Material Science Quiz Review

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

32 Terms

stress

the internal distribution of forces within a body that balance and react to the loads applied to it

(Stress is the force inside a material that pushes back against an external load.)

direct stress

force is perpendicular to the surface

sheer stress

force is parallel to the surface

force is what type of quantity?

Vector quantity: has magnitude + one direction

stress is what type of quantity?

Tensor quantity: has magnitude + direction + the plane or orientation it acts on

strain

a measure of distortion of a material

plastic strain

permanent deformation — the material does not return to its original shape after the load is removed

elastic strain

temporary deformation — the material returns to its original shape when the load is removed

Poisson contraction

when a material is stretched in one direction, it becomes thinner in the other directions

direct strain

Deformation due to stretching or compressing along the length of a material

shear strain

Deformation due to sliding layers of a material over each other, changing its shape

uniform shear strain

A deformation in which all layers of the material are displaced uniformly, so the angular distortion is constant throughout.

allowable stress

The maximum stress that a material or structure can safely withstand under service conditions.

strength

amount of stress material can withstand before yielding

stiffness

resistance to elastic deformation

toughness

ability to absorb energy before fracture (strength + ductility)

hardness

resistance to scratching / indentation / wear

ductility

amount of strain before breaking (stretchability)

impact energy

energy absorbed during fracture (fast toughness indicator)

yield stress

beginning of the plastic deformation

elastic region

linear

reversible

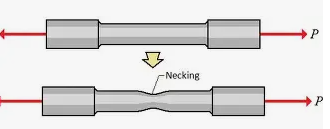

UTS (ultimate tensile stress)

highest stress before necking

necking

when a material starts to become thinner at a specific region (usually the middle) because it is being pulled

Fluids (liquids & gases)

Flow resistance depends on flow rate, not total deformation.

This resistance = viscosity.

Viscoelastic materials

Act part solid, part fluid.

Deform under stress, partly return to shape, partly stay deformed.

Non-linear behavior

Stress and strain are not proportional.

Response can change over time.

Thermo-viscoelasticity

Material behavior changes with temperature.

Non-Newtonian fluids

Shear thickening: Gets thicker when stressed more.

Shear thinning: Gets thinner when stressed more.

tension

positive stress

compression

negative stress

solids

elastic → then plastic → then fracture

fluids

cannot resist shear → constant deformation (flow)