Crystals- Defects

1/67

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

68 Terms

Crystal imperfections

Deviations from the reference state of a perfect crystal

How do line defects/dislocations impact material behavior?

They facilitate plasticity because they act as obstacles for the motion of dislocations

True or false- line defects act as both sinks and sources for dislocations and vacancies

True!

Grain size strengthening

Strengthening through decreasing grain size and increasing the area of grain boundaries (acts as an obstacle to dislocation motion)

Types of point defects

vacancies, interstitials, substitutions

Self-interstitial

A host atom that occupies a site between lattice points (A atoms in an interstitial site of A atoms)

Impurity intersitial

An atom that occupies a site between lattice points (B atoms in an interstitial site of A atoms)

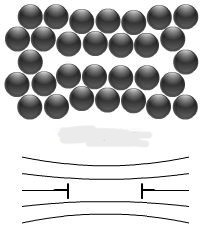

What is this? (+ definition)

Vacancy type dislocation loop- a half-plane of missing atoms in a planar loop

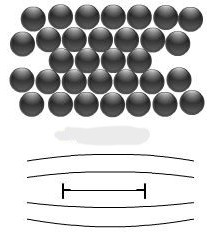

What is this? (+ definition)

Interstitial type dislocation loop- a half-plane of inserted atoms in a planar loop

Vacancies

Vacant unoccupied lattice/atomic sites relative to the perfect crystal reference state

Substitutions

Wrong atom occupancy on a given atomic site relative to the perfect crystal reference state

Interstitials

Atoms in interstitial positions that are unoccupied in the perfect crystal reference state

Types of intrinsic point defects

Vacancies, self-interstitials

Types of extrinsic point defects

Alloying additions, impurities (interstitials, substitutions)

True or false- vacancies do not occur in materials at equilibrium

False- there is an equilibrium concentration of vacancies (x_v)

True or false- the enthalpy of interstitial formation and enthalpy of vacancy formation (h_f) are roughly equal

False- h_f (interstitial) is about 5x h_f (vacancies)

Methods of creating non-equilibrium defect concentrations

Annealing and quenching, irradiation by energetic particles, ion implantation, cold-working

Anti-site defects

Atoms in the wrong sites in chemical compounds (A atom on a B-site), increased chemical disordering

Disordered solid solution

No defined LRO, vacancies in reference to the “average” atom and alloy composition, S close to 0

Ordered solid solution

Defined LRO, vacancies in reference to each atom sublattice, S close to 1

LRO parameter (S)

(r_a - F_a) / (1 - F_a), r_a = fraction of A sites occupied by A atoms

Types of point defects in ionic crystals

Schottky defects and Frenkel defects

Schottky defects

Charge-compensating cation-anion vacancies

Frenkel defects

Charge-compensating ion vacancy paired with an ion interstitial

True or false- defects in ionic crystals always have to be paired with another defect to keep charge neutrality

True!

True or false- comparative probability of defect pairings is determined by how many defects need to take place for charge neutrality

True- fewer defects needed = more probable

0D defects

point defects/site defects

1D defects

dislocations, partial dislocations

2D defects

stacking faults, grain boundaries

3D defects

precipitates, voids

True or false- dislocations are repulsed by each other if on the same glide/slip plane

False- they’re attracted to each other

Impact of annealing/heating on dislocations

Opposite sign dislocations can climb and glide to annihilate, decreasing dislocation density

True or false- the burger’s vector varies with location in a given dislocation

False- it’s constant for the dislocation

Direction of burger’s vector in reference to the tangent vector in dislocations

Parallel/antiparallel in screw dislocations, perpendicular to edge dislocations

Burger’s vector

The displacement vector showing the magnitude and direction of lattice displacement across a dislocation

Line/sense/tangent vector

A unit vector tangent to every point along the dislocation line

True or false- the line vector varies with location in a given dislocation

True- it is always tangent to the dislocation and will vary along curvilinear dislocations

Edge dislocations

Linear dislocations with an inserted/removed half-plane of atoms, causing compressive or tensile strain

Screw dislocations

Linear dislocations with shear displacement

True or false- parallel edge dislocations can experience shear stresses that repel, attract, or exist in metastable equilibrium (with no resultant shear stress)

True

Equation of the glide/slip plane in edge dislocations

b x t

Equation of the glide/slip plane in screw dislocations

undefined- any plane containing b works!

Equation of the glide/slip plane in mixed dislocations

b x t

Unit (perfect) dislocations

Dislocations where b is equal to the lattice translation

Positive edge dislocation

Upside-down T, t into the plane

Negative edge dislocation

T, t out of the plane

Screw component equation

b_s = (b.t)t

Edge component equation

b_e = b - b_s

Conservative motion

Glide motion, there is a displacement of b per dislocation in response to a resolved shear stress parallel to b

Non-conservative motion

Climb motion, requires the creation/destruction of lattice sites and the emission/absorption of vacancies

True or false- climb motion produces equivalent displacement effects to glide motion

True!

True or false- climb loops contain only screw dislocation segments

False- they contain only edge dislocation segments

True or false- dislocations in climb loops are contained in a plane that contains b and t

False- the plane contains t, but not b

Theoretical shear

The simultaneous breaking of bonds across a slip plane

Slip systems

pairings of close-packed planes and close-packed directions on the planes

Unit/perfect dislocations

Dislocations in which b is equal to a lattice translation

Stable cross-slip

Screw dislocations move to neighboring planes

Shockley partial dislocation

b = 1/6 * [112]

Frank partial dislocation

b = 1/3 * [111]

Stair-rod partial dislocation

b = 1/6 * [110]

Dislocation dissociation

Breaking a unit/perfect dislocation into multiple partial dislocations, favorability tested with elastic energy W

Elastic energy W

proportional to b^2

Double cross-slip

Screw dislocations move to a neighboring plane and return to the original plane

Likely slip plane for cF

{111}

Likely slip plane for cP

{011}, {010}

Anti-phase boundaries (APB)

planar faults in ordered compounds that show a shift in stacked planes

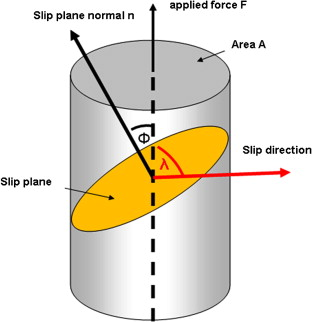

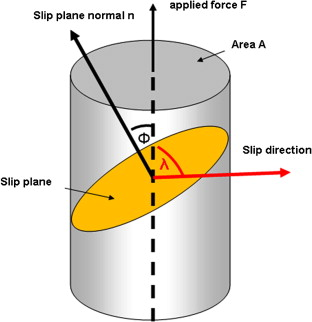

Schmid’s law

shear stress = normal stress * cos(lambda) * cos(phi)

Schmid factor

cos(lambda) * cos(phi), has its maximum value in the primary slip system