Chapter 2 Section B (Unit 1 and 2)

1/28

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

29 Terms

2-14

A main difference between Lockbolt/Huckbolt tension and shear fasteners (other than their application) is in the

A– method of installation.

B– number of locking collar grooves.

C– shape of the head.

2-14. Answer B. JSAT 2B

HuckBolt® fasteners and lockbolts are manufactured to the same Federal Standard. In each case, the tension-type has 4 to 5 locking grooves and the shear-type has 2.

2-15

One of the main advantages of Hi-Lok type fasteners over earlier generations is that

A– the squeezed on collar installation provides a more secure, tighter fit.

B– they can be removed and reused again.

C– they can be installed with ordinary hand tools.

2-15. Answer C. JSAT 2B

The hand tools used for installation of Hi-Lok® bolts are an open end wrench and hex key (Allen wrench).

2-16

Alloy 2117 rivets are heat treated:

A– to a temperature of 910 to 930°F and quenched in cold water.

B– by the manufacturer and do not require heat treatment before being driven.

C– by the manufacturer but require reheat treatment before being driven.

2-16. Answer B. JSAT 2B, FGH

The 2117-T rivet, known as the field rivet, is used more than any other for riveting aluminum alloy structures. The field rivet is in wide demand because it is ready for use as received, and needs no further heat treating or annealing.

2-17

The markings on the head of a Dzus fastener identify the

A– manufacturer and type of material.

B– body type, head diameter, and type of material.

C– body diameter, type of head, and length of the fastener.

2-17. Answer C. JSAT 2B, FGH

When working with Dzus® fasteners, it is worthwhile to know that the body diameter, length, and head type may be identified by the markings found on the head of the stud.

2-18

The Dzus turnlock fastener consists of a stud, grommet, and receptacle. The stud length is measured in

A– sixteenths of an inch.

B– tenths of an inch.

C– hundredths of an inch.

2-18. Answer C. JSAT 2B, FGH

The length of a Dzus fastener is measured in hundredths of an inch and is the distance from the head of the stud to the bottom of the spring hole.

2-19

The Dzus turnlock fastener consists of a stud, grommet, and receptacle. The stud diameter is measured in

A– sixteenths of an inch.

B– hundredths of an inch.

C– tenths of an inch.

2-19. Answer A. JSAT 2B, FGH

The diameter of a Dzus fastener is always measured in sixteenths of an inch.

2-20

Threaded rivets (Rivnuts) are commonly used to

A– join two or more pieces of sheet metal where shear strength is desired.

B– join two or more pieces of sheet metal where bearing strength is desired.

C– attach parts or components with screws to sheet metal.

2-20. Answer C. JSAT 2B

Rivnut® fasteners are a combination of rivet and nut. A hole is drilled through the skin and the fastener, which resembles a hollow rivet with threads inside its shank, is slipped into the hole and upset with a special puller.

2-21

Cherrymx and Olympic-Lok rivets

A– may be installed with ordinary hand tools.

B– utilize a pulling tool for installation.

C– utilize a rivet gun, special rivet set, and bucking bar for installation.

2-21. Answer B. JSAT 2B

Both CherryMAX® and OLYMPIC-LOK® rivets require special pulling type tools for installation.

2-22

Select the alternative which best describes the function of the flute section of a twist drill.

A– Forms the cutting edges of the drill point.

B– Forms the area where the drill bit attaches to the drill motor.

C– Prevents overheating of the drill point.

2-22. Answer A. JSAT 2B, FGH

The flutes are the valley between the lands. The flute forms the cutting edge of the drill point. They provide a method for carrying material out of the hole as well as delivering cooling oil and drill lubricant to the cutting surface.

2-23

What should be the included angle of a twist drill for soft metals?

A– 118°

B– 90°

C– 65°

2-23. Answer B. JSAT 2B

An included angle of 90 degrees should be used for drilling soft metals such as lead, copper, or very soft aluminum and other soft materials such as plastic.

2-24

When comparing the machining techniques for stainless steel sheet material to those for aluminum alloy sheet, it is normally considered good practice to drill the stainless steel at a

A– higher speed with less pressure applied to the drill.

B– lower speed with less pressure applied to the drill.

C– lower speed with more pressure applied to the drill.

2-24. Answer C. JSAT 2B, FAH

When drilling hard metals such as titanium or stainless steel, the included angle should be 140° and the operator should use a slower drill speed and a higher pressure on the bit then would be used for aluminum or steel.

2-25

When drilling stainless steel, the drill used should have an included angle of

A– 140° and turn at a low speed.

B– 118° and turn at a high speed.

C– 90° and turn at a low speed.

2-25. Answer A. JSAT 2B

When drilling hard metals such as titanium or stainless steel, the included angle should be 140° and the operator should use a slower drill speed and a higher pressure on the bit then would be used for aluminum or steel.

2-26

Which is correct concerning the use of a file?

A– A smoother finish can be obtained by using a double cut file than by using a single cut file.

B– Apply pressure on the forward stroke, only, except when filing very soft metals such as lead or aluminum.

C– The terms “double cut” and “second cut” have the same meaning in reference to files.

2-26. Answer B. JSAT 2B, FGH

Files which have one row of teeth are known as “single-cut,” and those with two rows of teeth as “double-cut.” The coarseness of the teeth are rated from coarse to fine: Coarse cut, bastard cut, second cut, smooth cut, and dead smooth cut. Generally speaking, double cut files are used for removing the most material. When cutting with the file, one should apply pressure only on the forward cut, unless the material is soft. In this case the file may be permitted to remain in contact with the material on the return to help remove chips from the teeth.

2-27

Which procedure is correct when using a reamer to finish a drilled hole to the correct size?

A– Turn the reamer only in the cutting direction.

B– Apply considerable pressure on the reamer when starting the cut and reduce the pressure when finishing the cut.

C– Turn the reamer in the cutting direction when enlarging the hole and in the opposite direction to remove from the hole.

2-27. Answer A. JSGT 9A, FGH

When a reamer is being used, it should be rotated in the cutting direction only. The reamer should be turned steadily and evenly to prevent chattering or marking and scoring of the walls.

2-28

What should be the included angle of a twist drill for hard metal?

A– 118°

B– 90°

C– 100°

2-28. Answer A. JSAT 2B, FGH

For most drilling, a twist drill with a cutting angle of 118° will be sufficient; however, when drilling softer metals, a cutting angle of 90° may be more efficient.

2-29

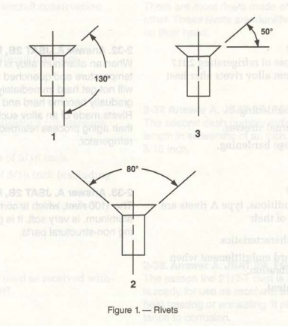

(Refer to figure 1.)

Which of the rivets shown will accurately fit the conical depression made by a 100° countersink?

A– 3.

B– 2.

C– 1.

2-29. Answer C. JSAT 2B

When a rivet has a 100° countersunk head, it has a head whose sides form a 100° angle. Drawing 1 shows a 260° angle, not including the rivet’s head. This leaves 100° for the head of the rivet.

2-30

The identifying marks on the heads of aluminum alloy rivets indicate the

A– degree of dimensional and process control observed during manufacture.

B– specific alloy used in the manufacture of the rivets.

C– head shape, shank size, material used, and specifications adhered to during manufacture.

2-30. Answer B. JSAT 2B, FGH

Markings on the heads of rivets are used to classify their characteristics. The different markings indicate the composition of the rivet stock.

2-31

When an MS20470D rivet is installed, its full shear strength is obtained

A– by the cold working of the rivet metal in forming a shop head.

B– only after a period of age hardening.

C– by heat treating just prior to being driven.

2-31. Answer B. JSAT 2B

The “D” and “DD” series rivets are known as “icebox” rivets because they must be stored at low temperatures after heat-treating. The low temperature storage retards the naturally occurring age hardening that occurs in the 2017 and 2024 alloys following heat-treating. Within minutes after removal from refrigeration, these rivets will begin to age harden. These rivets will only achieve their full strength after the age hardening process is complete.

2-32

What is the purpose of refrigerating 2017 and 2024 aluminum alloy rivets after heat treatment?

A– To retard age hardening.

B– To relieve internal stresses.

C– To accelerate age hardening.

2-32. Answer A. JSAT 2B, FGH

When an aluminum alloy is heated to a specific temperature and quenched in water or in brine, it will not get hard immediately as steel does, but will gradually become hard and gain its full strength. Rivets made of an alloy such as 2017 can have their aging process retarded by storing them in a refrigerator.

2-33

Under certain conditions, type A rivets are not used because of their

A– low strength characteristics.

B– tendency toward embrittlement when subjected to vibration.

C– high alloy content.

2-33. Answer A. JSAT 2B, FGH

The 1100 rivet, which is composed of 99.45% pure aluminum, is very soft. It is generally used for riveting non-structural parts.

2-34

Heat treated rivets in the D and DD series that are not driven within the prescribed time after heat treatment or removal from refrigeration

A– may be returned to refrigeration and used later without retreatment.

B– must be reheat treated before use.

C– must be discarded.

2-34. Answer B. JSAT 2B, FGH

Rivets classed as “D” and “DD” become hard within a few hours of being heat treated. If this happens, they must be heat treated again before they can be used.

2-35

The dimensions of an MS20430AD-4-8 rivet are

A– 1/8 inch in diameter and 1/2 inch long.

B– 1/8 inch in diameter and 1/4 inch long.

C– 4/16 inch in diameter and 8/32 inch long.

2-35. Answer A. JSAT 2B

The first number following the letter (material code) indicates the diameter of the rivet in 1/32 inch increments. 4/32 = 1/8 inch diameter. The number following the dash is the length in 1/16 inch increments. 8/16 = 1/2 inch.

2-36

Most rivets used in aircraft construction have

A– a raised dot.

B– smooth heads without markings.

C– dimples.

2-36. Answer C. JSAT 2B, FGH

There are more rivets made of 2117 alloy than any other. These rivets are identified by a single dimple on their head.

2-37

MS20426AD-6-5 indicates a countersunk rivet which has

A– an overall length of 5/16 inch.

B– a shank length of 5/16 inch (excluding head).

C– a shank length of 5/32 inch (excluding head).

2-37. Answer A. JSAT 2B, FGH

The second dash number indicates the rivet’s length in sixteenths of an inch. In this case, it is 5/16 inch.

2-38

Which rivet may be used as received without further treatment?

A– 2117-T3.

B– 2017-T3.

C– 2024-T4.

2-38. Answer A. JSAT 2B, FGH

The reason the 2117-T rivet is so popular is that it is ready for use as received, and needs no further heat treating or annealing. It also has a high resistance to corrosion.

2-39

A “DD” rivet is heat treated before use to

A– soften and facilitate riveting.

B– harden and increase strength.

C– relieve internal stresses.

2-39. Answer A. JSAT 2B, FGH

A “DD” rivet is made from 2024-T4 aluminum alloy. These rivets are stored in a refrigerator until used. They may be heat treated just before use to soften them, which makes the riveting easier.

2-40

Which rivet is used for riveting magnesium alloy structures?

A– 5056 aluminum.

B– Monel.

C– Mild steel.

2-40. Answer A. JSAT 2B, FGH

The 5056 rivet is used for riveting magnesium alloy structures because of its corrosion resistant qualities in combination with magnesium.

2-41

Which rivet is used for riveting nickel steel alloys?

A– Mild steel.

B– Monel.

C– 2024 aluminum.

2-41. Answer B. JSAT 2B, FGH

Monel rivets are used for riveting nickel/steel alloys. They can be substituted for those made of corrosion-resistant steel in some cases.

2-42

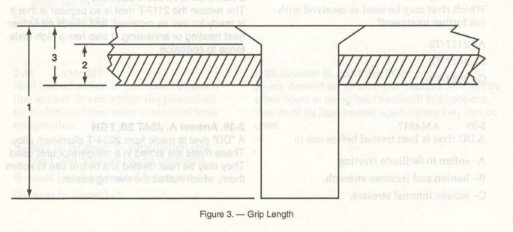

(Refer to figure 3.)

Which is the grip length of the flush rivet?

A– 2.

B– 3.

C– 1.

2-42. Answer B. JSAT 2B, FAH

The grip length of a rivet is that portion of the rivet which is passing through the material.