Unit 7

1/29

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

30 Terms

Types of point defects

vacancies, interstitials, substitutional

Types of Line defects

dislocations

Types of area defects

interfaces (grain boundaries, phase boundaries, solid-liquid interfaces)

Vacancies

a type of point defect

vacant atomic sites in a structure

Self-interstitials

a type of point defect

“extra” host atoms position in interstitial positions between atoms

alloy

where impurity (solute) atoms are added to the host atoms to modify specific properties/characteristics of the materials

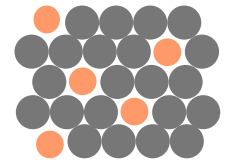

What type of impurity is this?

Substitutional solid solution

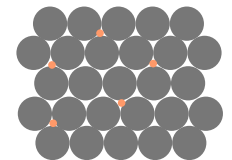

What type of impurity is this?

Interstitial solid solution

Solvent

host atom

Solute

impurity atom

Hume-Rothery Rules

Conditions for formation of substitutional solid solutions

1) difference in atomic radius < 15%

2) Proximity in periodic table (similar electronegativities)

3) Same crystal structure for pure metals

4) Valences: all else being equal, a metal will have a greater tendency to dissolve a metal of higher valence than one of lower valence

Estimate strength of a perfect material

Bonds typically break if stretched more than 10%. That is the stress is greater than E/10

Differences between ideal and actual strength for material types

metals: big difference

polymers: smallest difference

ceramics: biggest difference

Why are Polymers typically close to their ideal strength?

Polymer strands are almost perfect

Why are metals and ceramics typically not close to their ideal strength?

They are crystalline structures. Crystals are full of defects which decrease the strength of the material

Dislocations

caused by non-perfect alignment of crystallographic planes due to extra planes or shear planes

Edge dislocation

extra half plane

screw dislocation

if a region is slipped within a crystal

Moving dislocations

when a dislocation moves, only a line of bonds needs to be broken at one time. Significantly less force than breaking a whole plane of atoms

dislocations move when stresses are applied.

permanent (plastic) deformation results from dislocation motion

Slip planes

atoms like to slip along planes with the highest density of atoms (smallest jump to neighbor)

Where does slip occur?

on close packed planes in close packed directions

Glide or slip

dislocations move on the close packed plane in the close packed direction. Screw and edge dislocations move in different directions given the same applied force

Types of Interfaces in metallic systems

External (solid-vapor) surfaces, solid-liquid interface, phase boundaries, grain boundaries, twin boundaries

External (Solid-vapor) surfaces

interfaces where crystal structure ends. surface atom are not bonded to the maximum number of nearest neighbors. These atoms are at higher energy state than atoms at interior positions

Solid-liquid interfae

interfaces separating solid and liquid states of a material

plays key role during materials processing

Phase boundaries

an interface separating multiphase materials, in which a different phase exists on each side of the boundary

each of the constitute phases has its own distinctive physical and or chemical characteristics

Grain Boundaries

polycrystalline materials are composes of many crystals (called grains) that meet at internal interfaces, called grain boundaries

An interface that separate two grains (or crystals) of the same materials but having different orientations

Twin boundaries

a special type of grain boundary where there is a mirror lattice symmetry

atoms on one side of the boundary are located in mirror-image positions to those of the atoms on the other side

result from applies mechanicals stresses (mechanical twins) or during heating (annealing twins)

stacking faults

interfacial defect are found in FCC when there is interruption in the stacking sequence

In FCC the normal sequence is ABCABC becomes ABCABABC when there is a packing fault

Bulk defects

pores, cracks, and foreign inclusions

typically form during processing and fabrication