industrial chemistry:- Ethanol

1/7

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

8 Terms

uses of ethanol

synthesis of acetaldehyde and ethylene

used as a solvent

important reactor for ether synthesis

important gasoline additive (ethanol blending: current target in india is 10%)

carbon source for single cell protein

worldwide production stats

Synthetic production in 1998: 2.6*106 tonnes per year

By fermentation of agricultural products (sugarcane molasses and corn starch) in 1997: 24.1*106 tonnes per year.

production by synthetic methods

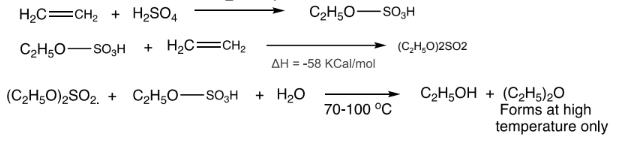

by indirect hydration, addition of H2SO4 and subsequent saponification of sulfuric acid ester

by direct catalytic hydration

indirect hydration

synthesis of ethanol requires conc H2SO4 (94-98% purity) for that purpose submerged burners are used to evaporate water form commercially available dil. H2SO4

Disadvantage: -

corrosion problems

concentrating H2SO4 is an expensive process

submerged burner produces SO2 as a side product

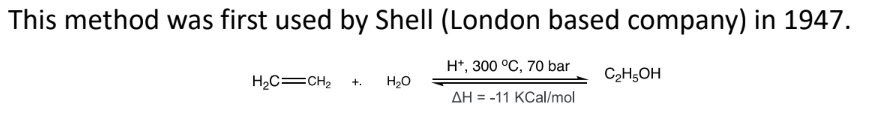

catalytic direct hydration

addition of water is carried out in gas phase and acid catalyst used is H3PO4

/SiO2

the synthesized ethanol is isolated from dilute aqueous solution

H2O azeotrope distillation

H2O removal by adding entraining agent like benzene: - increases volatility of water

disadvantages

C2H4 conversion is low (abt 4%)

high purity ethene required

continuous loss of H3PO4

high energy consumption

production of ethanol from sugarcane

procuring the grain or the plant

converting this to sugar

fermentation

distillation

industrial scale production of ethanol

fermentation of molasses

molasses is the mother liquor left after crystallization of sugarcane juice

dark colored viscous fluid

contains abt 60% fermentable sugar

process of industrial scale production of ethanol

dilution of molasses: molasses is first diluted with water in 1:5 molasses: water ratio by volume

ammonium sulphate: if nitrogen content of the molasses is less, it is fortified with ammonium sulphate to provide adequate supply of nitrogen to yeast

addition of sulfuric acid: fortified solution of molasses is then acidified with small quantity of sulfuric acid. addition of acid favors growth of yeast but unfavors growth of useless bacteria

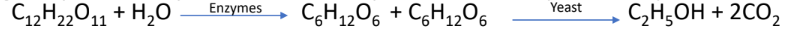

Fermentation The resulting solution is received in a large tank and yeast is added to it at 35°C and kept for 2

to 3 days. During this period, enzymes sucrose and zymase which are present in yeast, convert sugar into ethyl alcohol

Fractional distillation: Alcohol obtained by fermentation is called wash which is about 15-18% pure. by using fractional distillation, it is converted to 92% pure alcohol, known as rectified spirit or commercial alcohol.