Materials 2

0.0(0)

0.0(0)

Card Sorting

1/110

Earn XP

Description and Tags

Study Analytics

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

111 Terms

1

New cards

atomic bonding in solid

allows atoms to reduce potential energy state (become more negative)

* more desirable

* more desirable

2

New cards

larger bond energy

stronger the bond

* heat or tensile stress increase interatomic distance and PE

* heat or tensile stress increase interatomic distance and PE

3

New cards

ionic bond

* electrons are transferred

* electrostatic attraction

* full valence shell = reduce PE

* have ions

* electrostatic attraction

* full valence shell = reduce PE

* have ions

4

New cards

covalent bond

* electrons are shared (not 50 50)

* fixed bond lengths and angle

* orbitals overlap

* dipoles

* fixed bond lengths and angle

* orbitals overlap

* dipoles

5

New cards

metallic

* metal bond with another metal regardless of electrons in valence shell

* driving force is need to have full valence shell

* delocalised electron; electron cloud/sea of electron

* electrons are shared

* driving force is need to have full valence shell

* delocalised electron; electron cloud/sea of electron

* electrons are shared

6

New cards

bond type affect conductivity

* metallic bonds allow electron flow bc e- free to travel

* in other bonds, e- not free to travel so insulators

* in other bonds, e- not free to travel so insulators

7

New cards

hydrogen bonds

* molecule has to have hydrogen present

* bond bw water mlc

* electrostatic attraction bw H and O (dipoles)

* weak bond

* bond bw water mlc

* electrostatic attraction bw H and O (dipoles)

* weak bond

8

New cards

bond affect melting point

* heat increase interatomic distance

* larger bond energy, higher melting pt

* E0 = bond energy from peak to x-axis

* E0 = solid = atom vibrate but stay in ‘well’ in solid state

* larger bond energy, higher melting pt

* E0 = bond energy from peak to x-axis

* E0 = solid = atom vibrate but stay in ‘well’ in solid state

9

New cards

polymers in civil and arch engineering

* sealants

* adhesive

* repair and restoration

* interior finishing

* composites

* adhesive

* repair and restoration

* interior finishing

* composites

10

New cards

polymers bonding

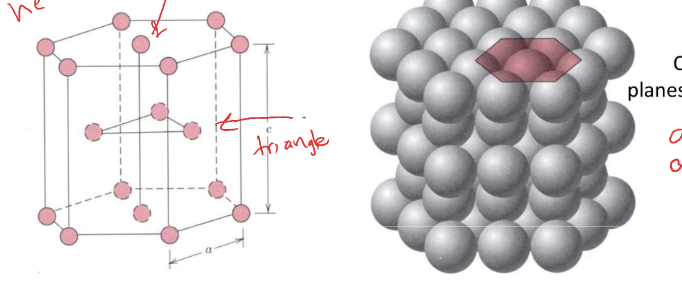

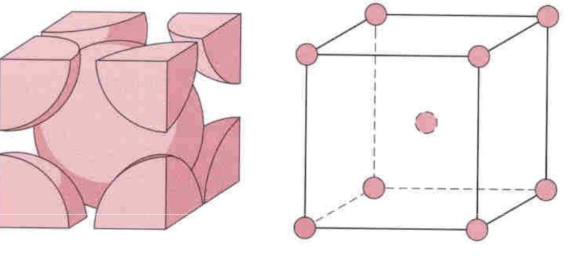

* hydrocarbons

* most are H and C; made from fossil fuels

* bonding impact mechanical and thermal properties

* really strong covalent bonds = lot energy to break = high bond energy

* covalent bw carbons; fixed bond length

* covalent bw C and H

* hydrogen bw chains; energy low but multiples across length of mlc

* plastic behavior

* most are H and C; made from fossil fuels

* bonding impact mechanical and thermal properties

* really strong covalent bonds = lot energy to break = high bond energy

* covalent bw carbons; fixed bond length

* covalent bw C and H

* hydrogen bw chains; energy low but multiples across length of mlc

* plastic behavior

11

New cards

chain length

* greater number of carbons, higher mlc weight and the more H bonds

* more condensed state at room temp

* from least to most carbons: gas, liquid, oil, grease, wax, plastic (polymer)

* more condensed state at room temp

* from least to most carbons: gas, liquid, oil, grease, wax, plastic (polymer)

12

New cards

polymer structure

amorphous

* chains are flexible (hydrocarbon chains)

* hydrogen atoms rotate along axis

* result: drained cooked spaghetti w covalent bonds inside each noodle and hydrogen bonds bw noodles ‘sticky’

* chains are flexible (hydrocarbon chains)

* hydrogen atoms rotate along axis

* result: drained cooked spaghetti w covalent bonds inside each noodle and hydrogen bonds bw noodles ‘sticky’

13

New cards

polymer types

* named by smallest repeatable unit = monomer

* R is functional group

* R is functional group

14

New cards

thermoplastics

* linear chains of hydrocarbons

* melt at low temperature

* add functional groups increases yield strength of polymer = amt of stress to get plastic deformation

* decrease percent elongation

* functional group cause friction

* bigger functional group = more friction

* harder for chains to slide + uncoil

* melt at low temperature

* add functional groups increases yield strength of polymer = amt of stress to get plastic deformation

* decrease percent elongation

* functional group cause friction

* bigger functional group = more friction

* harder for chains to slide + uncoil

15

New cards

polyethylene (PE) functional group

R = H

16

New cards

polypropylene (PP) functional group

R = CH3

17

New cards

polyvinylchloride (PVC) functional group

R = Cl

18

New cards

polystyene (PS) functional group

R = C6H5

19

New cards

teflon/PTFE functional group

4R = F

20

New cards

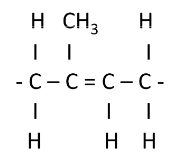

cis-natural rubber latex

21

New cards

plasticity

* ability to sustain large permanent deformation

* ex groccery bag

* reason: large chains of polymers can uncoil wo breaking primary bonds

* breaking hydrogen bonds bw chains and form new ones

* H-bonds are weak, stress needed to cause permanent deformation low

* ex groccery bag

* reason: large chains of polymers can uncoil wo breaking primary bonds

* breaking hydrogen bonds bw chains and form new ones

* H-bonds are weak, stress needed to cause permanent deformation low

22

New cards

tensile strength polymers

can engineer polymers have different degrees of plastic deformations, ductile or brittle, control by manipulating chemistry

23

New cards

thermal properties polymers

* when melt, covalent bonds stay intact but hydrogen bonds break

* some materials melt from solid to liquid

* thermoplastic have melting temp (Tm) and glass transition temp (Tg)

* below Tg, mvt of chain restricted bc material becomes brittle

* behavior driven by hydrogen bonds

* at extreme high temp scenario, H-bond broken and polymers melt (flow)

* polymers have low melting pt compared to other materials

* some materials melt from solid to liquid

* thermoplastic have melting temp (Tm) and glass transition temp (Tg)

* below Tg, mvt of chain restricted bc material becomes brittle

* behavior driven by hydrogen bonds

* at extreme high temp scenario, H-bond broken and polymers melt (flow)

* polymers have low melting pt compared to other materials

24

New cards

molecular weight polymers

* dep on number of carbons in mlc

* tensile strength increases w mlc weight bc more hydrogen bonds

* levels off as increase MW, so don’t need to max to see optimal strength

* viscosity also increases w decreasing processability

* tensile strength increases w mlc weight bc more hydrogen bonds

* levels off as increase MW, so don’t need to max to see optimal strength

* viscosity also increases w decreasing processability

25

New cards

branches in polymers

* affect density, crystallinity, ductility

* ex. polyethylene - high density

* regions where chanis are aligned = higher density

* more brances = can’t pack together tightly so density lower

* branches have diff composition

* co-polymers and terpolymers

* ex. polyethylene - high density

* regions where chanis are aligned = higher density

* more brances = can’t pack together tightly so density lower

* branches have diff composition

* co-polymers and terpolymers

26

New cards

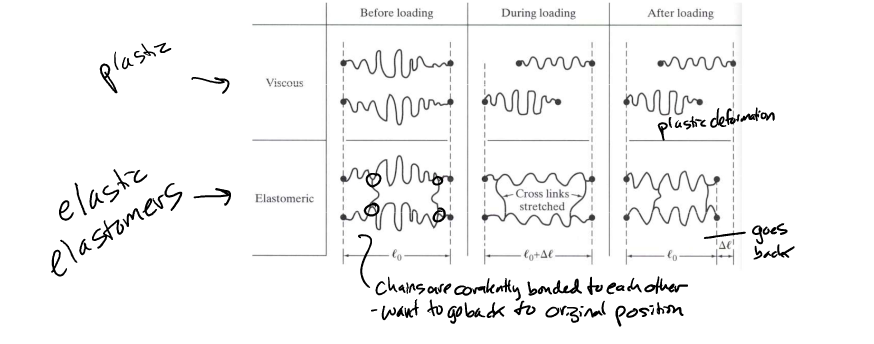

elasticity polymers

certain aspects of polymer composition and structure change deformation properties

* van der waals bonding bw chains

* steric hindrances (large R groups limit flexibility)

* primary chemical bonds bw chains (cross linking)

* van der waals bonding bw chains

* steric hindrances (large R groups limit flexibility)

* primary chemical bonds bw chains (cross linking)

27

New cards

rubber

* is elastomeric

* ‘volcanization’ invented by Goodyear in 1839

* sulfur added at high temps create cross-link

* tech breakthrough

* gummy substance given more rigidity and thermal stability

* latex = thermoplastic; melt the chain; add sulfur for crosslink → need to break cross link to get it to melt so doesn’t melt, it decomposes when heated

* ‘volcanization’ invented by Goodyear in 1839

* sulfur added at high temps create cross-link

* tech breakthrough

* gummy substance given more rigidity and thermal stability

* latex = thermoplastic; melt the chain; add sulfur for crosslink → need to break cross link to get it to melt so doesn’t melt, it decomposes when heated

28

New cards

thermosets

* are not chains

* are hydrocarbons

* have covalent and hydrogen bonds, so heavilty cross-linked called network polymers (like mesh grid)

* brittle and temperature-resistant (higher temp and higher decomposition temp)

* ex: epoxy, silicone, melamine

* negative aspect:

* not fire resistant

* not UV resistant

* thermal response give limited temp range

* are hydrocarbons

* have covalent and hydrogen bonds, so heavilty cross-linked called network polymers (like mesh grid)

* brittle and temperature-resistant (higher temp and higher decomposition temp)

* ex: epoxy, silicone, melamine

* negative aspect:

* not fire resistant

* not UV resistant

* thermal response give limited temp range

29

New cards

wood

naturally occurring polymer composite

* matrix and reinforcement (aligned fibers)

* matrix and reinforcement (aligned fibers)

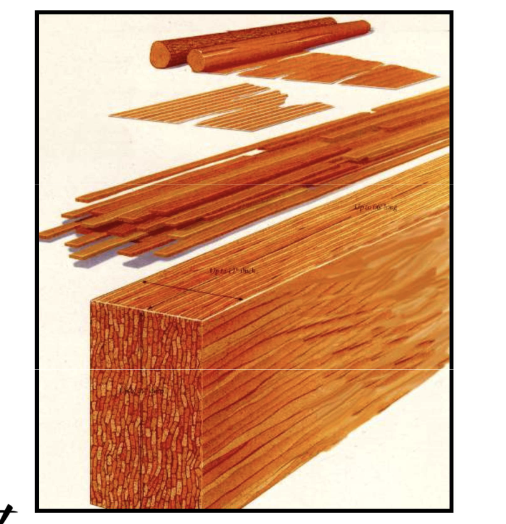

30

New cards

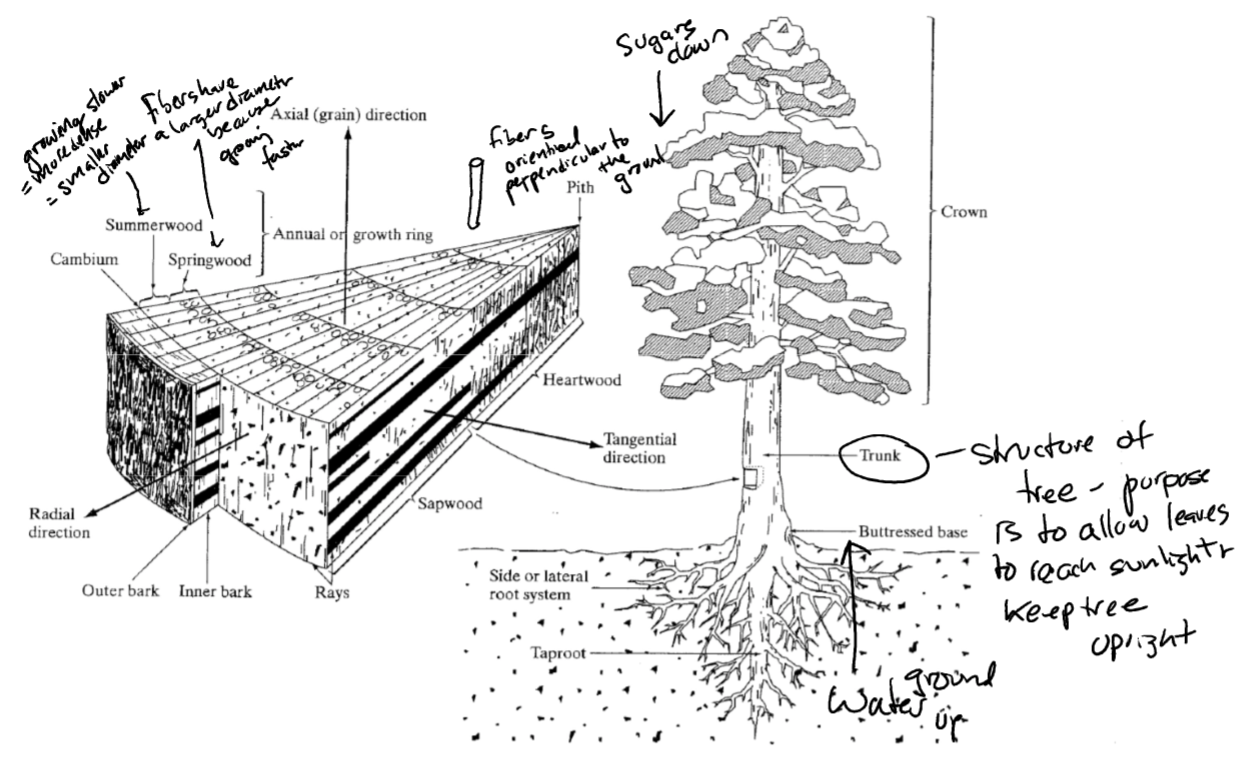

microstructure of wood

* summer wood: grow slower = more dense = smaller diameter

* spring wood: fiber share larger diameter bc growing faster

* fibers orient perpendicular to grain

* water travel from ground up

* trunk: allow leaves to reach sunlight; keep tree upright

* spring wood: fiber share larger diameter bc growing faster

* fibers orient perpendicular to grain

* water travel from ground up

* trunk: allow leaves to reach sunlight; keep tree upright

31

New cards

microstruture wood

* fibers 90% of material

* vertical cells, 2-5 mm, I/d = 100

* rays 10% transverse for transport

* vertical cells, 2-5 mm, I/d = 100

* rays 10% transverse for transport

32

New cards

softwood

most softwoods are soft

* needle like leaves

* can tell spring vs summer wood bc spring less dense and smaller holes

* needle like leaves

* can tell spring vs summer wood bc spring less dense and smaller holes

33

New cards

hardwood

most hardwoods are hard

* have broad leaves

* hardwoods have additional fibers and vessels

* have broad leaves

* hardwoods have additional fibers and vessels

34

New cards

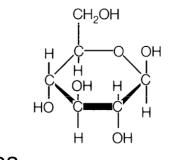

cellulose - aka fiber material

* glucose-based polymer, linear, w thousand units

* covalent bonds in polymer chain

* hydrogen bonding bw chains

* 65-90% crystallinity

* covalent bonds in polymer chain

* hydrogen bonding bw chains

* 65-90% crystallinity

35

New cards

hemicellulose

* polymers made from diff sugar mlc

* hemicellulose and lignins bind cellulose together

* hemicellulose and lignins bind cellulose together

36

New cards

Lignins aka like epoxy in FRP

* 3D structure of phenyl propane units

* provide rigidity

* like network, thermoset polymer = more rigid

* hemicellulose and lignins bind cellulose together

* provide rigidity

* like network, thermoset polymer = more rigid

* hemicellulose and lignins bind cellulose together

37

New cards

anistropic

properties are diff depending on direction of loading

(true of other continuously aligned fiber reinforced composite like FRP > steel reinforced concrete)

(true of other continuously aligned fiber reinforced composite like FRP > steel reinforced concrete)

38

New cards

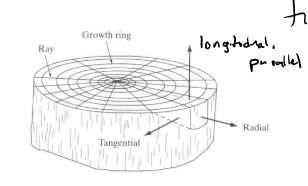

how is wood strongest

wood strongest in parallel to grain under compressive load

* mainly wood strongest under parallel to grain direction (longitudinal)

* perpendicular to grain = radial and tangential

* mainly wood strongest under parallel to grain direction (longitudinal)

* perpendicular to grain = radial and tangential

39

New cards

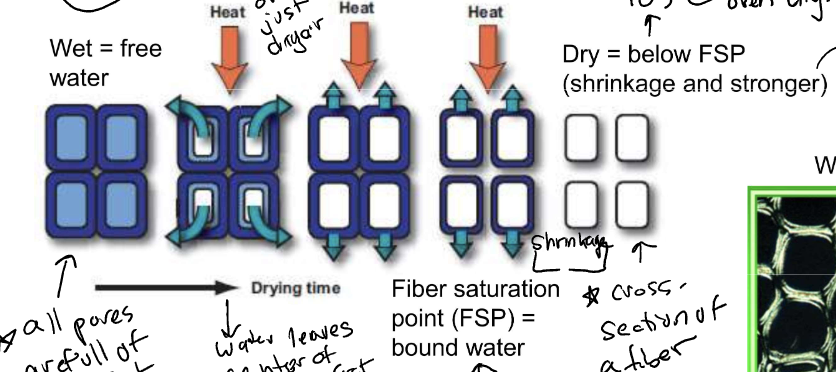

moisture in wood

* wet = free water

* all pores full of water and surface water

* water leaves center of fiber first

* fiber saturation point (FSP) = bound water

* center of water has evaporate but water on wall still

* Dry = below FSP

* shrink and become stronger, denser (over 105°C)

* all pores full of water and surface water

* water leaves center of fiber first

* fiber saturation point (FSP) = bound water

* center of water has evaporate but water on wall still

* Dry = below FSP

* shrink and become stronger, denser (over 105°C)

40

New cards

shrinkage of wood

* towards the edge more warping, in the middle less warping

* shrinking edge-grain wood or radial to growth rings

* mainly shrinking of flat-grain wood or tangential to growth ring

* shrink lengthwise very small (2% of radial shrinkage)

* shrinking edge-grain wood or radial to growth rings

* mainly shrinking of flat-grain wood or tangential to growth ring

* shrink lengthwise very small (2% of radial shrinkage)

41

New cards

flaws in wood

* lumber/wood have many flaw; wood are small specimen that are flaw free for testing

* flaws affect mech properties

* flaws affect mech properties

42

New cards

knot flaw

where branches where

43

New cards

check flaw

like a crack in wood

44

New cards

pros and cons of wood

pros:

* pretty

* sustainable

* lightweight (strength to weight ratio)

Cons:

* swelling

* mold, rot bc moisture

* size limited

* anisotropy

engineers solve these problems by creating engineered wood

* pretty

* sustainable

* lightweight (strength to weight ratio)

Cons:

* swelling

* mold, rot bc moisture

* size limited

* anisotropy

engineers solve these problems by creating engineered wood

45

New cards

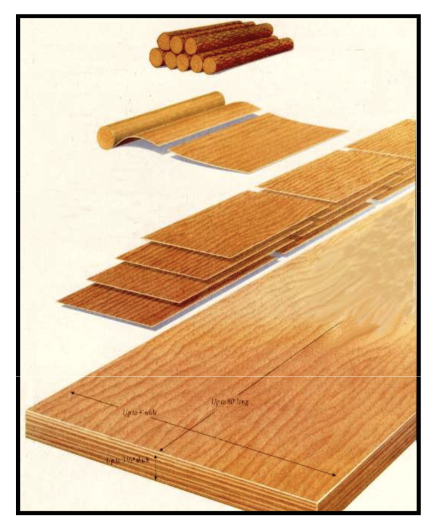

engineered panel products

* plywood: flaws only ply thick, allow bigger pieces

* waferboard

* composite

* structural particleboard: small pieces glued together; less waste, less anistropyl; flaw not important

* oriented strand board

* waferboard

* composite

* structural particleboard: small pieces glued together; less waste, less anistropyl; flaw not important

* oriented strand board

46

New cards

laminated veneer lumber

like shaving a tree and removing its circumference surface area

47

New cards

parallel strand lumber

cutting parallel strips from lumber

48

New cards

why use engineered lumber products

* consistency of products

* reduce swelling/shrinkage problems

* engineered lumber 6-8% moisture content from factory

* no warp, twist, crook, checking, wane

* COV < 11%

* design capabilities

* increased strength and stiffness

* environmental issues & availability

* reduced availability of old-growth timber

* more efficient use of wood fiber

* use under-valued species

* reduce swelling/shrinkage problems

* engineered lumber 6-8% moisture content from factory

* no warp, twist, crook, checking, wane

* COV < 11%

* design capabilities

* increased strength and stiffness

* environmental issues & availability

* reduced availability of old-growth timber

* more efficient use of wood fiber

* use under-valued species

49

New cards

SP #2

southern pine

50

New cards

rubber bridge bearings

bearing must resist:

* compressive forces from weight of bridge

* shear forces as bridge shortens and lengthens due to thermal expansion and contraction

* need steel plates bc reduce deformation under compression for more stability

* low maintenance alternative

* (before had mechanical steel bering w bolt and needed a lot of maintenance)

* compressive forces from weight of bridge

* shear forces as bridge shortens and lengthens due to thermal expansion and contraction

* need steel plates bc reduce deformation under compression for more stability

* low maintenance alternative

* (before had mechanical steel bering w bolt and needed a lot of maintenance)

51

New cards

based isolation bearings

reduce shaking of building during earthquake

52

New cards

Fiber reinforced polymer (FRP)

* fiber reinforced = reinforcement; polymer = matrix

* used to wrap damaged structural elements

* wrap elements in seismic regions

* used as substitute for steel-reinforcing bar

* used to wrap damaged structural elements

* wrap elements in seismic regions

* used as substitute for steel-reinforcing bar

53

New cards

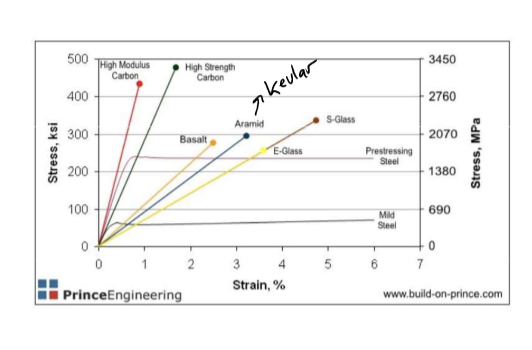

fiber reinforced (reinforcement)

* carbon

* e-glass

* aramid (kevlar)

* fiber strong - carry load

* fiber continuous and aligned (parallel)

* e-glass

* aramid (kevlar)

* fiber strong - carry load

* fiber continuous and aligned (parallel)

54

New cards

polymer as a matrix

* epoxy

* vinly ester

* polyesters

* polymers encase and protected; allow load transfer bw fibers

* vinly ester

* polyesters

* polymers encase and protected; allow load transfer bw fibers

55

New cards

CFRP

carbon + epoxy

56

New cards

GFRP

e-glass + vinyl ester

57

New cards

AFRP

aramid + polyesters

58

New cards

FRP stress vs strain

* fiber strong brittle, high E

* resin lopw E, ductile, weak E

* FRP composite in bewteen

* resin lopw E, ductile, weak E

* FRP composite in bewteen

59

New cards

forms of FRP

* rods

* shapes

* steel or FRP

* bars

* typically made from steel, but can be made from FRP bc doesn’t rust

* planks/strips

* shapes

* steel or FRP

* bars

* typically made from steel, but can be made from FRP bc doesn’t rust

* planks/strips

60

New cards

dry fabrics

* structural repair and strengthening

* flexible and easy to be installed (by wet lay-up or dry lay-up) to fit geometry of members

* workable in areas w limited space/access

* thin profile meet desirable asthetics

* flexible and easy to be installed (by wet lay-up or dry lay-up) to fit geometry of members

* workable in areas w limited space/access

* thin profile meet desirable asthetics

61

New cards

flexural strengthening FRP

* transverse straps for enhancing bonding and anchorage

* fiber’s orientation must be parallel to beam

* tensile strengthening along bottom of beam

* uses CFRP

* fiber’s orientation must be parallel to beam

* tensile strengthening along bottom of beam

* uses CFRP

62

New cards

confinement FRP

* fiber’s orientation horizontally around column

* in compression, poisson’s ratio causes middle to expand out

* FRP used to confine column for indirectly increasing compressive strength by putting column in triaxial stress

* in compression, poisson’s ratio causes middle to expand out

* FRP used to confine column for indirectly increasing compressive strength by putting column in triaxial stress

63

New cards

examples of FRP use

* fire damage repairment

* installed steel wire mesh for securing bonding

* polyethylene tubing installed for injecting epoxy to seal cracks

* cap and girders repairement: use fresh concrete to mimic shape of original member

* longitudinal and “U” wrap CFRP installed on girders per design

* installed steel wire mesh for securing bonding

* polyethylene tubing installed for injecting epoxy to seal cracks

* cap and girders repairement: use fresh concrete to mimic shape of original member

* longitudinal and “U” wrap CFRP installed on girders per design

64

New cards

asphalt

polymer composite

* asphalt is matrix

* aggregates are reinforcements (same as concrete)

* asphalt is matrix

* aggregates are reinforcements (same as concrete)

65

New cards

asphalt’s other name

* hot mix asphalt (HMA)

* blacktop

* tarmac

* Macadam

* plant mix

* bituminous material

* blacktop

* tarmac

* Macadam

* plant mix

* bituminous material

66

New cards

what is asphalt

* dark brown to black cementitious (adhesive) material where bitumens occur in nature or obtained in petroleum processing

* asphalt concrete = asphalt binder + 95% vol mineral aggregates

* asphalt concrete = asphalt binder + 95% vol mineral aggregates

67

New cards

how many paved roads in US are asphalt

800,000 roads (around 18 billion tons of asphalt)

68

New cards

reusability of asphalt

most reused product in america

* can add recycled tires, engine oil, slags, glass, shingles

* can add recycled tires, engine oil, slags, glass, shingles

69

New cards

asphalt history

first use in US in 1870

* use naturally occuring asphalt from surface of lake on island of Trinidad

1900s: petroleum asphalt develop

* waste product from refining of crude oil

* bottom of barrel

* use naturally occuring asphalt from surface of lake on island of Trinidad

1900s: petroleum asphalt develop

* waste product from refining of crude oil

* bottom of barrel

70

New cards

components of asphalt

* high mlc weight hydrocarbons

* long hydrocarbon chains = high mlc weight

* asphaltenes

* resins

* oils

* depending on proportions, mech properties of asphalt differ

* long hydrocarbon chains = high mlc weight

* asphaltenes

* resins

* oils

* depending on proportions, mech properties of asphalt differ

71

New cards

asphaltenes

* large, discrete solid inclusions (black)

* high viscocity

* highest mlc weight

* solid at room temp

* fewer = softer; more = harder

* high viscocity

* highest mlc weight

* solid at room temp

* fewer = softer; more = harder

72

New cards

resins asphalt

* semi-solid/solid at room temp

* fluid when heated; brittle when cold

* lower mlc weight than asphaltene

* fluid when heated; brittle when cold

* lower mlc weight than asphaltene

73

New cards

oil asphalt

* colorless liquid

* soluble in most solvent

* allow asphalt to flow

* soluble in most solvent

* allow asphalt to flow

74

New cards

asphalt uses

* pavements - have layers

* asphalt surface → granular base and subase (aggregates) → prepared subgrade

* sealing

* waterproofing

* repair

* asphalt surface → granular base and subase (aggregates) → prepared subgrade

* sealing

* waterproofing

* repair

75

New cards

making pavements

asphalt cement and agg mixed together at high temp and compacted on road while still hot

* fluid at high temp bc hydrogen bonds bw mlc break causing polymer to melt

* fluid at high temp bc hydrogen bonds bw mlc break causing polymer to melt

76

New cards

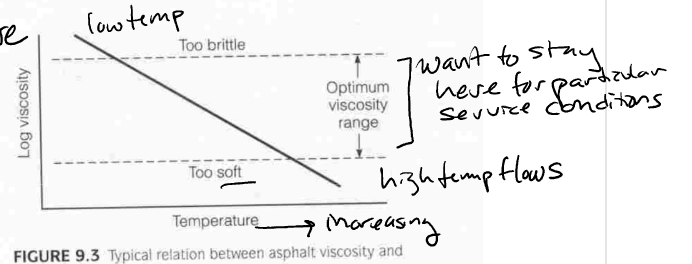

mix design pavement

addresses performace of asphalt under working conditions

* dep on

* climate (hot vs cold); too cold brittle; too hot flow

* loading (traffic)

* time (oxidation, moisture)

* dep on

* climate (hot vs cold); too cold brittle; too hot flow

* loading (traffic)

* time (oxidation, moisture)

77

New cards

hauling asphalt

tandem axle end dump truck

* hot asphalt + agg mixture

have paver at the back ususally

* hot asphalt + agg mixture

have paver at the back ususally

78

New cards

placement asphalt

self propelled paver

79

New cards

compacting asphalt pavement

vibratory roller

* prevent further compaction

* provide shear strength or resistance to rutting

* ensure mixture is waterproof

* prevent excessive oxidation of asphalt binder

* prevent further compaction

* provide shear strength or resistance to rutting

* ensure mixture is waterproof

* prevent excessive oxidation of asphalt binder

80

New cards

climate design criteria for pavements

* behavior temp dependent like thermoplastic polymer

* when heated

* asphaltenes dissolve in resins

* resins dissolve in oils

* less viscous (flow more)

* when cooled = opposite

* choose correct type of binder for climate

* hot climates: use harder grade to avoid rutting

* cold climates: use softer grades to avoid temp cracking

* when heated

* asphaltenes dissolve in resins

* resins dissolve in oils

* less viscous (flow more)

* when cooled = opposite

* choose correct type of binder for climate

* hot climates: use harder grade to avoid rutting

* cold climates: use softer grades to avoid temp cracking

81

New cards

loading design criteria pavement

function of repeated traffic loads over time in wheel paths create fatigue cracking

82

New cards

time design criteria asphalt

* aging/oxidation and moisture damage occur over time

* can lead to rutting, cracking, and agg debonding

* can lead to rutting, cracking, and agg debonding

83

New cards

other design criteria for pavements

* resistance to skidding (texture): test agg for abrasion resistance

* sufficient workability for mixing, placing, compaction

* cost and availability

* sufficient workability for mixing, placing, compaction

* cost and availability

84

New cards

SUPERPAVE

superior performing asphalt pavements: designed in 1987

* is performance-based

* choose asphalt binder **NOT** on components **BUT** on potential for rutting, fatigue cracking, thermal cracking (based on climate, load, time)

* have trade offs: binders good load resistance = low temp cracking

* is performance-based

* choose asphalt binder **NOT** on components **BUT** on potential for rutting, fatigue cracking, thermal cracking (based on climate, load, time)

* have trade offs: binders good load resistance = low temp cracking

85

New cards

SUPERPAVE concrete design

asphalt binder grade determined based on performance in lab

* bulk specific gravitiy

* shear

* tensile strength and fracture

* creep

* bending beam rheometer

* bulk specific gravitiy

* shear

* tensile strength and fracture

* creep

* bending beam rheometer

86

New cards

asphalt binder grading

performance grading “PG X-Y”

* X and Y max and min designing temps

* ex PG 52-28 => temp 52 to -28°C

* second number always negative

* X and Y max and min designing temps

* ex PG 52-28 => temp 52 to -28°C

* second number always negative

87

New cards

surface recycling

* more like reusing

* heat top 25 mm of pavement

* repair minor cracks and roughness

* heat top 25 mm of pavement

* repair minor cracks and roughness

88

New cards

central plant recycling

mill old pavement to get reclaimed asphalt pavement (RAP) and create new HMA

89

New cards

in place recycling

rip and pulverize old pavement - add new agg, water, asphalt emulsion - mix, grade, compact

90

New cards

add rubber tires to asphalt concrete

* increase elasticity and stiffness

* increase cement-agg bond

* reduce thermal cracking and freeze-thaw damange

* added w binder or w aggregate

* increase cement-agg bond

* reduce thermal cracking and freeze-thaw damange

* added w binder or w aggregate

91

New cards

metals in tension in elastic region

have elastic deformation bc stretching bonds bw atoms and when let go, atoms go back to preferred position which is min bond length and energy

92

New cards

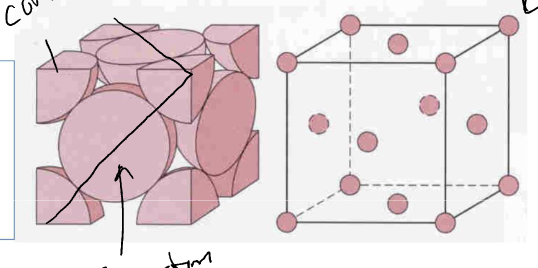

crystal

have regular, repeating patterns of atoms

93

New cards

amorphous

shapeless; random/semi-random arrangements of atoms

94

New cards

unit cell

repeated to make a pattern

* want close packing bc limited geometries for atoms of a single size to pack as closely as possible

* want close packing bc limited geometries for atoms of a single size to pack as closely as possible

95

New cards

Face Centered Cubic (FCC)

* atom on each corner of cube and atom centered on each face at cube

* packing in close-packed plane

* all optimal bond distance

* line through face diagonals doesn’t go through empty space

* packing in close-packed plane

* all optimal bond distance

* line through face diagonals doesn’t go through empty space

96

New cards

hexagonal close packed (HCP)

* packing in closed packed plane

* hexagonal ring with face centered and triangle in middle

* alternating layers of those packed plane

* hexagonal ring with face centered and triangle in middle

* alternating layers of those packed plane

97

New cards

Body Centered Cubic (BCC)

* atoms on each corner of cube and one in center of body

* closely packed planes intersect diagonally

* closely packed planes intersect diagonally

98

New cards

defects in crystals

* they exist (almost all crystals have defect)

* exist bc of entropy (chaos)

* interstitials and vacancies happen spontaneously in all crystals;

* can control substitutions and manipulate them to achieve properties of material

* exist bc of entropy (chaos)

* interstitials and vacancies happen spontaneously in all crystals;

* can control substitutions and manipulate them to achieve properties of material

99

New cards

1-D imperfection

simple cubic unit cell crystal

* point defects

* in region of defect, surrounding atoms are not at idea bond length, so not at lowest energy state

* point defects

* in region of defect, surrounding atoms are not at idea bond length, so not at lowest energy state

100

New cards

vacancy

single missing atom

* surrounding atoms pull toward empty space

* surrounding atoms pull toward empty space