Chapter 3: Quality System Operations: Traceability in Food Supply Chains

1/40

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

41 Terms

What does increased supply chain visibility support discussions on?

Quality: consumers trust in food product origins, consumer surplus —> premium products

Safety: prevent/reduce potential problems (recalls), legal requirements / legislation (e.g. EFSA)

Sustainability: Environmental aspects (e.g. carbon footprint), social aspects (e.g. fair trade)

What are the four major areas of influence covering many research disciplines each representing different perspectives on the production, trade and distribution of food?

Economics, technology, social/legal, environment

What is meant by the economics area of influence?

The economics area of influence is related to efficiency (cost-benefit perspective) and to consumer orientation.

What is meant by environment area of influence?

The environmental area of influence relates to the way production, trade and distribution of food is embedded in its environment.

Important issues: energy use and emissions from production and distribution, recycling of waste and packaging materials, sustainable food production systems.

What is meant by technological areas of influence?

The technological areas of influence relate to the way technology (product and process technology, transport technology, information and communication technology) can be applied to improve production and distribution of high quality and safe food products.

Important issues: standards related to national/international legislation and regulation, systems to guide and control processes (tracking/tracing, HACCP), provision of product and process information to the public.

What is meant by social/legal area of influence?

The social/legal area of influence related to societal constraints to product, distribution and trade of food and to issue like human well-being, animal welfare and sustainable social-economic development.

Important issues: national/EU legislation and secondary legislation, consumer expectations and behaviour regarding food products (GMOs), international legal/regulatory framework and the possibility to differentiate food products complying with higher health and animal welfare standards.

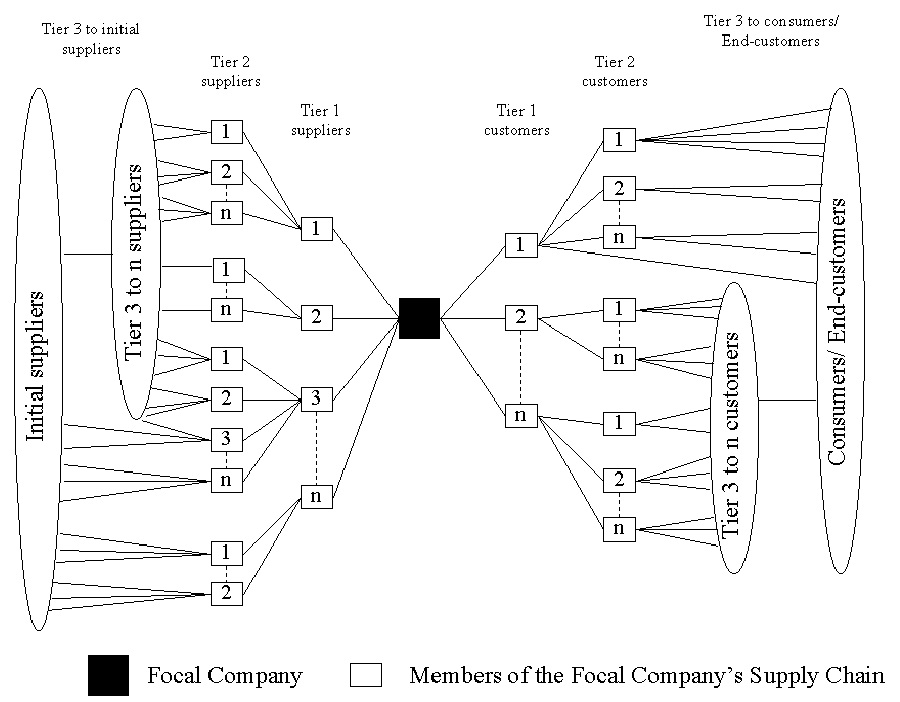

Describe the structure of a typical supply chain

Supply chain management views a company as being in the centre of the network of suppliers and customers.

What do quality assurance systems allow companies to do?

Quality assurance systems allow the application and verification of control measures intended to assure the quality and safety of food. They are required at each step in the food production chain.

What are the most important instruments to assure food safety and quality on a factory level?

Good manufacturing practices (GMP), hazard analysis and critical control points (HACCP) and ISO-certificates.

Describe the certification systems for sustainability agriculture (30 initiatives)

This system focuses on environmentally friendly production and the use of specific quality standards. Traceability takes place through documentation. Disadvantage: Heavy administration load for farmers.

Describe the national or sectorial quality assurance systems (26 initiatives)

These systems aim at control of the primary production phase by defining standards and monitoring performances. These standards don’t refer to sustainable production methods but aim at healthy and safe food products. Comply with Government standards with important focus on animal welfare and traceability system.

Describe the quality assurance systems initiated by food industries (8 initiatives)

These are certificates of branches that are managed by national or international businesses that aim for specific and distinct processes. Traceability system example, Hipp’s traceability system, allowing producers of baby-food to trace origin of all raw materials.

Describe retailer systems (17 initiatives).

These systems are controlled by European retailers. Most important systems aim at sustainable production and high quality and are based in countries where the large European retailers have an important market share.

Describe the regional or traditional quality assurance systems (22 initiatives).

These systems include all initiatives that refer to regional or local production and have implemented their own standards (e.g. NL Nautilus). These systems aim at physical health of animals on the farm and not on issues such as animal welfare (e.g. beef quality assurance (BQA), national cattlemen’s beef association (NCBA).

What does the ISO 9001 quality standards require for product traceability?

It requires that a product should be able to be traced from the current stage back through all its stages of manufacture through accurate and timely record keeping.

What are the traceability requirements for the stakeholder consumers?

Protect food safety by effective product recall

Enable avoidance of specific foods and food ingredients, whether because of allergy, food intolerance of lifestyle choices.

What are the traceability requirements for the stakeholder Government?

Protect public health through the withdrawal of food products

Help to prevent fraud where analysis cannot be used for authentication.

Control zoonotic disease e.g. Salmonella

Enable control with regard to human and animal health in energencies

Control livestock diseases through the rapid identification of disease sources and dangerous contact.

Monitor and control livestock numbers for subsidy claims.

What are the traceability requirements for the stakeholder industry?

To comply with relevant legislation

To be able to take prompt action to remove products from safe and protect brand reputation

To minimize the spread of any contagious disease among livestock.

To protect the food chain against the effects of animal disease

To assure meat and meat products and maintain markets and consumer confidence

To create differentiated products in the market place because of the way they have been produced

Enable avoidance of specific foods and food ingredients, whether because of allergy, food intolerance or lifestyle choices.

What are the traceability benefits from the perspective of stakeholder consumers?

Protect food safety by effective product recall.

Enable avoidance of specific foods and food ingredients, whether because of allergy, food intolerance or lifestyle choices.

What are the traceability benefits from the perspective of stakeholder Government?

Increase consumer trust

Protect public health through the withdrawal of food products

Help to prevent fraud where analysis cannot be used for authentication

Enable control with regard to human and animal health in emergencies

Monitor and control for subsidy claims

What are the traceability benefits from the perspective of stakeholder business?

Comply with relevant legislation

Be able to take prompt action to remove products from sale

Be able to diagnose problems on liability where relevant

Assure food products and maintain market and consumer confidence.

What is the EU guidance in general food law?

Traceability is a risk management tool

EU food law is worked in terms of its goal and intended results rather than in terms of prescribing how that result is to be achieved

Required is on step back and on step forward approach

The chain covers the importer/growth up to the retailer outlet

Required is information on physical flows; not just commercial flows (maybe 1 sale in multiple shipments/batches).

Recall batch size is responsibility of company (smaller obviously better, but difficult)

Record keeping = MIN (5 years, BBD + 6 months)

Direct informing of food safety authorities in case of food incident

What are the 4 perspectives to describe different traceability views for looking at a (food) supply chain process?

Enterprise: perspective focuses on functions and different levels of activities of a single organisation within the supply chain.

Multi-site: An organisation having multiple locations, flow of materials and info comprise of a complex network of related sister organisations.

Supply chain: Perspective includes the entire supply chain from primary producer to consumer.

External environment: includes the stakeholders of the supply chain, not directly involved in processing the product. e.g. consumer organisations, authorities and society as a whole.

What should a company system provide regarding traceability on a company level?

They should provide information on the location of the product and on the history of the product.

What should a company system provide regarding traceability on a chain level?

A company should provide information on the location of product and also information on the origin of the product.

What are traceability systems used for?

They are used for recall-management, consumer information, logistic management in distribution centers, quality management, risk management, efficient sales process at the supermarkets etc.

What are examples of demands that can be included in a collaborative chain information system?

Identification, tracking of items, traceability.

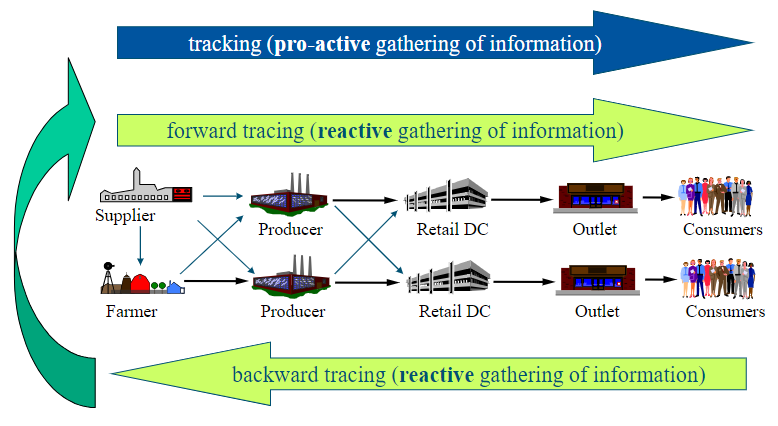

Describe the difference between tracking and tracing

What are the three chain strategies for traceability? And describe them.

Compliance-oriented strategy: Comply to rules and regulation with the help of minimal documentation (process as black box) —> just cost considerations

Process improvement-oriented strategy: Control within the own link by means of production integrated measures that achieve both compliance with governmental rules and regulations and a better returns —> cost and local benefit

Market-oriented (branding) strategy: Aim for full traceability within the supply chain to achieve competitive advantage (by creating added value in the market place) —> cost and chain benefit.

What are the six types of traceability data?

Inherent properties of a product: seen or otherwise measured on the product. Most properties can change over time (e.g. taste, content of chemical components, bacteriological status, visual attractiveness), some are not likely to change (e.g. size)

Process properties: Constitute the history of what has happened to a unit.

Properties of means of production used on the product: An extension of the previous (process properties), includes machines and labour. Machines —> contamination issues. Labour —> ethical issues.

Origin of provenance data of a product: deals with information about the processes associated actors, resources raw materials and intermediate products that have been used to produce the product.

Actors involved: They execute processes, ‘produce’ products, services and information. Properties of actors may be ‘inherited’ by their processes and product properties.

Relationships between the entities: If a process consumes inputs, uses machines and produces according to some specification, properties may be associated with that combination of entities.

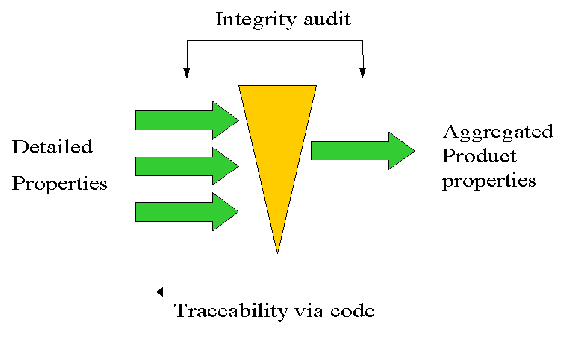

What is meant by the term information de-coupling?

When goods are exchanged between enterprises, most information that can be linked to products is left at the supplying company, information is de-coupled and only aggregate information accompanies the product further through the chain.

Describe the information de-coupling point.

Information de-coupling points must be defined carefully.

What is the definition of lot?

A number of products (boxes, bags, pallets…) that have unique and homogeneous characteristics with a common history in process conditions.

What is traceability all about?

Knowing the wishes of your customers concerning food safety

Deciding what performance level to strive for (how fast can the tracing operation take place?, what is the max recall size that can be accepted?)

Deciding on the lot segregation in your goods flow

Following lots through the process.

What can be said about the traceability of batches?

Most of the time products are tracked and traced by the group of trade items (the lot), which have undergone the same transformations, i.e. by batches (same production process) or logistic units (same transport conditions). Each time the unit is processed or transformed, it should be assigned a new identifier.

Name and describe the 10 factors that have the biggest effect on the complexity regarding traceability.

Diverging and converging product streams: That make it difficult to follow the different raw materials that go into the product and all the end product that result at the end of the process.

The in-homogeneity of raw materials and (inter0) mediate products, business entities: Exchanged between business process due to e.g. weather conditions, biological variation and seasonality, but also a possible result of variation in production. A typical characteristic of food products is their variability in form, shape taste etc.

Contamination of (many) different batches of raw materials: Because batches in many food industries are mixed, cross contamination of batches is a general problem in food industries.

Batch of continuous production: If production takes place in batches, identification can be kept per batch. However, in the case of continuous production (e.g. milk) identification can only be kept thorough time of production.

Many sources of batches of raw materials: (home and abroad). Because of internationalization of food chains and networks, sourcing becomes more and more international. This makes traceability hard to achieve.

Many actors with formal and informal relationships in the chain: In the food chain often transactions take place through arm’s length relationships. Solid administration of transaction often lacks.

Lack of connections between physical and administrative product flow: In general one may say that food chains and (chain) processes within then are complex systems. Realizing traceability and transparency systems is consequently also complex.

Variable and multi-level recipes: Products can be based on more than one recipe, for example different raw material and use of different production means can lead to similar products.

Presence of active material: Active material, for example protein, is contained in other material components of the product and determines the value of end products. The concentration, amount or percentage can vary. Registration of the total product quantity therefore is not sufficient, but the active component should be identified separately.

Perishability of products: For certain materials storage life constraints apply. As a consequence, using up material according to first in first out (FIFO) may not apply and different batches of the same product, but of different age, cannot be grouped and must be handled separately.

What are important information systems functions at a trader of fruit and vegetables regarding supply, storage, assembly, packaging/labelling and sales?

Supply: Storing of purchase specification, coupling of lot number to supplier data and production data, coupling of lot number to entry control data.

Storage: Coupling of lot number to storage location and conditions (e.g. temp, time)

Assembly: Registration of new lot numbers linked with preceding lot numbers

Packaging/labelling: Coupling of lot numbers with label

Sales: Coupling of lot number to invoice data, coupling of lot numbers to distribution data.

What are the main bottlenecks of full, fast and reliable traceability in the food chain?

Indefinite and differentiated performance levels concerning traceability.

Little economical incentive for traceability

High investment in infrastructures for 100% traceability

Lack of chain organization and chain transparency

Traceability of products in quality assurance schemes is restricted: schemes often focus on part of the supply chain not the whole supply chain

Lack of standardization: each actor registers information differently making exchange of info difficult.

Businesses in food supply chains have such specific characteristics that each supply chain has its own specific elements: standardization difficult.

What are the four chain traceability performance indicators?

Depth: number of links in the supply chain that can be traced backwards and forwards.

Precision: the tracing unit that defines the level at which the traced object is uniquely identified

Time: Time needed for tracing the products

Reliability: the reliability of the tracing

How is risk calculated?

Risk = the chance of an incident occurrence X severity of the incident X volume of infected lot X reaction time

What are the most important success factors that were identified for traceability?

Defines the legally required functionalities of traceability systems in food supply chains and the minimal performance requirements unmistakably

Identify, register and exchange data in all links of supply chain.

Makes a risk assessment of the supply chain and focuses on biggest risks.

Make the added value of traceability visible to everyone (recalls etc.)

Uses a joint approach by all chain participants, traceability system that is suitable for a large number of specific situations in food supply chain.

Reduces the number of suppliers, makes chain transparent.