FMR_WOOD

1/47

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

48 Terms

Wood

organic material

comes from fiber part of a tree, rather than the bark

has grain, used for transporting water and nutrients from roots to the leaves

grain

makes each piece of natural wood unique - no two trees are identical

growth rings

Created as trees increase in diameter.

Each ring represents one year of growth.

Some trees may have multiple growth rings in one year if they grow in more than one season.

Annual rings

Rings formed by trees growing in one season, producing one ring per year.

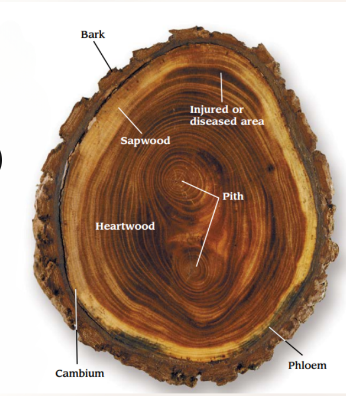

Heartwood

The inner part of wood.

may be darker in color than the sapwood (does not effect strength)

sapwood

outer part of the wood

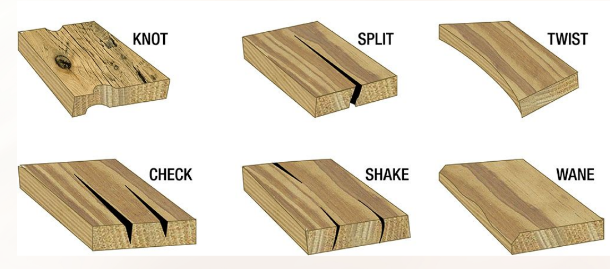

knots

caused when a branch grows from the side of the tree

considered imperfection by some

can be unique of decorative feature

anatomy of a tree

timber

Wood that has been prepared for use in construction or carpentry.

hardwoods

softwoods

wood classifications

softwood

Type of wood derived from gymnosperm trees (coniferous trees).

may be called evergreen

Generally lighter in color and less dense compared to hardwood.

Commonly used in construction, furniture, and paper production.

Examples include pine, cedar, and spruce.

hardwood

Type of wood derived from angiosperm trees (broadleaf trees).

Typically denser and harder than softwood.

Often used for high-quality furniture, flooring, and decorative purposes.

Examples include oak, maple, and cherry.

angiosperms

A group of plants whose seeds are enclosed within an ovary.

conifers

A group of gymnosperm plants characterized by cones and needle-like or scale-like leaves.

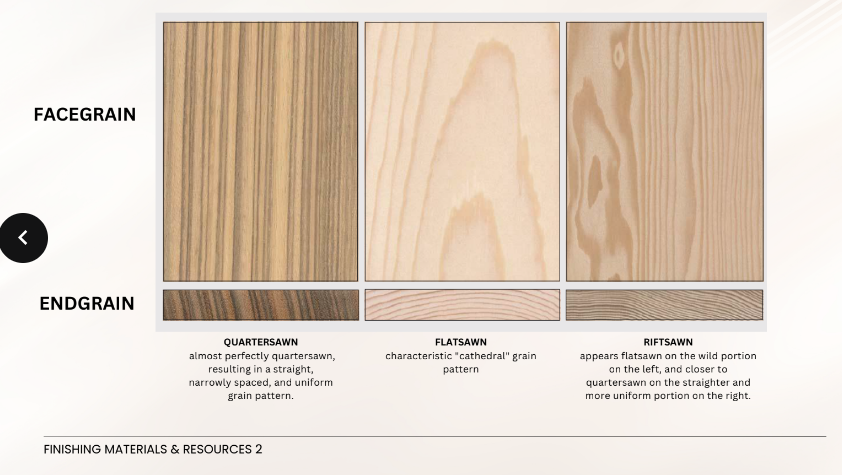

Endgrain

The section where a board is typically viewed on its end.

Often referred to as the most useful plane for wood identification.

Sometimes called the transverse surface or cross-section in processed lumber.

Quartersawn Section

Radial Surface - Wood surface that radiates out from the center of the log like spokes on a wheel.

Crosses the growth rings at a 90-degree angle.

Also known as vertical grain.

Provides distinctive grain patterns and stability in woodworking

Flatsawn Section

Tangential Surface - Wood surface more or less tangent to the growth rings.

Often results in a distinctive grain pattern characterized by cathedral-like arches.

Typically exhibits more variation in grain pattern compared to quartersawn sections.

Commonly used in woodworking for its aesthetic appeal.

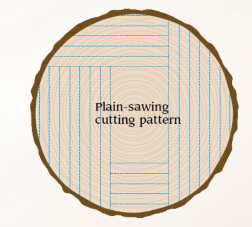

Plain-sawing

Flat-sawing

Cutting the log to maximize lumber without including the center pith area.

Involves rotating the log to make successive cuts around the pith.

Economical method for producing lumber for construction and woodworking.

Cuts are made tangentially to the growth rings, leading to increased wood movement.

Lumber is more prone to distortion compared to quartersawn lumber.

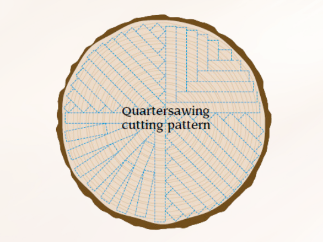

Quartersawing

A method to produce dimensionally stable lumber by rotating a log in quarter-turn increments and cutting around the center pith area.

Less efficient in maximizing board yield compared to plainsawing.

Results in lumber with increased dimensional stability.

Prominent medullary rays are displayed in quartersawn oak, which may not show if the boards were plainsawn.

kk

kk

Rift sawn

A method of cutting wood that produces a unique linear or vertical grain pattern with no flecking.

Annual growth rings are typically between 30 and 60 degrees.

flooring are aesthetically more appealing due to minimal grain activity.

Results in more dimensionally stable flooring compared to other cuts.

Live sawn

A method of cutting wood that starts with a straight cut through the log, providing a full range of the wood's natural characteristics.

Results in a varied grain pattern, with vertical grain on the edges.

Produces a naturally beautiful floor, showcasing the full range of wood's characteristics.

The wider the plank, the more uniquely beautiful the grain pattern.

bet

bet

air-drying

kiln-drying

lumber drying methods

air-drying

short lengths of scrap wood (called stickers) are inserted between each board in a stack to allow air to circulate all around the board

may take months or years

without stickers, lumber may dry unevenly and attract mold

kiln-drying

once stickered lumber is loaded to this, it will be closed up and heated evenly for several weeks until the moisture inside is reduced to acceptable levels

drying time may vary on the grade of lumber

faster method of producing general-purpose lumber

gets

gets

lumber defects

knot

split

twist

check

shake

wane

spalling

case-hardened boards

done

done

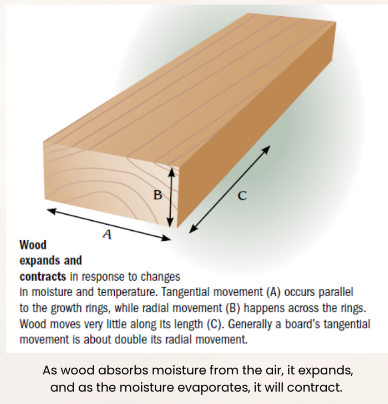

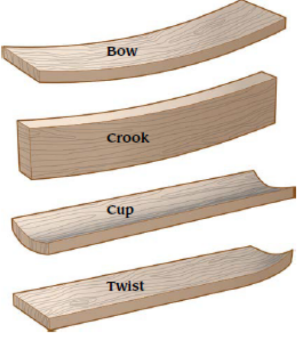

lumber distortion

bow

crook

cup

twist

bow

flat width

face curves lengthwise

crooked

flat across the face

curves along the edges in one direction

like the rocker of the rocking chair

cupping

flat along it’s edges

curls across it’s width

twist

one or both ends of the board twist

faces are no longer flat

wow

wow

grabe

grabe

tamad

tatamad na ko magtype

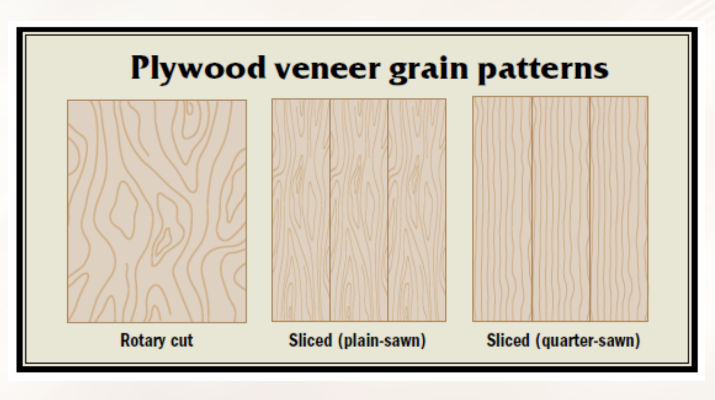

plywood

fashioned from sheets of wood veneer, primarily pine and fir

Orienting the wood grain of each laminated sheet so adjacent sheets are perpendicular.

Results in a product capable of withstanding greater stress compared to construction lumber of the same thickness.

Offers increased dimensional stability due to its crosswise orientation of wood grains.

Often used in construction for its strength and stability.

Particleboard

Engineered wood product

Made from wood particles and binder

Dimensionally stable

Suitable for countertops and tabletops

Smooth surface for laminate

Wide range of thicknesses and sizes

Inexpensive

Lacks stiffness and shear strength

Poor screw-holding ability

Degrades in moisture

Coarse core, hard to shape

Heavy

Medium-Density Fiberboard (MDF)

Similar to particleboard

Denser and heavier

Smooth and dense surface

Good substrate for veneered projects

Bonds cleanly with thin wood veneer

Layers can be laminated to create structural components

Increasing popularity in trim molding applications

Melamine board

Particleboard core

Plastic laminate faces

Thicknesses range from 1⁄4 to 3⁄4 inch

Stock colors limited to white, gray, almond, and sometimes black

Panels oversized by 1 inch for edge chipping prevention

Fresh edges may need trimming due to brittleness

veneer

Thin layer of wood sliced or peeled from a log

Used to cover surfaces for decorative purposes

Provides the appearance of solid wood

Can be applied to plywood, particleboard, or MDF substrates

Offers a wide range of wood species and finishes

High Pressure Laminate (HPL)

Produced by saturating multiple layers of kraft paper with phenolic resin

Decor paper layer placed on top before pressing

Fused together under heat and pressure (more than 1,000 PSI)

Curing process transforms resin and paper sheets into a single, rigid laminated sheet

Common thickness: 1.2mm

Standard size: 2.4m

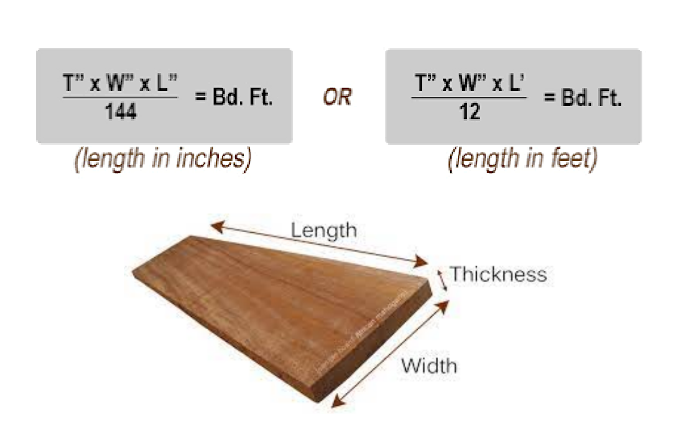

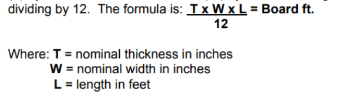

Board Measure

Standard unit for measuring the volume of lumber

Represents the volume of a board 1 inch thick, 12 inches wide, and 1 foot long

Used primarily for softwood lumber, particularly in commercial and industrial contexts

Board Footage

Measurement unit for the volume of lumber

Represents the volume equivalent to a board that is 1 foot long, 1 foot wide, and 1 inch thick

Used to quantify the amount of lumber, particularly in purchasing and selling transactions

Surface Measure

Measures the surface area of lumber

Typically used for calculating the amount of material needed for projects like flooring, paneling, or siding

Expressed in square feet or square meters

Lineal Measure

Measures the length of lumber in linear units, typically feet or meters.

Used for determining the length of lumber pieces, such as boards or beams.

formula