Ch07

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

17 Terms

What causes plastic deformation in metals?

Motion of dislocations (ความคลาดเคลื่อน/ตำหนิในโครงผลึก).

What is slip?

The process of plastic deformation by dislocation motion (การเลื่อนตัวของระนาบอะตอม).

What is a slip system?

Combination of slip plane (ระนาบลื่น) and slip direction (ทิศทางลื่น).

Which crystal structure has the most slip systems and is very ductile (เหนียว)?

FCC → 12 slip systems.

?!

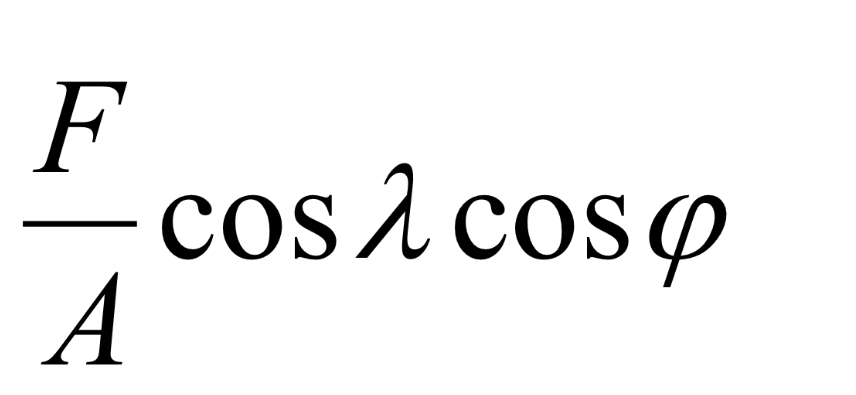

the equation for resolved shear stress (τR)

What is CRSS (Critical Resolved Shear Stress)?

The minimum shear stress (ค่าความเค้นเฉือนวิกฤติ) required to initiate slip.

In polycrystalline materials, what is the difference before and after rolling (การรีด)?

Before: grains equiaxed & random → isotropic (สมบัติเท่ากันทุกทิศ).

After: grains elongated → anisotropic (สมบัติขึ้นกับทิศ).

three strengthening mechanisms.

Grain size reduction (ลดขนาดเกรน).

Solid solution strengthening (การเสริมความแข็งด้วยสารละลายของแข็ง).

Strain hardening / Cold work (การแข็งตัวจากการแปรรูปเย็น).

How does grain size reduction strengthen metals?

Smaller grains → more grain boundaries → dislocation motion hindered.

How do impurity atoms strengthen metals (solid solution strengthening)?

They distort the lattice (บิดเบี้ยวโครงผลึก) and make dislocation motion harder.

Why does cold working increase strength?

More dislocations created → dislocation–dislocation interactions → block motion.

What are the three stages of annealing (การอบคืนไฟ)?

Recovery (ฟื้นตัว)

Recrystallization (ตกผลึกใหม่)

Grain growth (เจริญเกรน)

Recovery (การฟื้นตัว)

Dislocations rearrange and annihilate, reducing internal stresses. Electrical and thermal conductivity are restored. Strength changes little.

Recrystallization (การตกผลึกใหม่)

New strain-free grains with low dislocation density form, replacing deformed grains. Strength decreases, ductility increases significantly

Grain Growth (การเจริญของเกรน)

If heating continues, grains grow larger. Strength decreases further, ductility increases, but too much grain growth may weaken the metal.

What are the property changes after annealing?

Metal becomes softer (นิ่มลง), weaker (อ่อนแรงลง), but more ductile (เหนียวขึ้น).

What are the property changes after annealing compared to cold work

Cold work: Strength ↑, Hardness ↑, Ductility ↓.

Annealing: Strength ↓, Hardness ↓, Ductility ↑.