3- metal ceramic restorations

1/28

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

29 Terms

What does a metal ceramic restoration consist of?

ceramic veneer mechanically and chemically bonded to metal substructure by firing

Why do we use metal ceramic prosthesis?(4)

Superior fit of a casting and aesthetic

Doesn’t discolour

Longevity

Combining brittle and elastic material achieves good physical properties

Porcelains resist…

Compressive loading but tend to succumb to tensile stress

To avoid fracture, veneer shouldn’t be over 2mm thic

More abrasive to opposing teeth

When should you prepare the framework design that lies underneath porcelain and what does proper evaluation allow for?

During treatment planning, evaluate during tooth prep and waxing stages- this allows for:

even thickness of porcelain

good connector design

optimal occlusal contacts

What are the 6 mechanical properties of major clinical relevance for dental-ceramic restorations?

Elastic modulus

Yield strength

Hardness

Creep or distortion at elevated temperatures

Thermal expansion/contraction

Density

What are the mechanical properties of minor clinical relevance for dental-ceramic restorations?

Ultimate tensile stress

Ductility

Toughness

Percentage of elongation

What are the percentages of noble elements in the 3 available alloy systems?

High noble- 60%- 40% of which is gold- not recommended for FDP

Noble- 25%, palladium based

Predominantly base metal- less than 25%, commonly use nickel-chromium, if allergic cobalt-chromium, high elastic modulus than noble

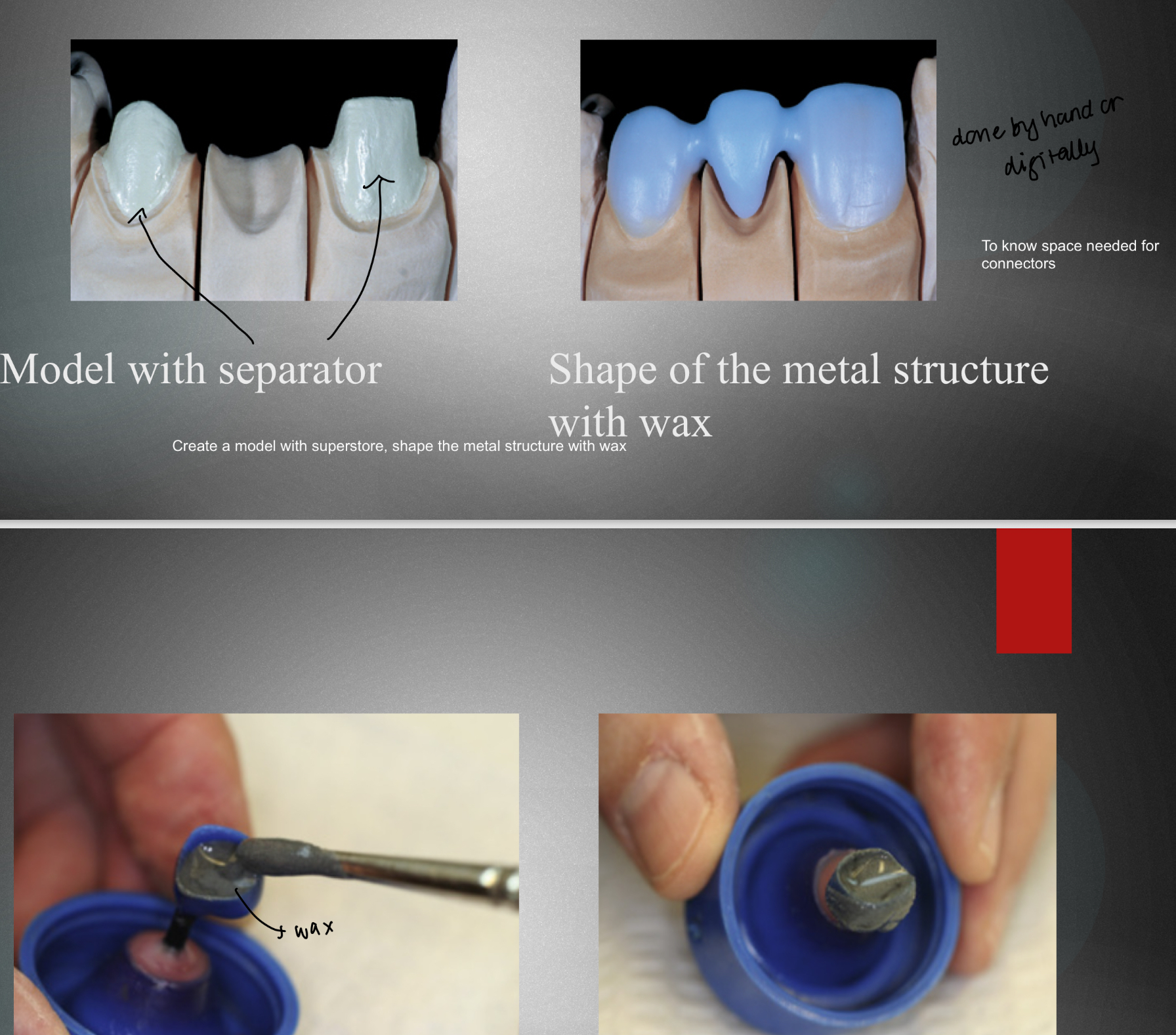

How to prepare metal?

Create a model with separator, shape the metal structure with wax

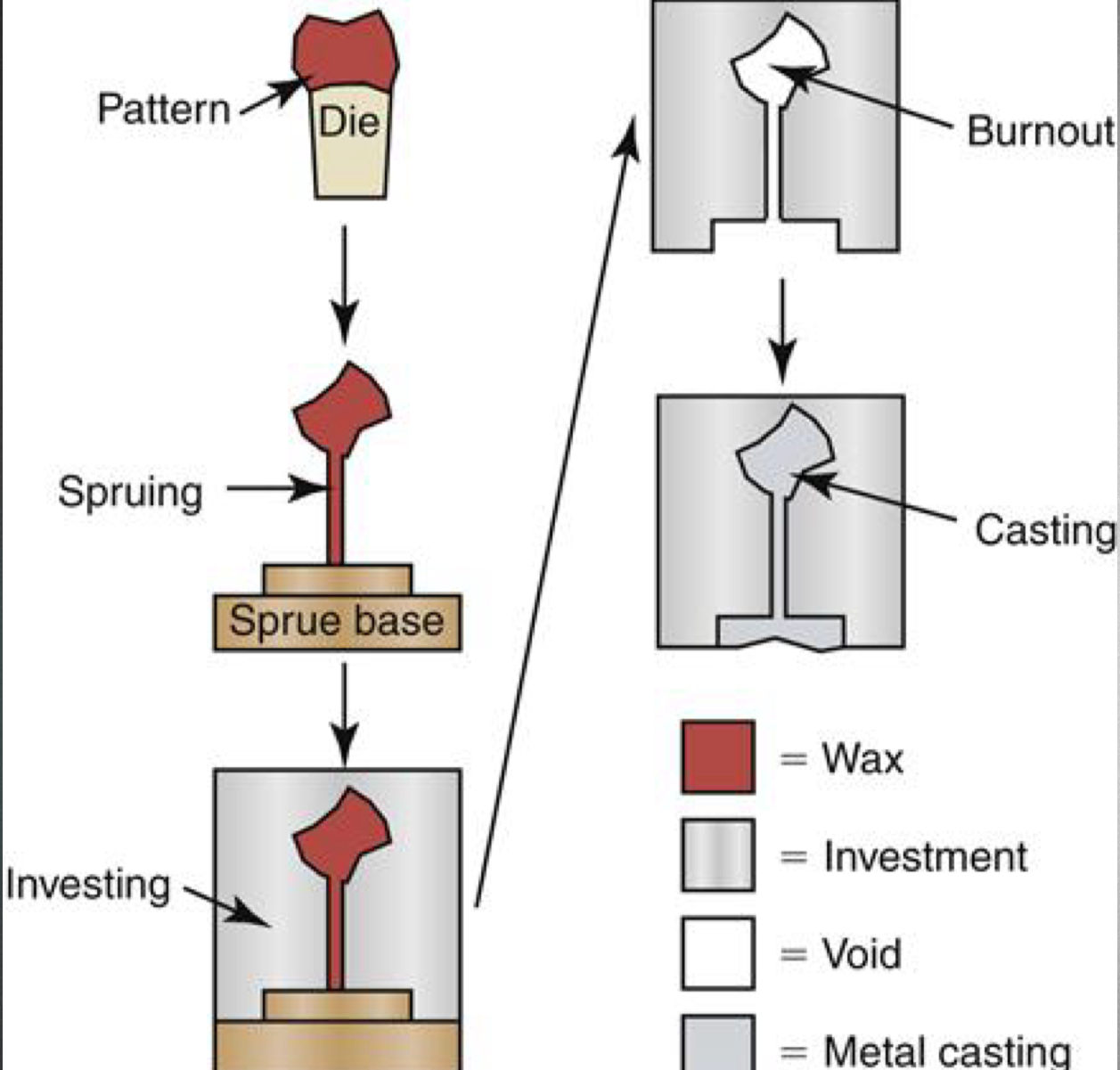

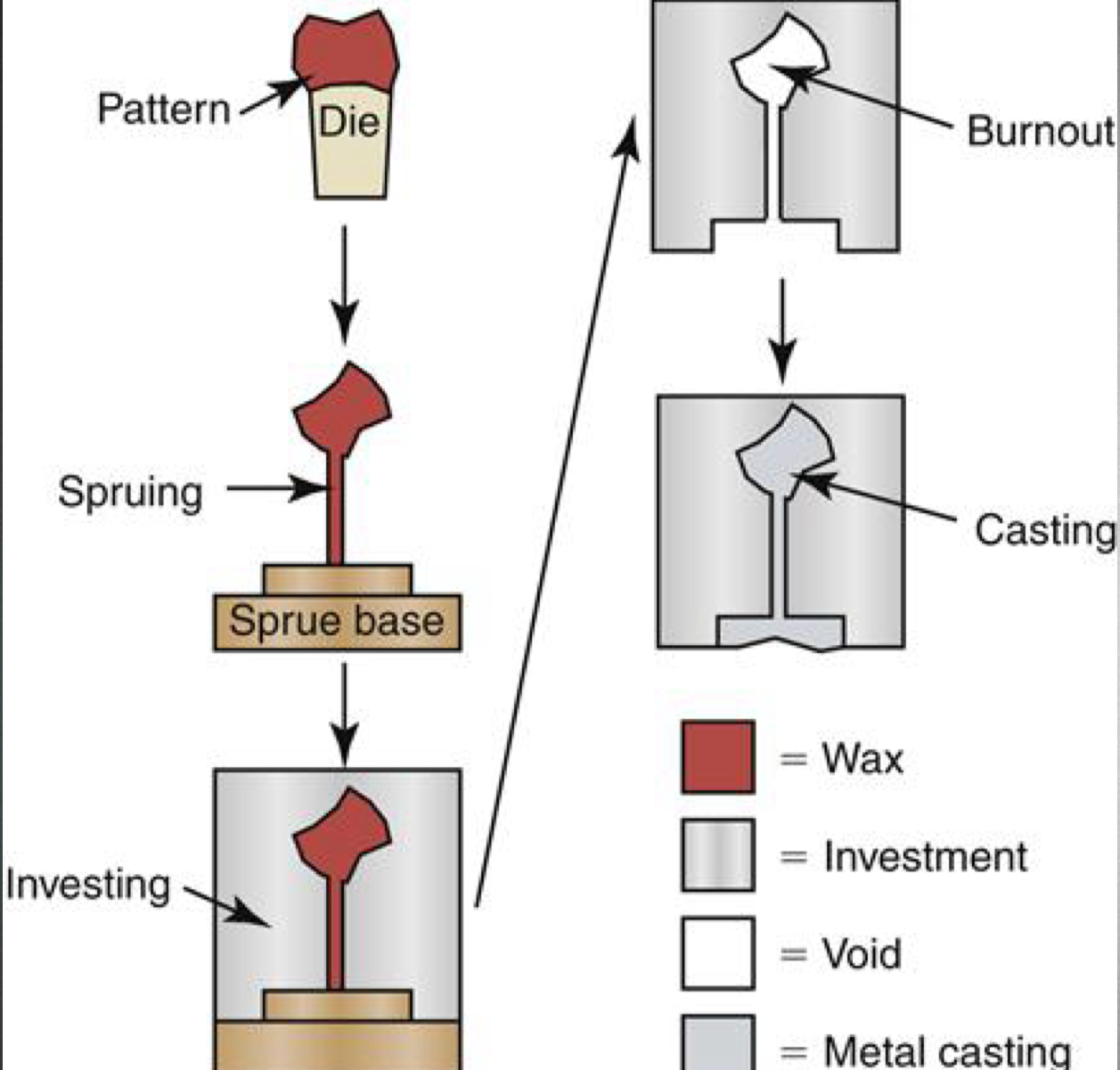

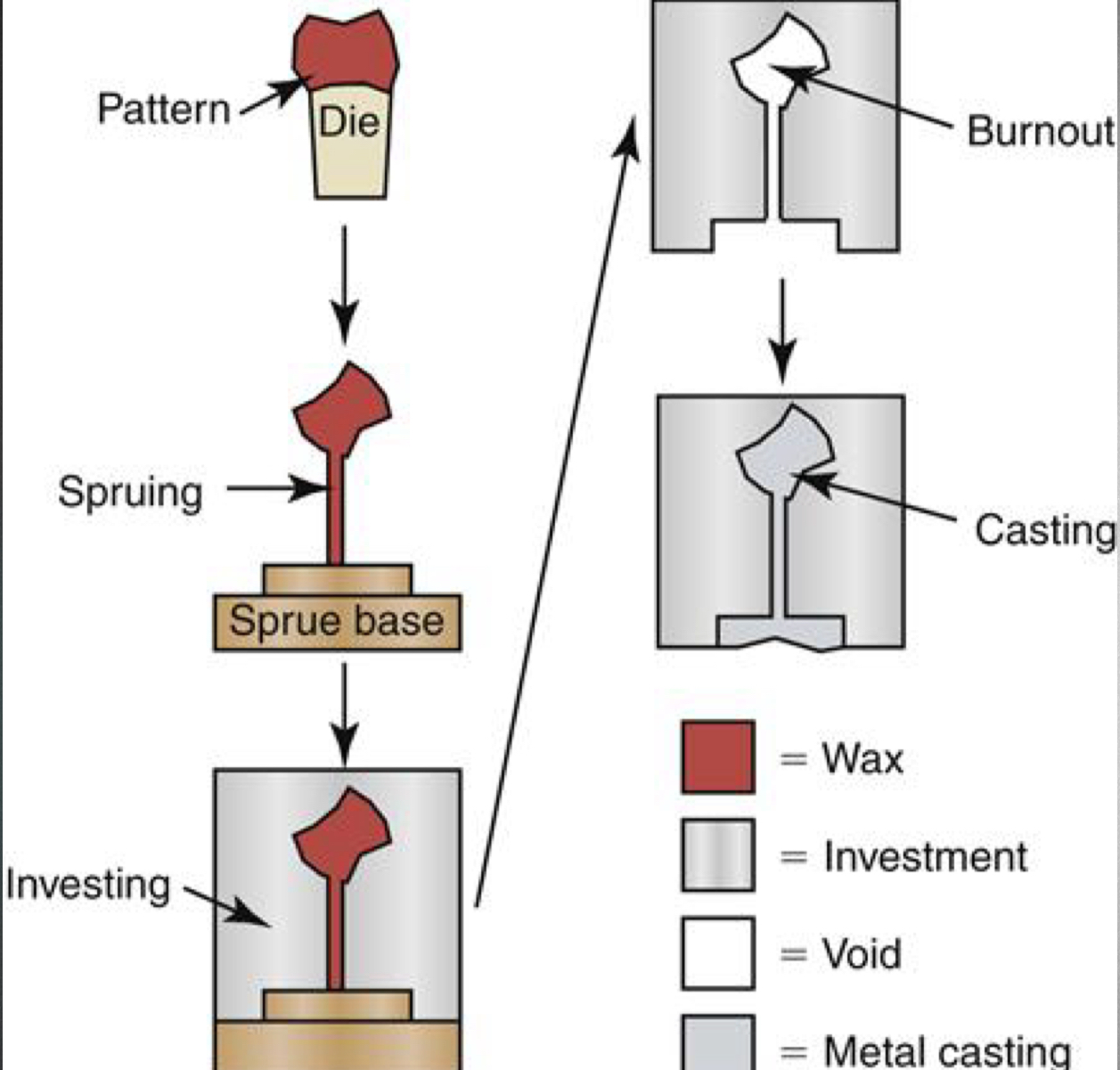

Spruce technique with investment removal

Complete the casting process, where wax replica is converted into a metal alloy

Sprue

channel in a refractory investment mold through which molten metal flows

what is investment?

Refractory material that becomes the mold

What is burnout?

Heating an invested mold to eliminate wax pattern

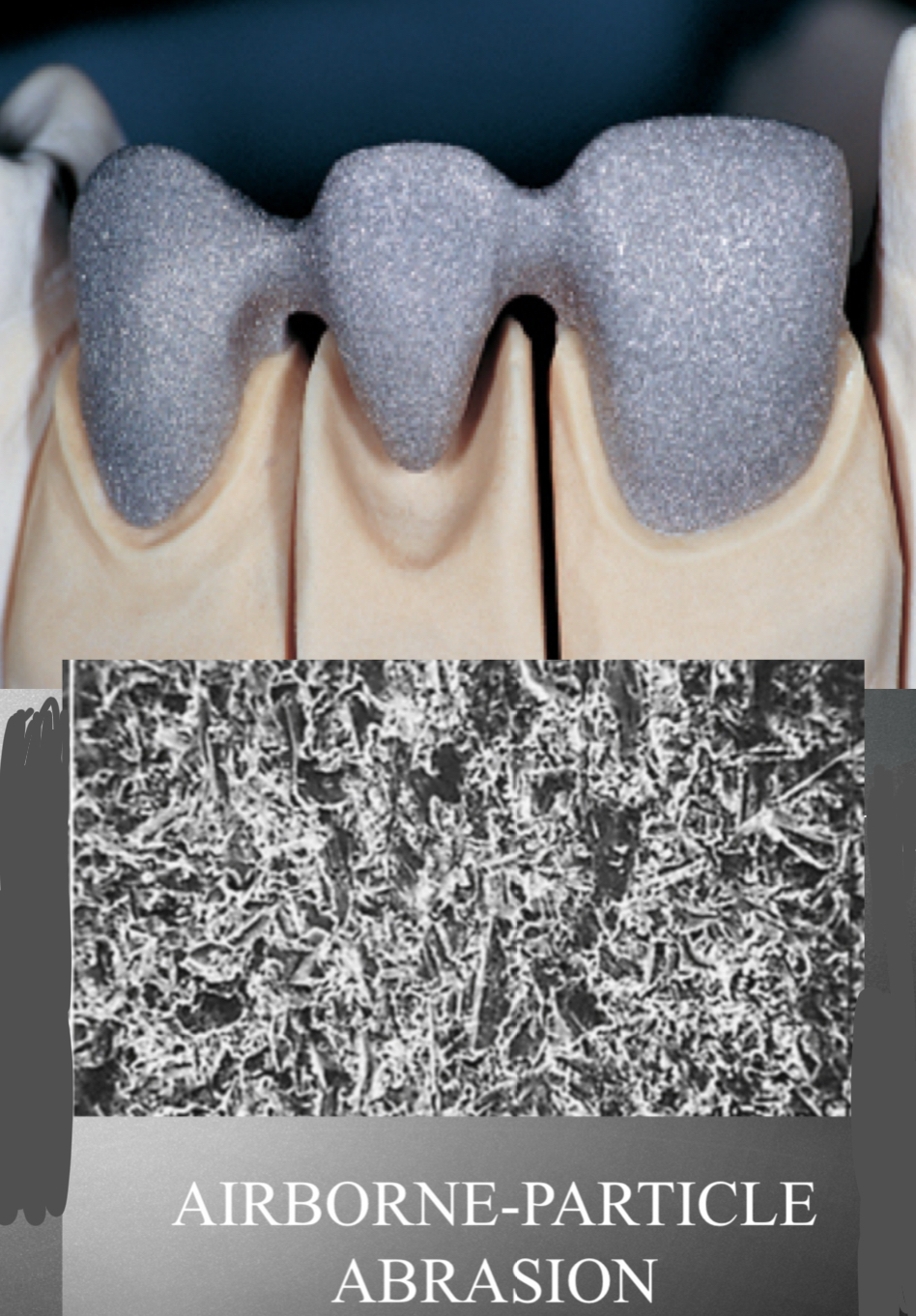

How is the oxide layer formed on the surface of metal during casting removed?

Partially remove with either acid or airborne particle abrasion- gives satin finish

How do you clean the prepared framework?

Either with cleaning solution in ultrasonic for 5 mins or steam cleaning then rinse with alcohol or distilled water

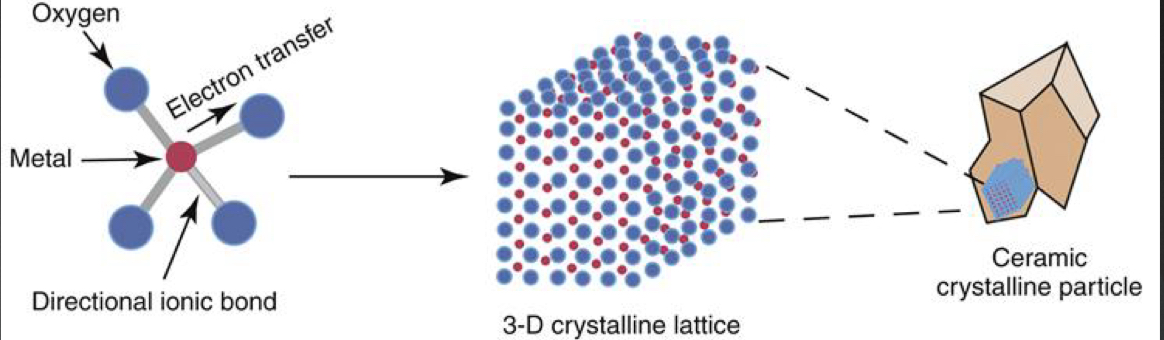

Why are ceramic materials distinct from alloys or polymers, its structure?

Ceramics contain strong directional ionic bonds between metal and oxygen- provide strength, intolerant to distortion- makes brittle

Metal and oxygen form 3D crystalline lattice

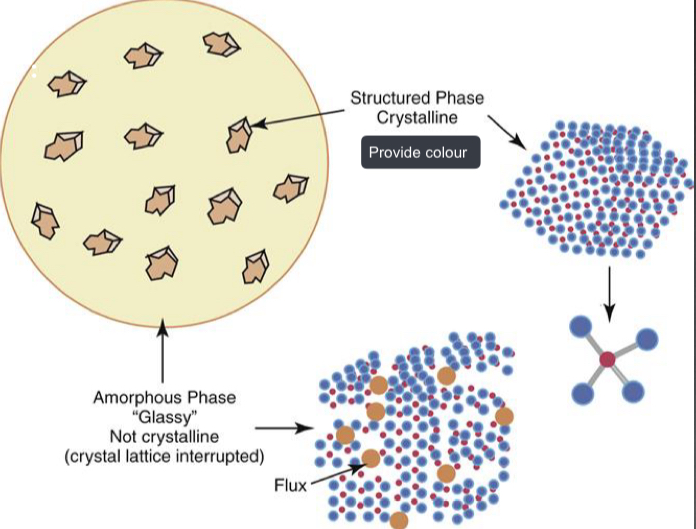

What areas do all ceramics contain?

Amorphous phase- metal ions disrupt metal oxygen crystal arrays, tend to be transparent

Crystal areas- opaque

Porcelain is a type of ceramic that results when…

Feldspar

Silica

Alumina

Are fired together with fluxes like sodium or potassium carbonate

During firing large amorphous ceramic areas are formed

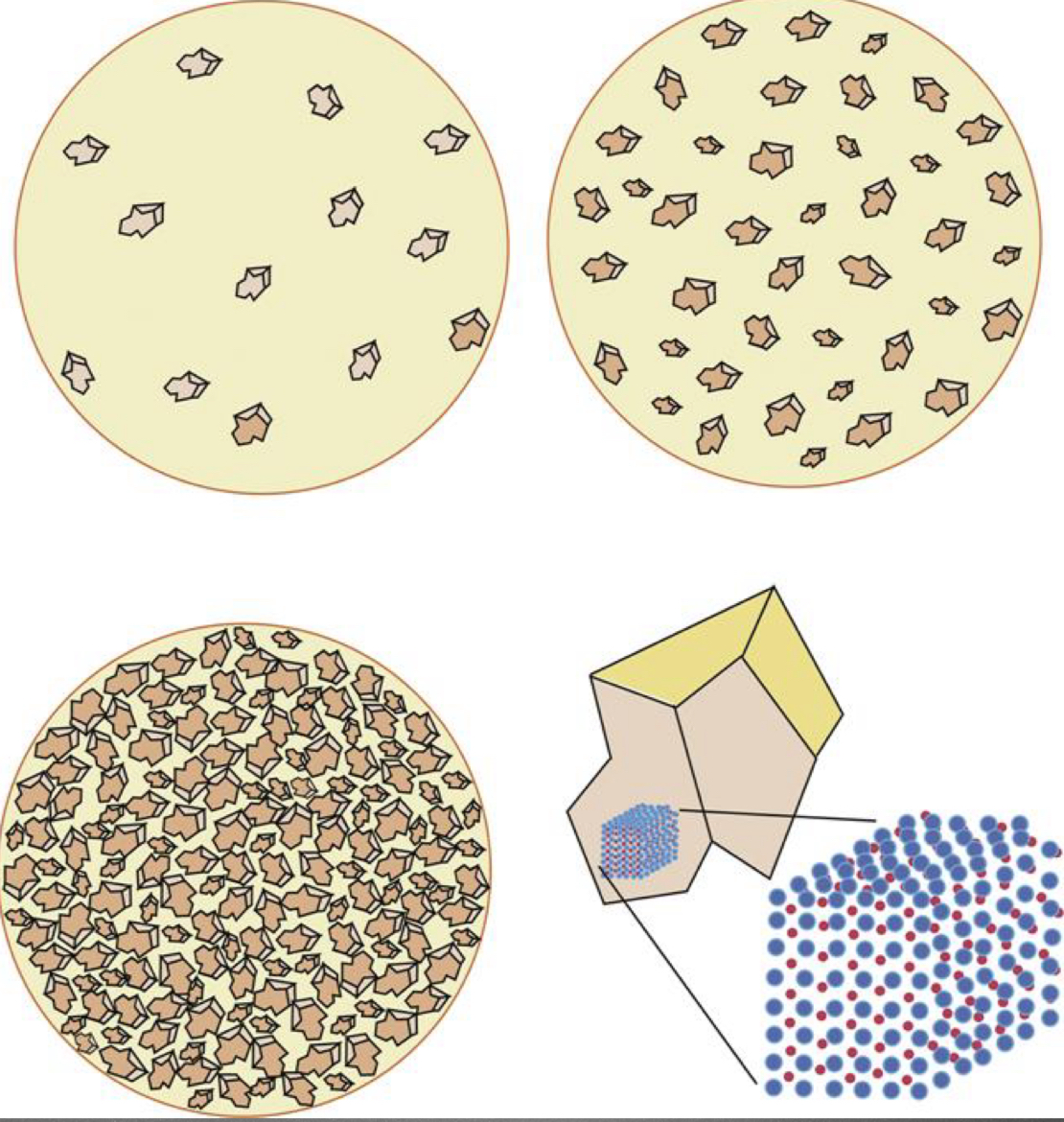

What are the 4 catergories of dental ceramics?

Feldespathic or glassy- Mostly amorphous glass with islands of crystalline phase-leucite

Crystalline dominated- mostly crystalline, many type of crystals,less transparent, stronger, opaque

Glass dominated

Crystalline- no glassy phase, strongest

How to combine ceramics with metal?

High, medium and low fusing

Metal ceramic veneer restorations fired in a range of 950-1020 degrees Celsius

How is porcelain manufactured?

Heat at high temp to form glassy mass

Quench in water to cool rapidly- mass fractures into small fragments- frit- repeat until desired particle size achieved

Wetting process- is powder and water/water based glycerin liquid

What are the 3 types of porcelain blends?

Opaque

Body

Incisal

What are the steps to make the metal look like a natural tooth?

Opaque masks colour of alloy, responsible for metal ceramic bond- done through porcelain wetting process

Why is it important that opaque porcelain must wet the surface easily?(3)

For proper mechanical bind and chemical interaction at interface

Primary source of colour of resto

Opaque thickness shouldn’t be over 0.1mm- will be overcontoured

What is the purpose of body porcelain?

Fired into opaque layer

Provides translucency, contains metallic oxides that help shade matching

What is the purpose of incisal porcelain?

Usually translucent

Colour of resto more influenced by body and opaque porcelain

5 Indications for metal ceramics?

Need complete coverage- aesthetic

Retainer for FDP

Long span FDP

Rest for removable prosthesis

Extensive tooth destruction/endo teeth

3 Contraindications of metal ceramic crowns

Active caries, untreated periodontal disease

Young patients with large pulp chambers

L/B walls intact

4 Advantages of metal ceramics?

Natural appearance

Retentive- all axial walls included in prep

Can correct axial form

Easy to prep

5 Disadvantages of metal ceramics?

Need significant tooth reduction to gain space

If facial margin on anterior resto is placed subgingivally- increase risk of periodontal disease

Inferior aesthetics- hard shade match

Brittle fracture

Expensive

Preparation steps for metal ceramic crowns in anterior teeth?look at ppt

Place 3 grooves in the cervical 1/3 and incisal 2/3

Place incisal depth grooves

Incisal edge reduction- 2mm

Facial reduction in two planes, break proximal contact

Proximal reduction- 0.5mm lingual chamfer line

Finish