MCHE 3920 Week 6 Forging of Metals

1/29

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

30 Terms

metal, impact

Forging: Centuries old process of transforming ________ to a desired shape through __________

compressive, plastically

_ in forging: ____________ loads _________ deform material

high forces

Forging is Used for products that need to withstand _____________

knives, hand tools, mining equipment, auto and aerospace

examples of products that are forged

casting, form freedom, mechanical properties

Compared to _________, forging offers less ___________ but better ___________

strength, ductility, hardness

forging offers superior _____, ______, ______

versatile, large, grams, tons, very high, one-offs

Forging is a __________ process with

_________ practical weight range (_____ to _____)

Potential for ____________ production volumes

Can also be made by hand as _____________

improved, deforms, continuous, fibrous, fewer

Forging of metals: The ___________material properties are largely due to the fact that the grain __________ along with the part creating a ___________ and ____________ grain structure with _________ weak spots

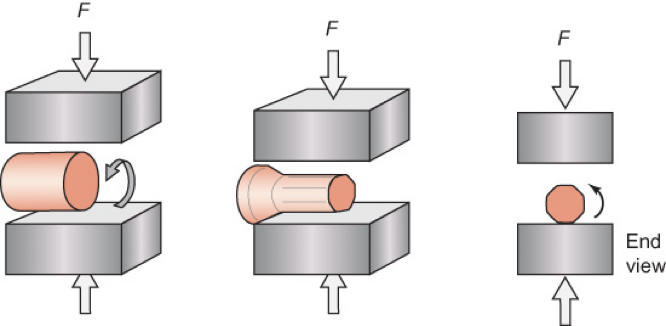

billet, work piece, blank, slug, flat dies, decrease, constant, upsetting

Metal forging: In simplest operation a ________, (aka, _________, _________or ________) is compressed between __________ to produce a ____________ in height

Volume stays __________, so diameter increases

Method is called ___________

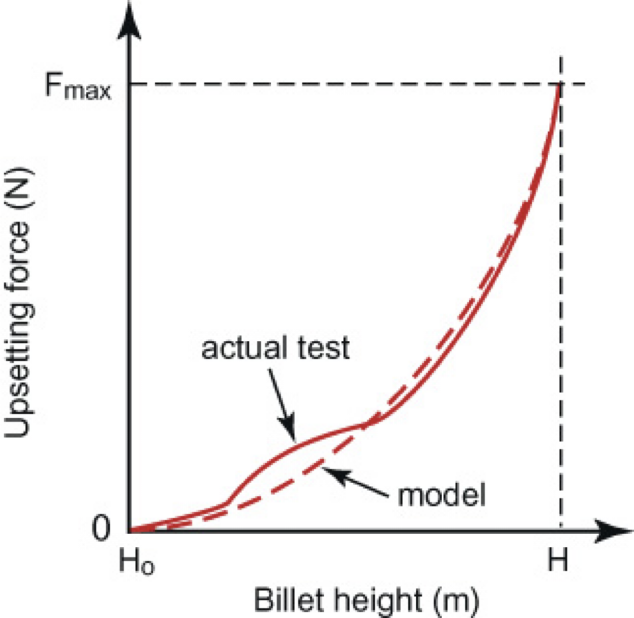

upsetting force, billet heights, exponential, large forces

Plotting _____________ vs. ____________shows an ____________ relationship- large shape changes require ________

increases, force, stress, cold, strain hardening, friction

Three reasons for upsetting relationship

Cross sectional area ____________

More ______ required to produce same amount of __________

In_______ forging, _____________ takes place

__________ between the billet and the die makes the billet more resistant to deformation

upsetting, sigmat=Ket^n

For a given alloy, the s/s relationship in _______ can be fit to a simple model: _________

true, true stress, area, strain hardening, material constant

Simple upsetting model: s/s are _____; _________ is force divided by instantaneous ______, n is ____________ exponent, K is a _________

more difficult, main axis, elastically

In upsetting, it is ____________ to achieve tight tolerances in the ___________ because the dies will also deform ___________ under the compressive load

very large, series of impacts, series of dies, load

Forces involved are __________ , so shaping is often done with a ______________ to gradually change the shape and sometimes with a ______________ to better distribute the ___________ across the changing shape

Cold, 40%, hundreds of

______ forging is generally defined as forging below _________ of melting temperature (in Kelvin)

Can still be at ___________ degrees Celsius

Warm, 40%, 80%

______ forging is between ________ and _________ of melting temp

Hot, 80%

______ forging occurs above ________ of melting temp

solidification range, Tsolidus

in cold, warm, hot forging: Recall that most metals have a ________________ , so the melting temp here refers to the lower end of the range (______)

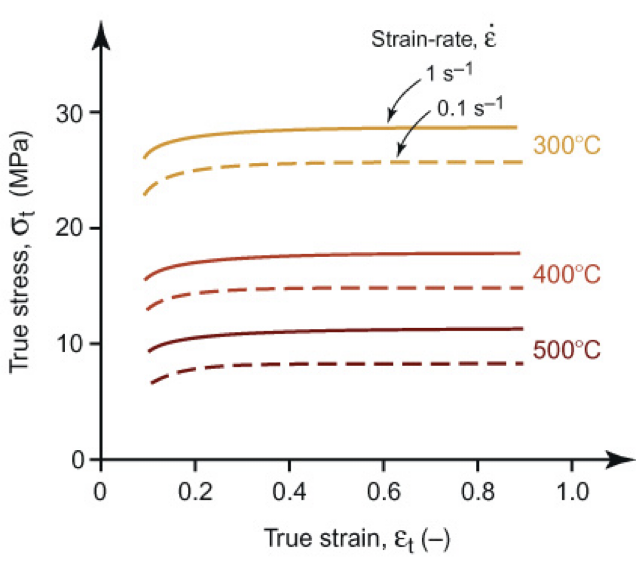

lower, strain rate, Zener-Hollomon

For HOT forging:

At elevated temperature, yield strength is much ________, so requires lower forces to deform metal

However, yield stress becomes a function of ____________, i.e., the how fast the metal is being deformed

Strain-rate and temperature are linked via the “_____________________”

ėe(Q/(RT)), ė, Q, R, yield stress

Zener-Hollomon Parameter is given by: Z=______, where _____ = strain rate, _____ = Activation energy, _____ = Universal gas constant

For a given material, the same Z value indicates the same ___________

tolerances, warpage, distortion, oxidation, cracks, surface faults, strain hardening, weaker, softening

Hot forging drawbacks:

Reduced control over _____________

_________ and ___________ can occur during cooling

_____________ can be severe at higher temperatures leading to __________ and ____________

At elevated temps, there is no _______________, so parts made by hard forging are ___________ than cold-forged parts

High temperatures can lead to recrystallization and grain growth, effectively ____________the material

dies, material, dead metal zone, impeded, radially, barreling

Effects of friction in forging: Friction between the __________and the _________ inhibits the material from the ends from deforming outward

Creates a _____________in which material does not deform

Away from ends, material is not _________ by friction and deforms __________

Called “___________”

open die forging, manipulated, two, blacksmith’s hammer, smith forging, slow, low, no

In __________: A metal block or rod is ____________ between ________ dies that move up and down in a fixed rhythm

Essentially a mechanized version of a _________________ , so it is sometimes called “______________”

Relatively ___________ process, so __________ production volumes, but __________ product specific investment

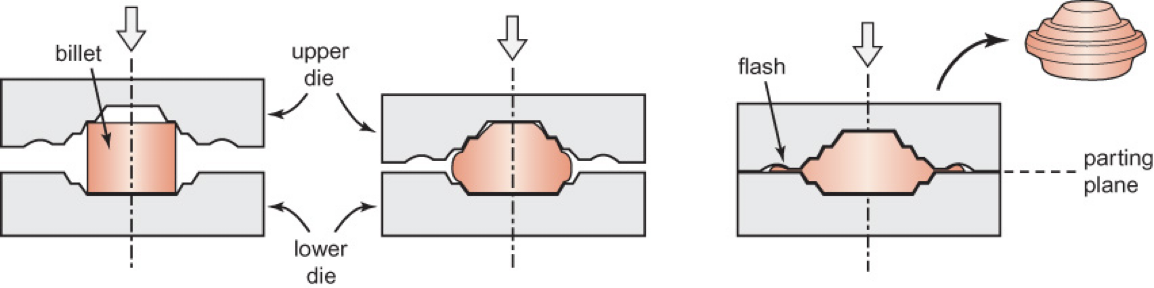

completely, 10%, 20%, flash, critical, corners, flash

In _________:

Uses profiled dies with goal being to fill the die __________

Often performed in steps

Usually uses ________ to __________ extra material that is squeezed between the dies

Known as “___________”

Makes billet size less __________

Material would rather flow into the ________ of the die than into the ___________ region

press forging, low, force, displacement, strain rate, flash, cool, reheated

In _______: Uses two dies brought together at ________ speed by hydraulics

Allows control over ________ and _________ (and thus __________)

Also generates __________

Because it is slower, the billet may _______during forging and need to be __________ during the process

Net-shape forging, impression die forming, eliminate, finishing, expensive, titanium

__________:

Essentially ____________________, but with very tight tolerances and control

Goal is to _________ waste and need for __________

Beneficial for ___________ materials (e.g., __________) or when the functional and/or quality requirements demand a tightly controlled process

Cold heading, fasteners, bolts, screws, at room temperature, impacting dies, grooved plates, strain hardening exponent (n)

_________:

Used exclusively for ___________ (e.g., ________ and __________)

Usually done _____________________

Head is formed by passing a thick metal wire through a series of ________________

Threads are made by rolling the parts between ______________

Only feasible with metals that have a low _______________________

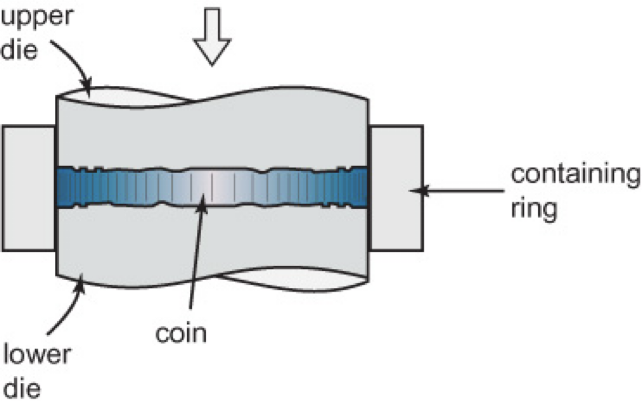

Coining, flash, convex, wouldn’t deform, positive imprints, negative pattern

__________: Used with thin disk-like billlets

Closed die process (i.e., no __________ is produced)

Dies are made to be slightly ________so contact and deformation starts in the center

Otherwise center _________

Coins have _________ imprints (i.e., ____________ on the die which is much more durable)