Compliant Materials

1/64

Earn XP

Description and Tags

3.1.2 Compliant Materials Product Design AQA A-Level

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

65 Terms

What is a compliant material

A material that can be easily worked using basic hand tools

What are the four types of compliant materials

Paper

Board

Foam

Film

How is paper made

Plant fibres are converted into a pulp before being pressed and rolled into sheet form

What are the generic properties of paper

Comes from a sustainable source

Available in a wide range of finishes, colours and weights

Easily recyclable as paper products have short lifecycles

What are the 5 types of paper

Treated paper

Layout paper

Bleedproof paper

Cartridge paper

Watercolour paper

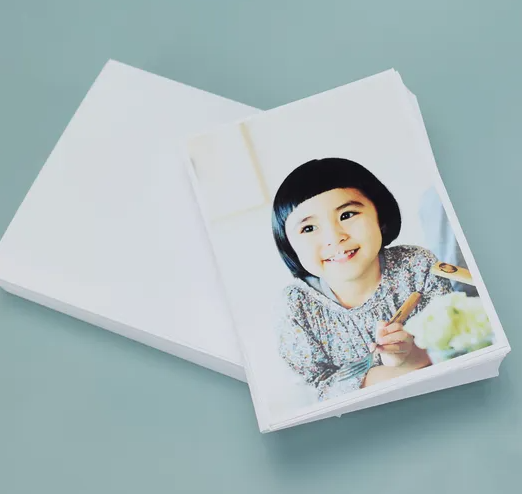

What are the properties and uses of treated paper

High quality paper available in a range of thicknesses and finishes

Used for printing high quality images and graphics

What are the properties and uses of layout paper

A strong paper with a degree of transparency

Used in the production of technical drawings and as overlays when tracing designs

What are the properties and uses of bleedproof paper

Coated on one side to prevent ink bleeding

Used with markers

What are the properties and uses of cartridge paper

Available in a range of finishes and weights

Used for quality drawings and graphics

What are the properties and uses of watercolour paper

An extremely heavyweight paper produced from cellulose and cotton fibres

Used in water based drawings as it does not distort with water

What is cardboard

Any multi-layered paper product

What is the generic properties of cardboard

Inexpensive

Can be scored, cut and folded into a net

Can be mass produced using die cutting

Can be easily printed on using flexography

Increased rigidity

Why is cardboard being inexpensive good

Important in a mass-produced disposable product

Why is cardboards increased rigidity useful

Makes it suitable for packaging boxes

What are the 5 types of cardboard

Corrugated card

Duplex board

Laminated / foil-backed card

Metal effect card

Mountboard

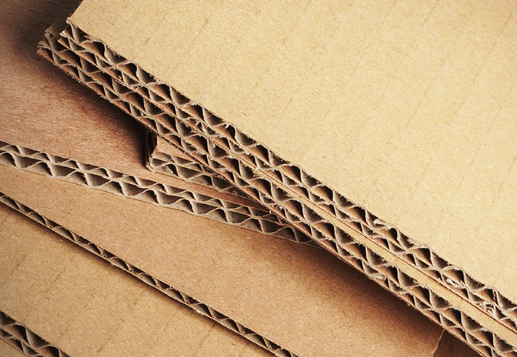

What are the properties and uses of corrugated card

Smooth on both sides with flutes inside to increase rigidity and shock absorption, easily printed on with flexography

Used in transportation boxes

What are the properties and uses of duplex board

Card with one high quality face suitable for printing onto and one natural card face

Used in the production of cereal and dried food boxes

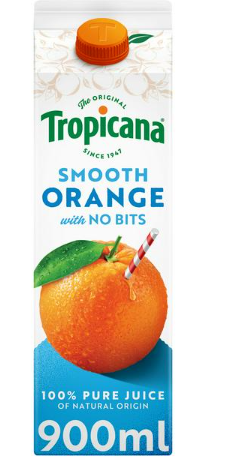

What are the properties and uses of laminated / foil-backed card

Card with aluminium foil or metallised polyester film on one side for decoration / hygiene. difficult to recycle

Used in the production of drink cartons and food packaging

What are the properties and uses of metal effect card

Card with a metallic finish applied to one side

Used in the production of packaging and gift boxes

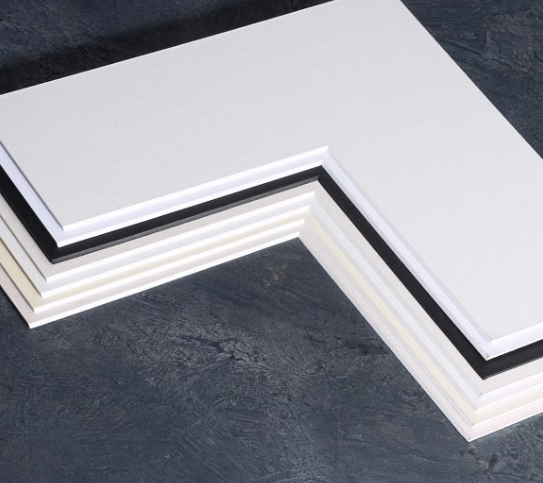

What are the properties and uses of mountboard

Card with greater than 1mm thick with high quality faces for displaying photographs or sketches

Ideal for model making

What is foam

A lightweight polymer construction with air pockets used for model making

What are the generic properties of foam

Lightweight cellular construction

Cushions impact due to elasticity of material

Easily workable with simple hand tools

Lack of grain structure means finish is uniform and stable

What are the 3 types of foam

Foamboard

Plastazote foam

Styrofoam

What are the properties and uses of foamboard

Two external layers of high quality gloss card with expanded foam centre for lightweight and rigidity, available in a bright white finish for aesthetics

Used for 3D architectural modelling and displays for printed graphics

What are the properties and uses of plastazote foam

A close celled polyethylene foam available in a wide range of colours

Used for model and prop making

What are the properties and uses of styrofoam

An easily shaped polystyrene foam with lightweight and fine surface finish

Used extensively in quick concept generation by designers

What is film

Thin flexible polymer materials used for hygeine / aesthetic purposes

What are the generic properties of foam

Thin flexible sheet material

Produced using calendaring

Used in packaging for aesthetic appeal

What is the name of the film

Cellulose Acetate

What are the properties and uses of cellulose acetate

Easily printed on and die cut film

Used in transport and packaging for its bright colours and clear windows

What is a polymer sheet

Polymer sheets are used in packaging and product design due to their flexibility and weather resitance

What are the generic properties of polymer sheets

Thin flexible sheet material

Produced using calendaring

Moisture and weather resistant

What are the 4 types of polymer sheets

Fluted polypropylene sheet

Translucent polypropylene sheet

Low density polyethylene sheet

Polyactide sheet and film

What are the properties and uses of fluted polypropylene sheet

Low density, rigid structure of polymer with hollow box section channels running between two thin polymer sheets, weather resistant and suitable external use

Suitable for printing on using flexography

What are the properties and uses of translucent polypropylene sheet

Flexible polymer, chemically resistant, easily laser cut, suitable for repeat bending

Used in packaging

What are the properties and uses of low density polyethylene sheet

A low density polymer sheet, chemically resistant, suitable for flexographic printing

Used in carrier bags

What are the properties and uses of polyactide sheet and film

A biodegradable alternative to low density polyethylene sheet

What are the properties and uses of moulded paper pulp

Made from recycled paper with water added to break down the fibres, reformed using heat and pressure to press into a mould, fully compostable meaning can be thrown into a compost bin, can be printed on once formed

Used in packaging such as egg boxes and to support electronic products as a replacement for expanded polystyrene.

What is a substrate

The material that the print ink is applied.

What is screen printing

A printing process used to apply an ink design to a flat surface.

What is the main use of screen printing

Ideal for small production runs and is very popular in producing personalised t-shirts, clothing and poster designs

What is the advantages of screen printing

-Stencils are easy to produce using a photo emulsion technique

-Versatile - can print on any flat surface

-Economical for short, hand produced runs

-Fully automatic methods capable of producing large volumes

What are the disadvantages of screen printing

-Generally difficult to achieve fine detail

-Requires long drying times

-Can only be done on a flat surface

What is the main use of offset lithography printing

Mainly used for large scale production (100,000 +) copies on porous substrates only. Mainly used on printing of card and paper for packaging

What is the advantages of offset lithography printing

-Consistent high image quality

-Suited to higher volumes print runs of 100,000 or more

-Quick and easy production of printing plates

-Long life of printing plates because they only come into contact with the printing blanket which is softer and less abrasive than the substrate

What are the disadvantages of offset lithography

-Expensive setup and running cost for small quantities

Name the 4 process colours used in offset lithography

CMYK

Cyan, Magenta, Yellow, Black

What are registration marks used for

To check that the colours are correct and that everything is aligned

What are the 4 printing processes

-Screen printing

-Offset lithography printing

-Digital printing

-Flexography printing

What is flexography printing mostly used for

Large scale production (100,000 +), copies on porous and non-porous substrates. An ideal alternative to Offset Lithography due to fast setting inks and suitability for printing on polymers, metals and corrugated card

What are the advantages of flexography printing

-High print speed

-Ideally suited for long production runs

-Prints on large variety of substates including both porous and non-porous

What are the disadvantages of flexography printing

-Cost of printing plates is high (they last for millions of runs though)

-Take a large amount of substrate to set up so there might be excess material wasted

-Any alterations to the graphic is time consuming and expensive as new printing plates must be produced

What is digital printing

Digital printers looks similar to large photocopiers and produce full colour, highly detailed print runs with the option for different designs and to print on both sides. They work similar to laser printers allowing the the ink to sit on top to be dried.

What is the main use of digital printing

Can be use for both low and high volume of prints. Used for mass customisation particularly for business flyers or cards

What are printing processes

They allow the designer and manufacturer to attract a consumer to a product as well as communicate information to the consumer. Colours images and text can provide aesthetic appeal as well as communicate barcodes, safety informations and ingredients

What are surface graphics

The process of adding a graphic to something already been printed on to enhance the aesthetic of functional properties of the design.

What are the 4 surface finishes

-Laminating

-Embossing / debossing

-Foil blocking

-Varnishing

What are the 2 types of lamination

-Lamination via encapsulation

-Lamination via a surface coating

What does lamination do

Coat the paper to protect it making it more durable

How is lamination via encapsulation applied

Seals a sheet of paper inside a polymer pouch creating a non-porous layer on both sides of the paper around the edge. The paper is fed through a laminating machine creating a heat seal around the paper

Lamination via a surface coating

Liquid lamination - can be applied with a roller or spray and is used for applications such as signage to protect from the effects of moisturise and dirt or UV light

Film lamination - can be done via hot or cold process and is used for products such as menu cards and business cards. Usually made of PP with an adhesive to make the laminate stick to the paper. The lamination is fed from a roller and pressure is applied as the paper is fed through

What does embossing do

Creates a raised design on the surface to give it a visual and tactile effect

What does debossing do

Creates an imprints/ lower design on the surface

What is embossing/ debossing used for

Popular to decorative techniques greeting cards, invitation cards and products such as chocolate boxes or packaging where the trade name or special feature is a raised area

How does embossing/ debossing work

1) Uses 2 dies (a male and a female) made for stainless steel or brass, they can be hot or cold

2) The substrate sheet is placed between two dies and held under pressure until the area is formed

3) Raised/ lowered area can have ink or foil applied to it or left natural (called blind debossing / embossing)