IB DT: Topic 4.4: Manufacturing processes

1/47

Earn XP

Description and Tags

credits: https://sites.google.com/view/designandinquiry/dp-sl-design/topic-4-final-production/4-4-manufacturing-processes/additive-manufacturing-techniques?authuser=0

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

48 Terms

what three step workflow do rapid prototyping processes follow?

first, a model is created in cad software which contains information about the physical form, shape and dimensions of a product

the 3d model is then processed by slicing software. this takes the model and slices it into layers. parameters such as layer thickness, wall thickness and infill can be set here.

the sliced file is then sent to the rapid prototyping device for manufacture. in most cases, this will involve the device cutting or depositing material in the pattern set by the slicer software.

what is paper-based rapid prototyping (PRP)?

in this process, layers of paper are cut and then glued together to create a 3d shape. this is cost-effective and useful in producing presentation models. it is also more environmentally friendly than other plastics-based rapid prototyping methods.

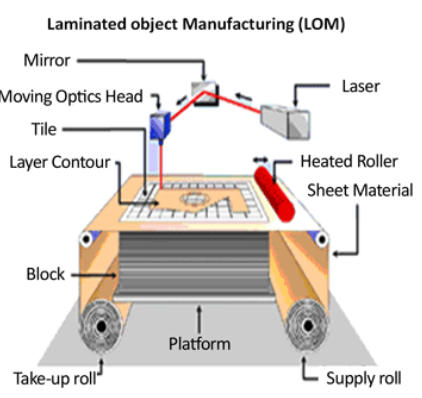

what is laminated object manufacturing (LOM)?

uses thin layers of polymer which are cut and layered together. this process is used to create scale and presentation models which can be used to gather client/user feedback on form.

what is stereolithography (SLA)?

in this process an object is created by selectively curing a thin layer of liquid resin with a laser. a laser heats selected areas of the resin, turning it into a solid. this process continues until the piece is completed.

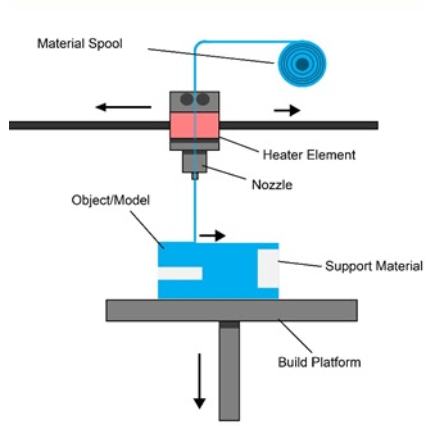

what is fused deposition modelling (FDM)?

the most accessible type of 3d printing technology, involving laying down thin layers of material, usually a type of plastic. the filament is heated in a nozzle and then “drawn” on layer-by-layer.

what is a subtractive manufacturing technique?

when material is cut away to create a product or component

what is machining?

a process whereby a cutting tool moves across and around the surface of a material. the machines can be CNC controlled or operated by a user.

what is turning?

rotating a material along a horizontal axis while a cutting tool is moved along the surface to remove material.

what is milling?

the movement of a rotating bit over the surface of a material, moving on a vertical axis. the material is fixed to a work surface, and the rotating bit is moved up and down and around the material.

what is drilling?

involves a spinning bit moving up and down the z-axis to create a hole in the material

what is abrading?

the process of using an abrasive to grind or rub away material. compounds that are used to grind, sand or polish a material - they can be used to remove material for shaping or to create a smooth surface. abrasives need to be harder than the material they are being used on in order for them to be effective.

what are abrasive grades?

the coarseness of an abrasive will affect how much material it removes as well as the smoothness of the surface. a coarse adhesive will remove material quickly, whereas a fine abrasive will remove material slowly and leave a smooth surface.

what is a grinder?

an abrasive compound embedded in a spinning disc. the material is held against the spinning disc and ground away. this process is used for shaping a form and removing marks from manufacturing.

what is a sander?

uses abrasives attached to a moving surface. the material is held against the surface and ground away. this process is used for shaping a form and removing marks from manufacturing.

what is polishing?

involves the use of compounds to achieve a very smooth surface with particular aesthetic qualities.

laser cutting…

injection moulding…

what do shaping techniques involve?

modifying the shape of a material using heat, pressure, and other forms of mechanical manipulation

what is a mould?

a hollow form into which a material like plastic, glass or metal is injected or placed. moulds allow for the accurate production of a product. designers need to consider the material and scale of production and match it to they type of moulding process.

what is injection moulding?

parts are produced by injecting a liquid material into a mould. as the material is heated and then cooled, it takes on the form of the mould. there is very little waste with this process. most commonly used with plastic, but also glass and metals also.

what is a use case for injection moulding?

solid forms, simple or complex shapes

most common type of plastic production method

what are the advantages and disadvantages of injection moulding?

advantages: highly accurate, fast production

disadvantages: requires expensive equipment, restrictions on part dimensions and forms

what is blow moulding?

the process of inflating a hot hollow plastic inside a mould. the heated material takes the form of the mould. also can use glass.

what are the use cases of blow moulding?

hollow forms such as drink bottles and containers

what are the advantages and disadvantages of blow moulding?

advantages: highly accurate, suitable for mass production, very low waste

disadvantages: high cost of equipment

what is compression moulding?

a heated sheet of thermoset plastic is places into a mould, the mould then applies pressure to shape the plastic.

what are the use cases of compression moulding?

flatware, tableware, electric plugs

what are the advantages and disadvantages of compression moulding?

advantages: lower production costs compared to other methods, ideal for high production costs, suitable for products requiring thick walls

disadvantages: limited to relatively simple forms

what is rotational moulding?

where a heated hollow mould is rotated as thermoplastic is poured in. the liquid plastic takes the form of the mould as it moves around the interior.

what is the use case for rotational moulding?

large hollow forms such as floats and toys where the inside surface is not important

what are the advantages and disadvantages of rotational moulding?

advantages: moulds are lower cost to produce, ideal for large forms, ideal for rigid and flexible shapes, low waste

disadvantages: material costs can be higher

what is thermoforming?

involves the heating of a sheet of thermoplastic to the point that it becomes pliable and soft. it is then placed into a mould to be formed into a shape. commonly uses vacuum forming.

what are the use cases of thermoforming?

disposable cups and containers, clamshell packaging and blister packaging, body parts for cars, machines or products.

what are the advantages and disadvantages of thermoforming?

advantages: high production speed, cost effective, low tooling costs

disadvantages: limitation on size and shapes

what is laminating?

the laying down of thin layers of materials joined with an adhesive

what are the use cases for laminating?

wood furniture, glass windows and plastic

what are the advantages and disadvantages of laminating?

advantages: cost effective, high strength to weight ratio, range of veneers can be applied

disadvantages: time consuming, bending requires special equipment and techniques

what is casting?

the pouring of molten metal into a mould. the shape that is produced is called a casting.

what are the use cases for casting?

cars, machine parts, heavy duty equipment

what are the advantages and disadvantages of casting?

advantages: complex shapes, range of scale

disadvantage: labour and energy intensive, may require finishing

what is a joining technique?

involves permanently or temporality connecting two or more similar or dissimilar materials

what are adhesives?

chemical substances that when dried creates a bond between two surfaces. needs to be carefully matched to the materials and use situations.

what is welding?

using high heat to join two similar metals together. their bond is very string. the high heat results in greater energy used and can deform the metal. great skill and specialised equipment is required.

what is brazing?

uses a (lower) heat and a filler metal to join two different metals together. uses less energy than welding and won’t deform the metal.

what is a permanent fastener?

a nail or rivet that binds two or more pieces together

what are the advantages and disadvantages of permanent fasteners?

advantages: low cost, easy to apply, create a strong mechanical bond

disadvantages: cannot be removed without damage, not for design for disassembly contexts

what are temporary fasteners used for?

used to join two or more dissimilar materials together, or in cases where pieces need to be joined and later separated.

what is design for manufacturing (dfm)?

refers to the manufacturing process driving the design process. as such, designers seek to optimise the process. when designers are selecting processes they should consider: material properties, cost and scale of production.