POLYMERISATION

1/53

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

54 Terms

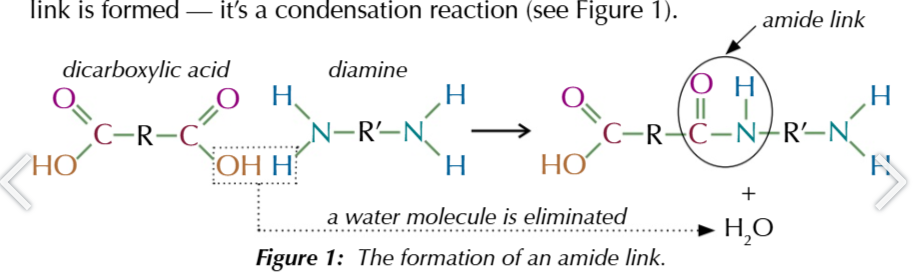

condensation polymerisation

involves 2 different types of monomer, each with at least 2 functional groups

each functional group reacts with a group on another monomer to form a link

creating polymer chains

as each link is formed

a small molecule is lost, usually water hence the name

examples of condensation polymers

polyesters

polypeptides (proteins)

polyamides

polyester link

(-COO-)

polyamide/polypeptide link

(-CONH-) aka peptide bonds

Dicarboxylic acid + diamides =

polyamides + H2O

because dicarboxylic acids and diamines have functional groups on both ends

they cna each form 2 amide links and long chains can be formed

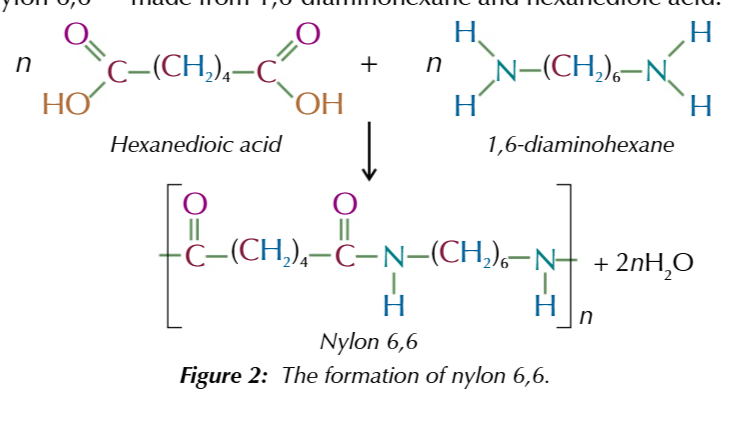

important polyamine reaction 1:

n [hexanedioic acid] + n [1,6-diaminohexane] = [nylon 6,6]n +[2H2O]n

![<p>n [hexanedioic acid] + n [1,6-diaminohexane] = [nylon 6,6]n +[2H<sub>2</sub>O]n</p>](https://knowt-user-attachments.s3.amazonaws.com/5636f019-20f7-4247-a014-685f1a9ca307.png)

nylon is strong and resistant to abrasion so has many uses:

clothing

carpet

rope

airbags

parachutes

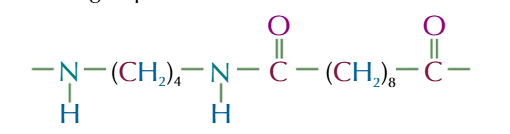

important polyamide reaction 2:

n [benzene-1,4-dicarboxylic acid] + n [1,4-diaminobenzene] = [Kevlar]n+ [2H2O]n

Kevlar is light and strong so has many uses:

bulletproof vests

boat construction

car tyres

lightweight sports equipment

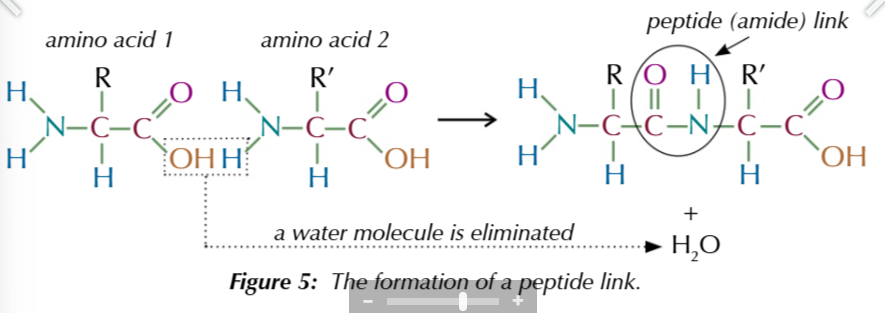

amino acids contain 2 functional groups

carboxylic acid and amine functional groups

amino acids react in a condensation reaction to form

peptides

amino acids contain chiral carbons

1 carbon is attached to NH2,H,COOH and R

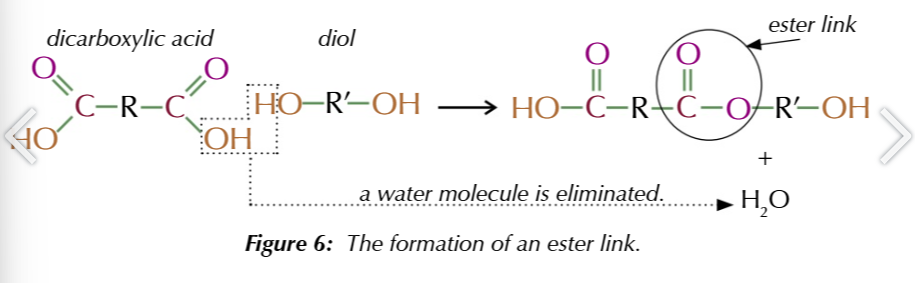

dicarboxylic acids + diols =

polyesters, the H from diol and OH from dicarboxylic form the water released +ester link

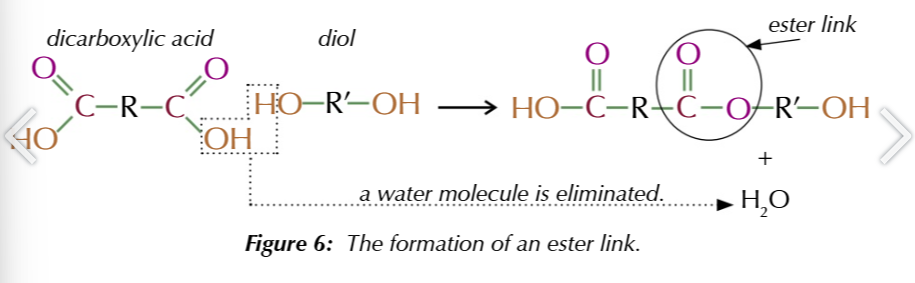

important polyester reaction:

n [benzene 1,4-dicarboxylic acid] + n [ethane-1,2-diol] → n[Terylene] + 2n[H2O]

hydrolysis

using water to split a molecule

![<p>n[monomer]<sup> condensation</sup>⇄<sub>hydrolysis</sub> polymer + water</p>](https://knowt-user-attachments.s3.amazonaws.com/22a3cdef-182c-40e8-8394-a4349d7fda5e.png)

n[monomer] condensation⇄hydrolysis polymer + water

n [polyamide] + 2n[H2O] → n [dicarboxylic acid] + n [diamine]

![<p>n [polyamide] + 2n[H<sub>2</sub>O] → n [dicarboxylic acid] + n [diamine]</p>](https://knowt-user-attachments.s3.amazonaws.com/aa3f2cf5-9a77-4ccd-9c7d-a57ae9785c70.png)

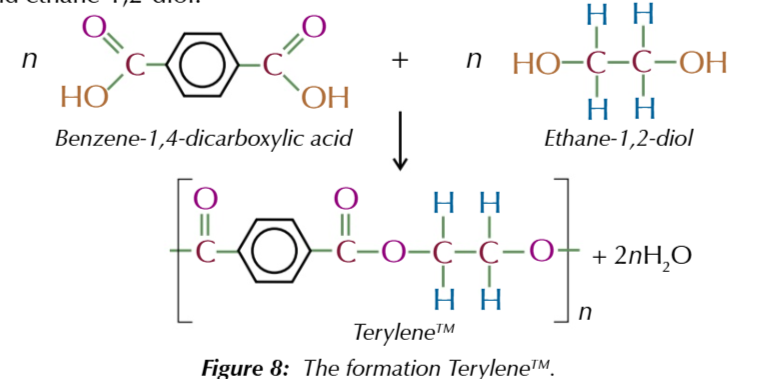

n [polyester] + 2n [H2O] → n [dicarboxylic acid] + n [diol]

in practice, water hydrolysis is too slow

in a lab the reaction is done using acids/alkalis

polyamides hydrolyse better in acidic conditions

polyesters hydrolyse more easily in basic conditions

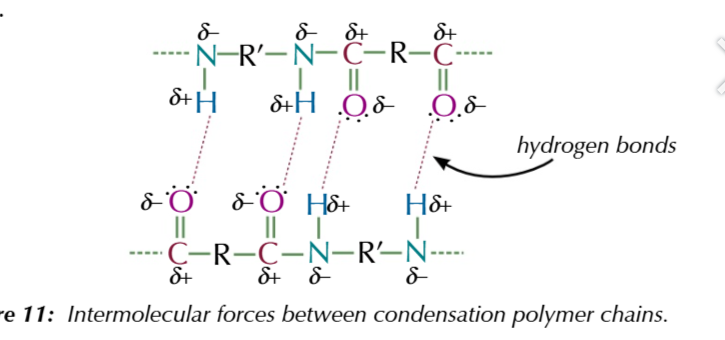

condensation polymers are generally stronger and more rigid than addition polymers

because condensation polymers chains consist of C=O and C=N polar bonds

these bonds + induced dipole-dipole forces + permanent dipole-dipole forces + hydrogen bonds between the polymer chain make it extremely strong

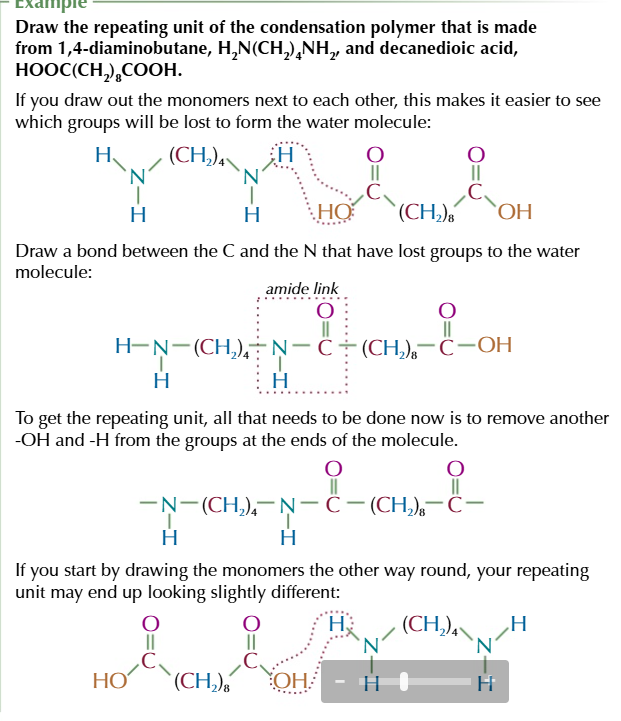

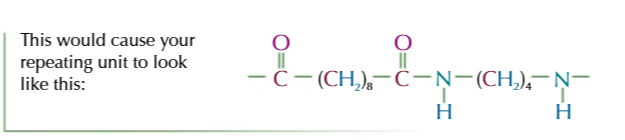

condensation polymers are made up of repeating units

if you know the formula of a pair of monomers you can work out the repeating unit of condensation polymer you form

steps to find the repeating unit of polyamides from diamines and dicarboxylic acids

draw out the 2 monomers

remove the OH from the dicarboxylic acid and the H from the diamine to create a water molecule

coin the C=O AND N together to make an amide link

take the H off the other NH2 and OH off the other COOH at the ends of your molecule

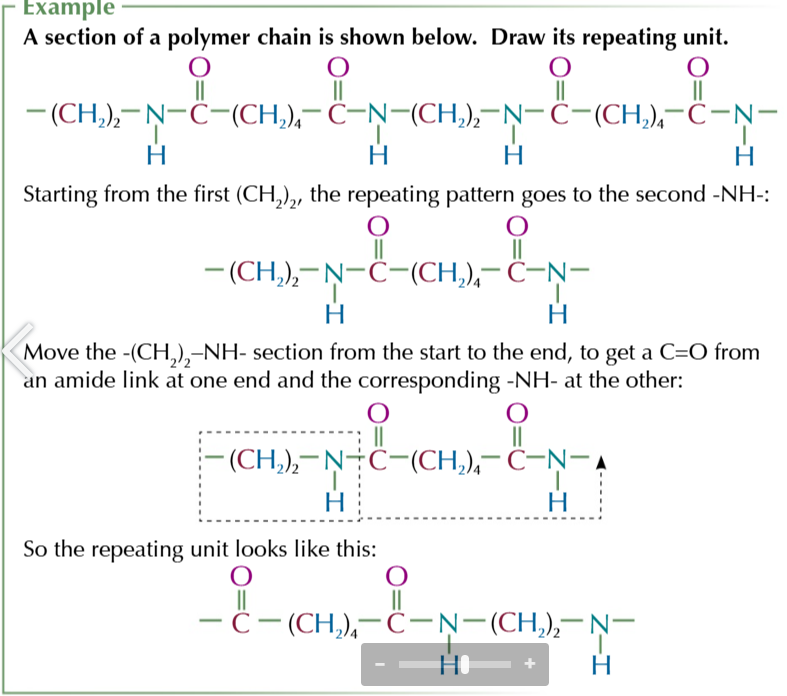

how to find the repeating unit from a longer chain section of polyester/polyamide

look along the chain and find the repeating pattern

starting from 1 end write out the chain until you get the end of the repeating section

the repeating unit should have a C=O from an ester/amide link and 1 end and the -O-/-NH- part of the link at the other end

if the secon youve written DOESNT find the amide/ester link, breake it and move the bit you’ve broken off from one end of the unit to the other

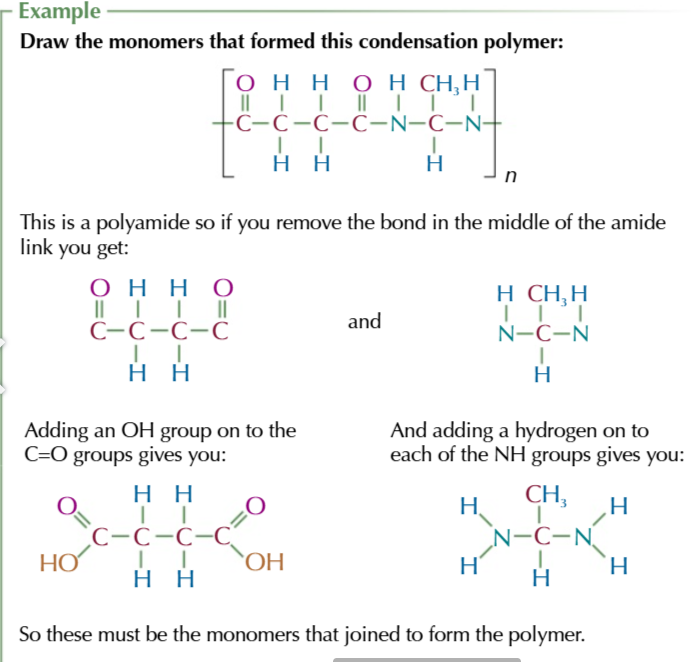

how to identify monomers

find the repeating unit

remove the bond in the middle of the central amide/ ester link:

-C=O group and -NH group in polyamides

-C=O group and Oxygen in polyesters

add -OH groups to the -C=O to make carboxylic groups

add H to NH to make NH2 in polyamides

add H to Oxygen to make -OH groups and add it to any terminal carbon atoms in polyesters

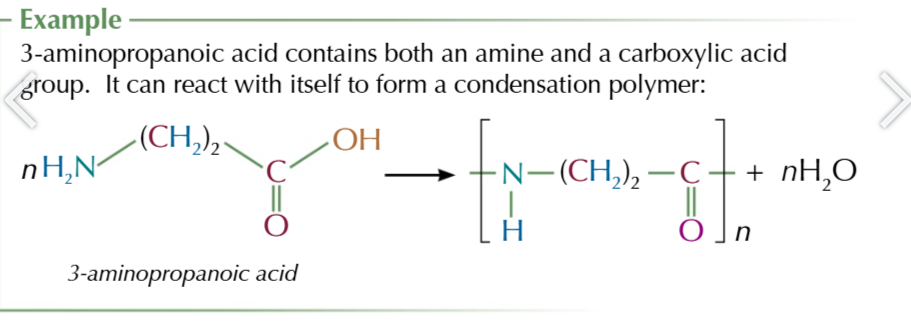

if an molecule can contain a carboxylic acid group AND an alcohol group/ amine group

it can polymerise with itself to form a condensation polymer with only 1 monomer

this is the case for amino acids which contain a carboxylic acid group AND amine group

they polymerise to form peptides

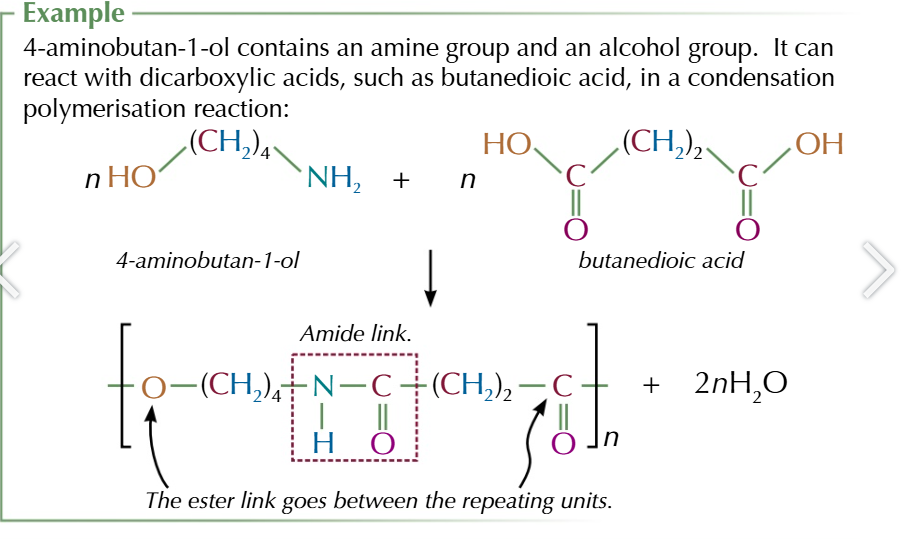

molecules with an amine group AND alcohol group can react with dicarboxylic acids in a condensation polymerisation reaction

the polymer they form contain both amide and ester links

synthetic polymers have loads of advantages

they are incredibly widespread

polyalkenes examples

polystyrene and polyethene

polyalkenes are chemicall inert

because the bonds between the repeating units are non polar (so not prone to nucleophilic attacks)

an advantage of being chemically inert

polystyrene wont react with coffe

disadvantage of being chemically inert

non biodegradable (their bonds can’t be hydrolysed and wont break down naturally)

condensation polymer examples

PET (a polyester that’s used to make fizzy drink bottles and carrier bags)

nylon (a polyamide)

condensation polymers CAN be broken down via hydrolysis

because the bonds between repeating units are polar so susceptible to nucleophilic attacks like by water

condensation polymers are biodegradable

they will break down naturally over a long period of time

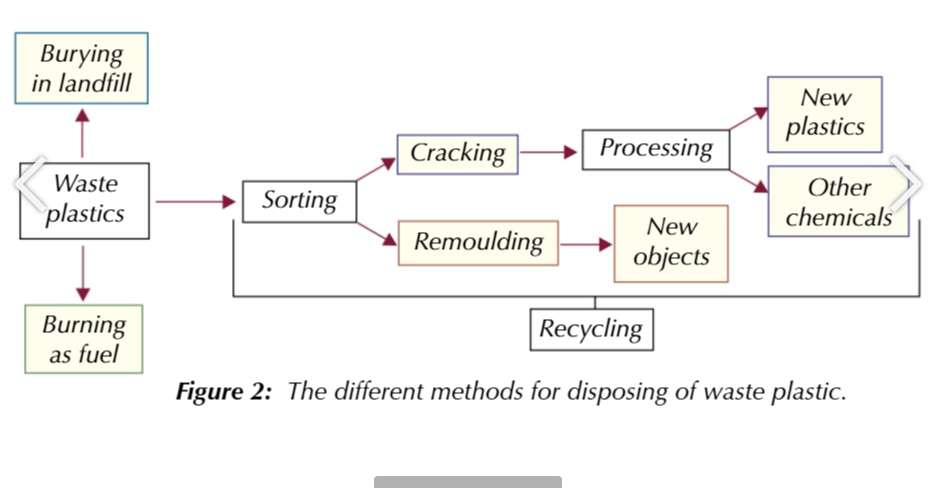

since plastics are either non biodegradable or biodegrade over a long period of time

the question becomes what to do with the 3 million tons of plastics thrown away every year

landfills are used when plastics are difficult to seperate from other waste

and what can be seperated is too little for the process to be financially worthwhile

and too difficult to recycle

landfill is a relatively cheap and easy method of waste disposal HOWEVER:

required areas of land

as waste decomposed it can release methane (GHG)

as waste decomposes it can release toxins which can be washed away and contaminate water supplies

waste plastics can be burned

and their heat used to generate electricity

burning plastics can release toxic gases so you must be careful

for example, polymers containing chlorine like PVC when burnt can release HCl

waste gases from the combustion are passed through scrubbers

this neutralises gases such as HCL by reacting them with bases

carbon dioxides is also a waste gas

which will contribute to global warming

many plastics are made from non renewable oil fractions

plastics need to be recycled as much as possible

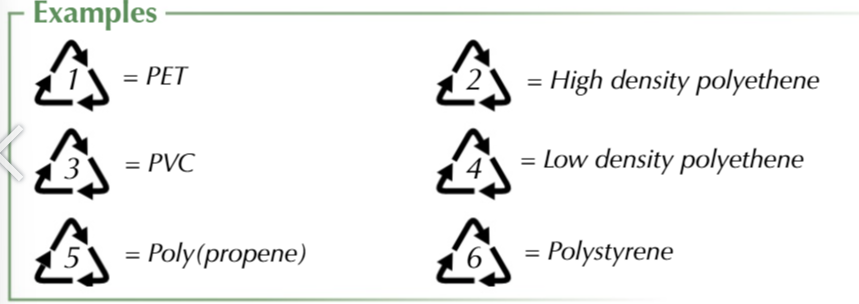

after sorting into different types of plastics

they can be melted and remoulded OR cracked into momomers which can me used to make more plastics/chemicals

plastic products are marked ot make sorting easier

advantages of recycling plastics

reduces the amount of waste going to land fills

saves raw materials which is important because oil is non renewable

the cost of recycling plastics is lower than making new plastics from scratch

produces less CO2 emission than burning plastcs

disadvantages of recycling plastics:

technically more difficult to recycle plastics

collecting sorting and processing plastics is mroe expensive than burning/landfills

often cant remake the plastic you started with, will have to make something else

plastics can be easily contaminated during recycling