Chapter 3: Nature of Materials

1/62

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

63 Terms

Levels of Structure

Atom → Molecule/Crystal/Amorphous → Grain

Atoms

made of a dense nucleus consisting of protons and neutrons

Valence Electrons

electrons in the outermost shell that are involved with bonding

3 types of Primary Bonds

Ionic

Covalent

Metallic

Ionic and Covalent bonds are typically found in _____ and _____

ceramics, polymers

Metallic bonds are typically found in ______ and ______

metals, alloys

Ionic bond

Electrons are transferred

Characteristics of materials joined by ionic bonds

High Density

Moderate to high strength

High hardness

Brittleness

High melting pint

LOW electrical + thermal conductivity

Covalent Bonds

Electron sharing

Characteristics of materials joined by covalent bonds

high strength

high melting point

brittle

conductivity depends on bond strength

Metallic bond

Valence electrons are not bound and free to move

Characteristics of materials joined by metallic bonds

highly mobile electrons

high electrical + thermal conductivity

bond strength, material strength, and melting point vary

low hardness

Van der Waals Forces

secondary/intermolecular bond formed between molecules that possess a nonsymmetrical distribution of electrical charge

Molecular Structures

Distinct number of atoms that are held together by primary bonds

Crystalline Structure

Atoms are arranged in a three-dimensional geometric arrays

Amorphous structures

Having a certain degree of local order, but no periodically ordered arrangement

Unit Cell

a unit building block that is repeated throughout space

Lattice

the arrangement of atoms in a three-dimensional geometric array

4 types of lattice structure

Simple Cubic (SC)

Body-centered cubic (BCC)

Face-centered cubic (FCC)

Hexagonal close-packed (HCP)

Packing efficiency of Simple Cubic

52%

Packing efficiency of Body-centered Cubic

68%

Packing efficiency of Face-centered Cubic

74%

Packing efficiency of Hexagonal close-packed

74%

Grains

small continuous regions of solid

Grain Boundaries

Surfaces that divide grains

Smallest unit of structure that can be observed by a light microscope

grains

(T/F) Small grain size can improve mechanical properties

True

Elastic Deformation

Temporary deformation of materials

Plastic Deformation

Permanent deformation of materials

Things mechanical properties are dependent on

Types of Lattice

Interatomic Forces (bond strength)

Spacing between adjacent planes

Density of atoms on various planes

Poisson’s Ratio

a measure of how much a material will shrink in one direction when it is stretched in another direction

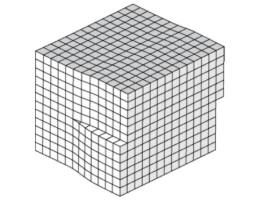

Slip

sliding of blocks of crystal over one other along definite crystallographic planes

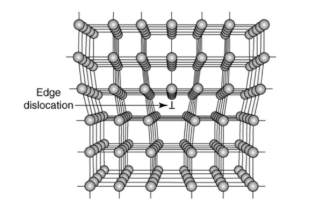

Dislocation

a type of defect within a crystal structure, specifically representing an irregularity in the arrangement of atoms

Line Type Defects

Localized imperfections in crystal

Edge Dislocation

The terminal edges of extra half-planes of atoms

Screw Dislocation

partial tearing of the crystal plane

Point Defect

a localized imperfection in a crystal structure

Types of point defects

Vacancy

Interstitial

Substitutional

Vacancy

missing atoms

Interstitial

extra atoms

Substitutional

different atoms replace host atoms

Strain/Work Hardening

The strengthening of metals through plastic deformation

Anisotropic

properties that vary with direction (undesirable)

Isotropic

properties that are uniform in all directions

Fracture

a material has cracked or broken apart due to stress

2 types of fractures

ductile fracture

brittle fracture

Ductile Fracture

plastic deformation occurs before the material breaks

Brittle Fracture

the break occurs before plastic deformation

Recrystallization

the process of reducing the internal energy through new crystal formation

Cold working

metals are plastically deformed at temperature below their recrystallization

Hot working

metals are plastically deformed above their recrystallization temperature

(T/F) Mechanical properties increase as grain size increases

False

3 ways a metal might respond to the addition of another element

Insoluble

Some degree of solubility

Intermetallic compound

Insoluble

base metal and alloying addition each maintain their individual identities, structure and properties.

Some Degree of Solubility

Two materials form a solid solution, where alloying element dissolve in metal base

Interstitial Solid Solution

the alloy element atoms squeeze into open spaces between atoms of base metal lattice

Substitutional solid solution

the alloy element atoms occupy lattice site normally filled by atoms of base metal

Intermetallic compound

atoms of alloying element interact with atoms of base metal in

definite proportions and indefinite geometric relationships

Intermetallic Compound Characteristics

bonded w/ ionic or covalent

tend to be hard, brittle and high strength

Electrical Conductivity

the net movement of a charge through a material

Electrical Resistance depends on…

lattice imperfections and temperature

Doping

enhancing the electrical conductivity of intrinsic semiconductor by adding impurity atoms