2.4.1 Production, Productivity, and Efficiency

1/39

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

40 Terms

Job production

involves the manufacture or delivery of one-off or a small number of items

↳ labour-extensive and expensive

benefits of job production

Can charge higher prices

Products tailored to customer needs

Motivated workers

disadvantages of job production

High costs

Slow production

Inconsistent work load

Batch production

involves the production of small quantities of identical products

↳ production is sped up making it less expensive

benefits of batch production

unit costs are lower because output is higher

production is flexible as each batch can vary

more use of machinery

disadvantages of batch production

more complex machinery needed = expensive

workers may be less motivated as they tend to be specialised in one process

Cell production

involves dividing the production into multi-skilled teams (cells) each responsible for a particular part

↳ combined elements of job and flow production

benefits of cell production

closeness of cell members should improve communication

workers become multi-skilled and more adaptable for future needs

greater work motivation

quality improves

disadvantages of cell production

workers may feel they are too pushed

may not allow a firm to use machinery as intensely as traditional flow production

the allocation of work : cells has to be efficient so they can cope

Flow production

involves the production of a large volume of identical products

benefits of flow production

economies of scale

quality stays consistent

high output efficiency

disadvantages of flow production

high initial machinery costs

machines can break

repetitive tasks may lower worker motivation

production

the level of output achieved by a business i.e. the total number of products produced in a given time

productivity

Productivity, on the other hand , is a measure of the rate of production

It is the amount of output that can be produced with a given input of resources

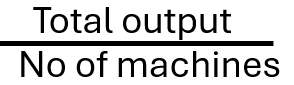

Factors influencing productivity of machinery

Age of machinery and maintenance

Training of operatives

Quality of inputs e.g. a high quality printer can jam if cheap paper is used

Hours used versus downtime

efficiency of programming

Unforeseen events e.g. power cuts

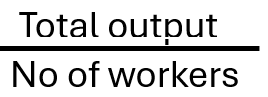

labour productivity

Labour productivity will be influenced by a number of factors including

Training and skills of the workforce

Motivation

Complexity of the product

Operational efficienc

involves maximising the output achieved from given inputs including machinery, materials and people

Efficiency can be improved using a number of methods, these include

Increasing capacity utilisation

Increasing labour productivity

Lean production techniques

Choosing the optimal resource mix, labour v capital intensive

Using technology

capital productivity

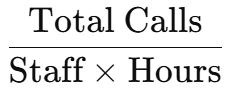

target productivity

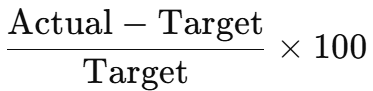

percentage difference for target productivity

Increasing labour productivity

lowers labour cost per unit (assuming employee costs stay the same) and hence unit cost

therefore it is important to use workers efficiently

labour productivity can be increased in a number of ways

Training

Increasing motivation e.g. financial or non - financial rewards, job design

Implement new technology

Better working practises

Improved recruitment and selection

why do firms want to increase productivity

to lower cost and increase profits

this makes them more competitive in the market

ways to improve productivity

specialisation and the division of Labour

Workers focus on specific tasks, increasing efficiency and output quality

Recruitment, selection and training

Hiring the right people and developing their skills boosts productivity

Motivation of workers

Motivated employees work harder and more efficiently

Working practises

efficient systems e.g. flexible hours or teamwork improve workflow and output

labour flexibility

Flexible workers can adapt to different roles, reducing downtime and increasing efficiency

technology

Automation and digital tools speed up production and reduce human error

If businesses can raise their productivity they will be able to produce more output with the same input resources. This will mean that cost will be lower. This enable businesses to be more competitive?

Lower costs mean the firm can reduce prices or increase profit margins. This allows the farm to compete better on price or reinvestment in quality or innovation

difficulties in increasing labour productivity

May impact negatively on quality and customer satisfaction

Damage to long term reputation

Increase waste affecting unit cost

Employees may feel exploited

Working harder for the same pay, may work with unions to negotiate higher wages

Business benefiting but not the employees

Increased workload leading to stress and demotivation

efficiency

this is about making the best use of a company’s resources

Operations management

involves combining the four factors of production or resource inputs:

Land

Labour

Capital

Enterprise

the optimal resource mix

the best way of combining the factors of production in order to meet these requirements within financial constraints

costs

often used to measure efficiencya

average unit costs

factors influencing efficiency

outsourcing

Hiring external firms can reduce costs and improve focus on core activities

relocating

Moving operations can lower labour or rent costs and improve access to resources

downsizing

reducing staff cuts costs and removes inefficiencies but may risk lower morale

delayering

Removing management layers speeds up communication and decision making

investing in new technology

Modern equipment boost speed, accuracy, and lower long term costs

lean production

minimising waste and maximising value improves efficiency and reduces costs

labour intensive

uses a relatively high proportion of labour i.e. workers in the production of a good or service

Production relies on human workers than machines

common in service industries or tasks needing personal input

tends to occur in the tertiary sector

capital intensive

uses a relatively high proportion of capital such as machinery in the production of a good or service

Production relies more in machinery and technology than Labour

Often used in mass production or automated industries

tends to occur in the secondary sector of economy i.e. manufacturing

advantages of capital intensive

Increased productivity

Improved quality and speed

Reduced labour costs

Greater opportunities for economies of scale (the benefits to a business of producing on a large scale that lead to a fall in unit costs)

disadvantages of capital intensive

High investment outlay

Lack of human initiative

Greater resistance to change by workforce e.g. retraining to use new equipment

advantages of labour intensive

Often cheaper, especially when produced in low wage locations

Workforce can easily adapt to change, especially if multi-skilled

Continuous improvement through workforce can benefit the firm e.g. new ideas

Government funding often available to protect jobs in the economy

disadvantages of labour intensive

Industrial relations can be a problem e.g. strikes

Lack of skilled workers in some industries

HRM costs can be very high e.g. recruitment, selection and training