Materials Exam 2

1/119

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

120 Terms

Dislocation motion results from what form(s) of stresses?

Shear Stresses

Which are properties of dislocations. Choose all that apply.

Dislocation motion in metals is generally easier in metals than ionically or covalently bonded materials

Dislocations interfere with each others motion through the lattice

Dislocations can multiply

Compressive and tensile stress fields exist around dislocations

What type of stress fields lies below a dislocation?

Tensile Stress Fields

What type of stress fields lies above a dislocation?

Compressive stress fields

If a compressive stress field is aligned with a tensile stress field, what is happening to the dislocations associated with each stress field?

The dislocations are being attracted to each other.

The slip system in a FCC crystal structure is

{111}<110>

Compare how the number of slip systems between different crystals relate

FCC=BCC>HCP

The criteria for tensile strength of metals based on crystal structures is evaluated by what 3 parameters?

Number of available slip systems

Density of slip planes/directions

Strength of bonds

In a FCC gold (Au) single crystal, a tensile stress of 210 MPa is applied along the [010] direction. Compute the resolved shear stress along the [111] direction on the (110) plane. The angles and are 54.7o and 45o. The critical resolved shear stress of this system is 118.36 MPa. From the options below, select what the resolved shear stress is and if it will result in slip (so select 2 of the 4 options below)

85 MPa

No, it will NOT slip

A single crystal metal is oriented such that the normal to the slip plane and the slip direction are at angles of 45oand 48o, respectively with the tensile axis. If the critically resolved shear stress is 890 psi what stress is necessary to initiate slip (in psi)?

1881

What are the 4 strengthening mechanisms common to all metals?

Work hardening

Second phase precipitation strengthening

Solid solution strengthening

Grain boundary strengthening (grain size reduction)

Grain boundaries hinder dislocation motion. If I want a strong steel rod, the best grain size would be…because it has the…

Highest grain boundary area

5 micrometers

What if the mechanism and effect of the recovery stage?

Mechanism: Reduction in lattice energy by removal of vacancies, interstitials and some dislocations by diffusion.

Effect: Mechanical properties are not drastically altered. Grains still have relatively high dislocation density and high internal strain

What is the mechanism and effect of recrystallization?

Mechanism: new dislocation free grains form at the old grain boundaries via atomic diffusion.

Effect: Strength & hardness decreases while ductile & toughness increases.

What is the mechanism and effect of grain growth?

Mechanism: Grain size increases, resulting in a decrease in lattice energy that comes from a high grain boundary surface area.

Effect: The microstructure is large, strain free grains. Strength & hardness decrease further; ductile & toughness increase

I have a steel ingot that has been beautifully cast. It has a homogeneous microstructure and nearly no internal defects. But, I need my grain structure to be as fine as possible. I want a higher strength!!! I am not worried about final shape. I just want good strength without a high dislocation density. Which of the following processes should I use?

Cold work > recovery > recrystallization

For hardening by second phase precipitates (and not by the precipitation harding mechanism) which situation probably offers a higher strength in a metal?

A microstructure whose 2nd phase is greatly out of alignment with the atomic planes of the matrix phase.

A superalloy fan disk from a jet engine undergoes a routine certification analysis and is found to contain a small void with a length of 7.7 mm and a crack tip radius of approximately 2 m. Determine the stress concentration factor expected for this defect.

89

True of False: The blunter the crack tip, the higher the magnified stress at said crack tip.

False

The total length of an internal crack is… while the total length of an external crack is…

2a

a

Brittle Material Failure characteristics

Almost no plastic deformation

Sharp, angular surfaces

Catastrophic failure

Ductile Material Failure Characteristics

Bending/yielding before failure

Rounded or blunted surfaces

Plastic deformation obvious before failure

The most common type of failure (in metals) is?

Fatigue

The WWII Liberty Troop transports failed mainly due to which mechanism?

Low temperature embrittlement

Which of the following statement(s) is/are true about plastic deformation in ductile metals?

It is the result of dislocation motion

It begins once the yield strength of the material is surpassed

It is permanent deformation

A dislocation moves best in a … and a …

Slip direction with high LPF

Slip plane with high PPF

During strain hardening…

dislocation motion becomes mpore difficult

dislocation stress field interactions increase

Dislocation density increases

Select all the factors, that if increased, will cause the magnified stress at the crack tip to also increase.

Applied stress

Crack length

Which of the following methods would NOT help engineer against creep?

Low stiffness

A structural component in the form of a wide plate is to be fabricated from a steel alloy that has a plane strain fracture toughness of 93 MPa-m1/2 and a yield strength of 864 MPa. If the design stress is one-half of the yield strength, what is the critical flaw length in mm? Assume Y = 1.13.

11.6

A flat metal plate has an internal crack with length 2.2 mm. What is the maximum tensile stress, in MPa, the plate can experience without failing? The plane strain fracture toughness of the metal is 42 MPa-m1/2. Assume a plane strain fracture geometry, mode I with Y = 1.0.

714

Higher carbon phase

Fe3C, Cementite

Lower Carbon Phase

Alpha Ferrite

Pearlite can be seen on cooling through the steel eutectoid. What is pearlite?

A microstructure composed of two phases

A hypoeutectoid steel, upon cooling to room temperature, will have what microstructure?

Grain of proeutectoid alpha ferrite, and grains of pearlite

A hypereutectoid steel, upon cooling to room temperature, will have what microstructure?

Grains of proeutectoid cementite, and grains of pearlite

A eutectoid steel, upon cooling to room temperature, will have what microstructure?

Grains of pearlite

A hypoeutectoid steel, upon cooling to room temperature, will have what phases present?

Ferrite and Cementite

Low Nucleation Rate, High Growth Rate

High Temperatures

Maximum overall transformation rate

Middling Temperatures

High Nucleation Rate, Low Growth Rate

Low Temperatures

What is the fraction of ferrite phase in a steel that has a 100% pearlitic microstructure (i.e. no pro-eutectic phases)

89%

What is the compositions of the ferrite phase in a hypereutectic steel that has a an overall composition of 1.3 wt% carbon.

0.022 wt%C

Spheroidite

"large" grains of cementite in a continuous ferrite matrix

Pearlite

layers of cementite and ferrite

Bainite

Needles of cementite in a continuous ferrite matrix

Martensite

a BCT phase of steel

Tempered Martensite

“tiny” grains of cementite in a continuous ferrite matrix

Toughness in steel is obtained by having a continuous ferrite matrix

True

Bainite Diffusion Dimension

1D

Pearlite Diffusion Dimension

2D

Spheroidite Diffusion Dimension

3D

Martenstite

No diffusion

Pearlite cooling rate

slow cooling

Tempered Martensite cooling rate

rapid quench followed by a reheat

Martensite cooling rate

rapid quench

Bainite cooling rate

Moderate cooling

Spheroidite cooling rate

verrrry slow cooling

What phases are typically present in tempered martensite?

cementite

ferrite

Martensite strength

Highest strength

tempered martensite strength

higher strength

Bainite strength

high strength

pearlite strength

average strength

spheroidite strength

lowest strength

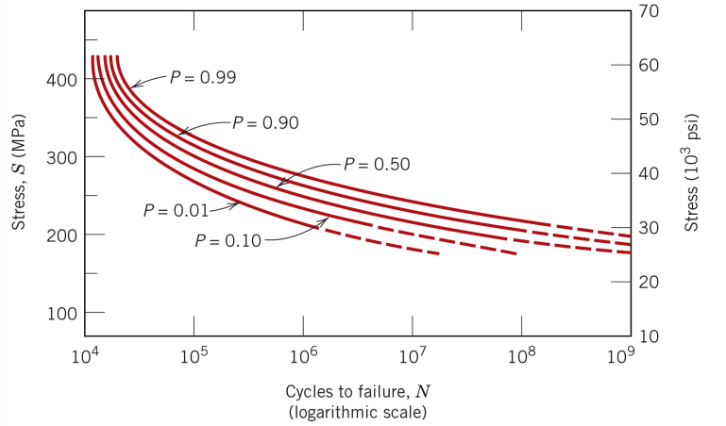

Metal components will be subjected to an environment where they will experience asymmetric cyclical with maximum tensile and compressive stresses of 400 and 100 MPa, respectively. Determine the anticipated number of cycles until failure for 90% of the components.

3×10^6 cycles

TTT Curves differ from phase diagrams, select which reason best explains why.

TTT Curves show what transformations occur when cooled at non-equilibrium rates, phase diagrams only show equilibrium transformations

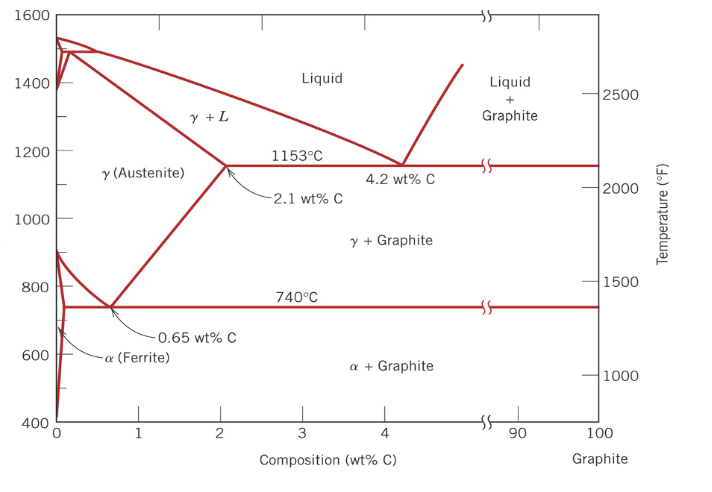

Most cast irons contain C in the form of graphite.

True

Cast irons typically have compositions that contain…

more carbon than most steels

Cast irons all generally contain more than … wt% C.

2.1

An alloy system that can effectively be precipitation hardened must have both a … and a …

an appreciable maximum solubility of one component in the other

a steep solvus line

The most brittle steels are generally?

High carbon steels

Titanium is a strong yet ductile metal due to its HCP crystal structure

False

Titanium forms an incoherent oxide

False

Method of the “forming” category

Rolling

Extruding

Method of additive manufacturing

Power Bed Fusion

Direct Energy Deposition

Methods that involve pouring liquid metal

Lost Foam Casting

Sand Casting

Titanium is highly sought in manufacturing because…

Less dense than steel

Higher specific mechanical properties than steel

Titanium is exceptionally corrosion resistant

Element X assumes a diamond cubic crystal structure. If the atomic radius of X is 0.199 nm, what is the lattice parameter of its unit cell in nm?

0.92

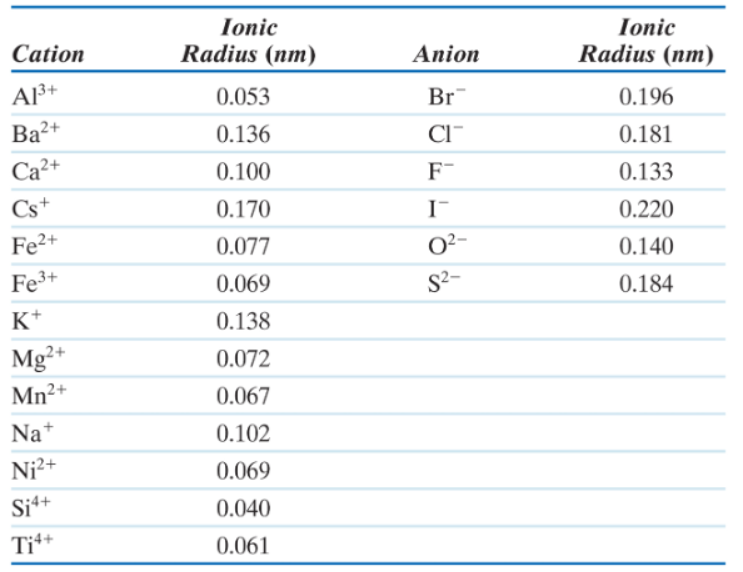

As the ionic radius in an ionic compound increases, the coordination number?

increases

Ceramic materials typically have which of the following characteristics?

High compressive strength

Hard

Brittle

The radius of the atoms in a covalently bonded DC lattice ceramic material is 0.126 nm. Determine the lattice parameter of the unit cell in nm?

0.582

Determine the density (in g/cm3) of an AX ionic compound in which the ionic radii and atomic weights of the cation and anion are given below:

cation: radius = 0.100 nm A = 37.9 g/mol

anion: radius = 0.186 nm A = 41.6 g/mol

2.82

The radius ratios for the ions in an AX ceramic compound are given below. Determine the coordination number of the bonding.

0.502

Octahedral (6)

The radius ratios for the ions in an AX ceramic compound are given below. Determine the coordination number of the bonding.

0.800

Cubic (8)

The radius ratios for the ions in an AX ceramic compound are given below. Determine the coordination number of the bonding.

0.305

Tetrahedral (4)

The radius ratios for the ions in an AX ceramic compound are given below. Determine the coordination number of the bonding.

1.050

Dodecahedral (12)

For anions in an ionic crystal structure, which of the following properties are generally true?

negatively charged

gain valence electrons

typical larger than cation

Barium titanate is a piezoelectric material. Each unit cell of BaTiO3 has an electrical dipole associated with it because the center of cation positive charge in the unit cell is not coincident with the center of negative anion charge.

True

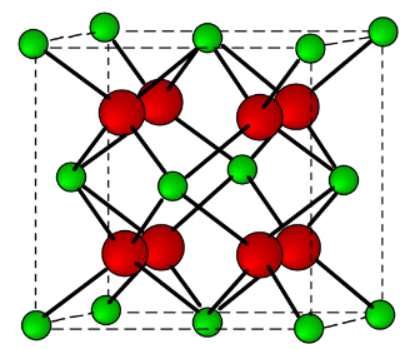

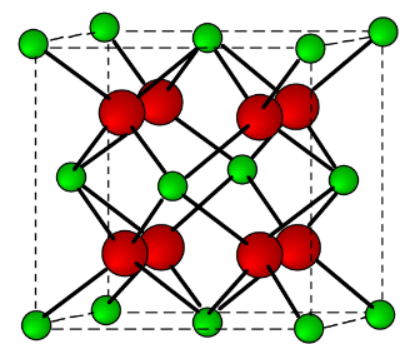

A ceramic material has the crystal structure depicted below. If the charge on the smaller, green cations is +4, what must the charge be on the larger, red anions for this structure to be electrically stable?

-2

Quartz, fused silica and cristobalite are silicates that all share ___ corner oxygen atoms between SiO4-4 tetrahedra?

4

Networks modifiers "break up" the SiO4-4 tetrahedral network in fused silica glasses. The common network modifiers are Na, Ca and B. Match these elements to the type of bond it forms in the silica glass?

B

Bridging bond between 3 tetrahdra

Networks modifiers "break up" the SiO4-4 tetrahedral network in fused silica glasses. The common network modifiers are Na, Ca and B. Match these elements to the type of bond it forms in the silica glass?

Na

Terminating bond

Networks modifiers "break up" the SiO4-4 tetrahedral network in fused silica glasses. The common network modifiers are Na, Ca and B. Match these elements to the type of bond it forms in the silica glass?

Ca

Bridging bond between 2 tetrahdra

Stainless steels all contain what other alloying element other than carbon?

chromium (Cr)

What is the most probable crystal structure of MnS assuming bonding in this material is mostly ionic in nature.

zinc-blende

Precipitation hardened alloys achieve strength by?

Introducing coherent, second phase particles that impost stress on the lattice

The precipitation hardening process proceeds in the following order

formation of solid solution

quenching

heating to allow controlled precipitation

When a precipitation hardened alloy is overaged, the results are?

formation of incoherent precipitate

decreased strength

Ceramic materials typically have which of the following characteristics?

High electrical resistivity

Brittle

High compressive strength

Hard

This is the fluorite structure. Based on the arrangement of anions, what is the Bravais lattice for this structure?

SC