biomechanics final

1/34

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

35 Terms

isotropic

materials that have UNIFORM properties in ALL directions

isotropic: stress and strain dimensions

3D

isotropic: stress/strain units

stress (Pa), strain (dimensionless)

orthotropic

materials that have DIFFERENT properties in 3 mutually perpendicular directions

orthotropic: stress and strain dimensions

3D

orthotropic: stress/strain units

stress (Pa), strain (dimensionless)

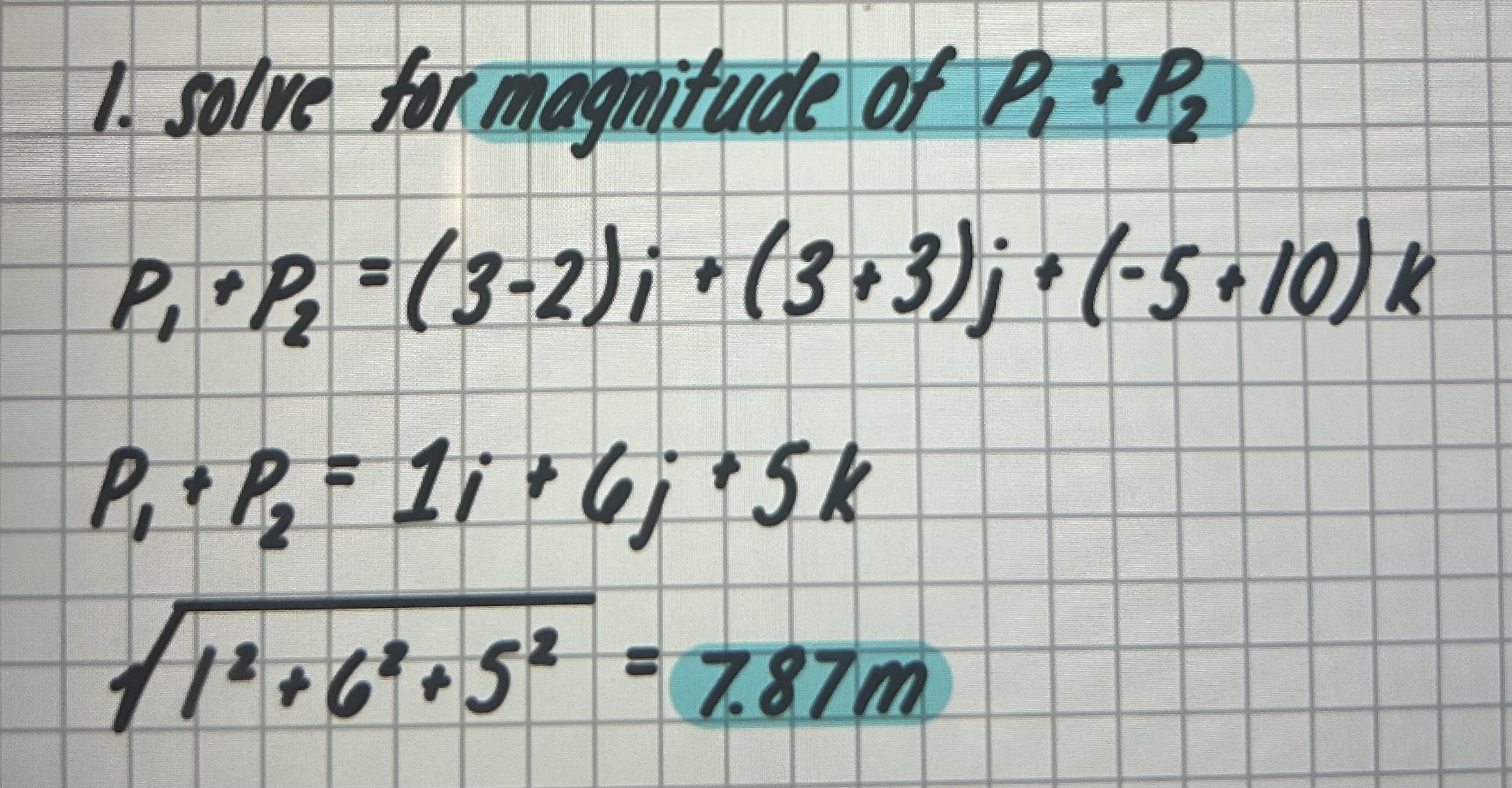

Vector Algebra: solve for magnitude of P1 + P2

P1 = (3i + 3j - 5k) P2 = (-2i + 3j + 10k)

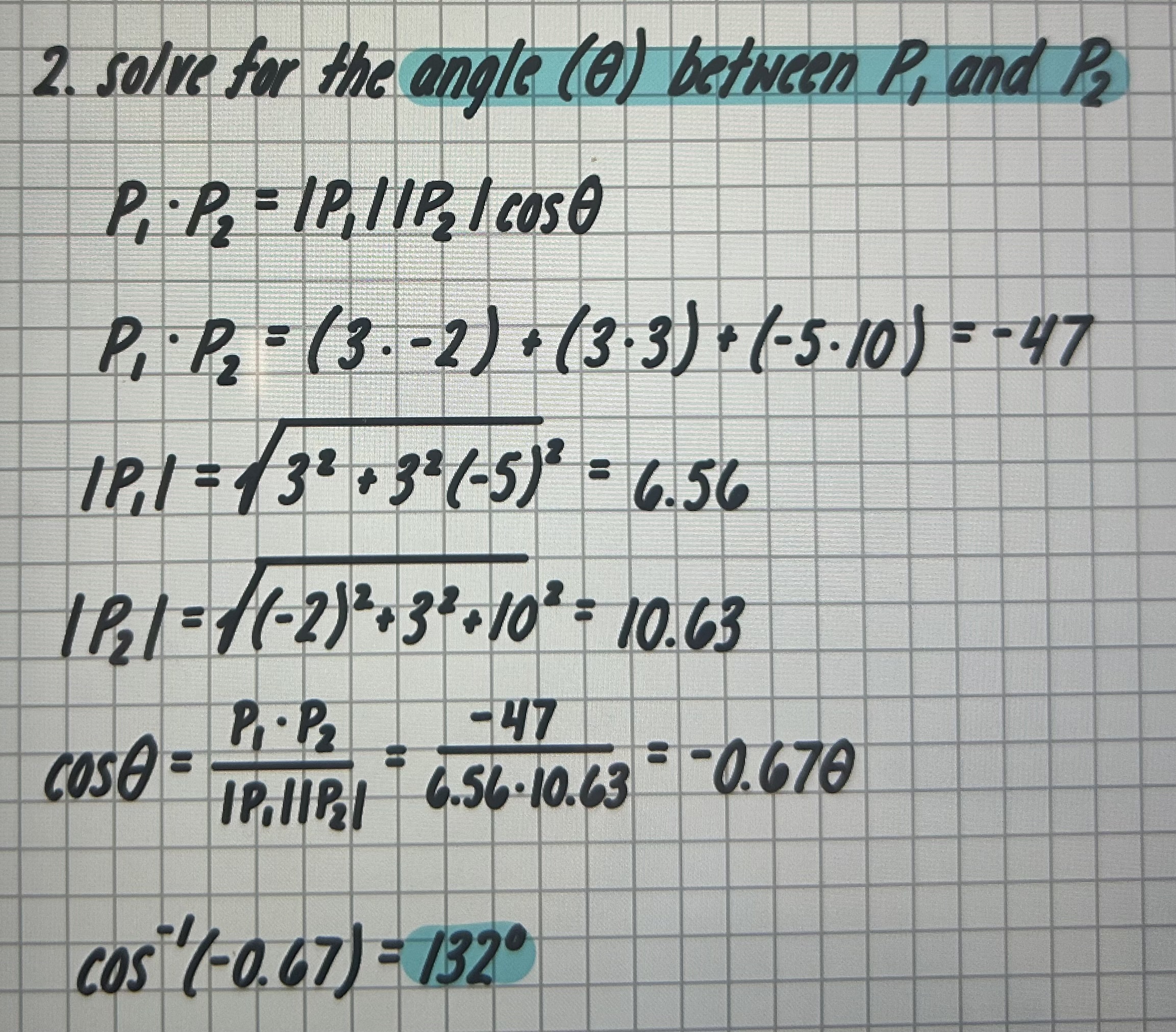

Vector Algebra: solve for angle between P1 and P2

P1 = (3i + 3j - 5k) P2 = (-2i + 3j + 10k)

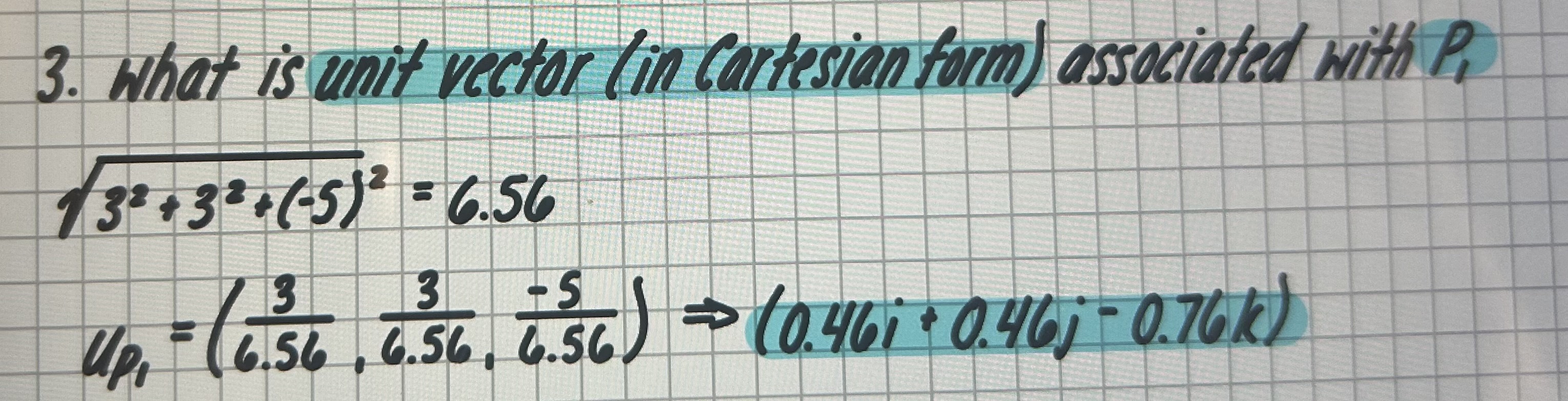

Vector Algebra: what is unit vector (in Cartesian form) associated with P1

P1 = (3i + 3j - 5k) P2 = (-2i + 3j + 10k)

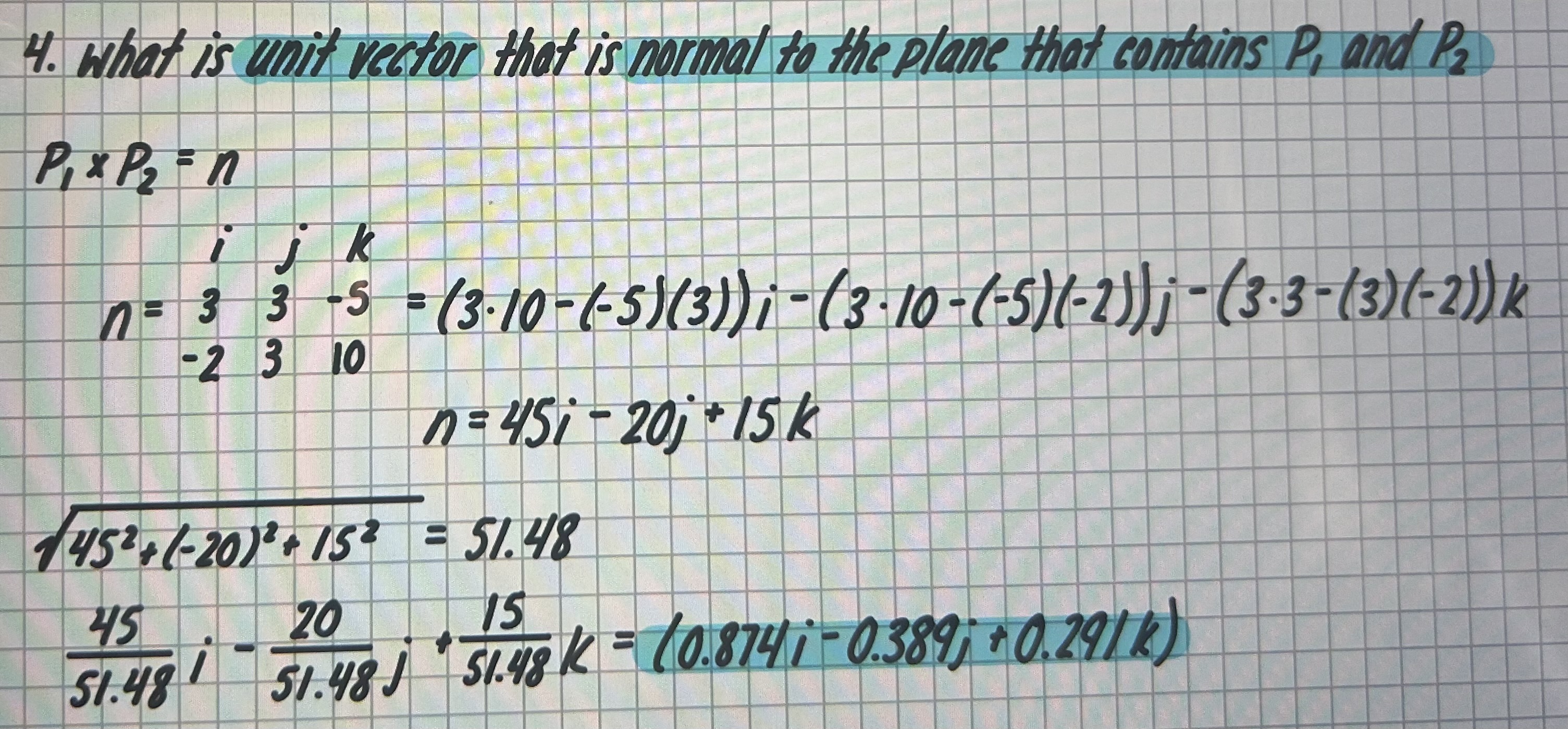

Vector Algebra: what is unit vector that is normal to the plane that contains P1 and P2

P1 = (3i + 3j - 5k) P2 = (-2i + 3j + 10k)

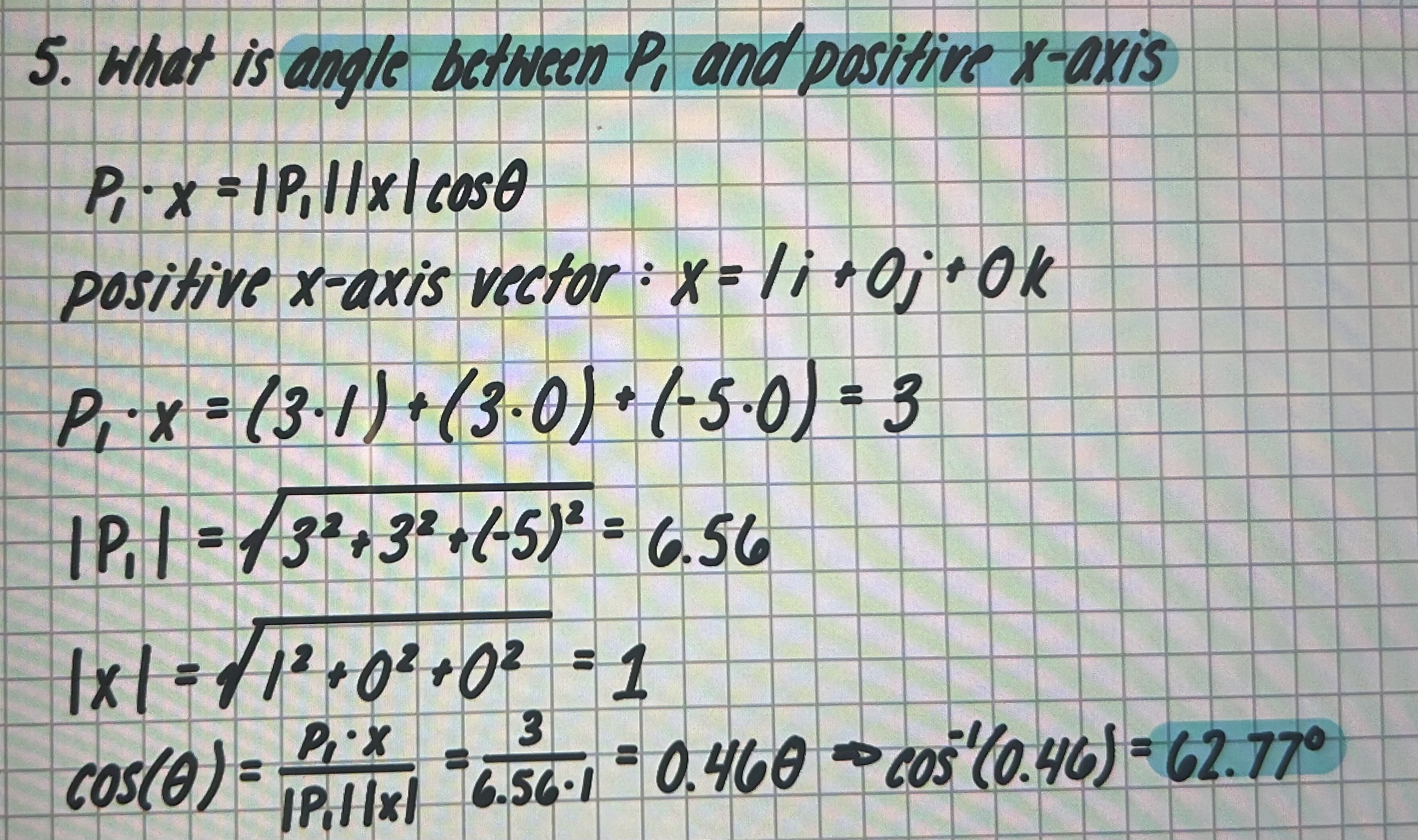

Vector Algebra: what is angle between P1 and positive x-axis

P1 = (3i + 3j - 5k) P2 = (-2i + 3j + 10k)

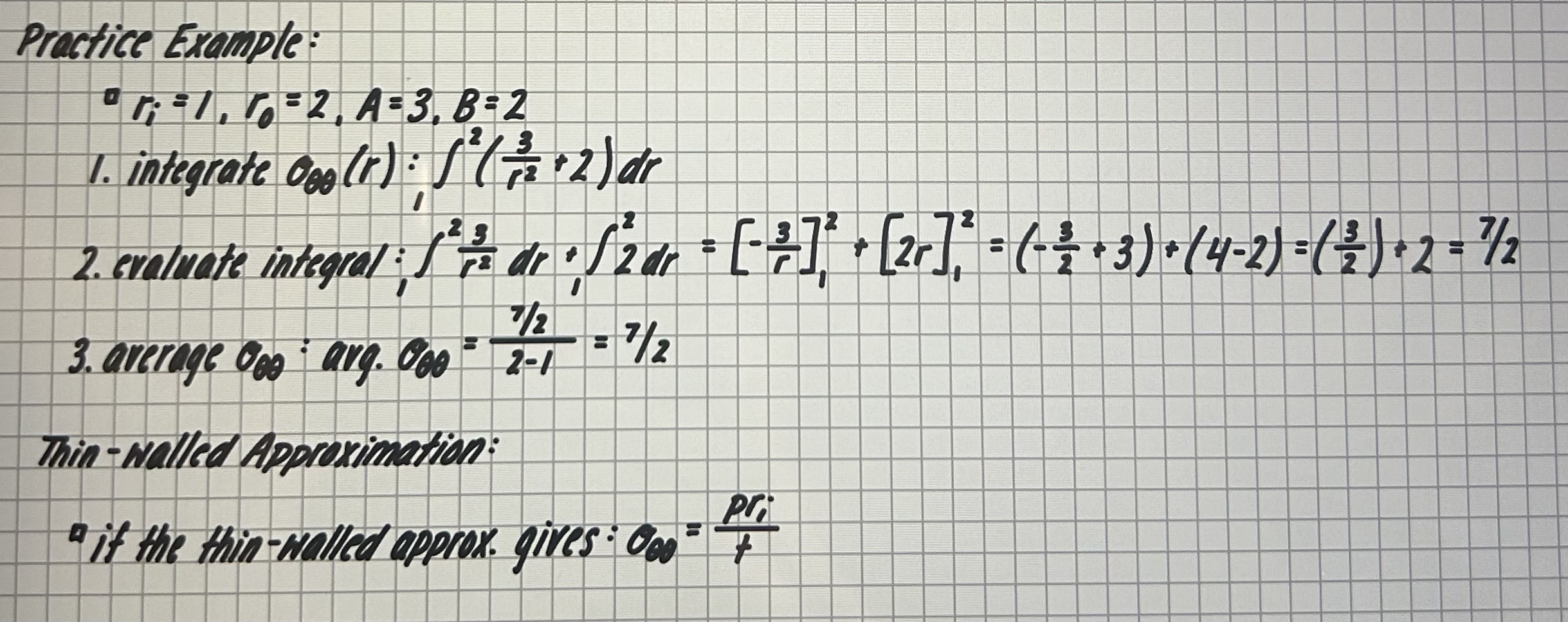

Thick-walled cylinder

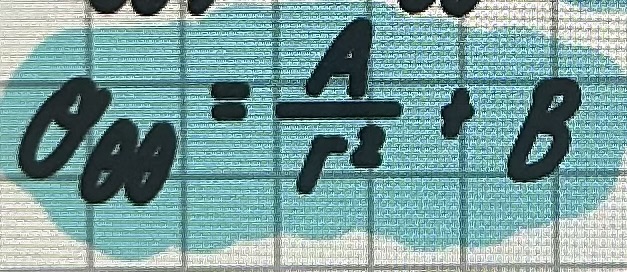

circumferential stress (sigma theta,theta) varies in a thick-walled cylinder with radius r

typically given by formula in picture where A and B are constants determined by boundary conditions

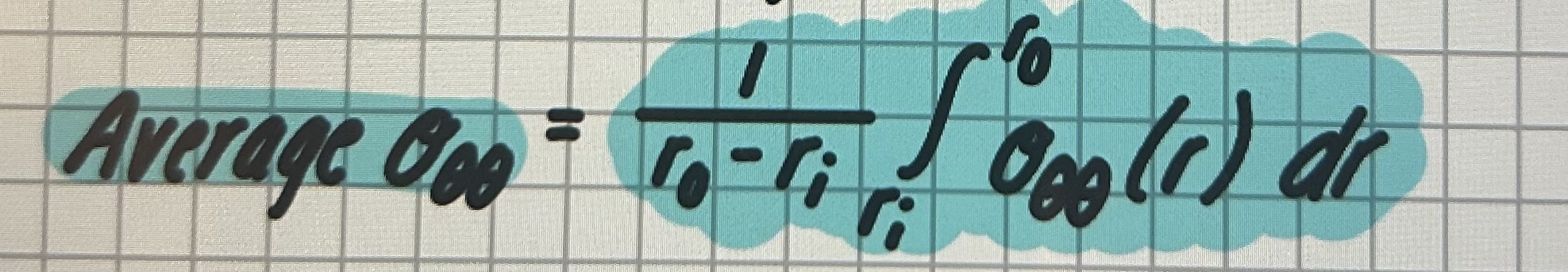

average circumferential stress process

integrate sigma theta, theta (r) over radial distance from ri to ro (inner to outer)

divide by length of the interval

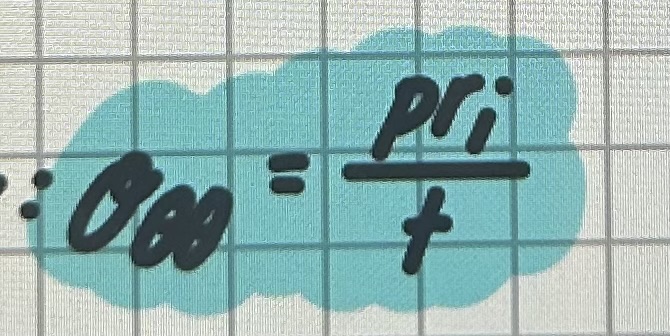

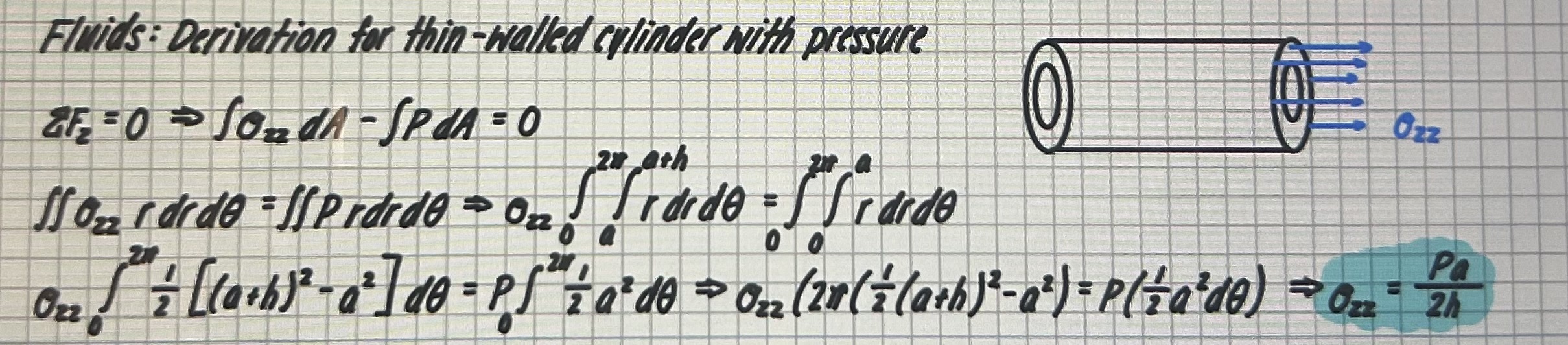

Thin-walled cylinder

circumferential stress is assumed to be UNIFORM and can be approximated by formula in picture

p: internal pressure

ri: inner radius

t: wall thickness

compare thick-walled vs thin-walled averages

to compare need to evaluate the integral for the thick-walled cylinder and see if it matches the thin-walled approximation

practice example for thick vs thin-walled average comparison

continuum hypothesis

treats ALL properties and variables as continuous smooth mathematical functions

ALL properties and variables are DIFFERENTIABLE

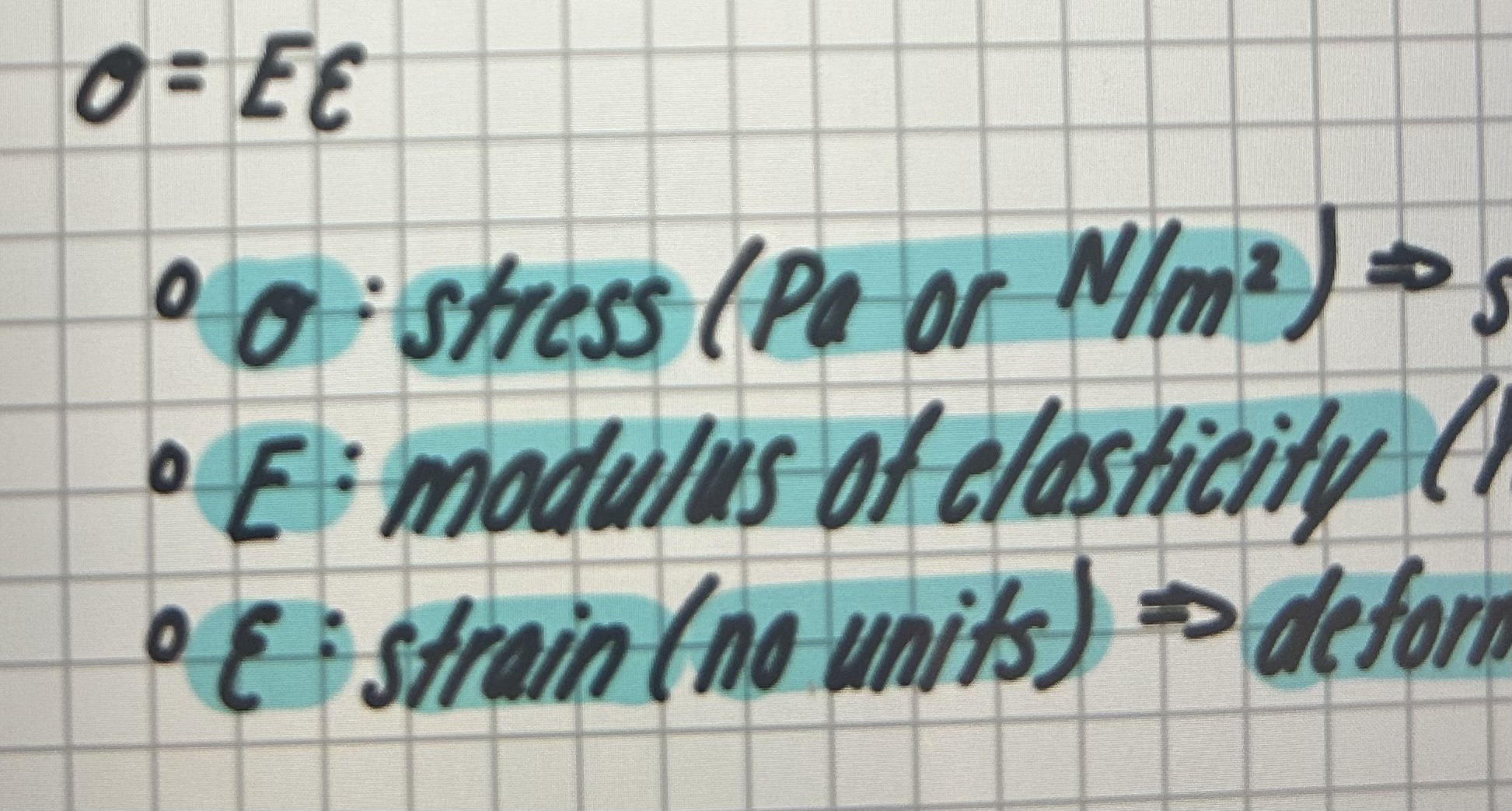

Hooke’s Law

describes relationship between stress and strain in elastic materials

strain in a material is proportional to the applied stress within elastic limit of the material

stress

Pa or N/m2

stress is force applied per unit area within materials

Modulus of Elasticity (E)

Young’s Modulus

Pa

measure of stiffness of a material

strain

no units

deformation or displacement of material relative to its original length

normal/shear stresses

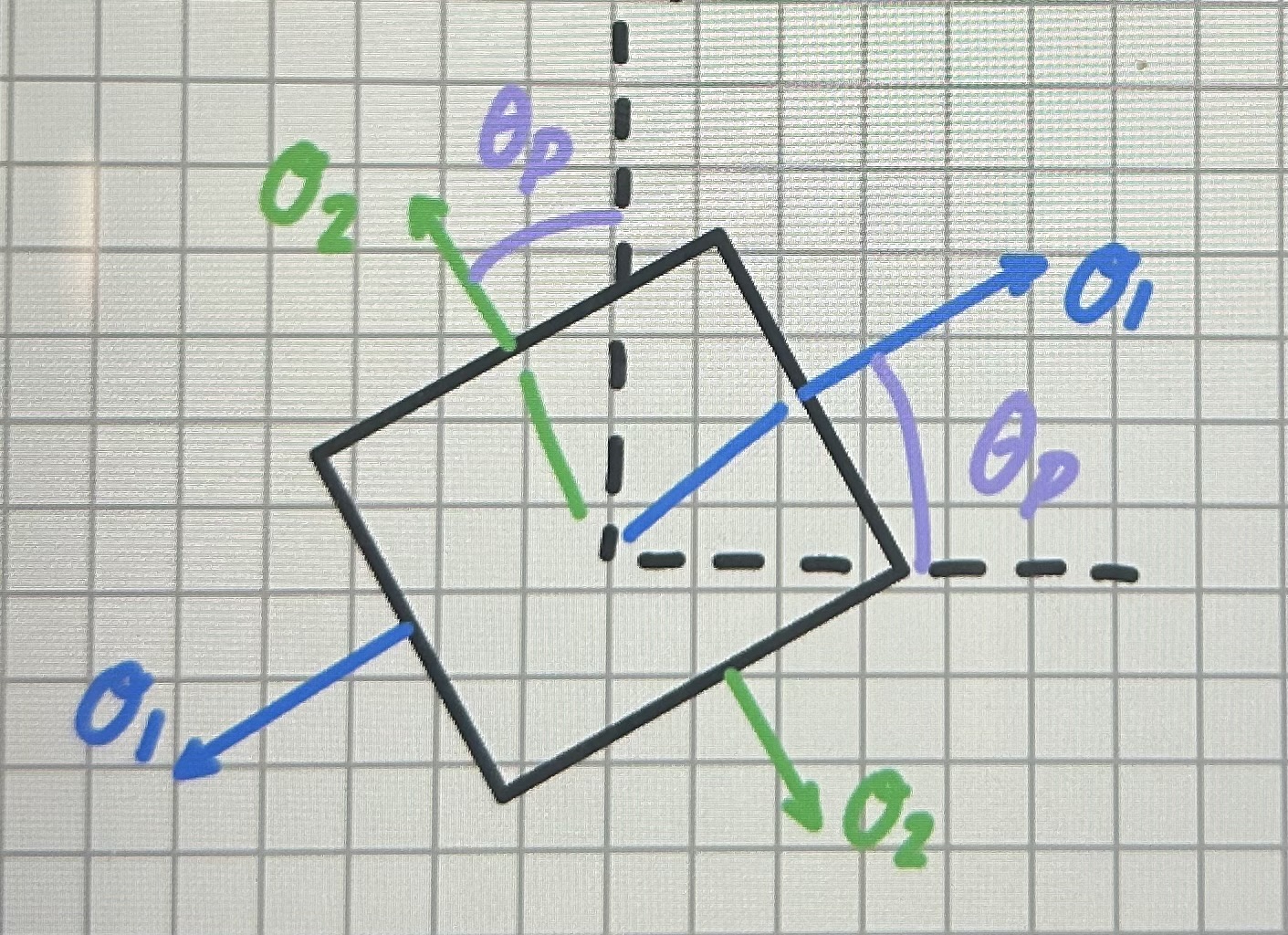

draw a principal stress

what tensor is a principal stress

2nd order tensor

scalar

normal stresses on principal planes (no shear)

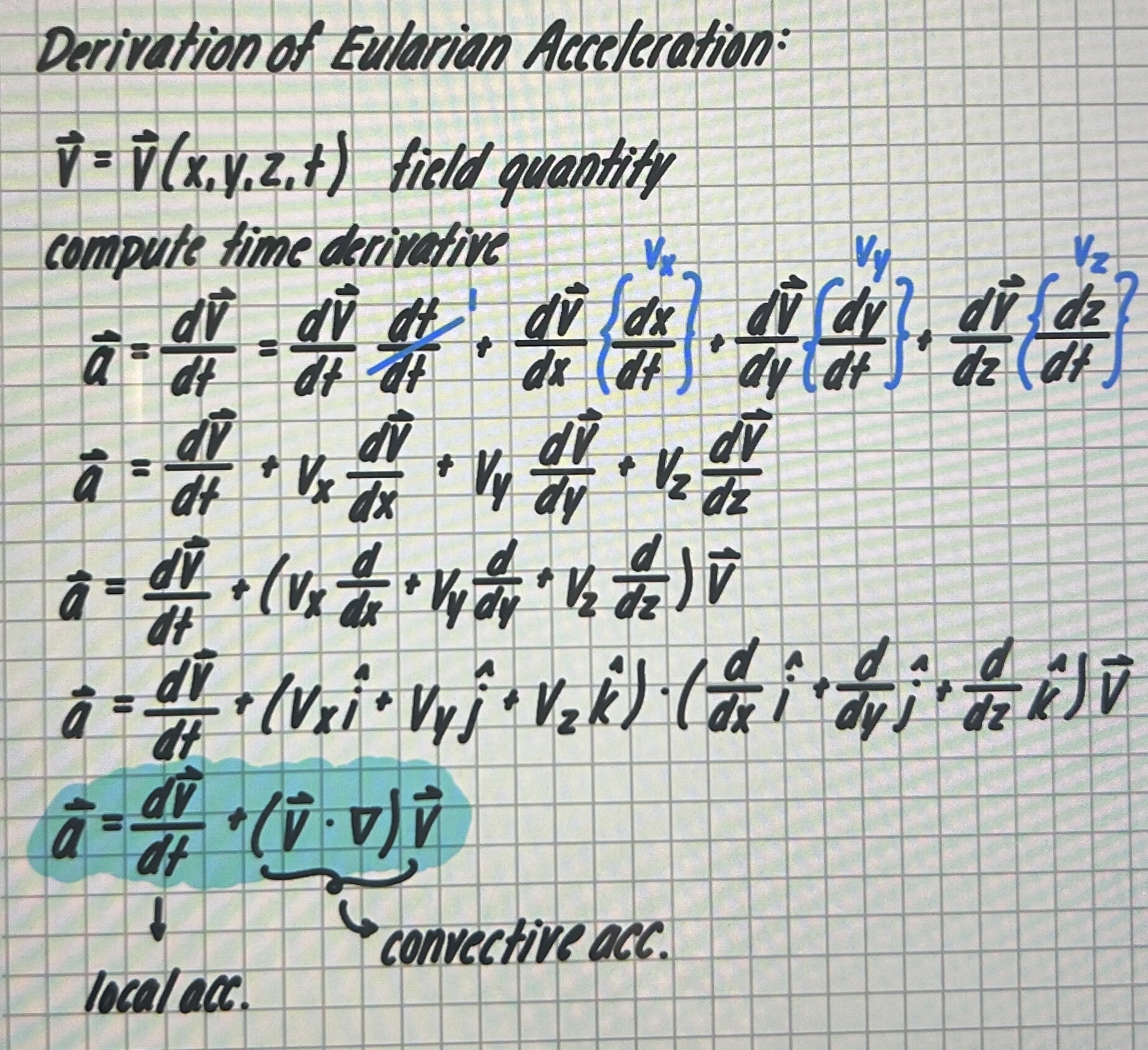

describe 2 reasons why you use Eularian acceleration in fluid mechanics

convective acceleration

local acceleration

convective acceleration

change due to movement through fluid

in steady flow

local acceleration

time-rate of change at a fixed point

unsteady flow

Derivation of Eularian Acceleration

Eularian

focuses on FIXED POINTS in space and observes how MATERIAL FLOWS PAST THEM

ex. watching water pass a buoy

Lagrangian

tracks INDIVIDUAL PARTICLES or MATERIAL POINTS as they move through space and time

ex. watching a swimmer

Derivation for thin-walled cylinder with pressure (closed ends)

For universal solutions, are stresses the same across different materials

No

universal solutions must account for SPECIFIC MECHANICAL PROPERTIES (stress response of materials under load)

constitutive equations

force displacement relationship depending on conditions of interest or stress and strain

FBD for only equilibrium

No

used for both equilibrium/non-equilibrium context problems

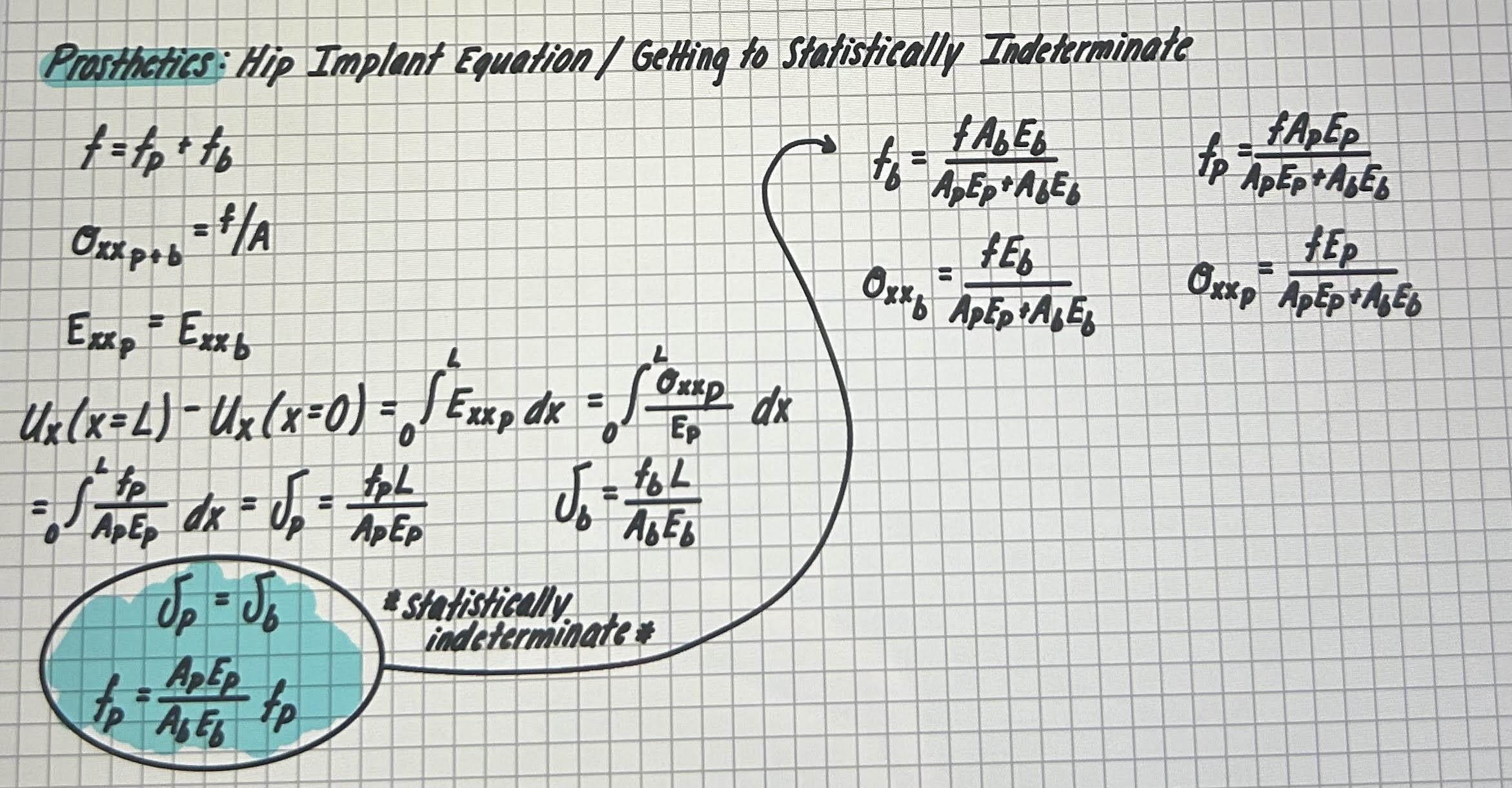

Prosthetic Hip Implant