L6 - Glass manufacture

1/34

Earn XP

Description and Tags

Basic composition, manufacturing/ foming, float glass, rolled and fibres

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

35 Terms

What sectors is the glass industry divided into?

–Containers (bottles and jars)

–Flat glass (building and transport glazing)

What is the definition of a glass?

•Product of fusion which has cooled to a rigid state without crystallisation

•By definition amorphous (without a clearly defined shape or form)

• Supercooled liquid

What are the properties of glass?

–Transparency (with or without colour)

–Durability

–Electrical and thermal resistance

–Range of thermal expansions (change its shape, area, or volume in response to a change in temperature)

–Hardness, rigidity and stability

What is the basic composition of commercial glass?

1) Former of silica sand (SiO2)

–Fusion temperature in excess of 1700oC

2) Fluxing agents – e.g. Sodium Oxide

– reduce fusion temperature (1500-1650oC)

3) Stabilising agents – e.g.

–Limestone (Calcium Oxide)

–or alumina

What is natural glass?

•Naturally fused silica:

non-crystalline solid formed when molten material cools so quickly that atoms cannot form a crystal structure.

•Volcanic – Obsidian

•Lightning - Fulgurite

What is mixed former glasses?

•Borosilicate glasses = Boric Oxide (B2O3) + Silica

•Temperature and thermal shock resistance

•Used in technical applications

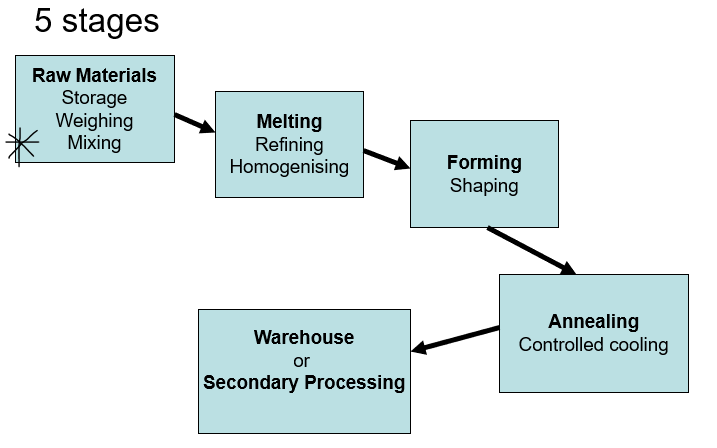

What are the 5 stages of the glass manufacturing procecesses?

Raw materials - Storage, weighing, mixing.

Melting - refining homogenising (make uniform)

Forming - shaping

Annealing - controlled cooling

Warehouse or secondary processing

Why are raw materials needed for the glass manufacturing process?

–Consistency of composition

–Freedom from impurities

Historically what were glass making centres based on?

–quality silica sources

–fuel

–Expertise

What is waste glass (cullet) used for?

–Assists melting process

–Either from factory or external recycling into raw materials for new glass

What does the glass melting process need?

Furnaces

Construction of refractory blocks

What is a tank furnace used for?

–Produce a continuous flow of glass to feed automatic glass forming machines

When is a float glass furnace used?

For flat glass

When is a refractory pot furnace used?

–For small scale, high purity production e.g. handmade lead crystal glass

What is the refining stage of glass melting?

•As raw materials melt

–Gases (water and carbon dioxide) emitted

•Melt must be at sufficient temperature to allow all gas to rise to the surface

What ensures homogenisation in the glass melting process?

Thermal or mechanical stirring of melt

What happens when glass cools?

•As molten glass cools

–Become more viscous (thick and sticky - between liquid and solid)

–Eventually forms solid

What happens if glass is held at range of 800-1000degrees for too long?

devitirification takes place (crystal formation)

What does annealing do?

•Glass contracts on cooling

•Due to low thermal conductivity does not cool uniformly

•Uncontrolled cooling set up stress in object

•Annealing reduces these stresses

Where does annealing take place?

Annealing kilns

Continuous lehrs (=specialised oven) - (heated space through which glass passes on slow moving conveyor)

What is cooling glass characterised by?

•continuous change in viscosity with temperature

•Permits molten glass to be formed into range of shaped products e.g.

–Containers

–Flat sheets

–Glass filaments

What is the oldest method of glass forming?

Mouth blowing - 19th century

use moulds

20th century mechanised blowing and forming

What is a sign of glass blown in a mould?

Produces characteristic mould seams or line

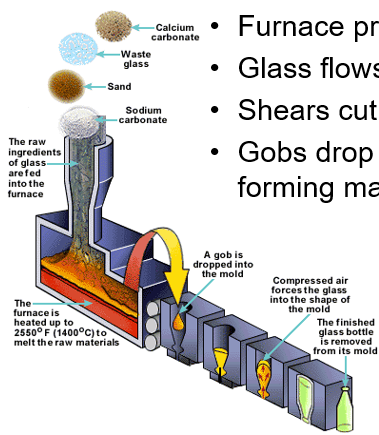

What is the automatic glass container forming?

•Furnace produced fully melted glass

•Glass flows at controlled temperature

•Shears cut glass lengths (gobs)

•Gobs drop into moulds of automatic forming machine

What are two different automated blowing processes?

–Press and blow process (wide neck jars)

–Blow and blow process (bottles)

•Released from mould at about 500oC

•Transferred to belt for annealing lehr

What is float glass?

•Greatest tonnage (weight)

•High quality glazing products

What is rolled glass?

•Wired glass

•Patterned glass

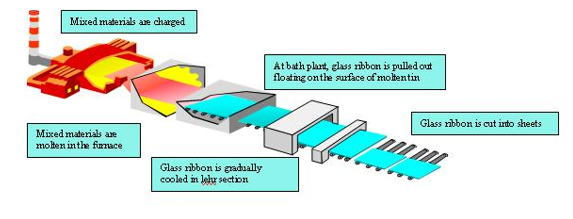

How is float glass made?

•Fully homogenised glass emerges from melting furnace

•Flows into float chamber

–Bath of molten tin

–Non-oxidising atmosphere

•Glass forms ribbon that is drawn continuously along the tin bath

•Glass held at 1000oC (long enough) for irregularities to flow out

•Thickness range from 2.5 – 25mm

•Ribbon cooled to about 600oC and transferred to rollers

•Cooled in annealing lehr

•Cut to warehouse lengths

What is the rolled glass process?

•Continuous stream of molten glass

•Poured between water cooled cast iron or steel rollers

•Used for

–Patterned glass

–Wired glass

How is patterned glass made?

made by single pass process

–Glass flows between the rollers at about 10500C

–The bottom roller with the pattern

•Ribbon leaves rollers at about 8500C

•Transported on set of rollers to the annealing lehr

How is wired glass made?

Double pass process

•Two pairs of independently driven, water cooled, steel rollers

•Each fed from separate flow of molten glass from common furnace

•1st pair of rollers produce sheet half thickness of end product

•This sheet overlain with wire mesh

•2nd glass sheet overlies on top of mesh

•Glass mesh sandwich enter 2nd pair of rollers

•Which goes on to annealing and cutting

What are the two fibre glass products?

–Continuous glass filament

•Used for manufacture of composite materials (reinforcement of plastics, rubber, gypsum)

–Glass wool

Used for thermal insulation

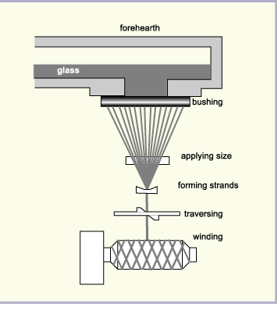

How is continuous glass fibre made?

•Continuous strand, made up of large number of individual glass filaments

•Glass flows from furnace

•Fed to series of bushings (holes)

•Extruded glass filaments drawn onto high speed winder

How is glass wool made?

•Glass flows from furnace

•Into bushing

•Into rapidly rotating steel dish

–with several hundred fine holes

–Molten glass thrown out through holes by centrifugal force

–Forms fine filaments

•Further extended into fine fibres by high velocity blast of hot gas

•Sprayed with bonding agent

•Drawn by suction onto horizontal moving conveyor

•The mat of fibres carried to oven for curing

What is optical fibre?

Consist of two distinct glasses

–Core of highly refracting glass

–Outer layer of lower refractive glass