MCHE 3310 Quiz 2

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

21 Terms

Diffusion Mechanisms

For an atom to diffuse, two conditions must be met:

• There must have an empty adjacent site

• The atom must have sufficient energy to break bonds with its neighbor atoms and then

cause some lattice distortion during the displacement.

Vacancy Diffusion

atoms exchange with vacancies

applies to substitutional impurities (atoms)

rate depends on number of vacancies and activation energy to exchange

Interstitial Diffusion

• Smaller atoms, e.g., H, C, N and O, can diffuse into or between interstitial positions.

• Interstitial diffusion occurs much more rapidly than vacancy diffusion

• There are more empty interstitial position than vacancies in a solid.

• Interstitial diffusion is an important method to improve materials' mechanical

properties, particularly the surface hardness and strength.

Steady State Diffusion

Rate of diffusion is independent of time

• Flux proportional to concentration gradient

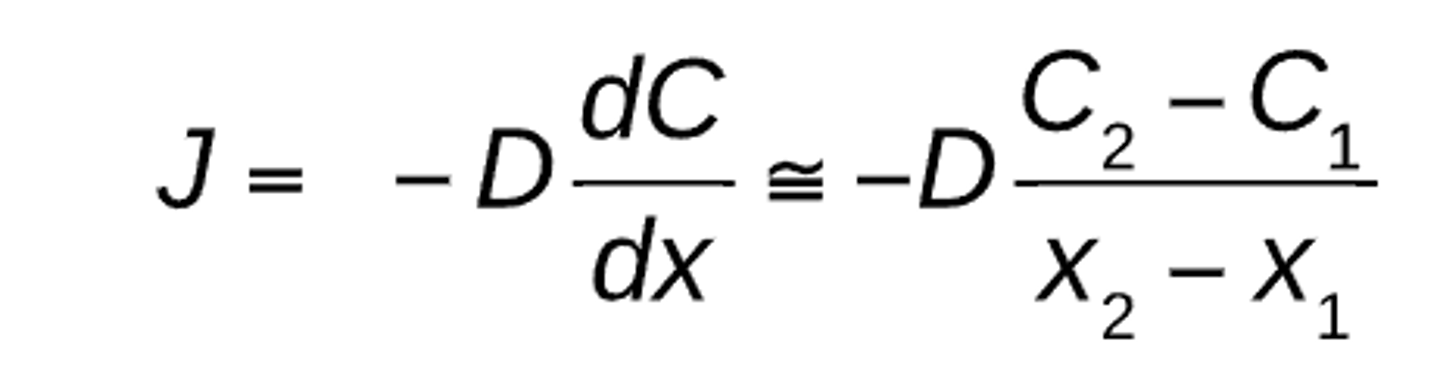

Fick's First Law

The diffusion flux is proportional to the concentration gradient. This relationship is used for steady-state diffusion situations.

Non-Steady State Diffusion

Diffusion flux and the concentration gradient at some particular point in a solid vary with time, resulting in a net accumulation or depletion of the diffusion species resulting

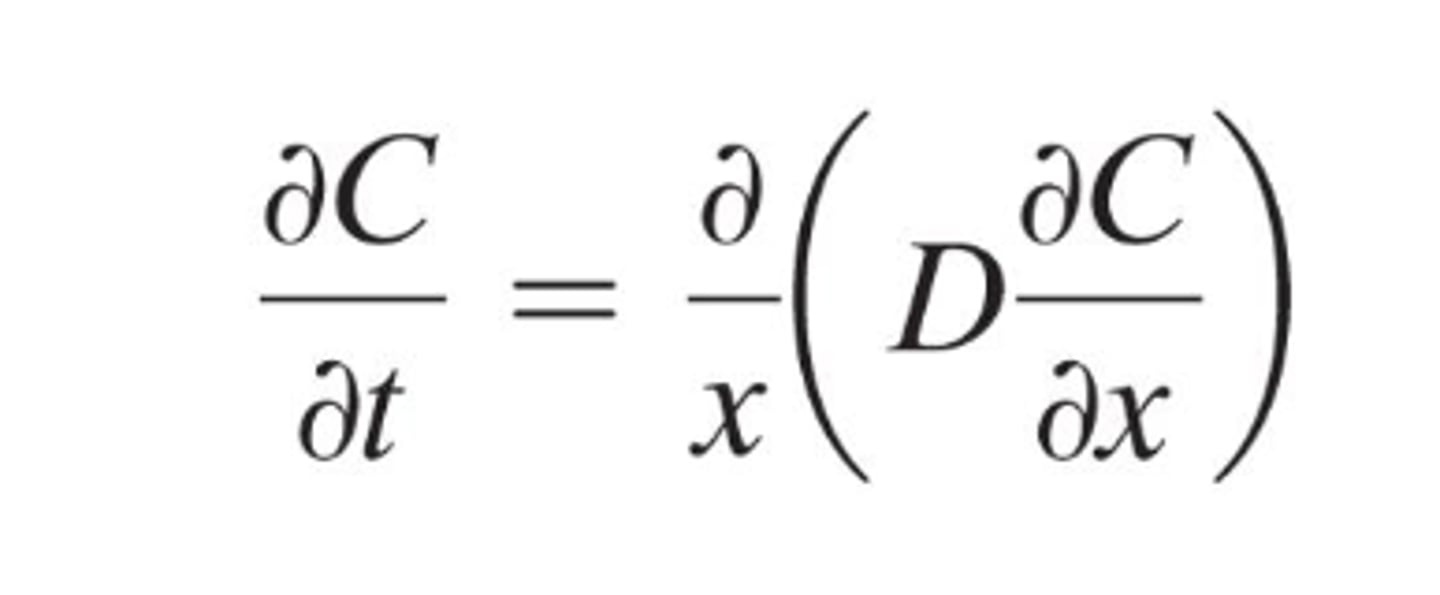

Fick's Second Law

The time rate of change of concentration is proportional to the second derivative of concentration. This relationship is used in nonsteady-state diffusion situations.

Modulus of Elasticity (Young's Modulus)

Measure of stiffness of an object, defined as the amount of strain resulting from applying a given stress.

Since all geometric influences have been removed, E

represents the inherent properties of the materials,

which is the direct manifestation of the strength of the

interatomic bonds. The strain is achieved by actually

increasing the interatomic distances in the crystal.

• For materials with strong bonds, the moduli are high

and a given stress produce only a small strain.

• For metal, E is between 45 GPa (Mg) to 407 GPa (W).

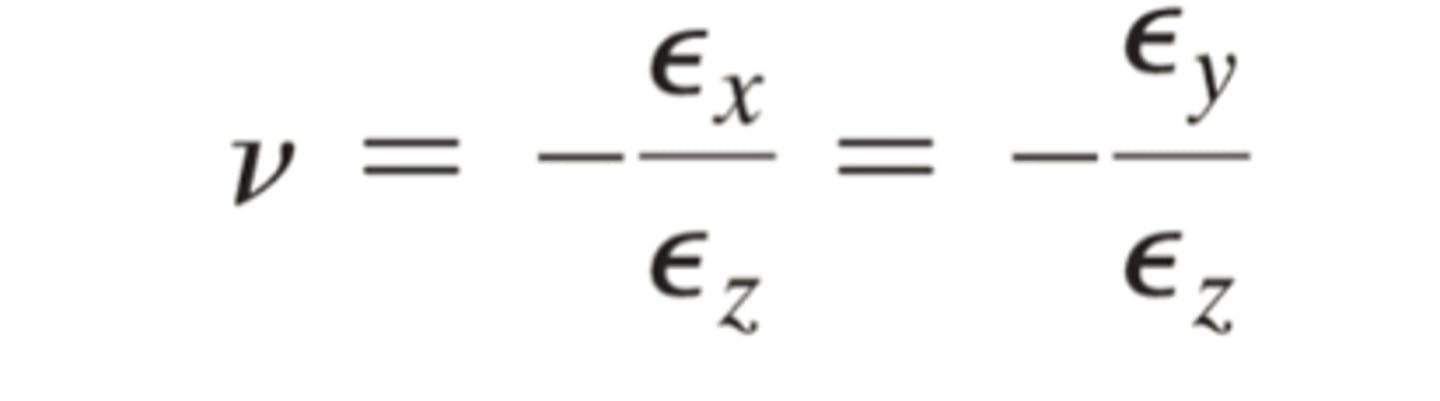

Poisson's Ratio

the ratio of lateral strain

( ex or ey) and axial strain ( ez ):

yield strength

The stress required to produce a very slight yet specified amount of plastic strain; a strain offset of 0.002 is commonly used.

tensile strength

A measure of how much stress from pulling, or tension, a material can withstand before breaking. (maximum strength of a material)

Characteristics of Dislocations

Dislocation causes atomic lattice distortion around it• Tensile, compressive and shear lattice strains are imposed on the neighboring atoms

Dislocation Slip Systems

• Dislocations don't move with the same degree of ease on all crystallographic planes of atoms and in all crystallographic directions.

• Slip plane: plane on which easiest slippage occurs has the densest atomic packing - the greatest planar density

• Slip direction: direction of movement on the slip plane is most closely packed with atoms - the highest linear density

• Slip system: combination of slip plane and slip direction

effect of heat treatment

Annealing can:

• decreases tensile strength

• increases ductility

• nullify the effects of cold work

Three Stages During Heat Treatment

1. Recovery

2. Recrystallization

3. Grain Growth

critical shear stress

the minimum shear stress required to initiate slip and is a property of the material that determines when yielding occurs.

strain hardening

The increase in hardness and strength of a ductile metal as it is plastically deformed below its recrystallization temperature.

fatigue life

number of cycles to cause failure at a specified stress level

characteristic of crack surfaces

The process of fatigue failure involves three steps:

-- crack initiation - a small crack is formed

-- crack propagation - crack advances incrementally with each stress cycle

-- final failure - occurs rapidly once the advancing crack has reached a critical size

• Cracks always initiate (nucleate) on the surface of a component.

• Crack nucleation sites include surface scratches, sharp filets, keyways, threads, dents.

Two types of markings are observed on a fatigue fracture surface:

Beachmarks -Each beachmark band represents a period of time over which crack growth occurred

striation- Each striation represents the advance distance of a crack front during a single load cycle.

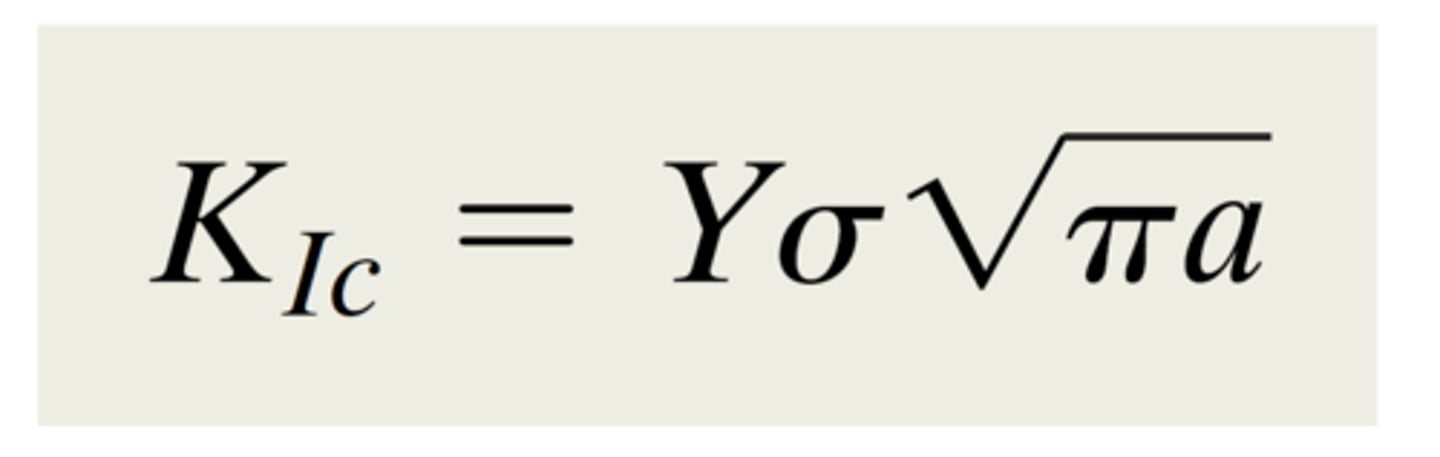

fracture toughness

a measure of a material's resistance to brittle fracture when a crack is present. It is defined as the amount of energy per volume that a material can absorb before rupturing.

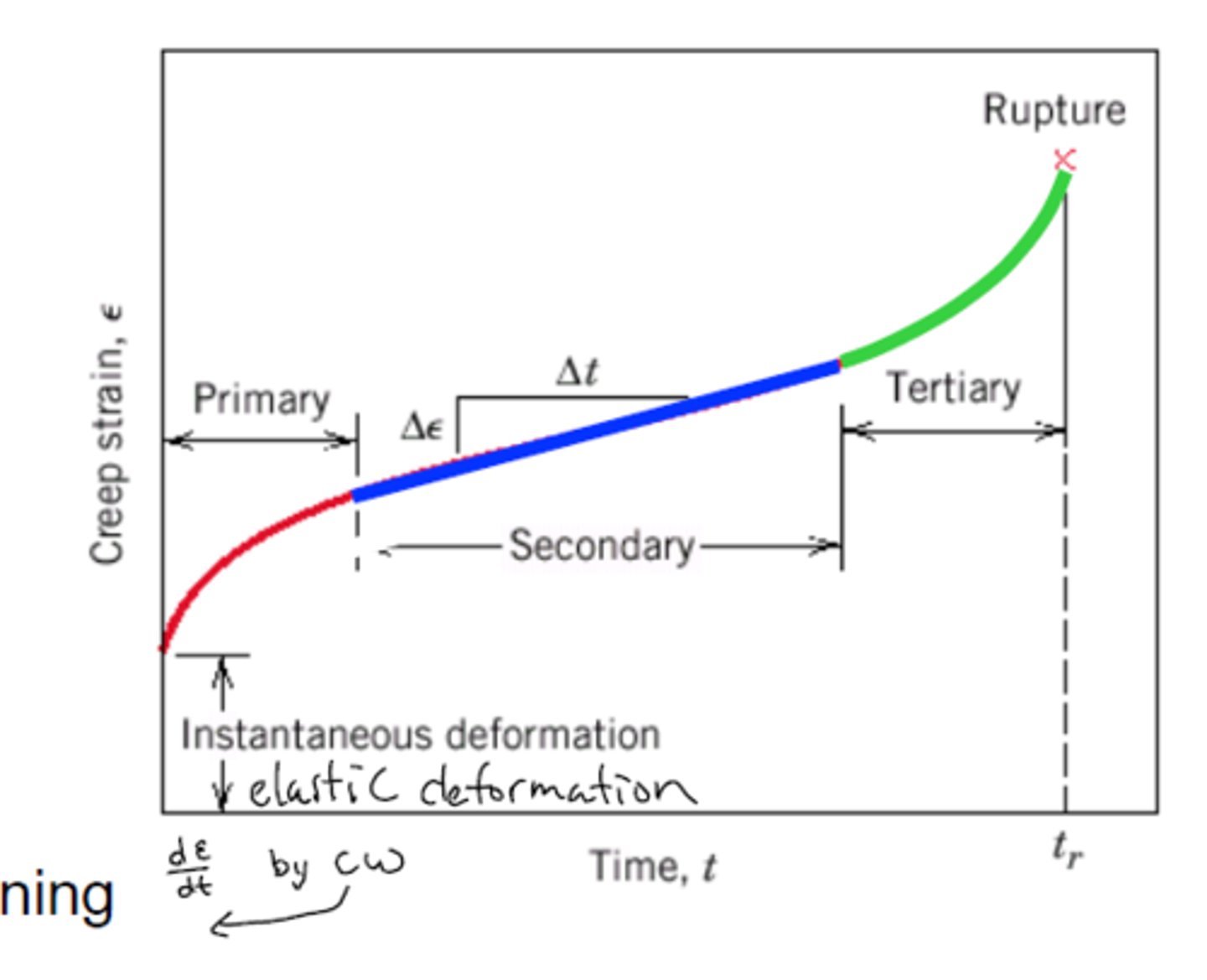

Creep stages