Actions of Soaps + Detergent

1/32

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

33 Terms

Soap Structure

Formed from base hydrolysis of fats and oils

Have a polar hydrophilic head, and a hydrophobic tail

Soap Benefits

Made from natural fats and is hence biodegradable

Effective for human hygiene

Soap Negatives

Able to form soap scum in hard water, which is water with high Ca2+ and Mg2+, and hence form insoluable salts, this is because a soap molecule contains a carboxylic ion, which is able to form an ionic force of attraction

Anionic Detergent Structure

Anionic, negatively charged

Still has hydrophobic tail

Head etc Benzene Sulfonate,

Anionic Detergent Benifets

Do not precipitate in hard water

Availability of materials, such as petrochemicals

Suitable for cleaning of textiles

Anionic Detergent Negatives

Non biodegradable

Excessive foaming

Not suitable for use in personal hygiene, strips away to much oil from body

Cationic Detergennt

Has a hydrophobic tail

Cationic Benefits

Don’t precipate in hard water

Cleans plastics better

Used as fabric softener, reduce friction and static electricity

Cationic Detergent Negatives

Can kill living things (biocidal)

Non Ionic Detergent Structure

Have a non ionic hydrophilic head, containing an oxygen atom in the chain and a terminal alkanol group

Hydrophobic taill

Non Ionic Detergent Benifets

Do not precipate in hard water

Low foaming detergent useful in low-sudsing applications

Such as dishwashers

Polymer Average MM

Related to number of monomer units

Longer the chain, higher the weight, hence higher strength dispersion force

Polymer Chain Branching

High Density:

Forms crystalline polymer (tightly ordered and packed)

Hard and dense material

Low Density:

Non crystalline

Low melting point, hence more flexible and soft

Polymer Chain Stiffening

If a monomer, has a side chain it leads to polymers with reduced flexibility

The larger the side chain, the less it is able to move around

Polymer Cross Linking

When two polymers are joined together in 2d network

Increases strength

Cross linking agent, such as sulfur is required

Polymer Solubility in Water

Polymer consist of long chains of carbon, hence dispersion forces are the most common

This is unless there are polar hydroxyl or carboxyl groups

Polymer Stabiltiy

Most polymers contain C-C, C-H bonds which are very stable

Some polymers, such as PVC contain C-Cl bonds, which are weaker than C-H and break down in the presence of UV light

Addition Polymer

A polymer formed by adding together without loss of atoms

Polymer Initiation

Initiator molecule breaks the double bond, (must have double bond)

etc Hydrogen Peroxide, when is reacted forms a free radical, which want to react

Polymer Elongation/Propagation

Once a free radical starts the reaction, a new monomer forms, forming another free radical

Propogation process

Polymer Termination

sf

Polyethene

Monomer Name: Ethene

Low Density Polyethene

Has branched chain

Amorphous (disordered)

Weak bonding due to disperson forces

Soft plastic

High Density Polyethene

Crystaline (ordered chains)

Stronger dispersion forces

Denser, tougher and rigid

Polychlorethene

Monomer is chloroethene

Polar C-Cl produces string dipole-dipole forces

C-Cl bond vulnerable to U.V light however

Adding plasticiser, will soften it by weakening the IMF

Polyphenylethene

Monomer Name, phenylethen

Looks like an ethene, but with a benzene ring swapped out with a hydrogen

Bulky side group hinders rotation and prevents chain flexibility

Use for takeaway containers

Polytetrafluoroethane

Monomer Name: 1,1,2,2 - tetrafluoroethane

Creates a highly polar, symmetrical polymer

Has weak disperson forces, so is non stick, non-polar, hard to interact

Condensation Polymerisation

Formed by condensation reaction, elimination of a small molecule, such as water when monomers join together

Polyamides

Formed by the reaction between dicarboxylic acid and diamine

There is an amide linkage

Water molecule is released each time

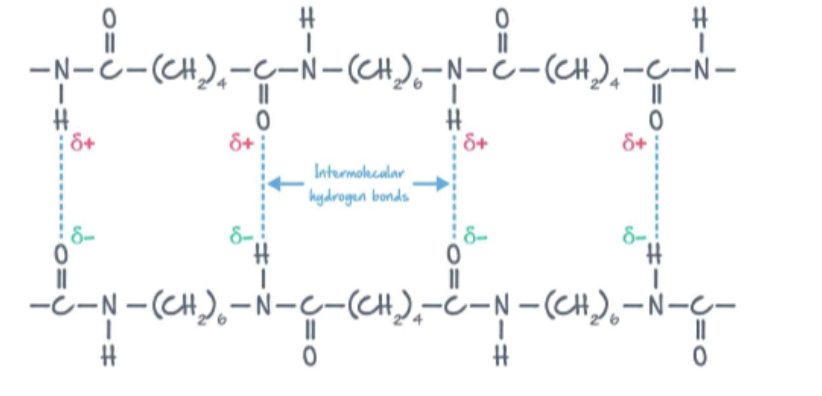

Nylon-6,6

Formed between Hexanedioic Acid and Hexane-1,6-diamine

An amide link is formed

Alternate between 4 CH2 and 6 CH2

Water is produced

High tensile strength (due to H bonding)

Lightweight material, stretch

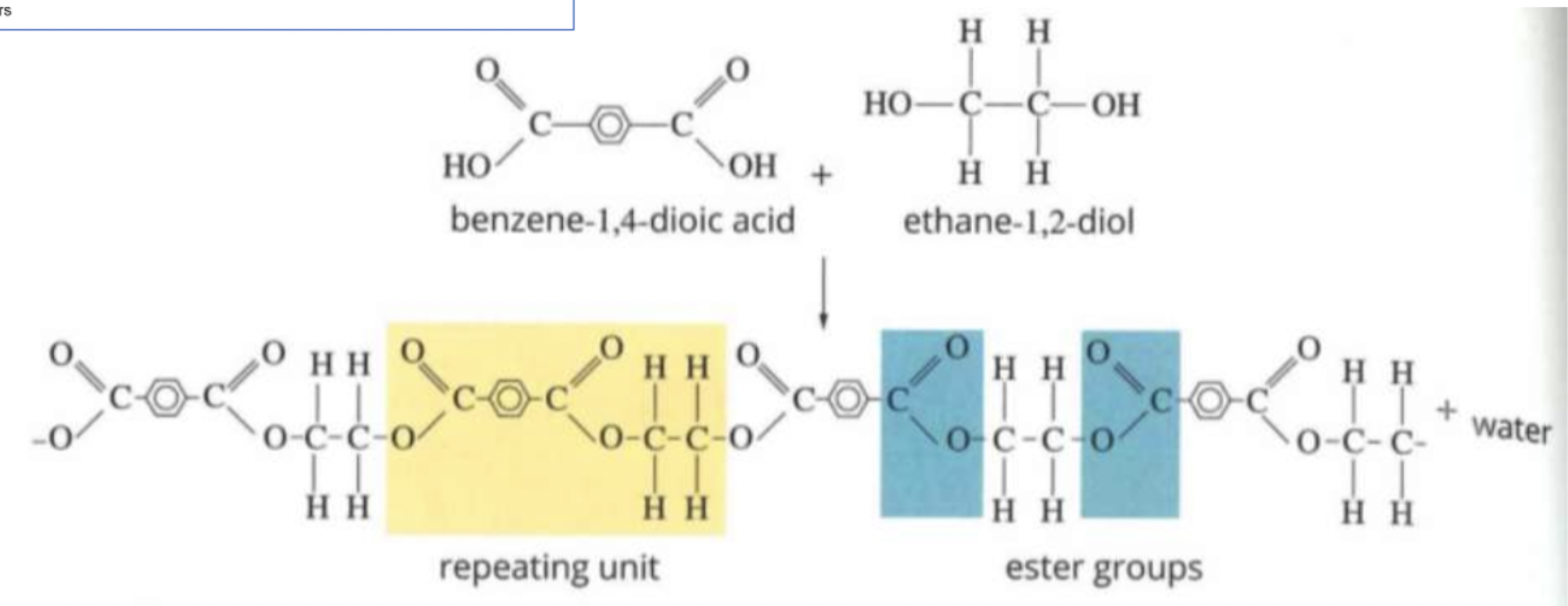

PET - Polyethene Terepthalate

Formed from Benzene-1,4-dioic acid and ethane-1,2-diol

High mechanical strength due to polar ester group

Large benzene ring gives strength and stiffness

Chemically inert

Used for packaging

Polyester

Formed by reaction between carboxylic acid, and alcohol