MD 1 FORMULAS

1/181

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

182 Terms

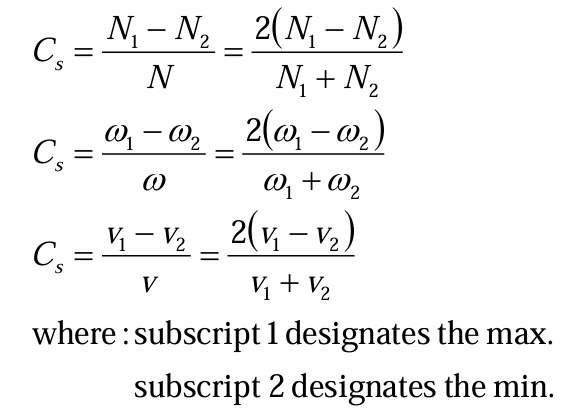

coefficient of fluctuation of speed or Cs

ultimate strength

Su = Force per stroke/A = Force per stroke/pi*d*t

energy per stroke

energy per stroke = ½ * force per stroke * plate thickness

energy per min

energy per min = energy per stroke * stroke per min

Power

Energy per min/nm

coefficient of steadiness

1/Cs

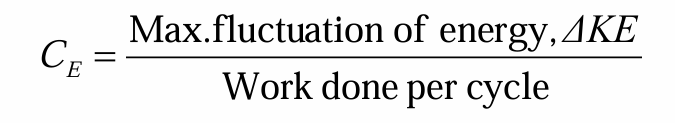

coefficient of fluctuation of energy or CE

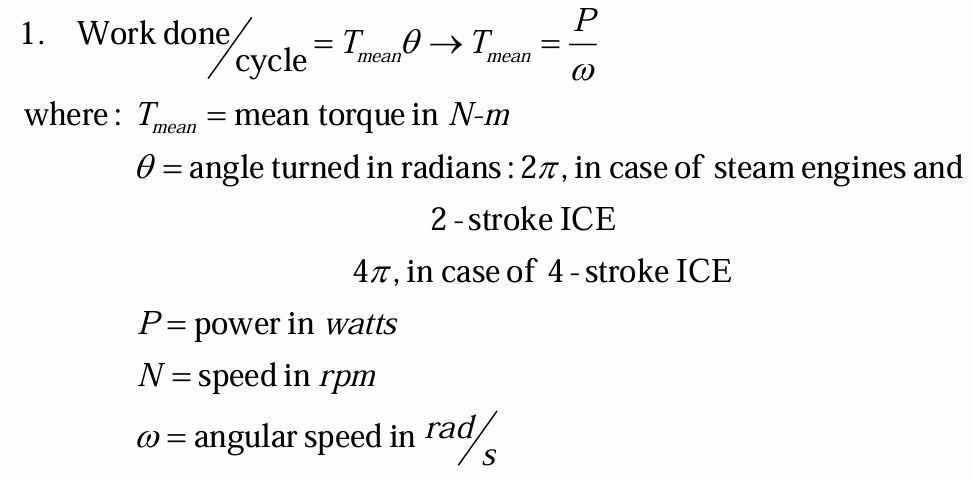

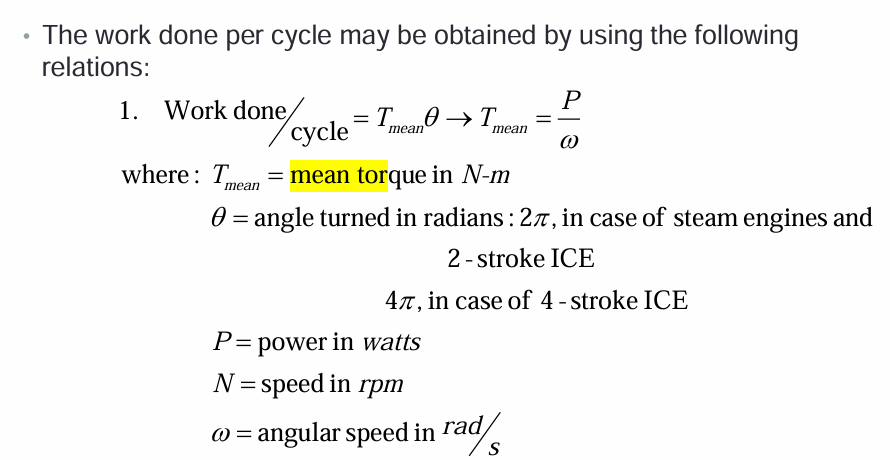

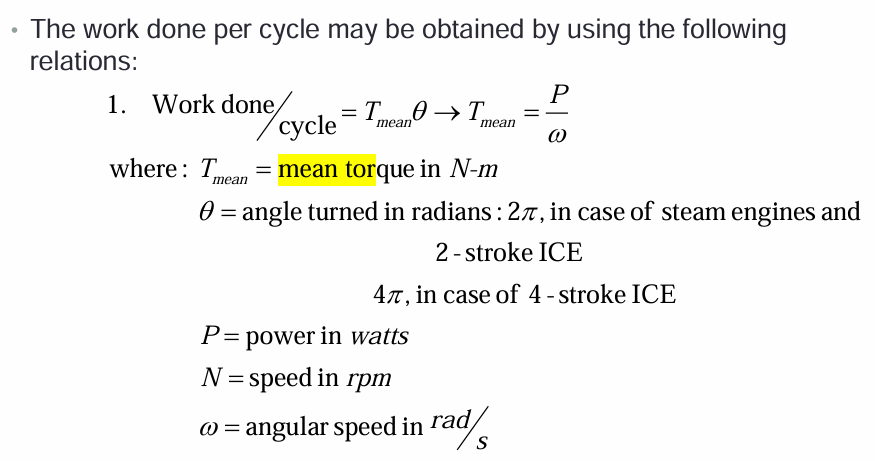

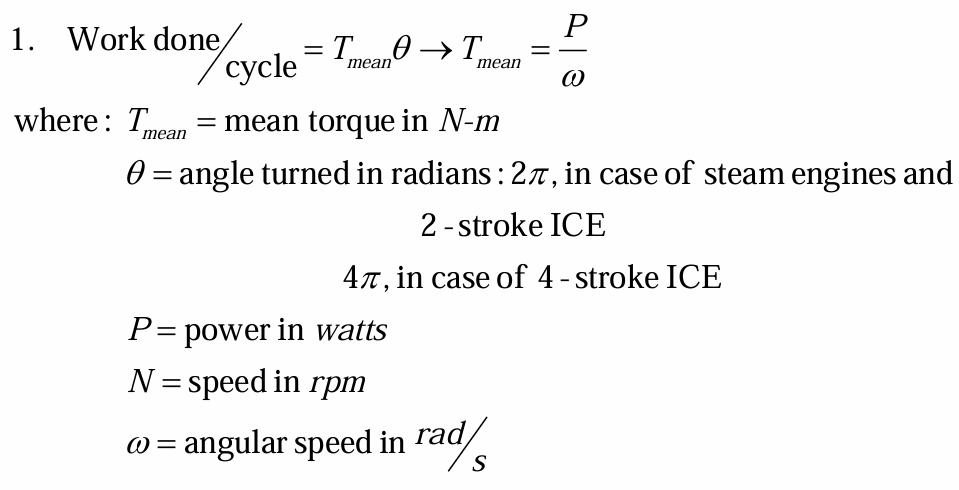

Work done per cycle using torque

mean torque

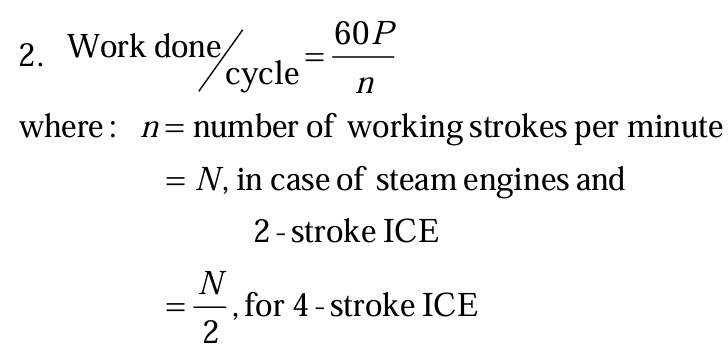

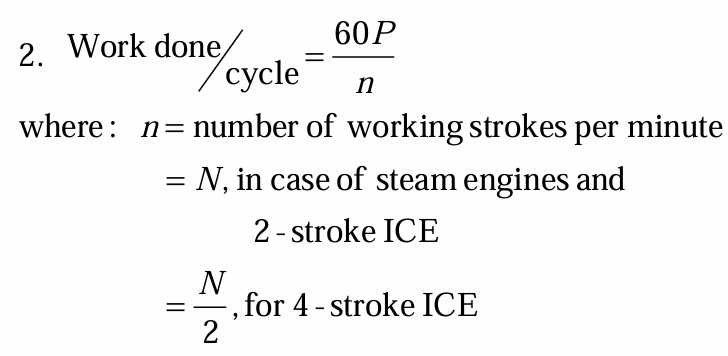

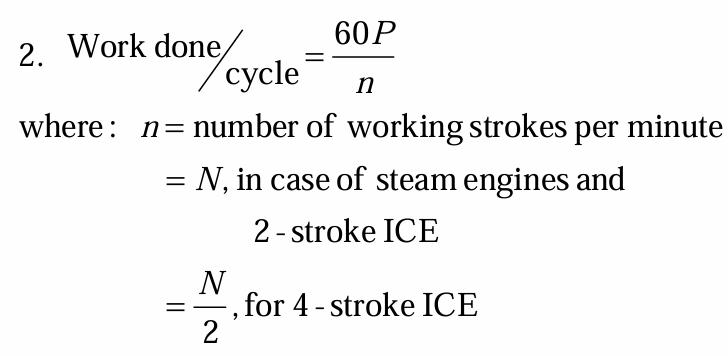

Work done per cycle using power

value of θ or angle turned if steam engine or 2-stroke

value of θ or angle turned if 4-stroke

value of n or number of working strokes if steam engine or 2-stroke

value of n or number of working strokes if 4-stroke

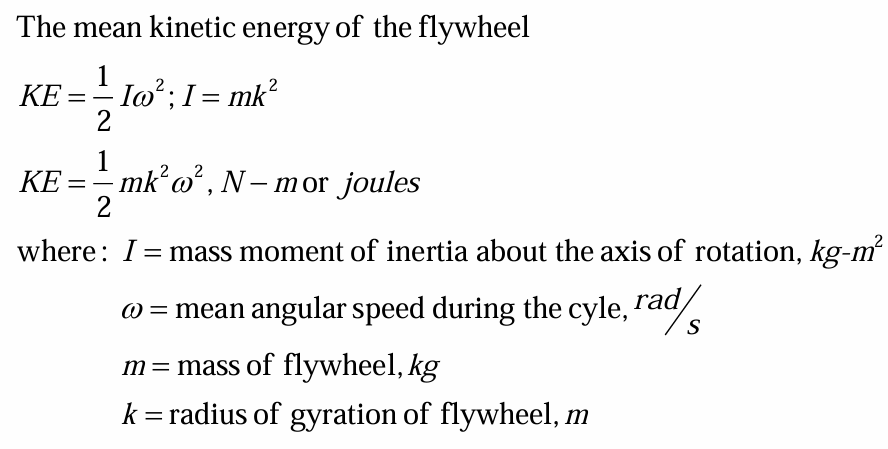

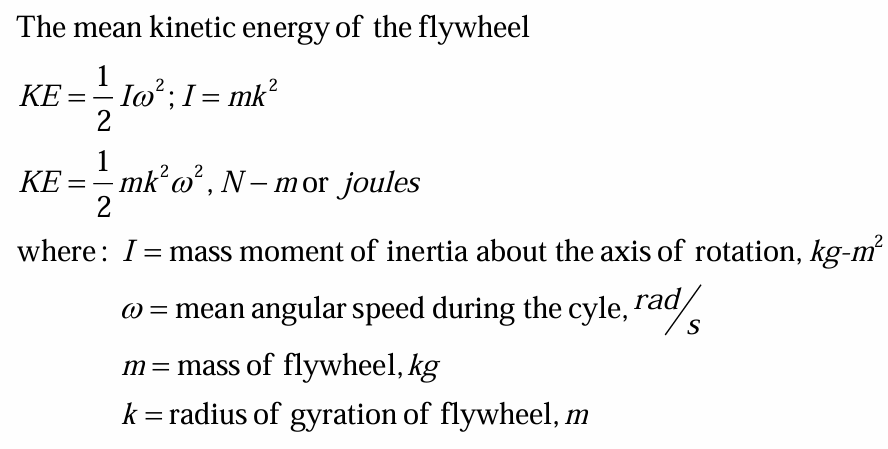

mean kinetic energy of the flywheel or KE

moment of inertia or I

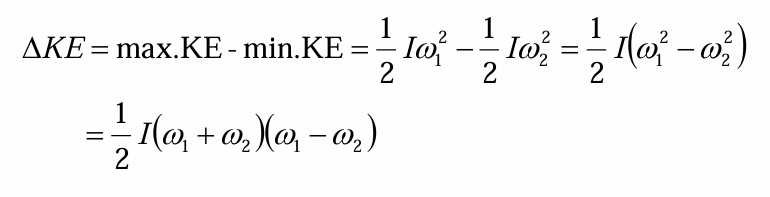

change in kinetic energy or delta KE

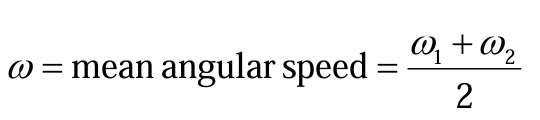

mean angular speed or omega

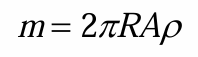

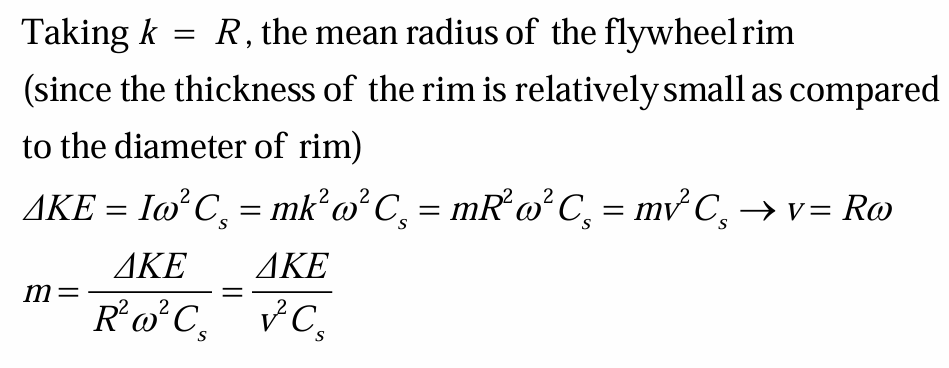

mass of flywheel

different delta KE formulas

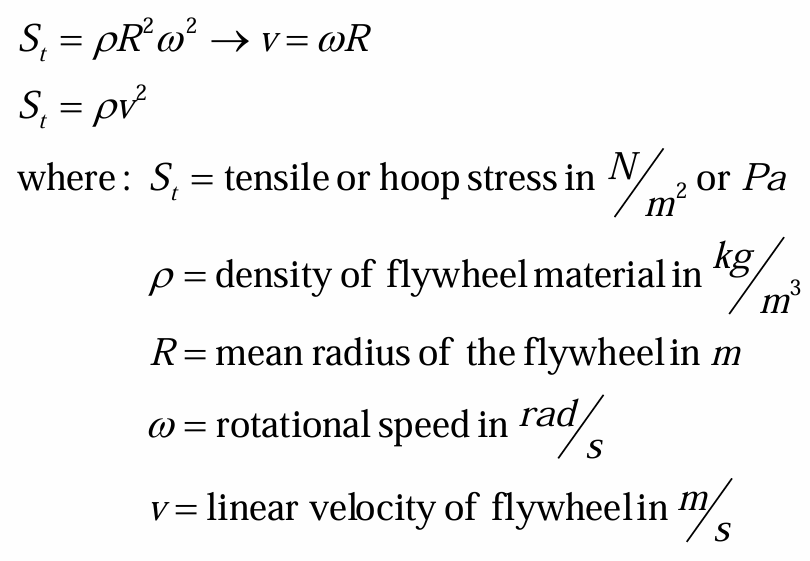

tensile stress in flywheel

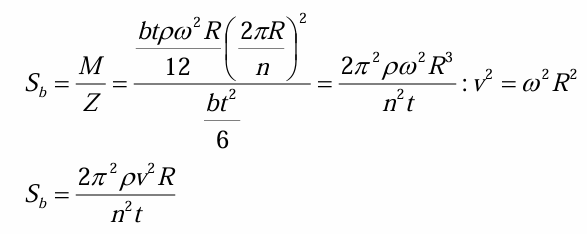

tensile bending stress in flywheel

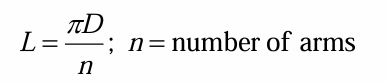

length between fixed ends in bending flywheel

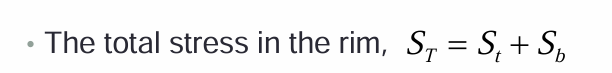

total stress in the rim

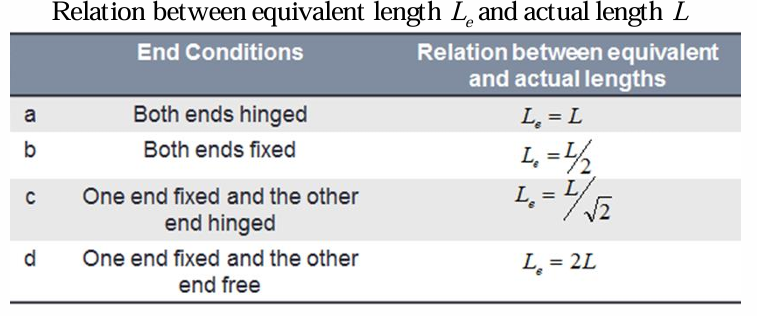

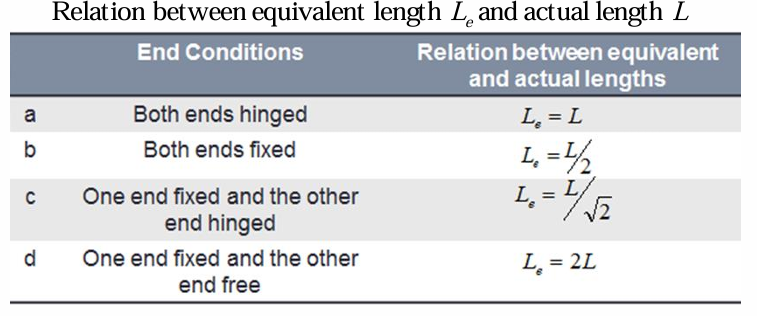

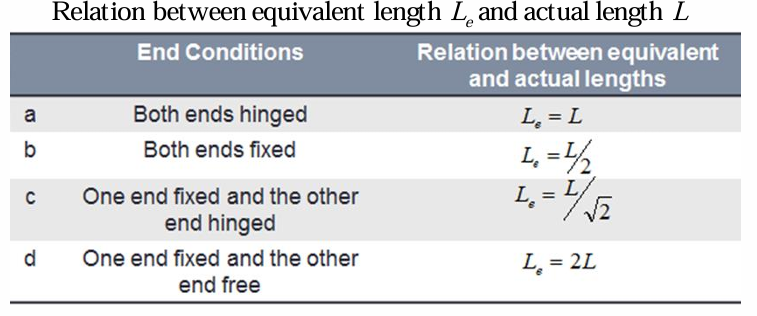

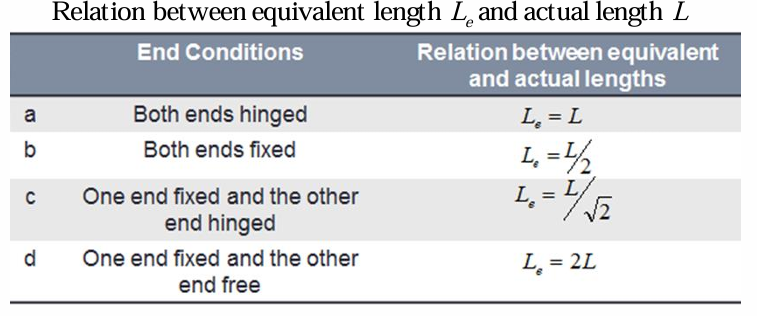

relation between equivalent length and actual length of both ends hinged

relation between equivalent length and actual length of both ends fixed

relation between equivalent length and actual length of one end fixed and the other end hinged

relation between equivalent length and actual length of one end fixed and the other free

slenderness ratio

radius of gyration

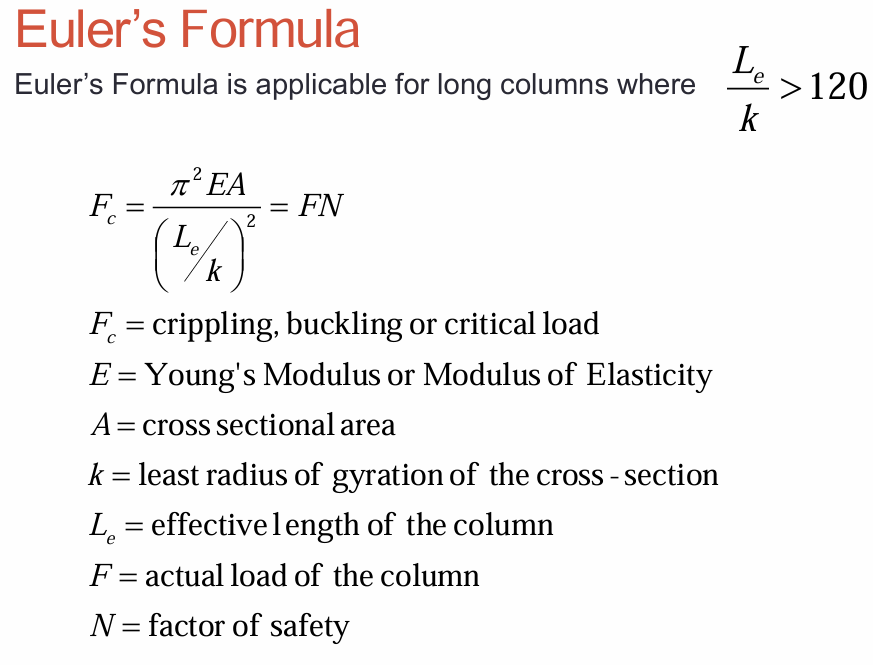

Euler's formula

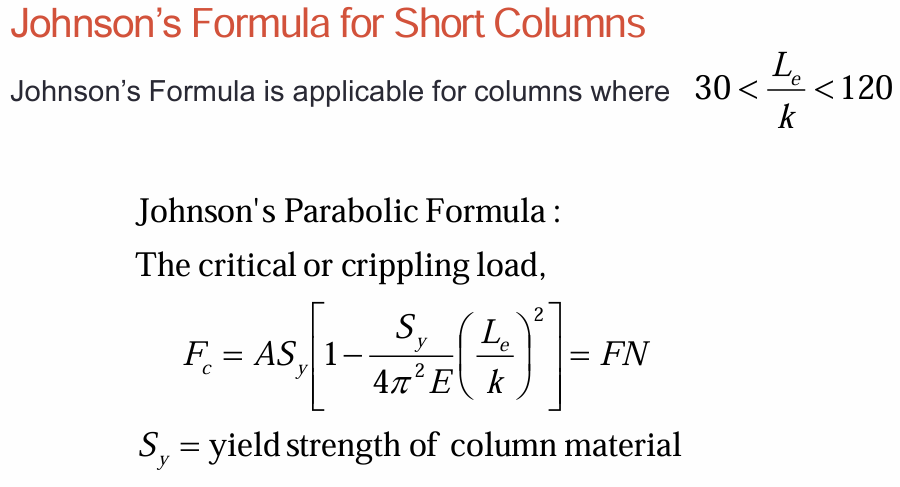

Johnson's formula

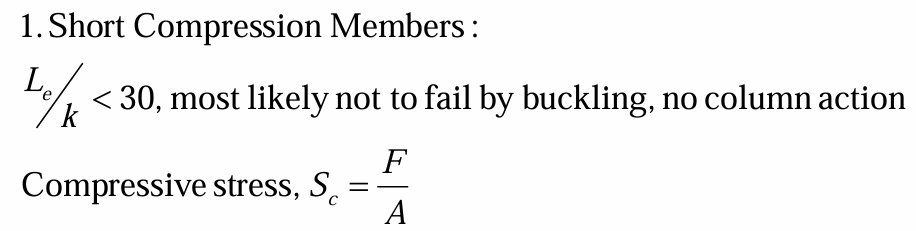

stresses for short compression members

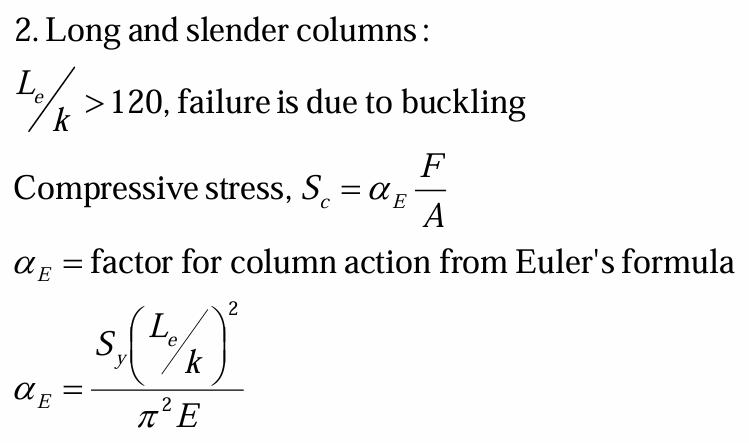

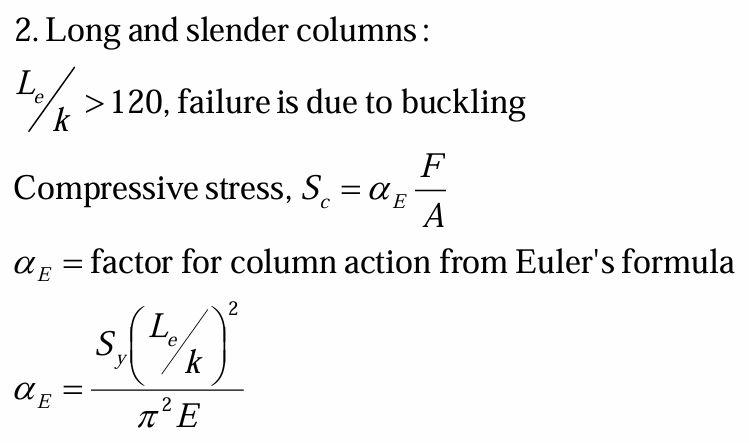

stresses for long and slender columns

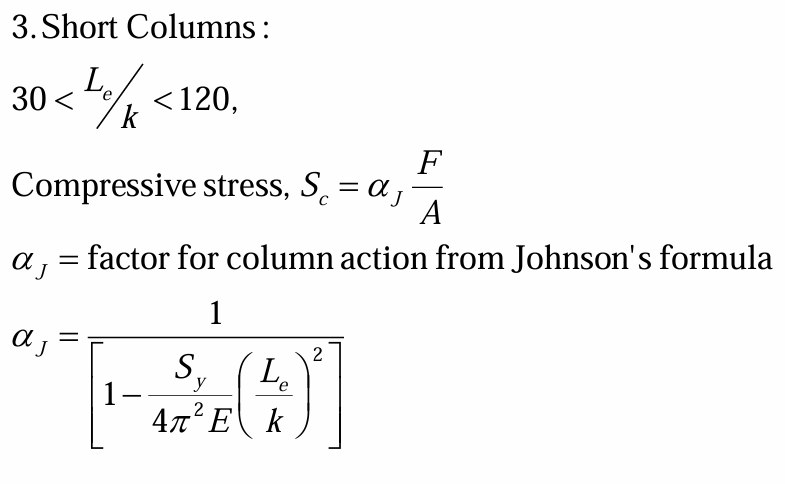

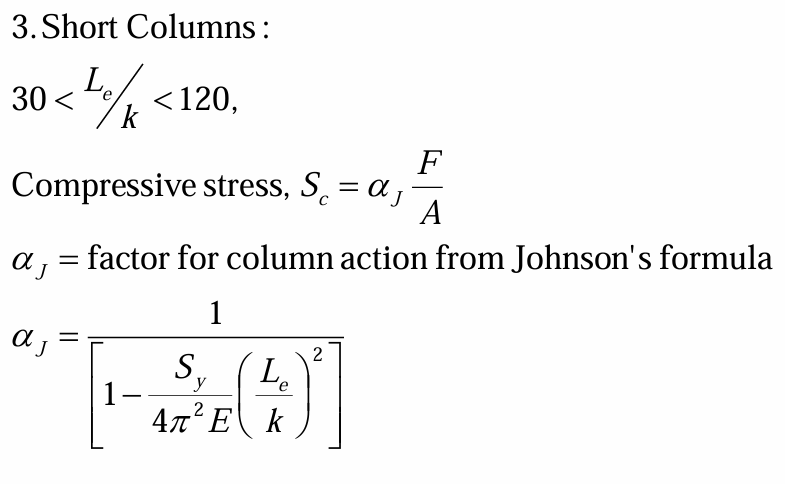

stresses for short columns

factor for column action from euler's formula

factor for column action from johnson's formula

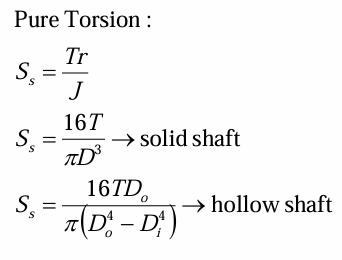

pure torsion stress in shaft

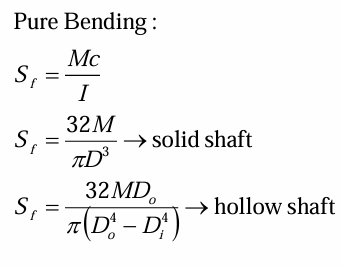

pure bending stress in shaft

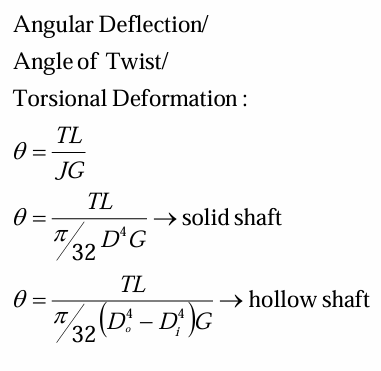

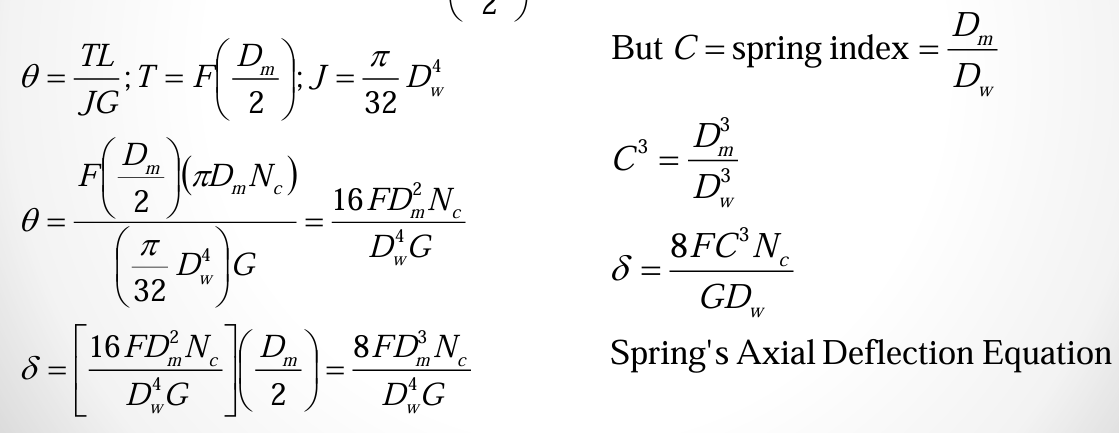

angular deflection/angle of twist/torsional deformation in shaft

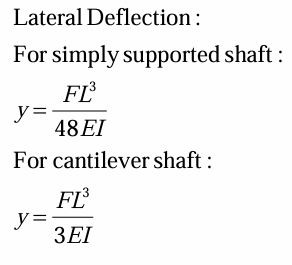

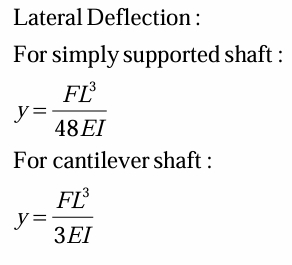

lateral deflection for simply supported shaft

lateral deflection for cantilever shaft

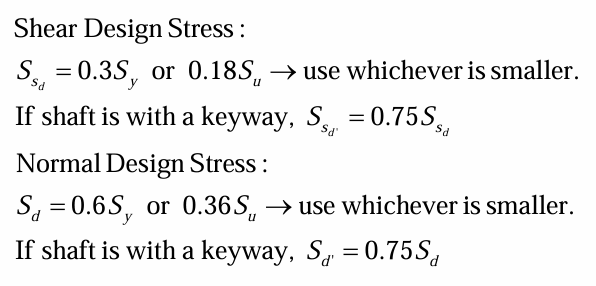

yield strength and ultimate strength for shear design stress of ASME

yield strength and ultimate strength for normal design stress of ASME

design stress with keyway of ASME

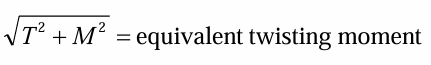

equivalent twisting moment

equivalent bending moment

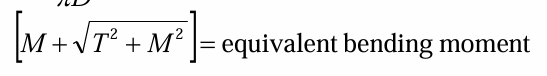

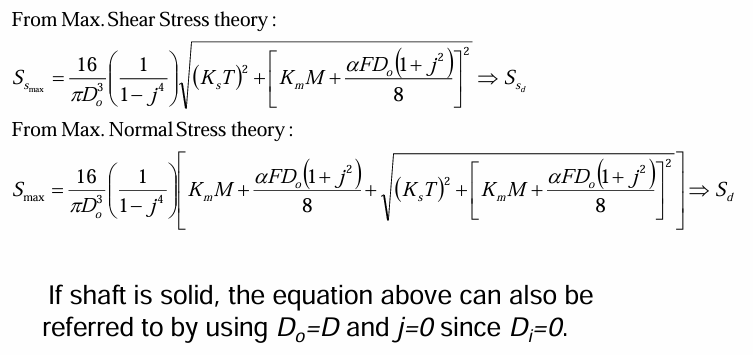

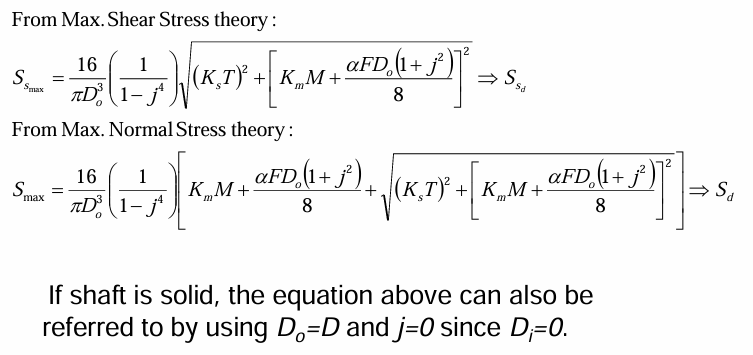

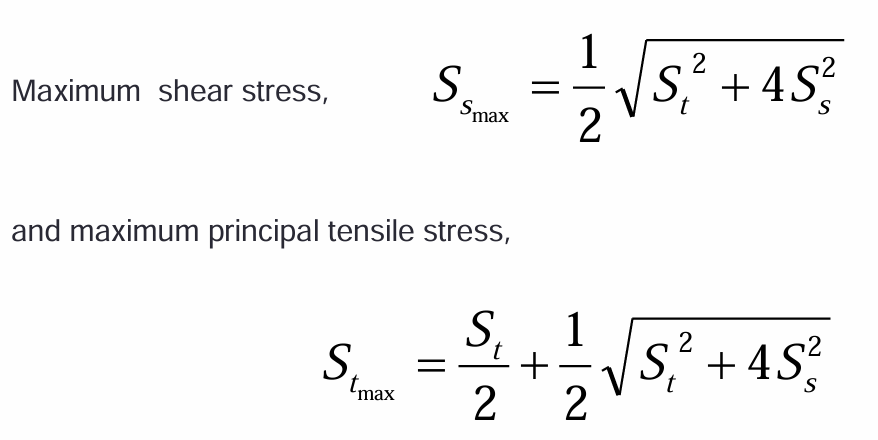

max shear stress thery for combined loads in ASME

max normal stress theory for combined loads in ASME

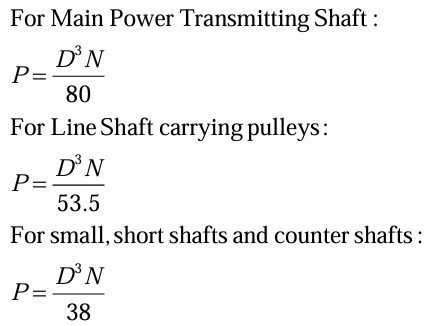

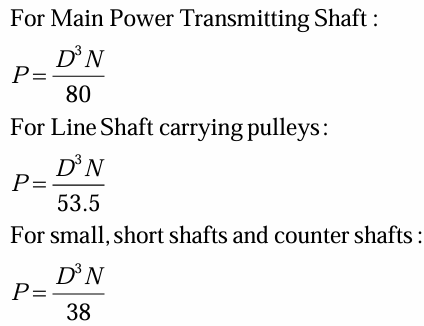

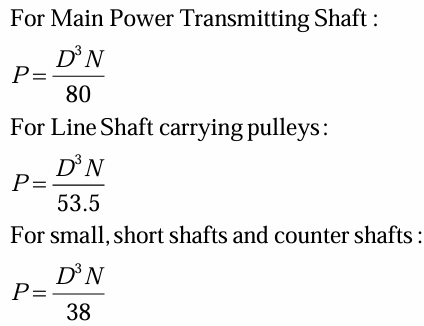

power of main power transmitting shaft by ASME

power of line shaft carrying pulleys by ASME

power of small,short, and counter shafts by ASME

tangential force of key

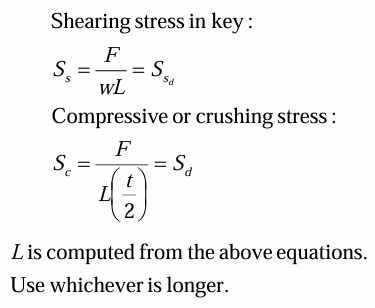

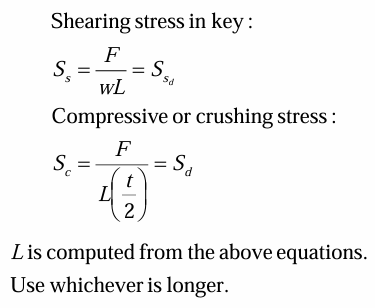

shearing stress in key

compressive or crushing stress of key

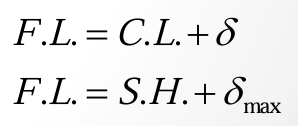

free length of spring

Mean Diameter

Dm = Do - Dw

axial load to axial deformation ratio for max value

Fmax/F=δmax/δ

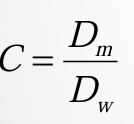

spring index

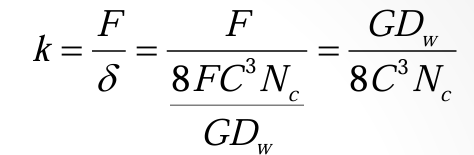

spring rate

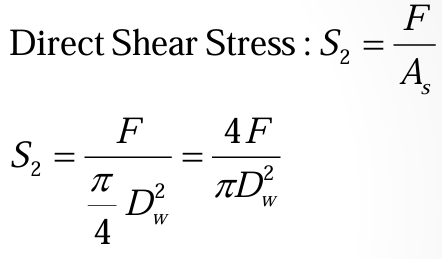

direct shear stress

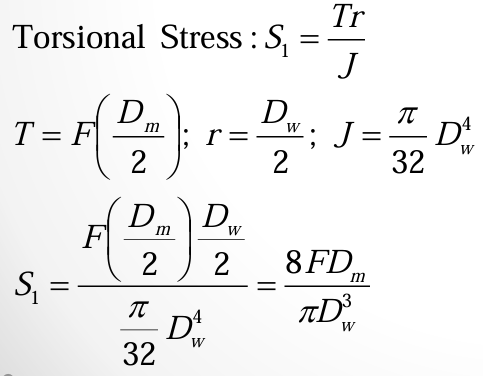

torsional stress in wire

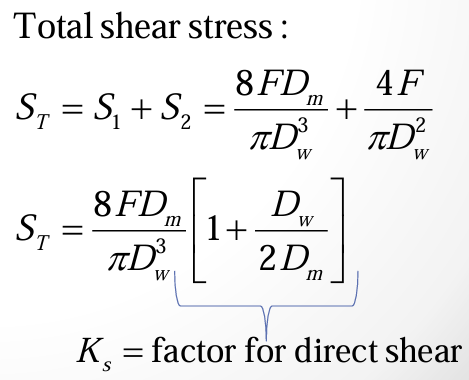

total shear stress in spring

factor for direct shear

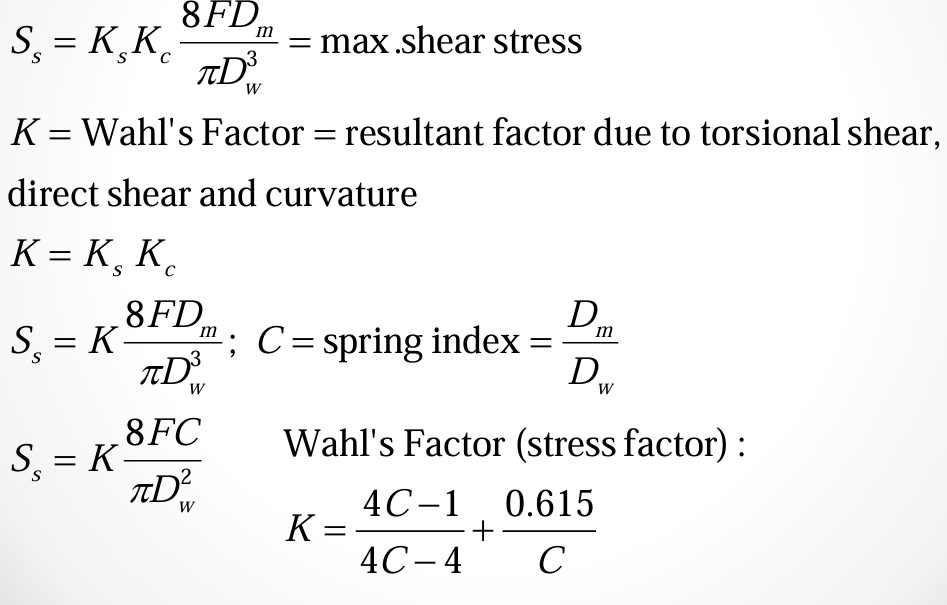

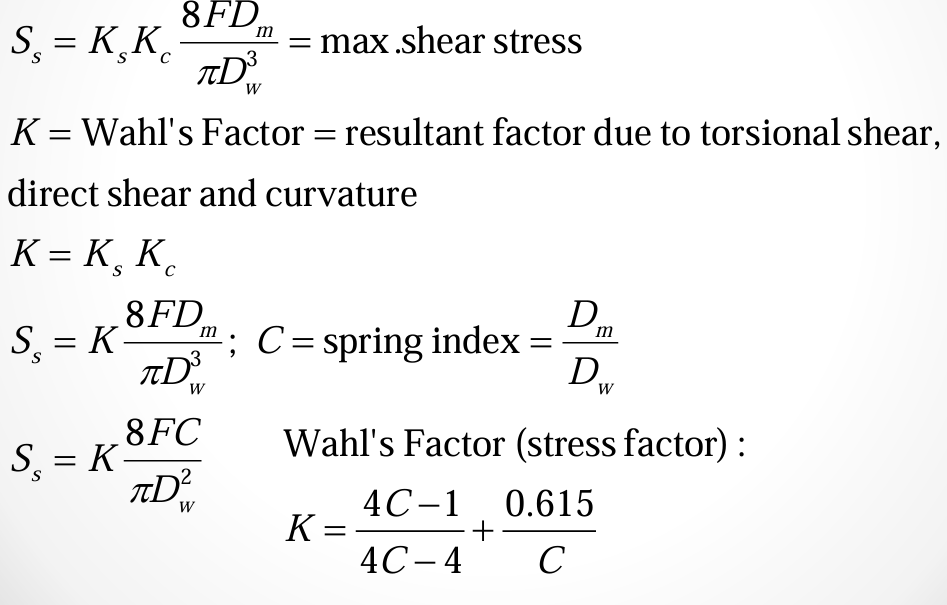

max shear stress

wahl's factor

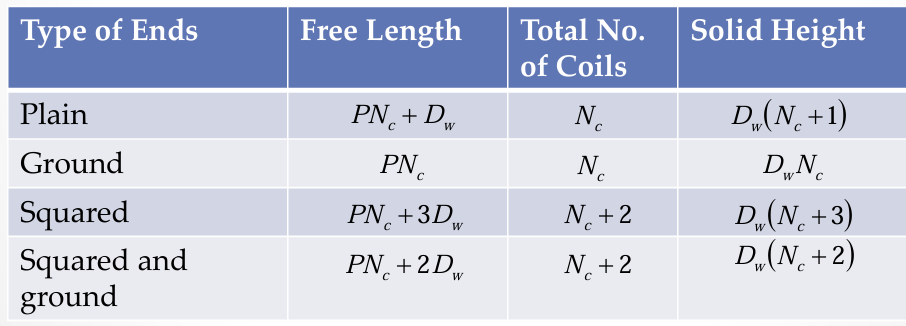

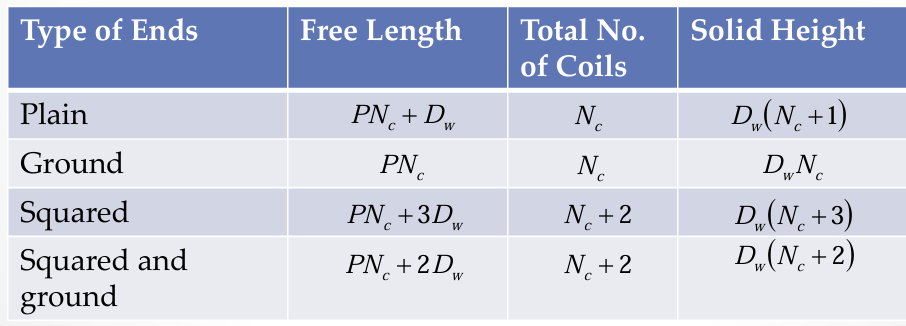

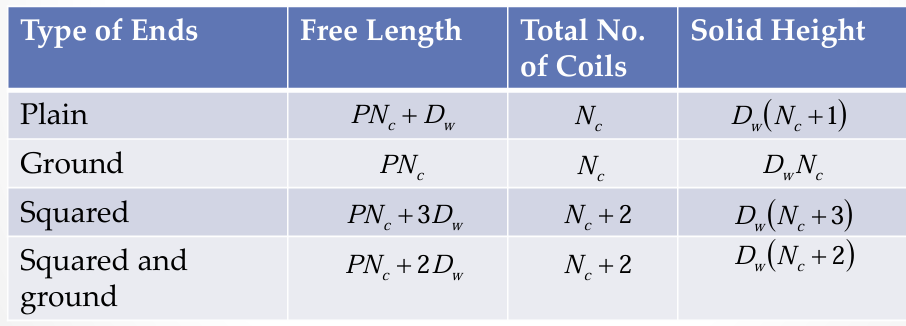

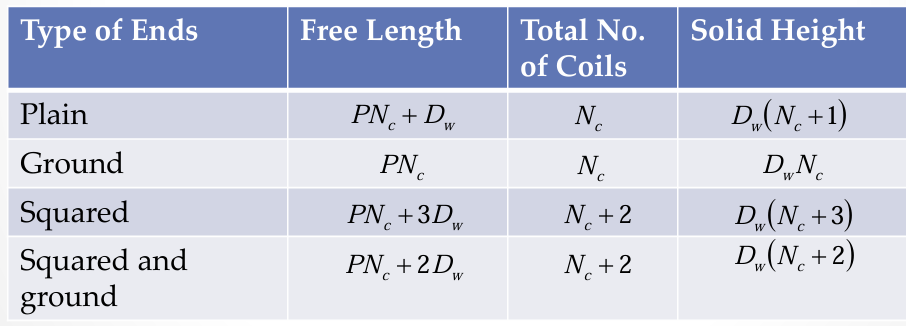

free length, total no. of coils, solid height of plain end

free length, total no. of coils, solid height of ground end

free length, total no. of coils, solid height of squared end

free length, total no. of coils, solid height of squared and ground end

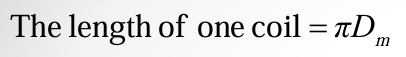

length of one coil

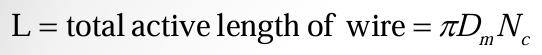

total active length of wire

axial deflection of spring

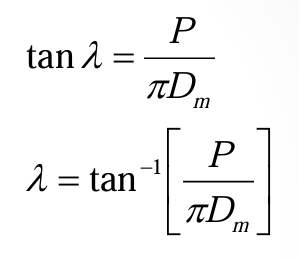

pitch angle of spring

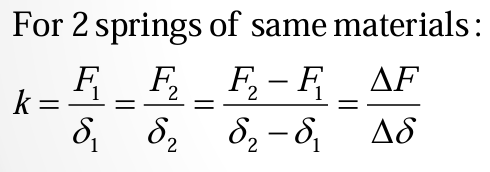

spring rate of 2 springs of same materials

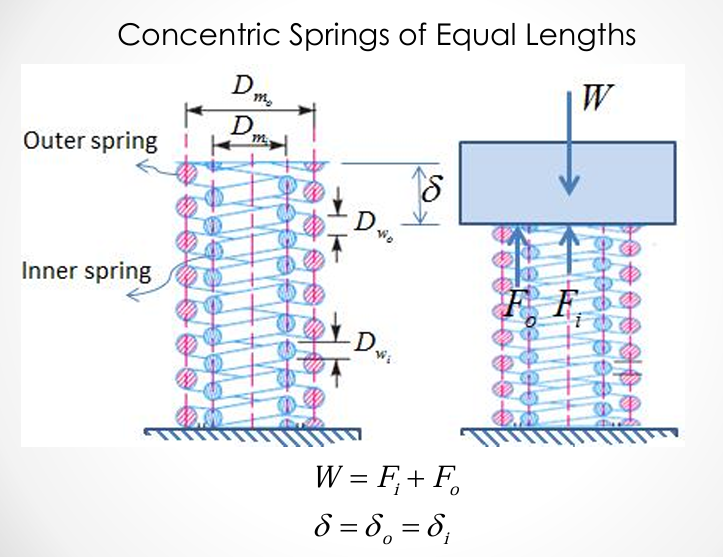

springs in parallel: concentric springs of equal lengths

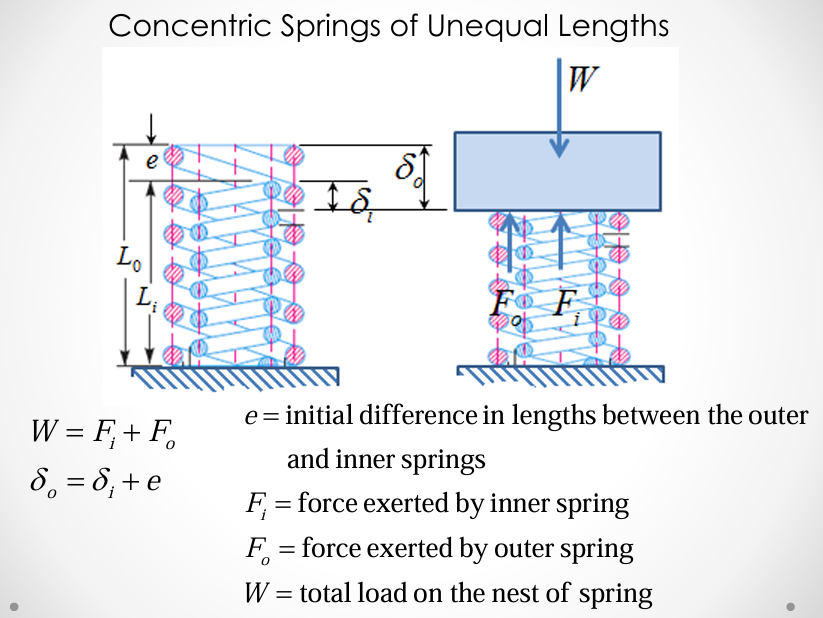

springs in parallel: concentric springs of unequal lengths

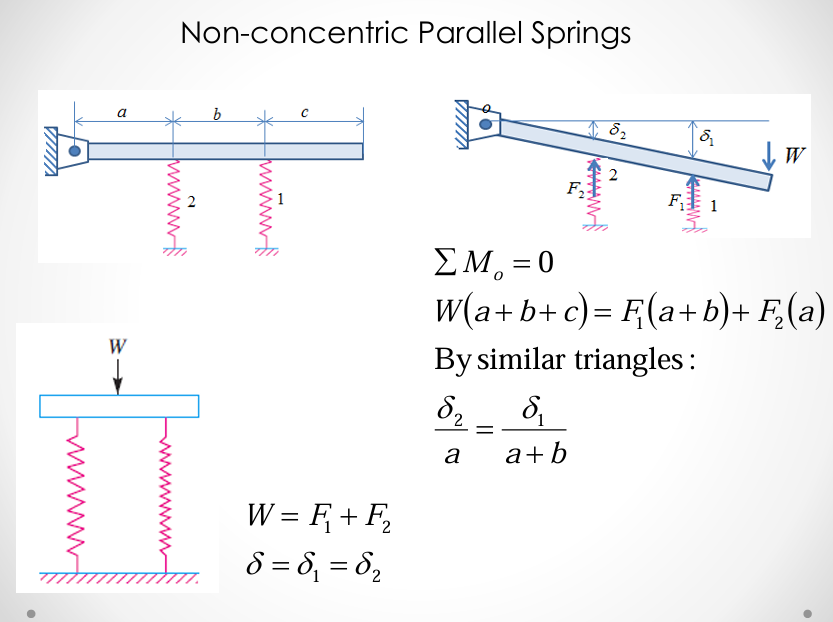

non-concentric parallel springs

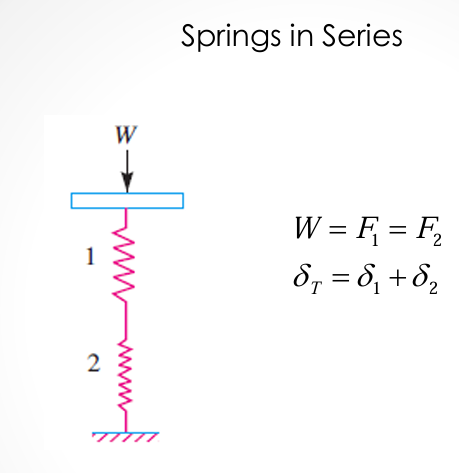

springs in series

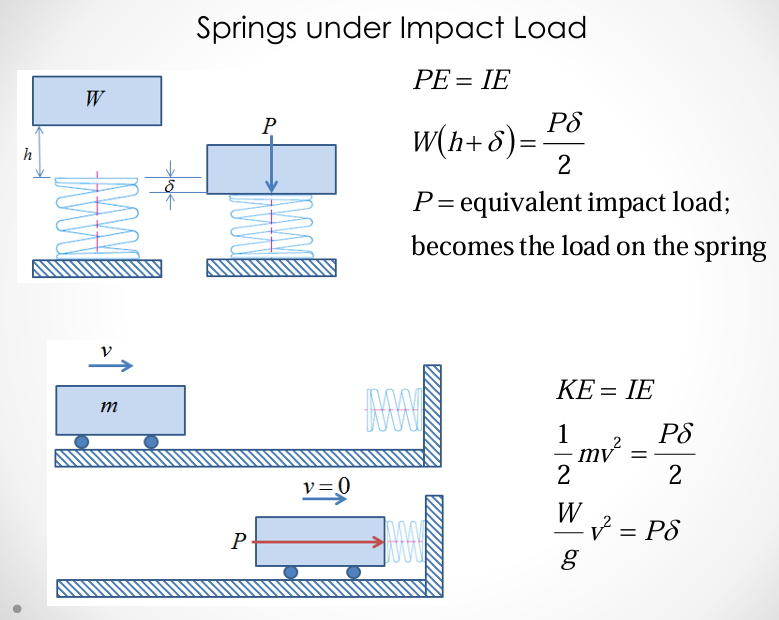

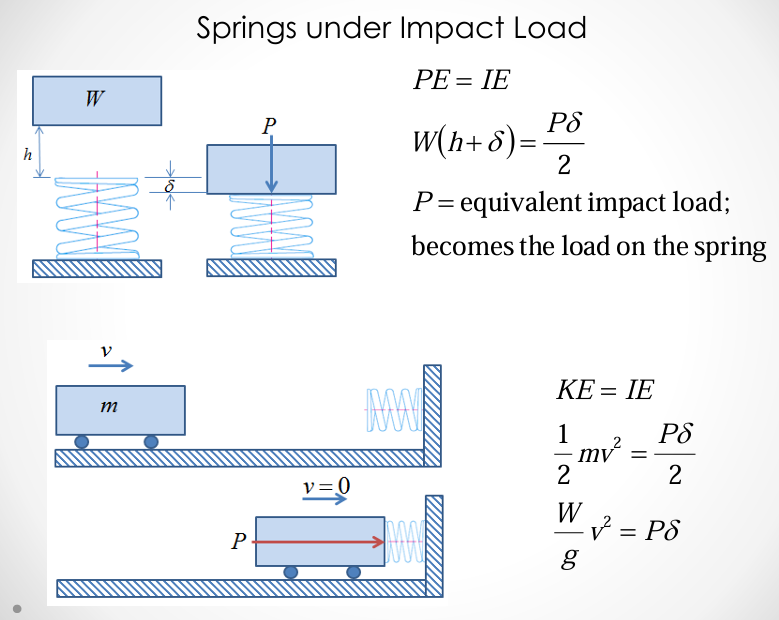

springs under impact load: potential

springs under impact load: kinetic

pitch

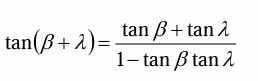

Expand tan(β+λ)

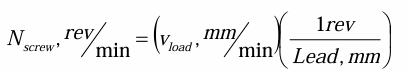

angular speed of screw or Nscrew

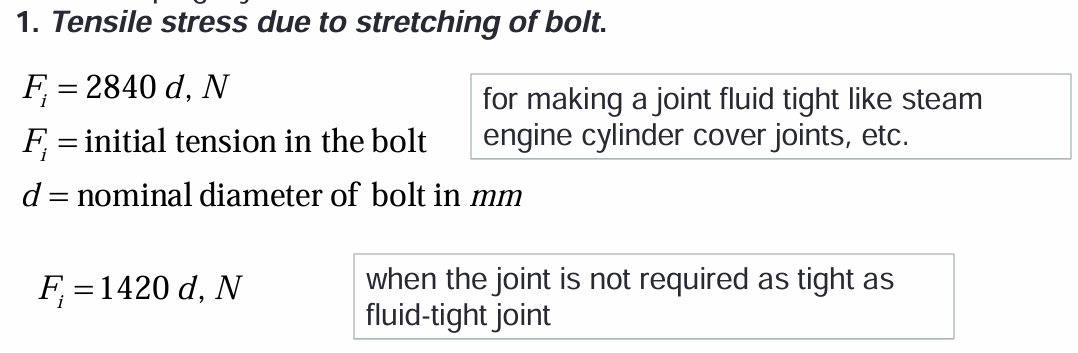

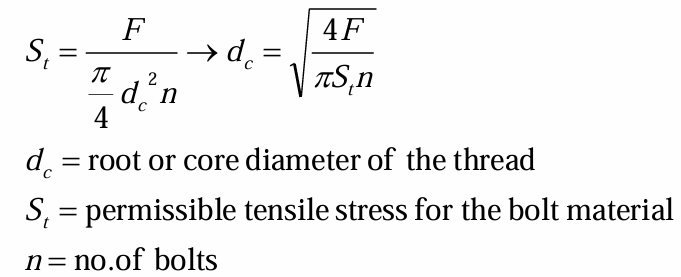

tensile stress due to stretching of bolt

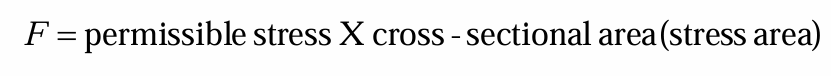

maximum safe axial load for initial tensile stress

stress area for initial tensile stress

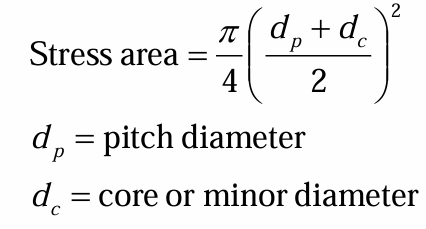

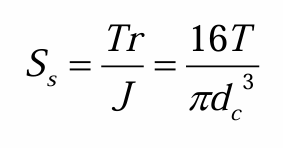

torsional shear stress caused by the frictional resistance of the threads during its tightening

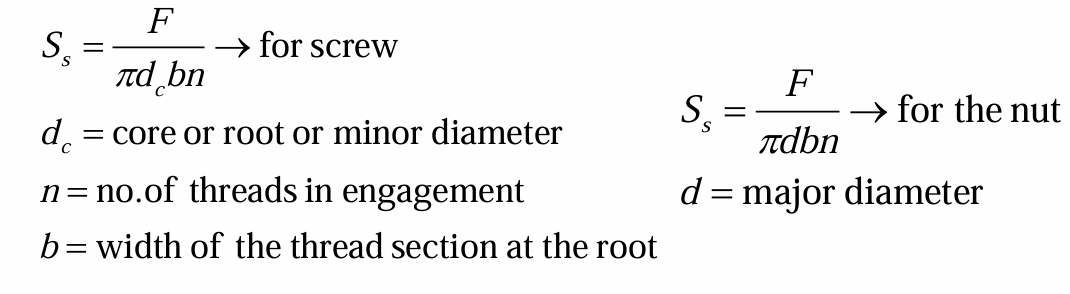

shear stress across the threads

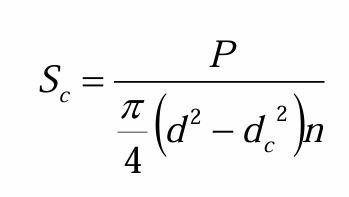

compression or crushing stress on threads

external tensile stress

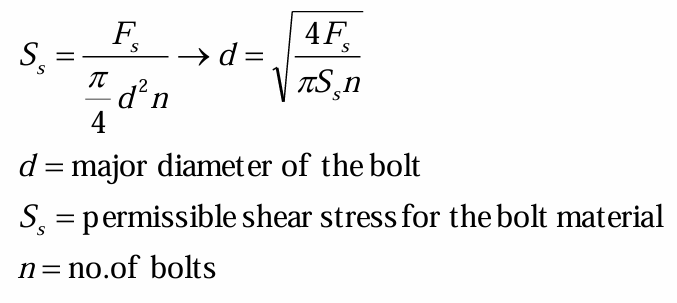

external shear stress

external combined tension and shear

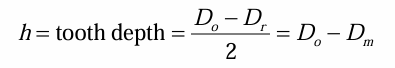

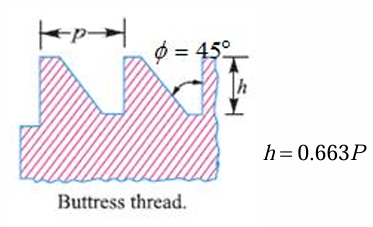

tooth depth

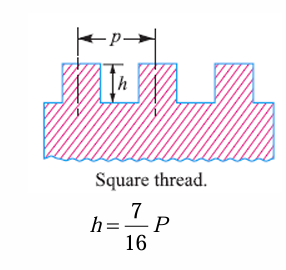

tooth depth for square

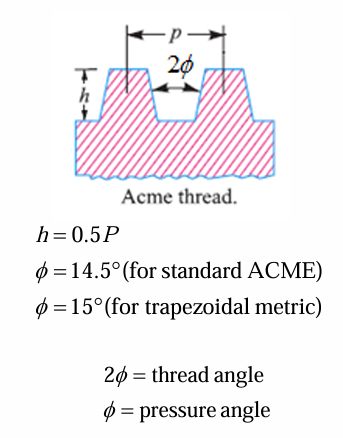

tooth depth for acme

tooth depth for buttress

pressure angle for acme, square, trapezoidal metric

14.5,0,15

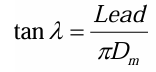

lead angle

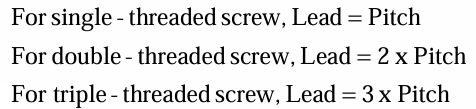

lead of single threaded, double threaded, and triple threaded screws