MCHE 3920 Shape Casting of Metals Week 3

1/66

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

67 Terms

3200 BCE

Oldest shape castings date back to?

3 main benefits of shape casting

Provides complex shapes, wide range of materials, and economical for large parts and high volume production

Auto, aero, machinery, pipes, construction equipment

Where are shape castings normally found?

slowly, oxidation

When filling a mold for shape casting: it is best to fill it _____ to prevent splashing and thus _________, and helps prevent gas entrapment

higher, not cast, cast

castings normally have _______ alloy content: Steel w/ Fe<2% C is typically _______, while Fe 2-4% C is typically _______

Lower viscosity, lower melting temp

Reasons why castings have higher alloy content

eutectic composition

What do we want casting metals to be near?

mechanical properties, decrease

Higher alloy content comes at expense of _________; toughness, ductility and fatitgue strength all ________ by presence of alloy

mechanical performance

what is a trade off w/ castability

liminal

Filling speed: want slow speeds s.t. flow is ________

turbulence

laminar flow minimizes _________ and thus oxidation and loss of material props

lower productivity, chance of cold running (cold shut)

trade offs of low filling speeds:

gates, injection pressure

_____ increase fill speed, increasing _________

preheated molds, energy consumption, costs

___________ preven cold running- increases __________ and ______

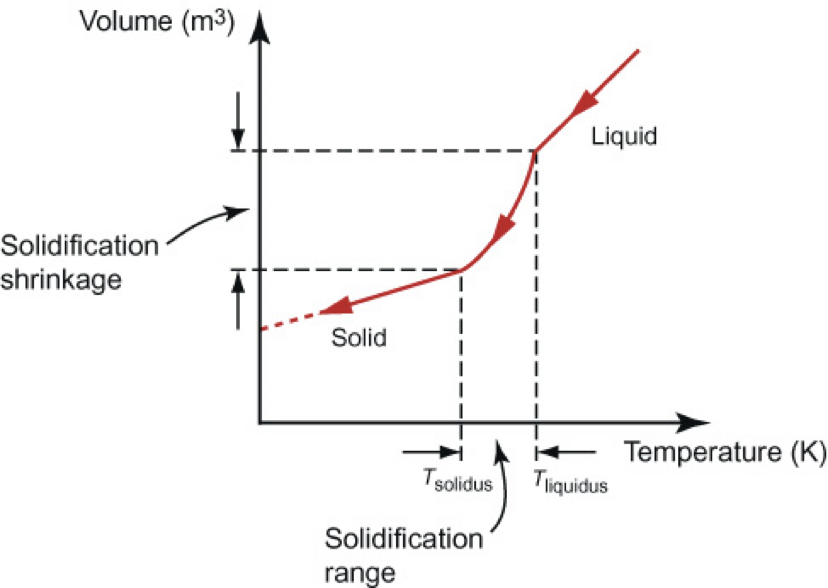

solidification range

rate of volume reduction is highest where?

Tpouring to Tsolidus- specific heat, liquid phase

Phase 1/3 of cooling:

Liquid to solid, latent heat of fusion

Phase 2/3 for cooling:

Tsolidus to RT, specific heat solid phase

Phase 3/3 of cooling:

add extra material during filling

What do we do about solidification shrinkage?

make mold bigger

what do we do about shrinkage after solidification?

how long is take for part to be cool and strong enough for handling (seconds)

Chorinov’s rule shows what?

large solid castings, underestimates

Chorinov’s rule works well for ______, but ________ time for hollow thin-walled parts

inner wall doesn’t absorb as much heat as outer walls

Why does Chorinov’s rule underestimate for hollow parts

solidification/cooling time, casting, insulator, V/A

For parts with walls <4mm, chorinov’s underestimates ________ becuase the mold expands while ________ contracts, creating an air gap that acts as an __________, a better model is proportional to _____

Porosity, internal stresses, distortion

3 main casting defects:

gas bubbles

second main cause for porosity: are released during solidification and trapped in the solid

shrinkage porosity

first main cause for porosity: not enough extra material in casting to account for solidification shrinkage

poorly designed, solidifies

shrinkage porosity occurs when a mold is ________, or a runner _______, blocking flow into thicker section

disperse gas into the solid so that only forms small bubbles

how to minimize gas bubbles effects

thinner

which cast sections cool quicker

temperature gradients

different sections w diff thicknesses cool at diff rates, leading to ____________ w/i the casting

eth=CLTE*deltaT

thermal strain equation

stresses exceed yield stress

when can permanent deformation occur in casting

computer simulation

bc of complex geometries, predicting internal stresses in casting requires ____________

casting metallurgy

choosing best alloy for the job

crystalline

metals have a what grain structure?

grain boundary

where grains grow w/i solid and along mold wall and impinge on each other

0.05,5

cast grans are typically ____ to_____ mm large

cooling rate, fast cooling, smaller grain, better properties

grain size dictated by _______, ______ leads to _________ leads to ________

improve processability, improve material properties, minimize impurities/improve microstructure

3 reasons alloying elements are used:

true

T/F: alloying elements can intro impurities that can be detrimental

segregation

non-unifrom distribution of dissolved elements during solidification

atomic soup

in liquid state, alloy elements dissolved in:

purer, enriched, impurities

during cooling, first solids formed are ______ than average, so remainder is relatively ________ which will lead to ___________

grain boundaries

last part to solidify in casting

inoculants

high melting point powders added before pouring

smaller, segregation

as liquid cools, solids form around the inoculant promoting ______ grains and less _________

small, tensile strength, poisoning

sometimes _____ additions of the right element can improve the _________ of a cast metal (this is known as _______)

silica sand a bonding agent

in sand casting, what forms the mold

wooden/plastic/metal patterns

in sand casting, what are used to form negative space in the mold

low, tolerances

patterns only support ___ filling speeds and pressures, and have poor ________

larger grains

in sand casting, long solidification times means

parting plane

in sand casting: plane where drag and cope meet

sprue

sand casting molds are filling through

feeder

in a sand casting mold, what shows when filling is complete

gravity die casting

casting method that uses reusable steel dies

finer microstructure

in gravity die casting, shorter cycle times lead to

smoother, tolerances, low, limited, aluminum, magnesium

gravity die casting: _____ products and good control over _______, filling speeds are _____, product size is more _______ than sand casting, ______ and _______ commonly cast using this method

low pressure die casting

casting method using reusable steel dies with pressures from 2 to 5 bar

aluminum and magenesium

elements commonly used in low pressure die casting

high pressure die casting

casting method w espensive steel dies up to 2000 bar

sand cores, sliding elements

high pressure die casting cannot use _______ but can use ________

fast throughput, lower quality, thinner products

with high injection speeds in high pressure die casting:

zinc, aluminum, magnesium

high pressure die casting is limited to these elements

investment casting

casting method using a wax-made pattern attached to the sprue (rare)

ceramic slurry, wax, mold, destroyed, complex geometries

investment casting: dipped into a _________ that cures while ____ melts away, hollow ceramic shell is then used as the ______, after casting the shell is ______. good for ________