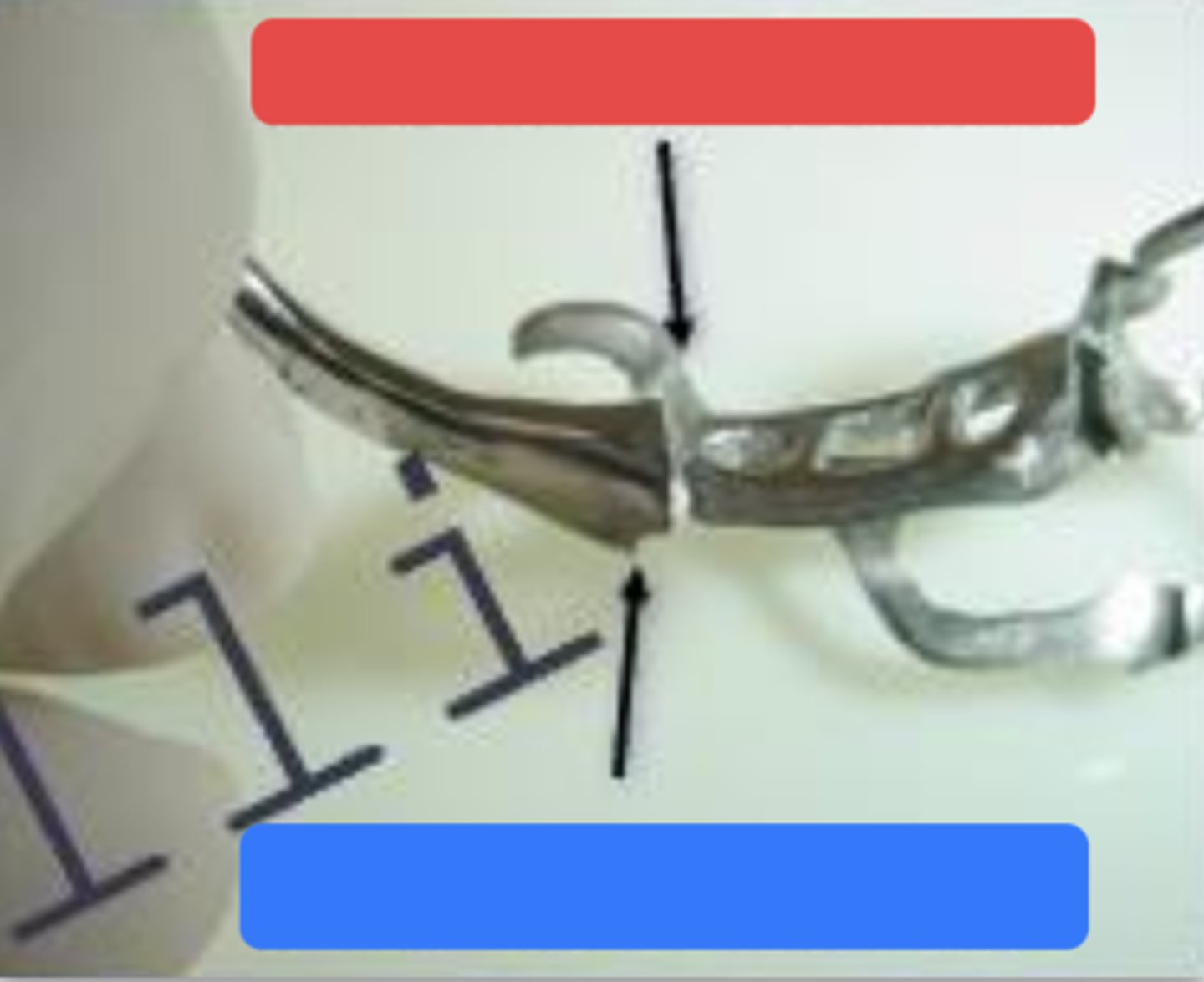

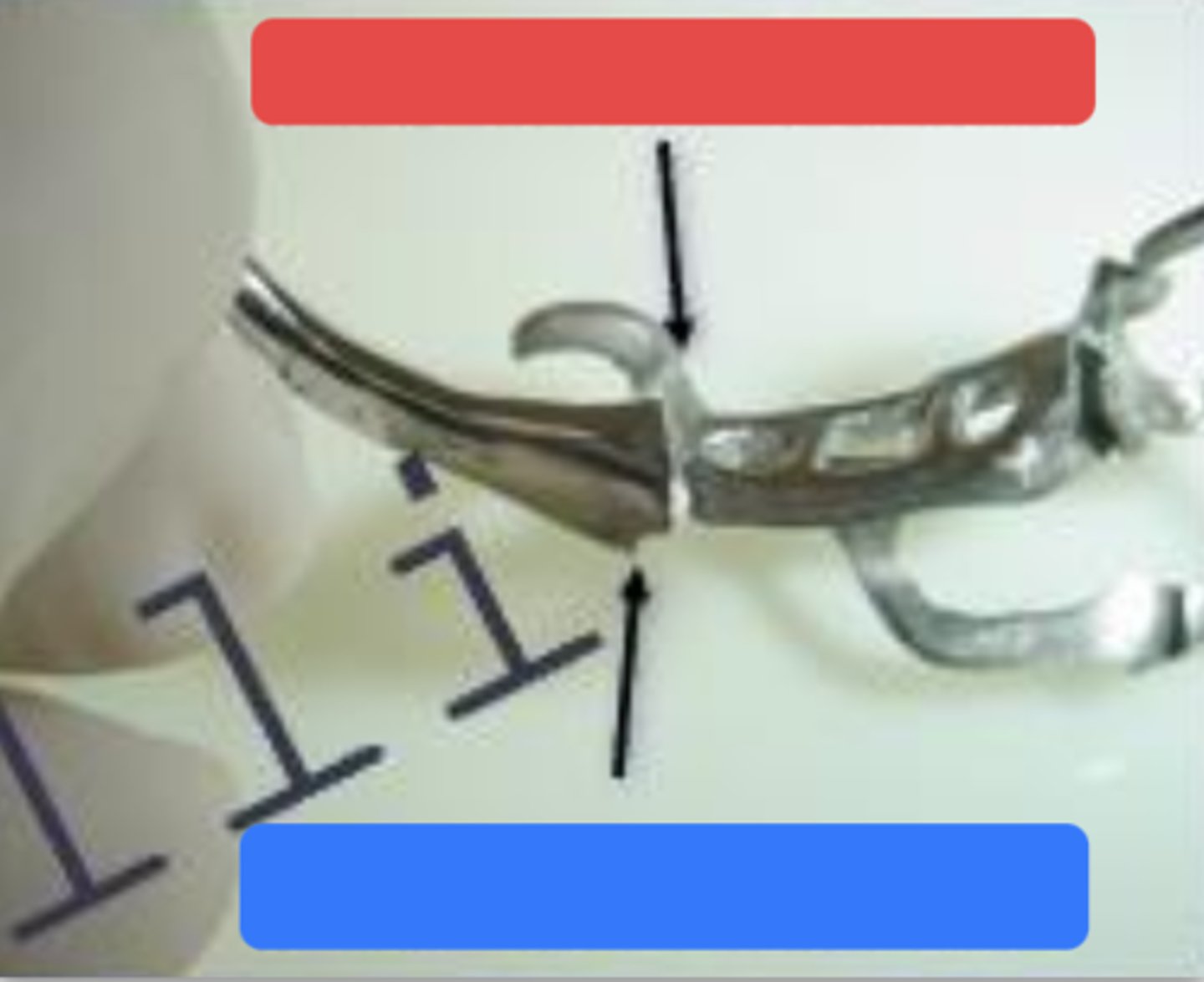

What is the box in red pointing to?

External finish line

What is the box in blue pointing to?

Internal finish line

What is the arrow pointing to?

External finish line

What is the arrow pointing to?

Internal finish line

t/f: the tissue surface of the maxillary major connector should be highly polished for intimate adaptation

false -- not highly polished for intimate adaptation