Six Sigma 1

1/34

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

35 Terms

What is Six Sigma

Both a methodology for process improvement and a statistical concept that seeks to define the variation inherent in any process.

Six Sigma symbol

6σ

What does σ define?

Standard Deviation of a dataset

What is standard deviation

Measure of how close the numbers are to the mean

If the standard deviation is big, then

then the data is more "dispersed" or "diverse".

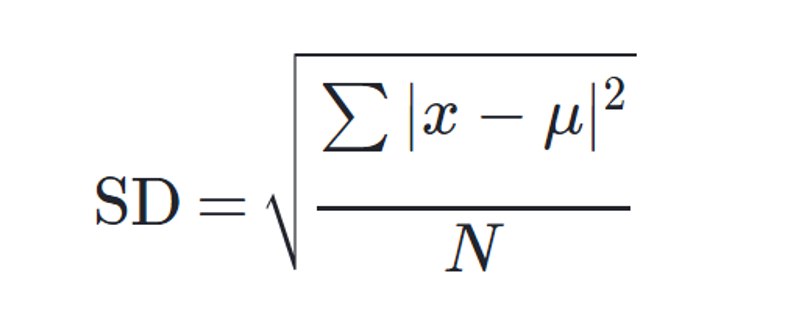

∑

sum of

μ

mean of the dataset

𝑥

value of the dataset

𝑁

number of data points in the population

Standard Deviation Equation

Why is variation important

Opportunities for error

Risks for product defects

Increase in process costs

Lower profitability

Poor customer satisfaction

You should never make decisions without

measurement and analysis

Why use Six Sigma

•Statistical representation for what many experts call a “perfect” process

•Methodology for process improvement with many tools and templates

•3.4 defects per million opportunities

How Six Sigma Works

•Requires understanding of processes and commitment to be methodical in problem solving

•Involves strategies based on measurement and metrics

•Works seamlessly with knowledge, skills, and experience

•Provides a mathematical approach (measurement and metrics) to decisions that used to be based on intuition and experience

•Offers a statistical foundation for decision making

•Can predict outcomes accurately with lower financial risk

•Validates “gut feel” and “assumptions”

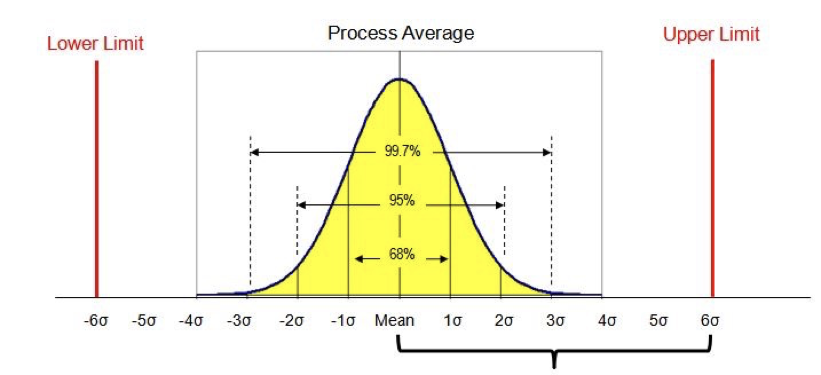

Explain this image

This bell curve shows how Six Sigma aims for 6 standard deviations between process mean and limits, minimizing defects to 3.4 per million

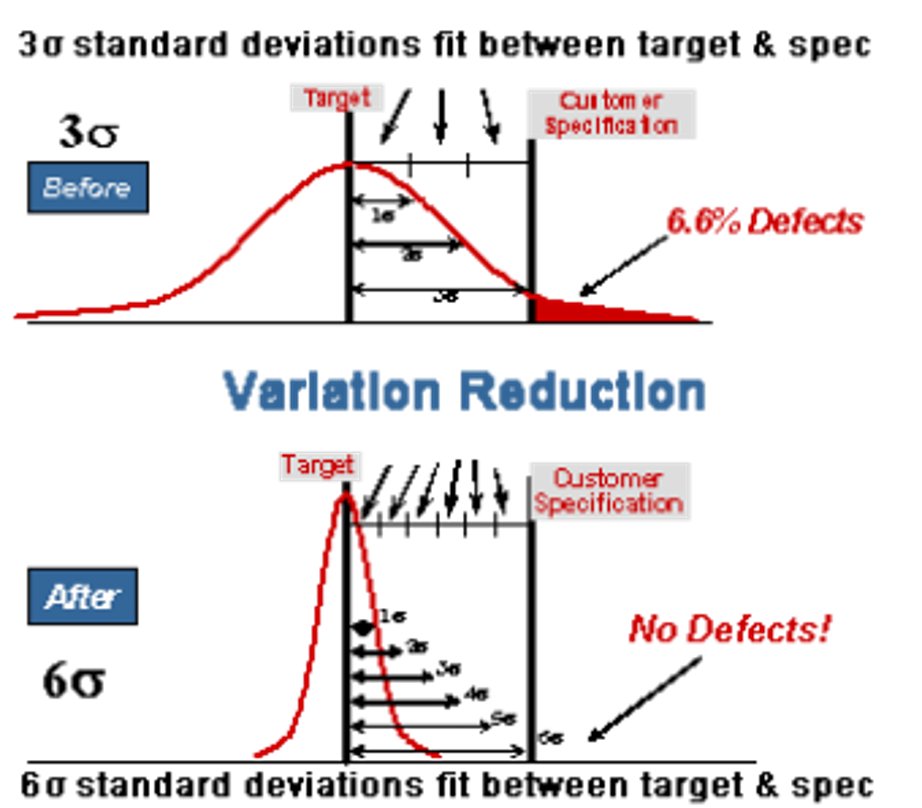

Explain this image

This shows a before and after six sigma approach, which shows how reducing process variation narrows output spread, increasing quality by minimizing defects within customer specifications

Under "Normal” distribution or “Gaussian” distribution, data is…

distributed under the normal curve symmetrically

What is a normal curve?

a symmetrical, uni-modal, bell shaped with mean median and mode having the same value

Much of the variation in nature and in industry follows the frequency distribution of ___?

Normal curves

What is the basis for many quality control techniques?

Normal curves

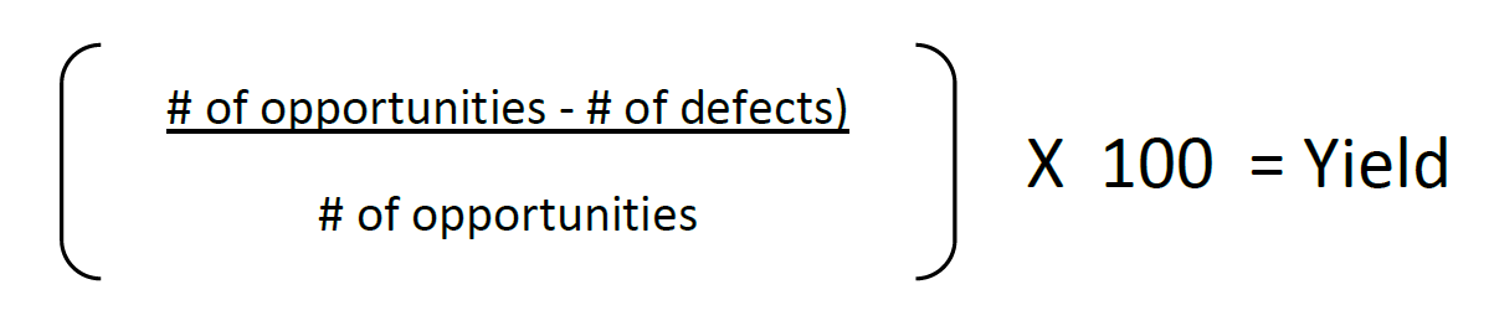

Yeild

How do processes tend to perform over time?

Processes tend to perform worse in the long term than in the short term

What happens to the number of sigmas over time?

The number of sigmas tends to drop over time due to increased process variation.

What is introduced to account for increased variation over time?

A 1.5 sigma shift is introduced to account for long-term process variation.

In the long term, how many sigmas fit between the mean and the specification limit in a 6 sigma process?

Only 4.5 sigma fit in the long term due to the 1.5 sigma shift.

What can customers inform in six sigma principles?

Additional features customers want and are willing to pay for

Product development/ new ideas based on feedback and changing trends

Areas of concern and prioritization based on how customers perceive

Test solutions and ideas before investing resources

What is a value stream in Six Sigma?

Sequence of all items, events, and people required to produce an end result

Continuous Process Improvement in Six Sigma

Move ever closer to the “perfect” level of 99.99966 accuracy for all processes within an organization while maintaining other goals and requirements

Variation in Six Sigma

Each process contains inherent variation….goal is to continuously improve processes to reduce the variation

What are the common principles of Six Sigma?

Voice of Customer

Value Stream

Continuous product improvement

Variation

Removing Waste

Equipping people

Controlling the process

Removing waste in six sigma

Items, actions, or people that are unnecessary to the outcome of a process—reduces processing time, opportunities for errors, and overall costs

Equipping people in Six Sigma

experts - define, plan, and implement an improvement

Controlling the process in six sigma

controls must be in place

employees must know how to use controls to ensure process remains in control

Challenges of six sigma

Lack of support

Lack of resources or knowledge

Poor project execution

Data access issues

Applicability in specific business