Supply Chain Management MidTerm

1/33

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

34 Terms

ABC Analysis

What: Categorizes products total consumption (price * volume)

Manufacturers use it to allocate limited inventory planning resources (daily planning of A items)

Retailers use it to allocate planning resources but also to decide what items to drop (C items)

Inventory management

can use ABC analysis

lower inventory carrying cost = increase cash flow, risk reduction, faster response to market changes, decrease interest expense, leaner supply chain

Demand planning

Used to help better manage inventory with fewer stock out and less excess inventory/holding cost

Use tech and data (Point of sale data) to make forecasting better —> and plan demand better

S&OP

Forecasting across sales. Operations, Finance and Supply chain management

It is very hard to achieve bc of each groups different objectives

Demand Shaping

Pushing the market twoard certain product

Methods like Buy one Get one

Toyota Production System (TPS)

A manufacturing management system reduces wast (inventory, set up time)

Key Processes: Utilizing front line workers, Value stream map, JIT/Pull, Pro active continue improvement

Six Sigma

A process improvment method that reduces variation

Patriots best super bowls

Super Bowel 51 (2017)

Epic comeback

First super bowl to be decided at overtime

Lady Gaga Performed

Set Up Time

Non Value added

Reducing set up time can increase capacity

Just in Time (Jits)

Producing what is needed when its needed

Economic Order Quantity (EOQ) Theory

What: Determine the optimal amounts of each order

Why: minimize total cost

Process Mapping

Best way to see inefficiencies and get rid of the bottle neck

Visualize process into individual small steps

Functional Product

Is a “need” product like groceries

Easy to forecast —> low tock outs

Cost is King

Low Margins

Long life cycle

Low Variety

Is a good fit for Just in time

Efficient Supply Chain

Firm schedule/info flow

Low cost

Low Inventory

Innovative Product

Is a “want” products

Difficult to forecast

Short lead time

High Margins

High variety

May also be called fashion

Poor fit for Just in time

Responsive SC

Flexible schedule

Differentiation

Short Lead times

Buffer inventory/capacity

Make to order

When manufacturing and supplies are waiting on stand by waiting for order to come in

Example: when you order food from restaurant the chef has the ingredients but doesn’t make the food until you order

An example of a pull system bc an order has to pull products through supply chain

Make to stock

Forecasting how much you think you can sell

Example: when you go to a clothing store and their is already a certain amount of inventory you can select from (there is no back what we have is what we have)

Push system bc we are pushing our inventory onto customers even though they haven’t yet laced orders

Engineer to order

Making a customized product for each order can’t finish product design until customer tells you what they want; everything is triggered by a customer order

Example: Commissioning a piece of art the artist can not start the process until the customer lets them know what type of art they want how big and so on

A pull system bc the item has to be pulled through the supply chain

Theory of Constraint (TOC)

Find/Relive bottleneck

Total Landed cost

The total price of a product once it has landed on a customers door

You get it by adding the original price with all the transportation cost custom duties and ect

Total Quality Management (TQM)

A structured approach to overall management

Process Analysis

A set of activities which take inputs (materials or info) and transform into an out put

Inventory management

2nd most important in supply chain

Can use ABC analysis & EOQ (TAC)

Lower inventory carrying cost

Increase cash flow

faster response to market change

risk reduction

decreased interest expense

leaner supply chain

Return On Assets (ROA)

ROA = Profit as percentage of sales × Asset turnover = Profit before taxes × Sales

Sales Total assets

Standard Work

Hard because no one likes change and resits

Don’t like loss of freedom

Remember the physicians and Cortez (either get with the program or get out)

Supplier Selection

Use “K matrix” to decide

Want to have trustworthy suppliers

Supplier Management

Tactical side of Sourcing— supplier scorecards , expediting, etc

Change Management

Challenges

Training/Qualified

Transition Ramp Up/Ramp Down

Loss of relationship/Working procedures

Inevitable start up cost/revenue

Economy of Scale

Lower costs with higher volume due to spreading fixed costs

when you make a lot of a product, it's cheaper to make each individual unit.

Diseconomy of Scale

Getting bigger leads to higher costs per unit, which can reduce overall efficiency and profitability.

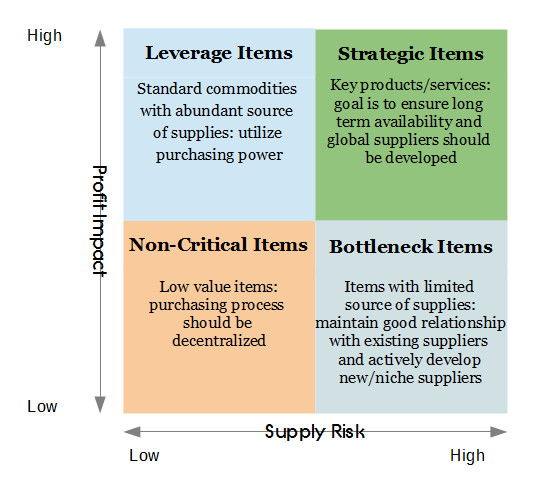

Category Strategy

Determine the types of products you have and how to best source them for maximum profit and minimized supply risk —> Use K Matrix