casting: materials gauntlet

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

21 Terms

aluminum/ zinc alloys

process = ingot casting

shapes = looks like gold bars

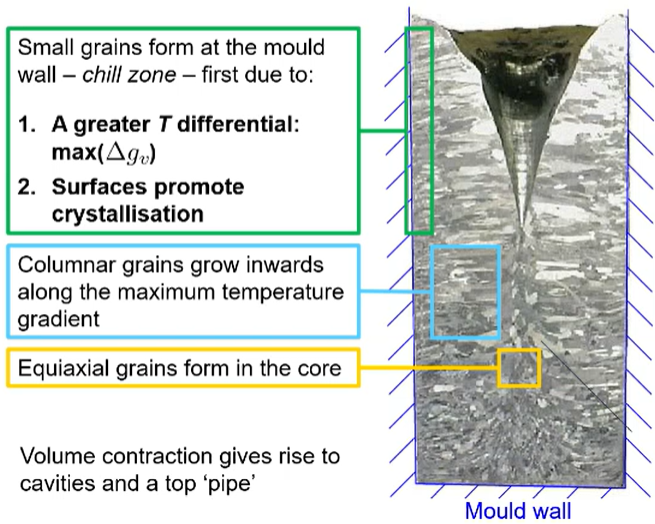

features/microstructure = small grains at mold wall (chill zone) / surface promotes crystallisation/ grains grow inwards along maximum temp grad/ large grains in the core

application =

ingot casting

taking a ladle from a furnace, which is filled with molten metal and heated to high temperatures in a furnace

then removed from the furnace and positioned over a platform which holds the molds on a base plate

so the mold is a container made from different materials or refractory bricks/ ceramics/ cast iron/ graphite mold which allows the molten phase to cool quickly

mold needs to withstand the melting point of the material casted

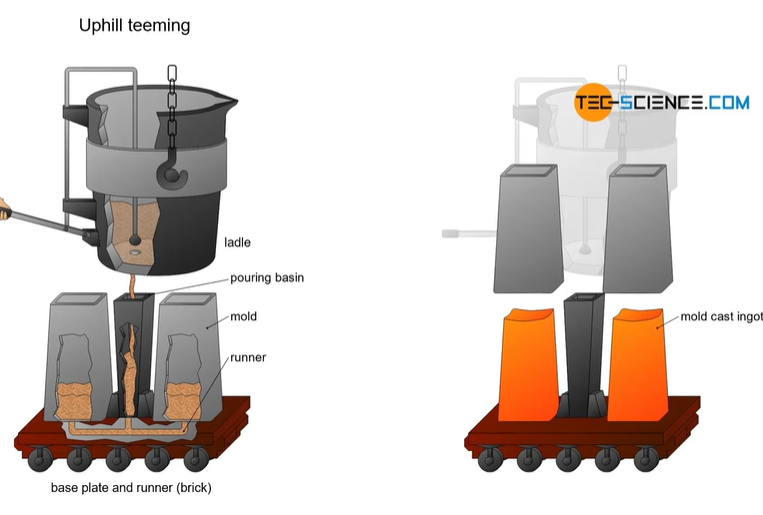

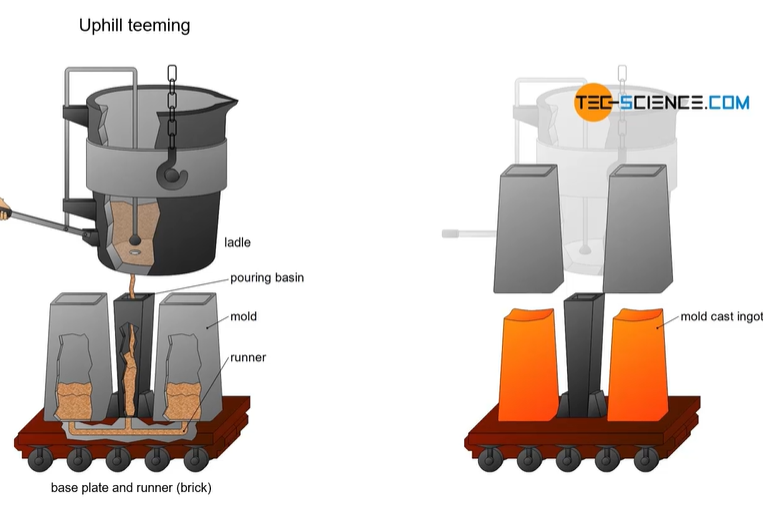

there is 2 processes = uphill teeming or downhill teeming (teeming = to pour)

open a valve in the ladle and molten phase just pours into the basin and flows below and up into the mold

leave to cool in air and remove mold

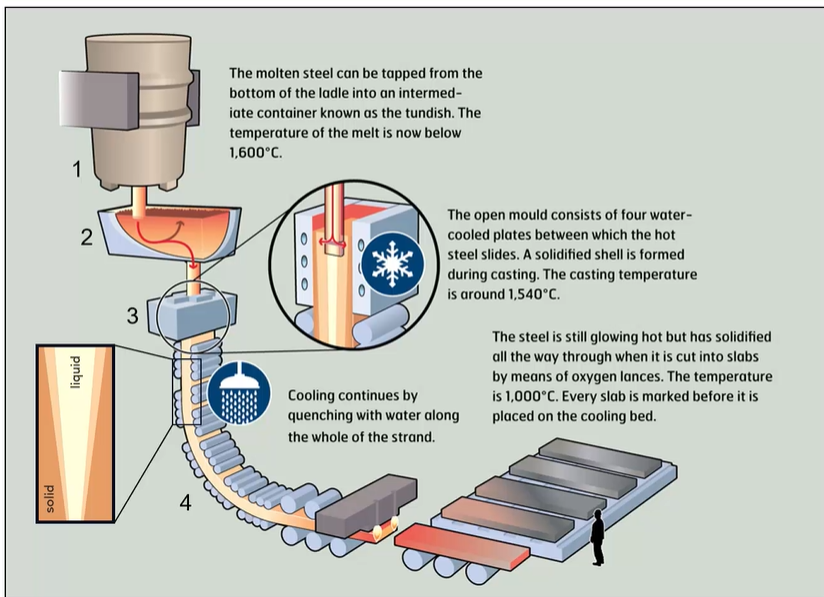

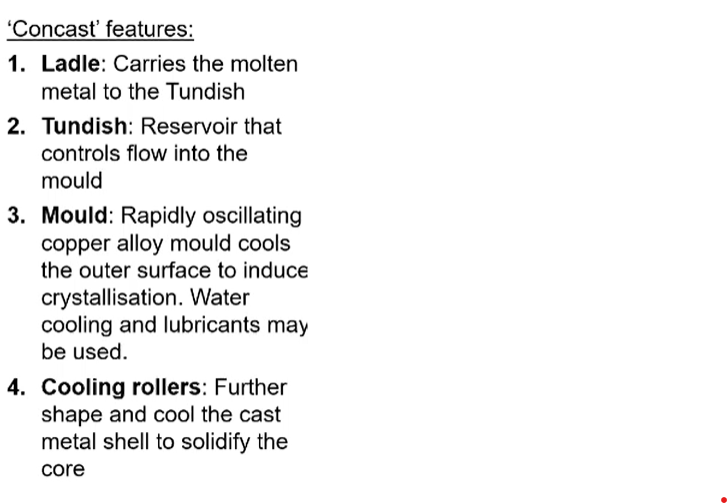

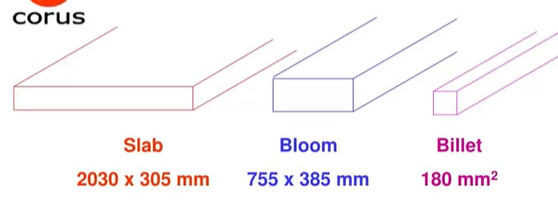

continuous casting

used to produce large scale slabs

continuously pouring and solidifying molten metal into desired shape

have to be post processed - hardened, worked, formed

aluminum slabs/ steel billets/ blooms/ slabs

process = continuous casting

features/ microstructure = fewer defects and more consistent microstructure

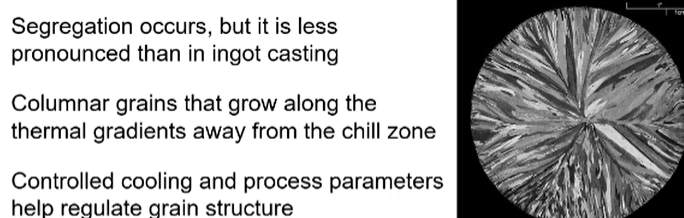

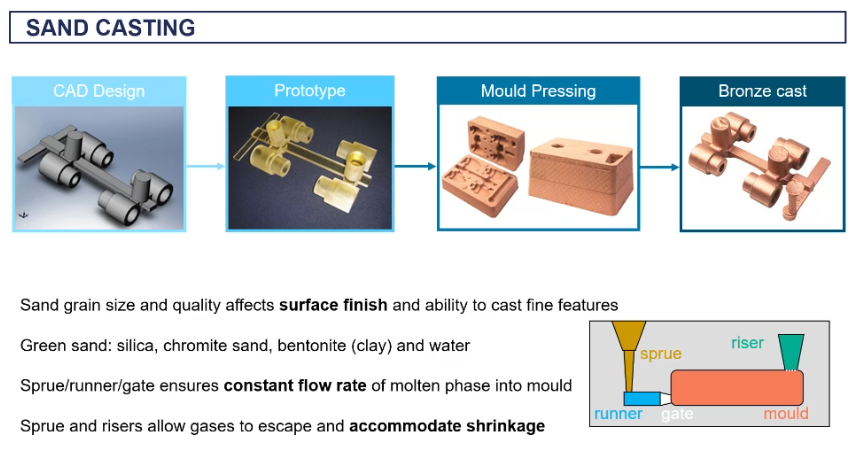

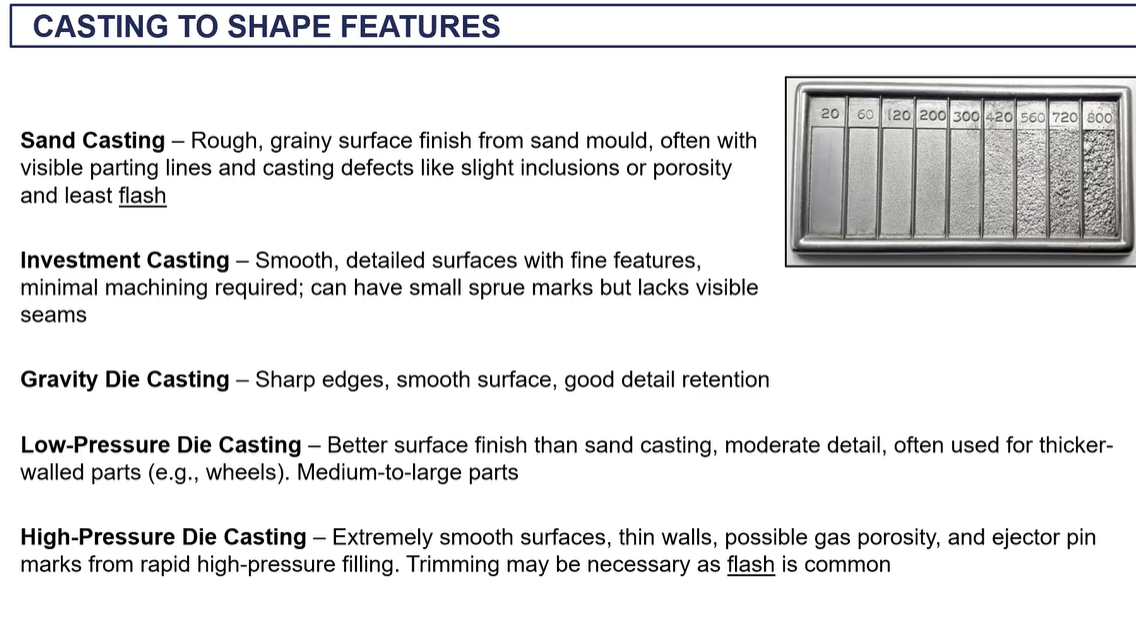

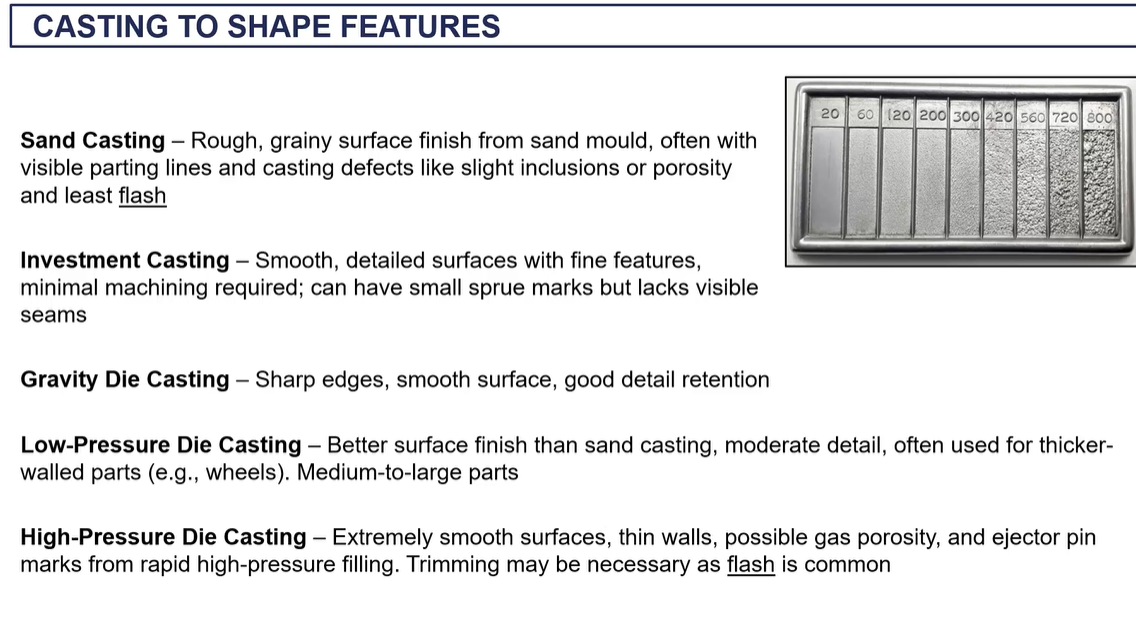

sand casting

is a 2 part mold made from a core and a drag and use a pattern to form a cavity in green sand and pour the molten metal

pattern can be used again

has shrinkage

non uniform grains and no direction associated with the crystal axis when in the center of the cast.

column of grains at the edge

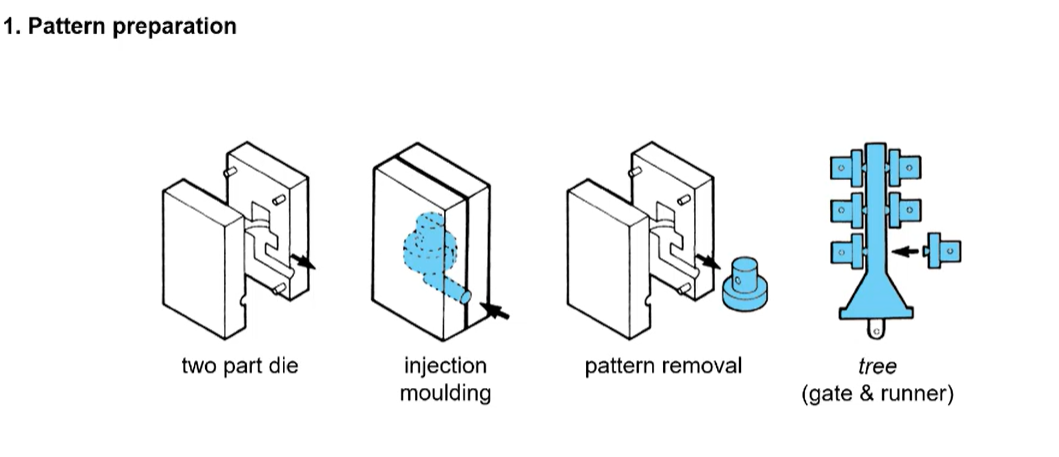

investment casting

can give finer details than sand casting

used for complex shapes with finer features

wax is injected in the die and separated to get the pattern.

the pattern than be stuck to a wax tree to cast multiple objects at the same time

dipped into slurry and refractory sand is then thrown on it building a thick layer for 6-7 mm

the autoclave then hardens the ceramic and creating a hard shell and the wax is loss due to the high heats

cool at room temp and remove the ceramic coating (via high pressure washing or vibration)

die casting

mass production process

used for non ferrous metal (zinc, aluminum magnesium)

uses a reusable metal mold (high thermal conductivity) and water cooling

3 types = gravity die casting/ pressure die casting low/ high pressure die casting

3D metal objects/ any metal alloy

process = sand casting

features = surface finish is rough and the pits are associated with the sand in the molds

application =

aluminum tree / turbine blades

process = investment casting - use this method because it you can make alot at the same time and they are all consistent

features/ microstructures = tree shape with multiple components on it / has a good surface finish as good as wax pattern

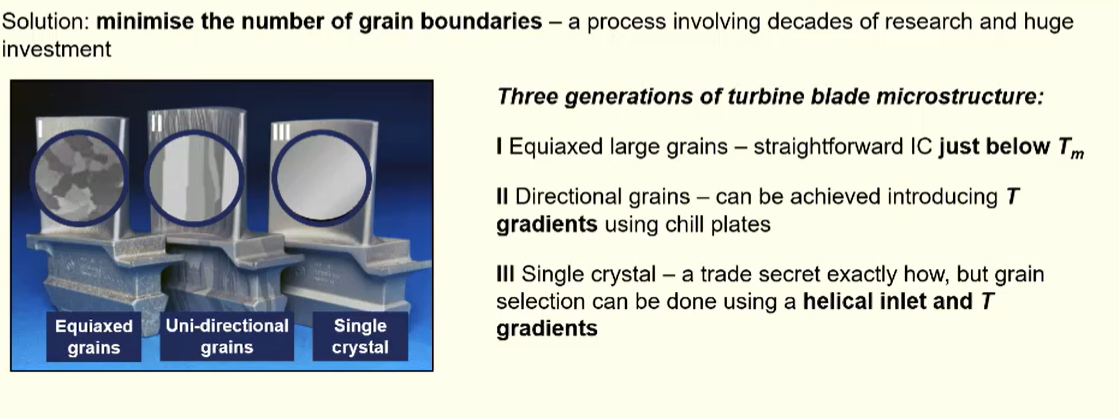

for blades they need excellent creep resistance

single crystal = no grain boundaries = no creep

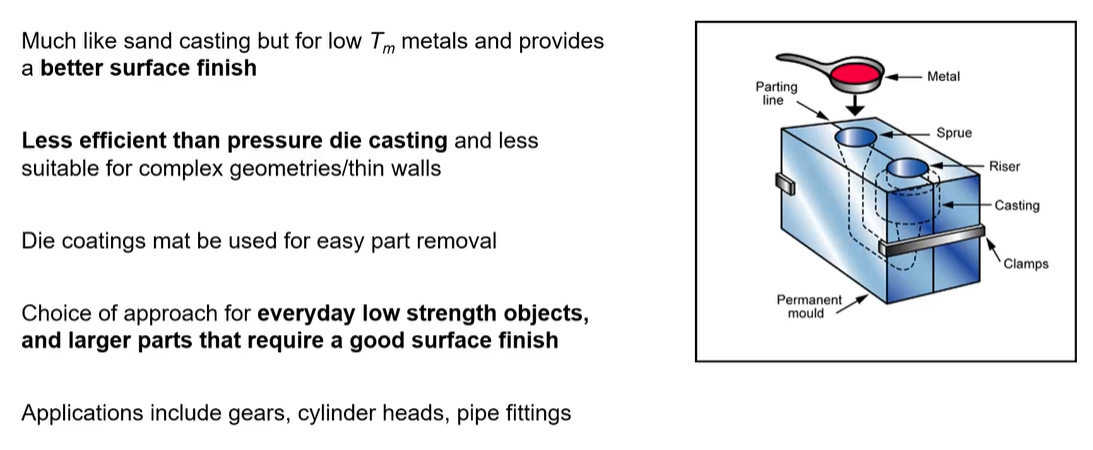

gearheads

process = die casting

features/microstructure = metal mold and water cooling cause small uniaxial grains to be produced

gears/ cylinder heads/ pipe fittings

process = gravity die casting

can reuse the mold, do not have to make a new 2 half of the mold

gives a good surface finish

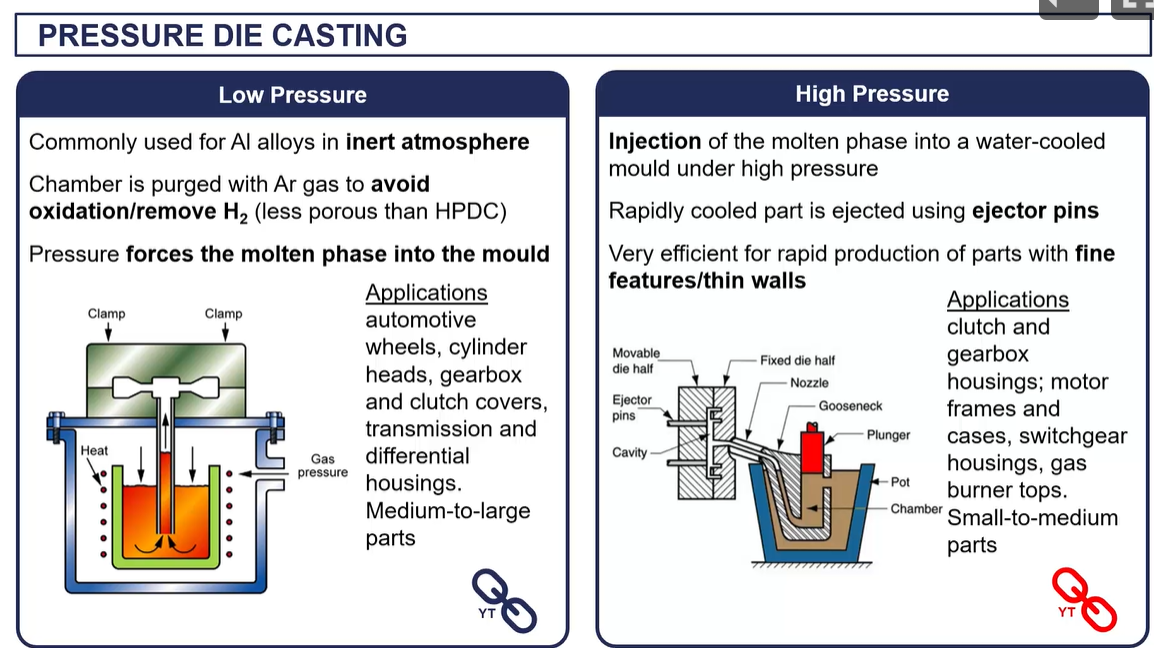

high and low pressure die casting

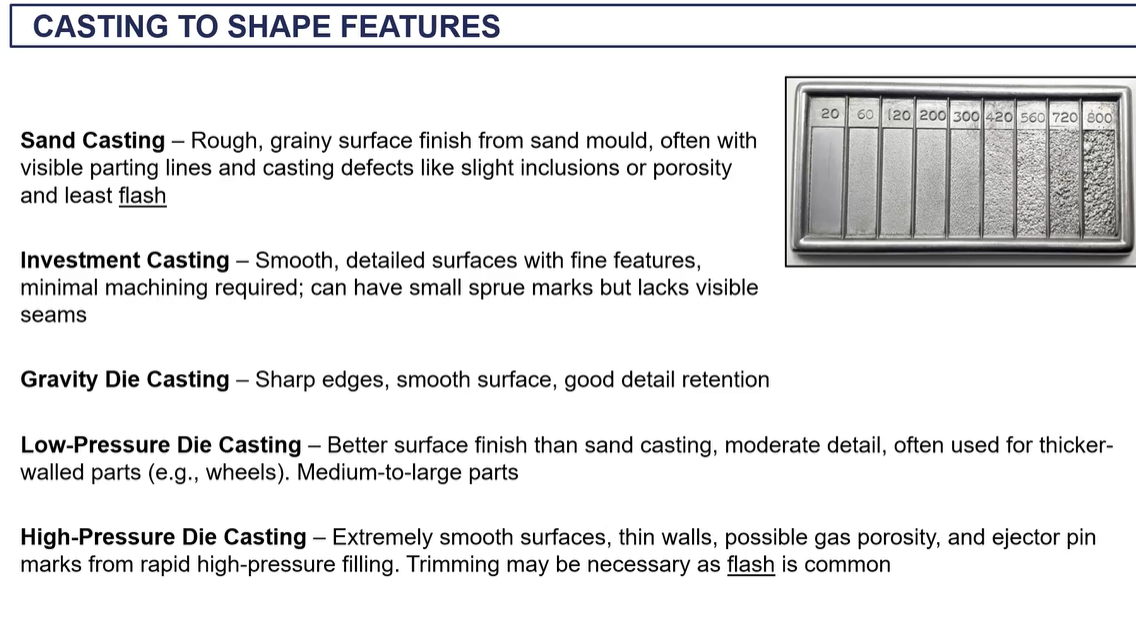

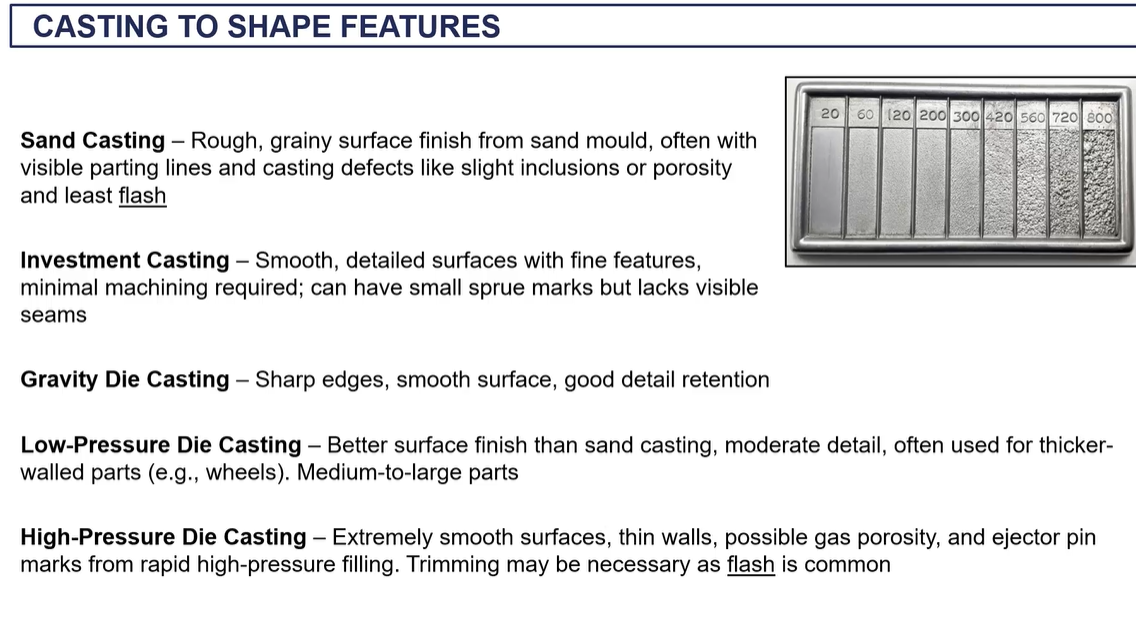

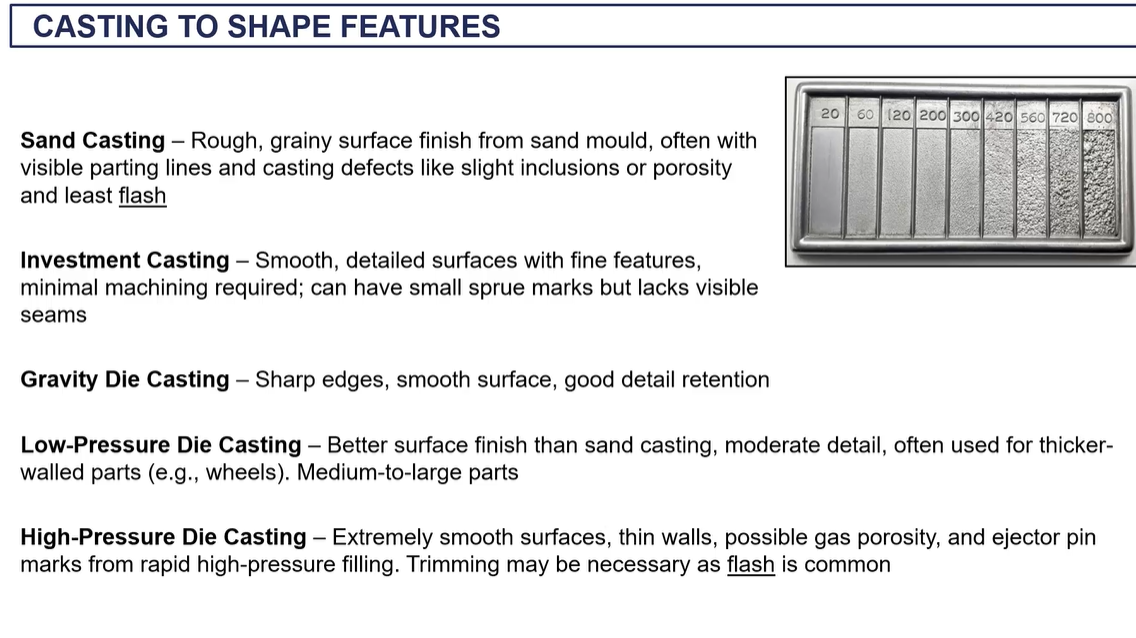

look out for sand casting

look out for investment casting

look out for gravity die casting

look out for low pressure die casting

look out for high pressure die casting

when to do sand casting, investment casting or die casting?

determined by the melting temperature/ type of metal you are using/ part size you want to produce/ detail you want to achieve/ surface finish you want/ how much time and money needed in order to prepare

ship anchor

process = sand casting

doesn’t need a good surface finish and is made from a ferrous material

what to make only a few so sand casting is used

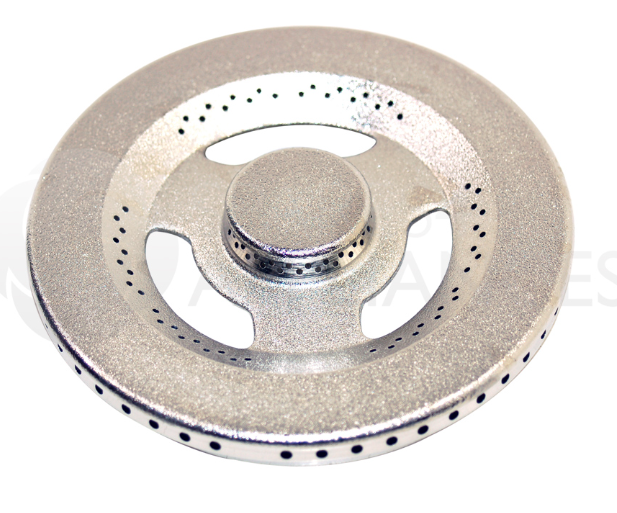

cooker hob/ ring burner

process = die casting

surface finish = good surface finish as it will be in someone’s kitchen

want to make multiple, therefore die cast is used

casting considerations

solidification and shrinkage

gas porosity

want consistently sized parts / uniform mechanical properties / uniform grain size

want to avoid porosity and segregation