STAGE III - Prefab Parametric

1/99

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

100 Terms

Parametric design is _____

Additive, Subtractive, & Bending

3 multiple choice options

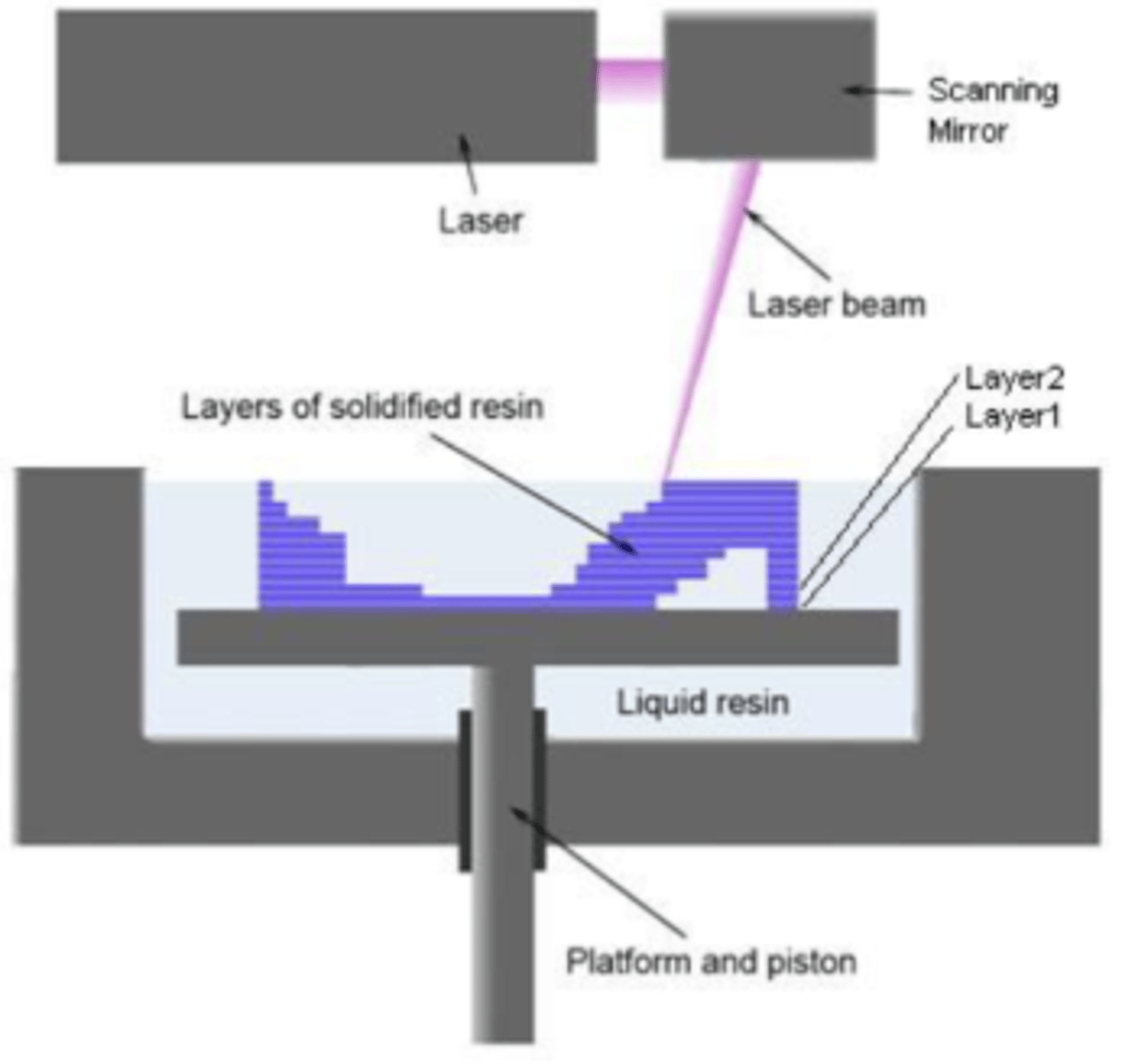

SLA meaning

Stereolithography Apparatus

SLA (Stereolithography Apparatus) process

Layers of liquid material hardened by UV light

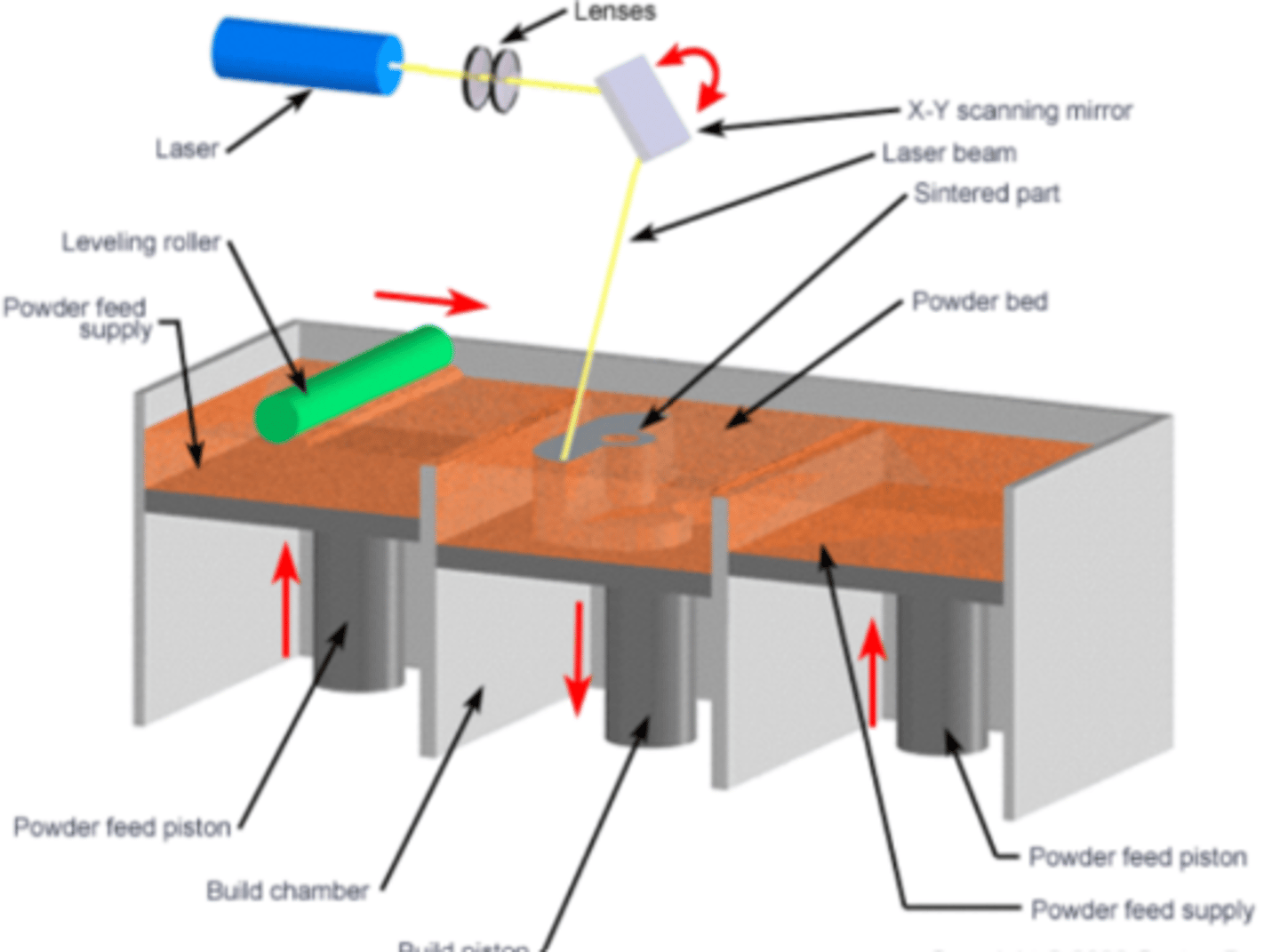

SLS meaning

Selective Laser Sintering

SLS (Selective Laser Sintering) process

Uses a laser to sinter powder-based materials together layer-by-layer, to form a solid model

FDM meaning

Fuse Deposition Modeling

Fuse Deposition Modeling was invented due to ____

3D printing

3D printed homes are: _____ bearing

non-load

3D printed homes are: _____weight

light

3D printed homes are: constructed by _____

layers added on top of each other

Steel can be _____ for intricate designs

laser cut

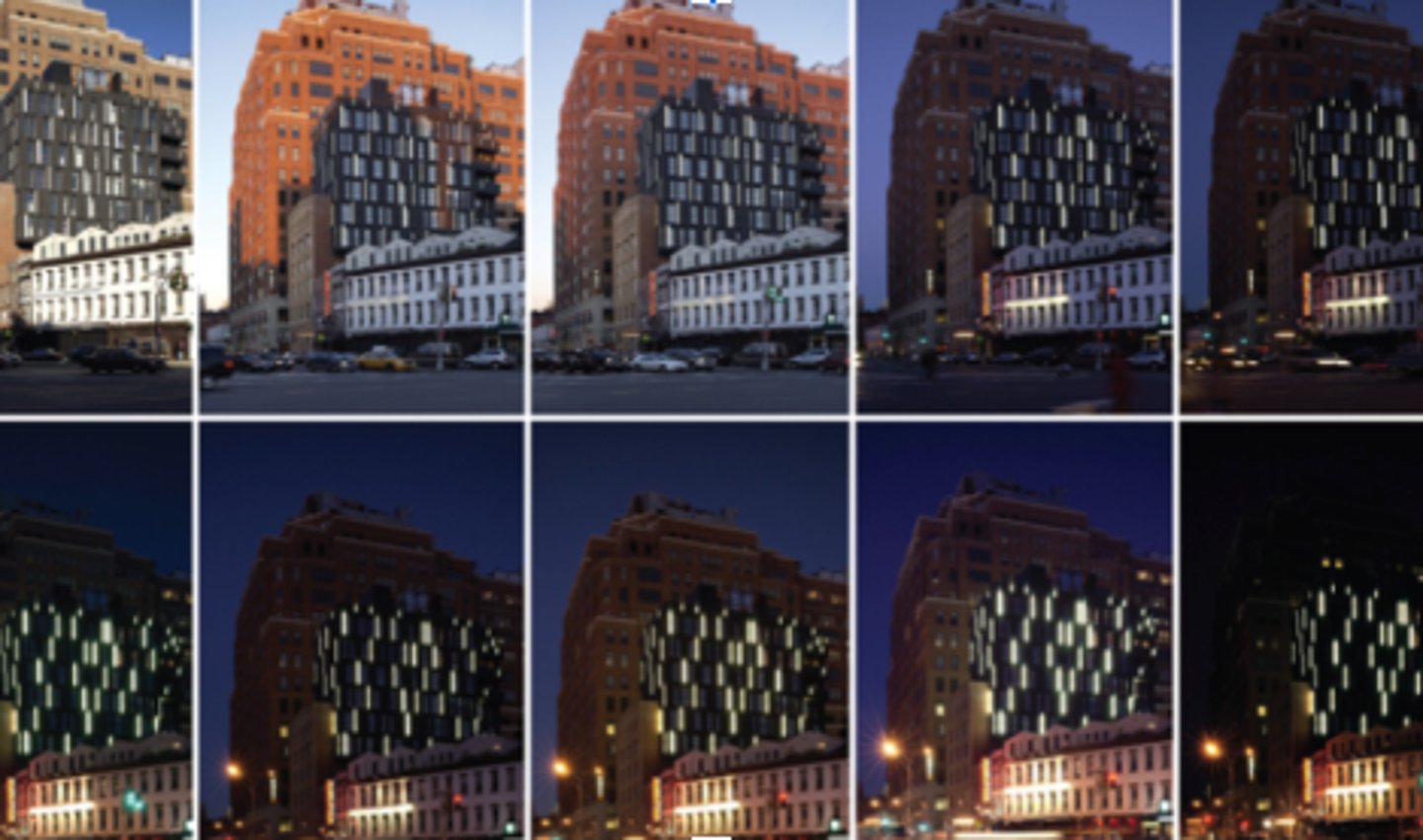

THE PORTER HOUSE: location & completion date

New York, 2003

THE POTER HOUSE: Architect

Gregg A. Pasquarelli [Architects SHoP]

![<p>Gregg A. Pasquarelli [Architects SHoP]</p>](https://knowt-user-attachments.s3.amazonaws.com/b3c40b09-2f34-4060-8d95-f554b69e0f9a.jpg)

THE PORTER HOUSE: The renovation and conversion of a six-story 30,000 sq. ft. warehouse to _____.

residential condominiums

THE POTER HOUSE: A new _____ to the existing building and an 8 ft. cantilever along the building's southern exposure.

20,000 sq. ft. addition added four stories

THE POTER HOUSE: Custom-fabricated _____ for the facade and floor-to-ceiling windows

zinc panel system

THE PORTER HOUSE: The metal framework of the extension is clad in _____

ANTHRA-ZINC

THE PORTER HOUSE: Zinc rainscreen emerges from a family of _____ profile types, from which there are _____ versions of profiles, yielding _____ total panels.

15, 50, 4000

3 multiple choice options

THE PORTER HOUSE: Variations were achieved by _____ each profile type of panel differently.

cutting & bending

THE PORTER HOUSE: Creators were going for an ambiance of _____ to fit in with the existing environment.

complexity & randomness

THE PORTER HOUSE: The use of building information modeling achieved huge gains in _____.

fabrication and installation time

THE PORTER HOUSE: Elevation pattern based on the most _____ of panels on a standard width of sheet material.

efficient layout

THE PORTER HOUSE: Standard zinc sheets of _____

39′′ x 118′′

THE PORTER HOUSE: The project team worked closely with the fabricator to _____

Minimize material waste

THE PORTER HOUSE: Software standard to the sheet-metal industry

rhino & solid works

THE PORTER HOUSE: The vertical light boxes, which draw the passer-by's eye upward day and night, give a sense of _____ to the addition.

lightness

THE PORTER HOUSE: How many pieces needed to be assembled?

3,800

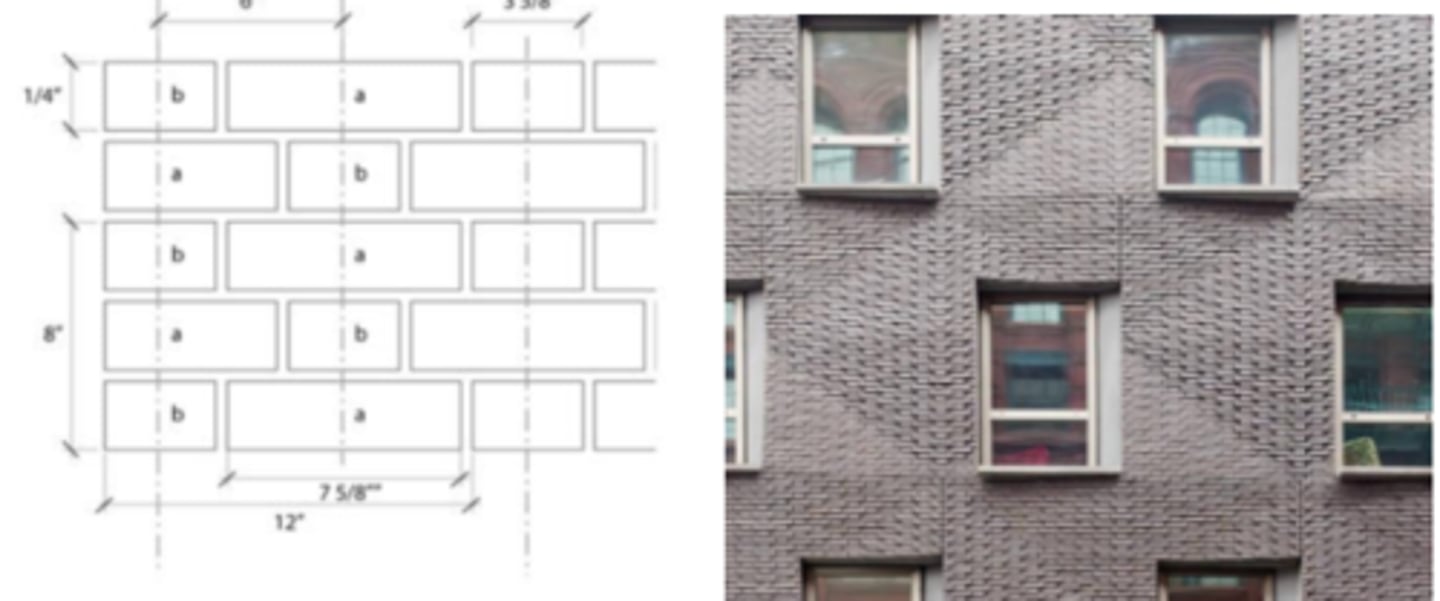

THE MULBERRY HOUSE: location

Nolita district of New York

THE MULBERRY HOUSE: consists of _____

9-unit residential condos

THE MULBERRY HOUSE: Must be mostly _____ to match the neighborhood

brick

THE MULBERRY HOUSE: uses a _____ bond

Flemish

THE MULBERRY HOUSE: why did they use Precast of composite brick and concrete panels (factory-made walls)?

saves labor costs & saves time on site.

THE MULBERRY HOUSE: Each brick is a ____ inch offset from its adjacent brick

3/4

THE MULBERRY HOUSE: Grid of six squares in proportion _____

3 to 2

THE MULBERRY HOUSE: Pattern breaks down into _____ different precast elements

8

THE MULBERRY HOUSE: Series of precast elements: Simplified _____

high-low-high

THE MULBERRY HOUSE: Each precast is created from bricks being held in a _____

mold

THE MULBERRY HOUSE: Concrete poured into the mold to the _____

brim

THE MULBERRY HOUSE: How was the mold formed?

Digital Fabrication | CNC routed

THE MULBERRY HOUSE: III: Pour concrete onto the ______ while in the form

back of the brick

THE MULBERRY HOUSE: IV: Remove Forms and _____

transport to site

THE MULBERRY HOUSE: V: Secure _____ to Structure. Secure _____ to the south facade.

panels & aluminum panels

THE MULBERRY HOUSE: V: Install _____ at street level and finish interior.

windows & glass doors

THE MULBERRY HOUSE: Additional mold was added, and the _____ was cast and bonded to the larger unit.

sill

THE MULBERRY HOUSE: _____ indicates the assembly sequence

No line

THE MULBERRY HOUSE: Steel anchors embedded into the _____

precast

THE MULBERRY HOUSE: Once the unit is completed, it is _____ into position

lifted

THE MULBERRY HOUSE: Façade completed: Together creates a ______

ripple effect

THE MULBERRY HOUSE: Gaps express the _____

construction process

THE MULBERRY HOUSE: Maximum undulation and minimum weight of _____

concrete

SFMOMA title

San Fransico Museum of Modern Art

SFMOMA Architect

Snohetta Architects

SFMOMA: 1st US _____

high-rise

SFMOMA: Most expensive use of _____ in a US architectural building project, to date.

FRP

SFMOMA: FRP panels meaning

Fiber-Reinforced Polymer

SFMOMA: Fiber-Reinforced Polymer is an _____

Undulating surface, reminiscent of rippling waters in nearby San Francisco

SFMOMA: Used Advanced developments in _____ technology

building skin

SFMOMA: The project originally called for _____

glass fiber-reinforced concrete (GFRC)

SFMOMA: FRP is a fraction of the _____ of GFRC

weight

SFMOMA: FRP is a _____

composite system

SFMOMA: The FRP is based on the _____

Curtain Wall system

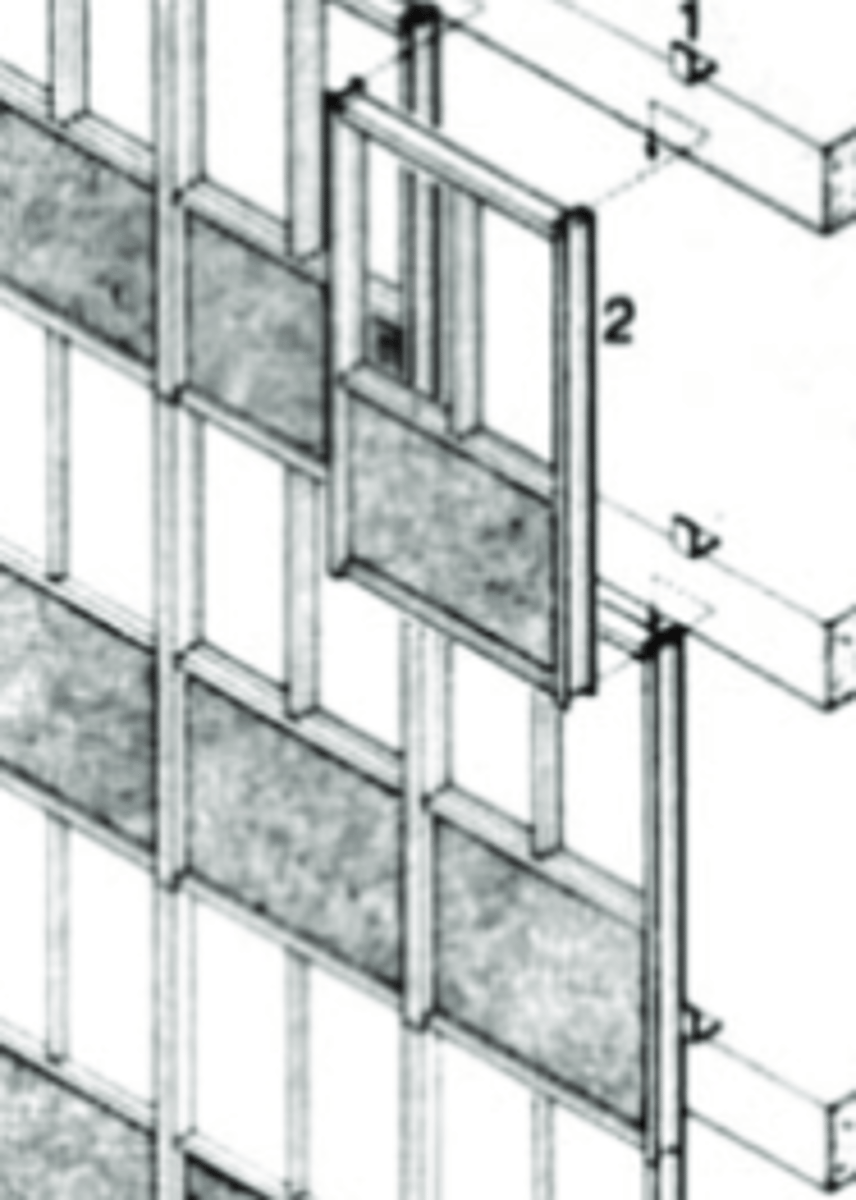

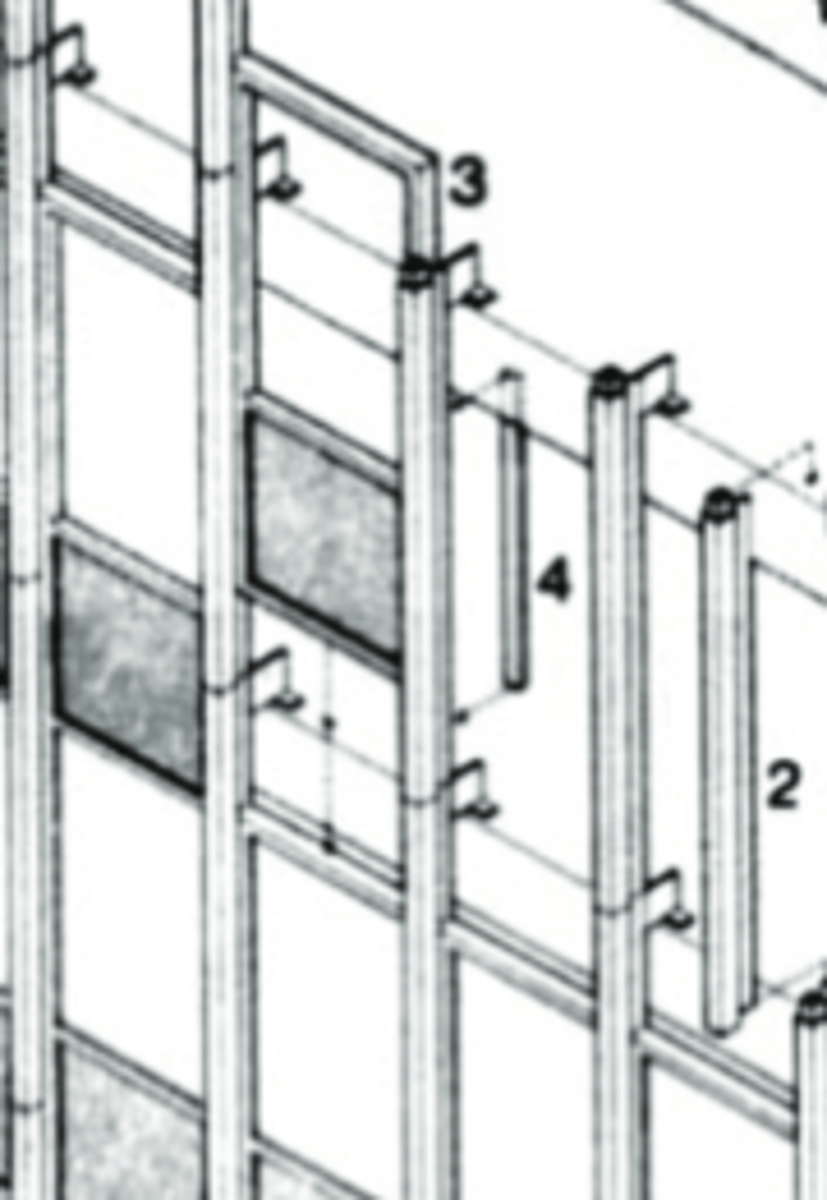

Two basic types of Curtain Wall systems

Unitized & Stick

Unitized Curtain Wall Systems: _____ of curtain wall technology

Newer adaptation

Unitized Curtain Wall Systems: The vertical and horizontal framing members are ______

figuratively split

Unitized Curtain Wall Systems: Independently framed “units” to be _____ in a factory.

assembled & glazed

Unitized Curtain Wall Systems: Concentrates fabrication and assembly in a _____, rather than in the _____.

controlled factory setting / field

Unitized Curtain Wall Systems: Factory completed units are shipped to the project site and simply _____.

hung onto the building

Unitized Curtain Wall Systems: Typically, unitized panel systems [a modernized, computer-modeled update to traditional curtain walls] feature _____ panels.

glass or metal

Unitized Curtain Wall Systems: Enclosed, typically, by a _____ thick aluminum frame.

203-mm

Unitized Curtain Wall Systems: The units can be designed to span multiple floors or multiple horizontal modules, and can incorporate _____.

multiple cladding elements such as operable vents and windows

Stick Curtain Wall Systems: Built from long ______ attached to the building structure

vertical extrusions (mullions)

Stick Curtain Wall Systems: Shorter horizontal extrusions spanning between the vertical mullions to create the ______.

frames

Stick Curtain Wall Systems: ______ are then installed into the frames

Cladding materials

Stick Curtain Wall Systems: Extrusions may be fabricated in ______, but all assembly, installation, and glazing takes place in _____.

the shop / the field

SFMOMA: A project's main contractor always prefers to minimize the number of ______.

subcontractors

SFMOMA: Part of the building that is latent with liability is the ______.

exterior wall

SFMOMA: eventually adopted the unitized system with a ______

FRP rainscreen

SFMOMA: Each contoured SFMOMA FRP rain screen panel would be attached to a ______

flat backing structure

SFMOMA: The FRP rainscreen panels were then attached to a unitized wall panel that includes a _____ for the building.

vapor barrier, insulation, and weather barrier

SFMOMA: The unitized wall system fabricator was _____

Enclos

SFMOMA: using one contractor eliminated _____

more than 450,000 kg of secondary steel structure

SFMOMA: Still required the use of a _____ framing system

secondary aluminum panel

SFMOMA: More than 700 panels, some as large as _____

1.5m wide x 9m long

SFMOMA: Totally 7,804 m2 of surface area, forming a ______

10-story contoured facade

SFMOMA: It is the first time a composite system has passed the rigorous _____ that permits its use above the fourth story on a high-rise exterior in the US.

fire regulation testing

SFMOMA: The Fire shield 285 panel system, and FRP system that passes the _____, has allowed economical use on buildings taller than 12m.

NFPA (National Fire Protection Agency) 285 fire-resistance certification

SFMOMA: Snohetta worked with _____ for pre-production preparation ["With over a year of design development"]

Kreysler & Associates'

SFMOMA: Snohetta enlist potential _____ long before anything gets built. "_____ are retained through a design assist contract."

subcontractors

SFMOMA: Distance varied not only for each panel, but even on the _____ of each panel.

left vs. the right side

SFMOMA: The FRP panel production program was driven by _____

digital fabrication tools

SFMOMA: Panel production required _____ that governed panel geometry

careful management of the 3D computer models

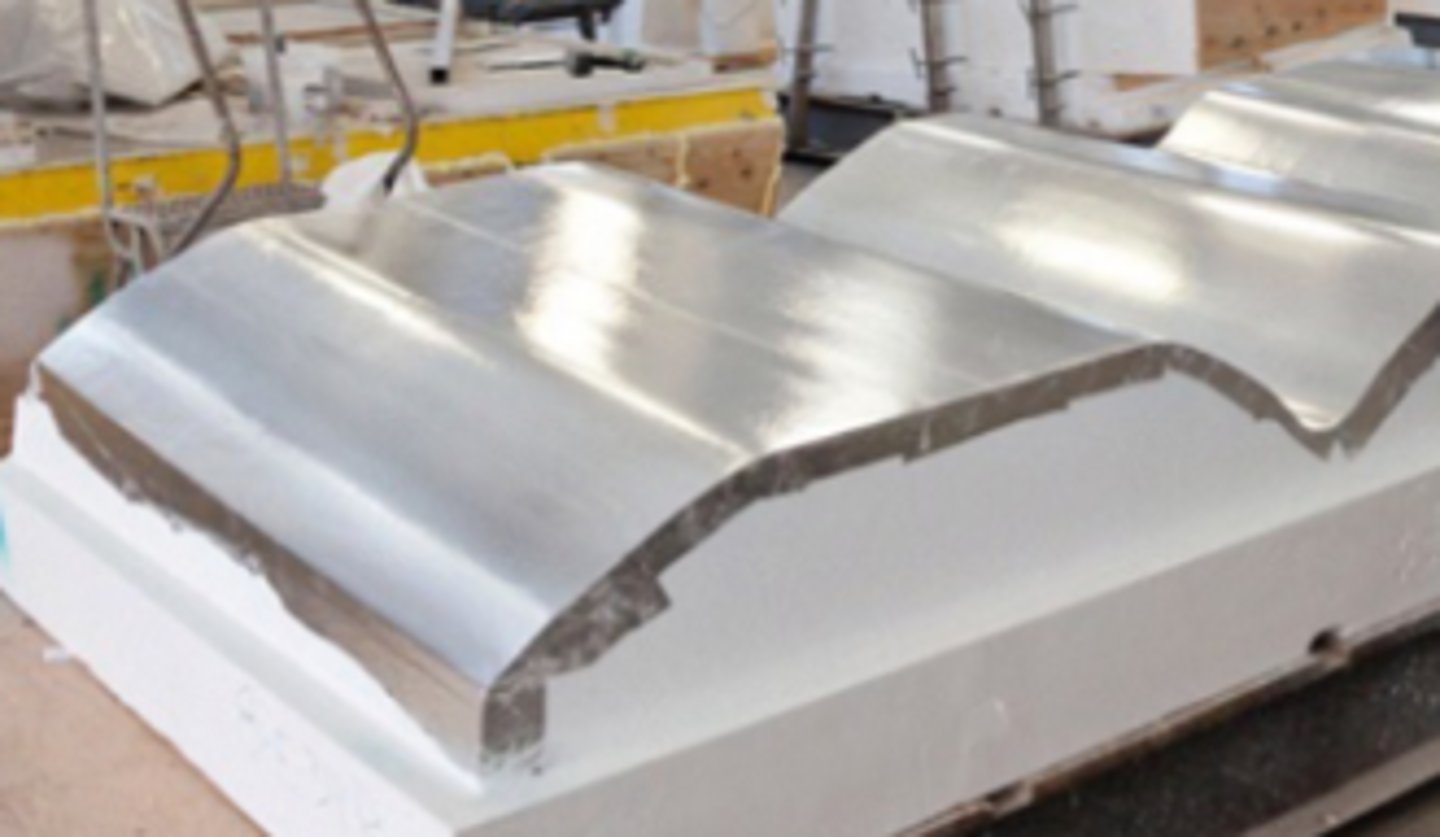

SFMOMA: Molds were CNC-machined from _____

EPS foam

SFMOMA: More than _____ unique molds were CNC-machined from expanded polystyrene (EPS) foam.

700

SFMOMA: After the foam was machined, it was covered in ______ as a mold release surface.

tin foil and waxed

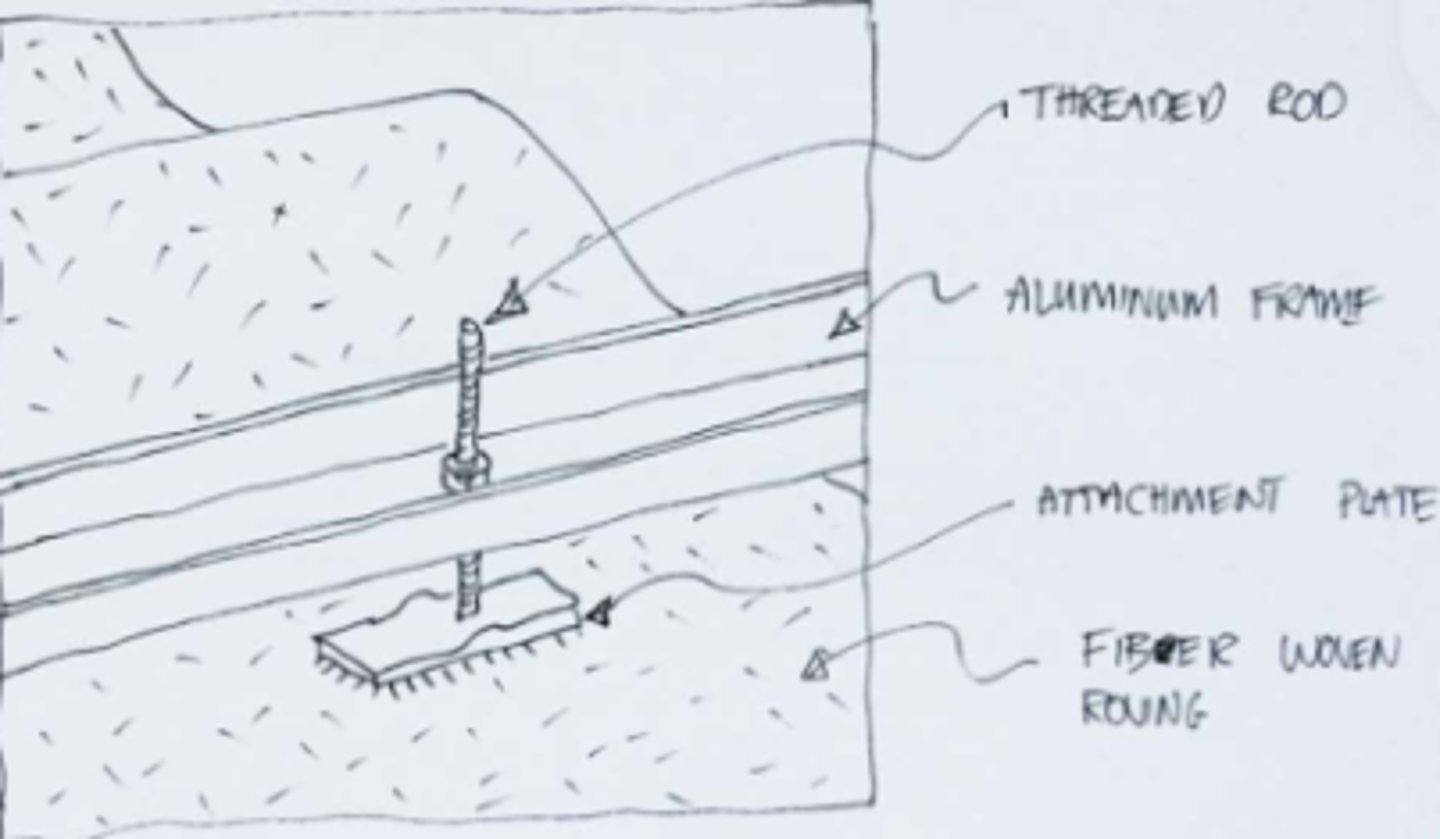

SFMOMA: Attached ______ on the sides to make edges for each panel

flat aluminum sheets

SFMOMA: After applying the mold release, Kreysler technicians sprayed on the ______

Fireshield 285 coating (gel coating)

SFMOMA: An impregnator was used to wet out ______ for each panel, which were then applied to and rolled out on the molds by hand.

three piles of glass fiber woven roving

SFMOMA: Attachment plates for aluminum framing were then bonded to the FRP: Enabling aluminum stiffening ribs to be mechanically fastened down _____

the length of each panel

SFMOMA: _____ aluminum framing was installed on all four edges with intermediate crossmembers to stiffen the panels.

4.8 mm thick x 1.7 m wide,

SFMOMA: _____ were inserted into holes drilled along the lengths of the intermediate stiffeners.

Steel rods