Chapter 6: Food production (subsystem, decisions, forecasting, planning, ingredient control, recipe, adjustment methods)

1/79

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

80 Terms

what is the objective of food production

the preparation of menu items in the needed quantity and with the desired quality, at a cost appropriate to the particular foodservice operation

define food production

Preparation of menu items in the needed quantity and the desired quality at a cost appropriate to the particular operation

define production

Preparation of menu items in the needed quantity and the desired quality at a cost appropriate to the particular operation

PLANNING FOR PRODUCTION

define planning for production

Establishment of program of action for transformation of resources into products and services

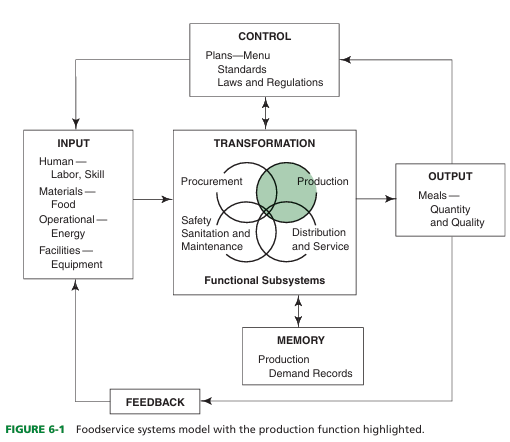

where does production fall in the foodservice graph

transformation

how often are decisions made

daily

about necessary quantities to produce and the quality that must be maintained within cost limitations

define elements of decision making

forecasting, planning, and production scheduling

production planning primarily is the effective synthesis of what 3 things

quantity, quality, and cost objectives

what are the secondary objectives for production decisions (4)

product/service characteristics

process characteristics (how food is processed, cooked)

product/service quality

efficiency (depends on labor, material and facility cost)

customer service

why is maintenance of quality a cost factor

because of employee training, inventory control of both raw and prepared food items, and sanitation programs

cost element in planning is result of the correlation of what 4 things

food

storage

issue

production costs with labor, facility, and energy costs

FORECASTING

define forecasting

Art and science of estimating events in the future, which provides a database for decision making and planning

foodservice managers are concerned with what (why we do forecasting)

food cost

define overproduction and its effects

Production of more food than is needed for service.

-generate extra costs due to food waste, extra labor costs

define underproduction and its effects

Production of less food than is needed for service

-increase cost AS MUCH as overproduction because disappoints customer, additional labor cost, and substitutions (recompensas) can be expensive

when it comes to forecasting, production managers should know estimated number of what

customers and servings of each menu item

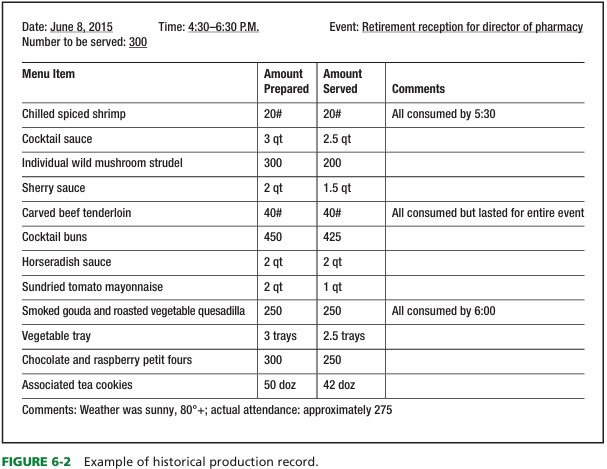

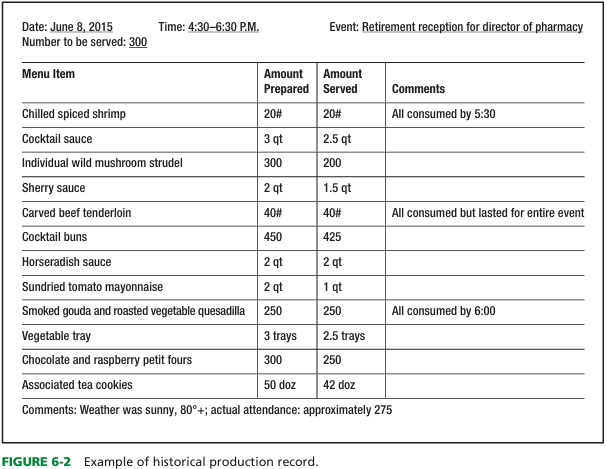

how do adequate historical records aid the forecasting process

can be used to see past customer counts, number of meals, menu items, or sales records

what should historical record include

Date and day of the week

Meal or hour of service

Notation of special event, holiday, and weather conditions, if applicable

Food items prepared

Quantity of each item prepared

Quantity of each item served

how is forecasting done??

usually models are used

what is the criteria for forecasting models (5)

Cost

Required accuracy

Relevancy of past data

Forecasting lead time- Lead time pertains to the length of time into the future that the forecasts are made

Underlying pattern of behavior

what are the 3 types of common forecasting models

time series

causal

subjective

explain the time series model

based on the assumption that actual occurrences follow an identificable pattern over time

when do time series models work the best

for short term forecast

what are the 2 main types of time series models

moving average AND exponential smoothing

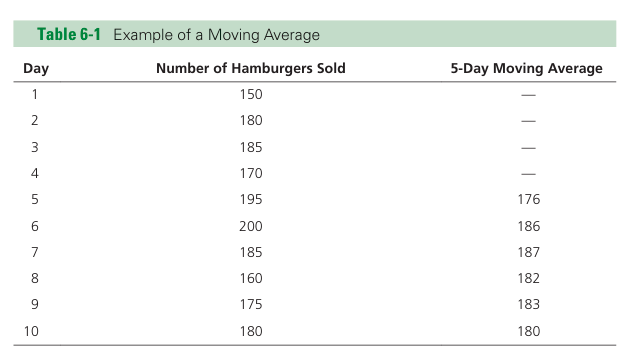

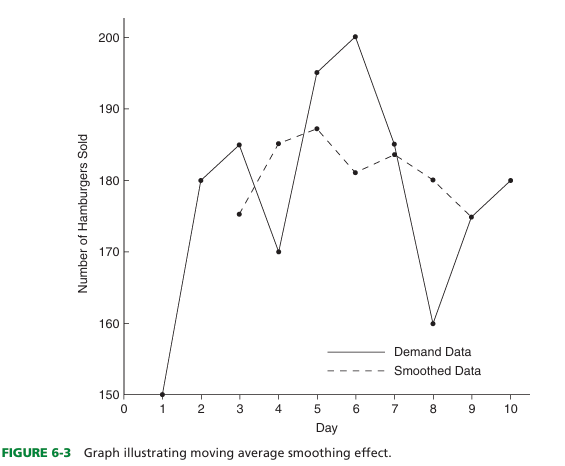

Define/explain moving average forecasting model

Time series model that uses a repetitive process for developing a trend line by averaging the number of servings for a specified number of times for the first point on the line and then dropping the oldest and adding the newest number of servings for subsequent points.

define/explain exponential smoothing forecasting model

Time series model in which an exponentially decreasing set of weights is used, giving recent values more weight than older ones

very similar to the moving average model except that it does not uniformly weigh past observations

explain causal model

similar to time series in sense that it assumes an identifiable relationship between item of forecast and other factors BUT is MORE COMPLEX as it takes in more factors

best for medium to long term forecast (like canned goods)

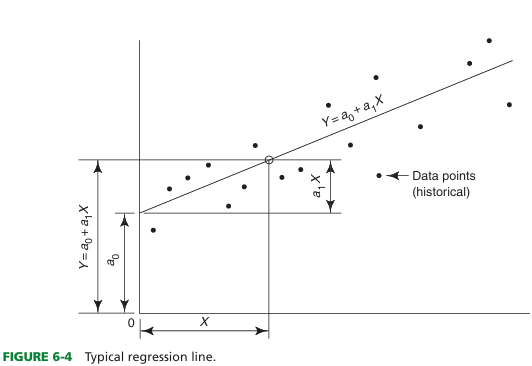

define/explain regression analysis forecasting models

Causal models that are based on the assumption that the linear relationship between variables will continue for a reasonable period of time.

define linear

signifies the intent of the analysis to find an equation for a straight line that fits the data points most closely

define dependent variable

the item being forecast

define Independent variable

the factors that affect it

explain subjective model (specially when it is used)

A subjective forecasting model generally is used when relevant data are scarce or patterns and relationships between data do not tend to persist over time

Forecasters must rely on opinions and other information, generally qualitative, that might relate to the item being forecast

define the Delphi technique

Panel of experts who individually complete questionnaires on a chosen topic until a consensus is reached

PRODUCTION SCHEDULING

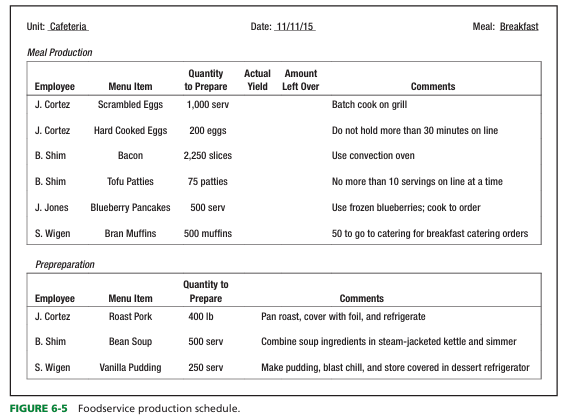

define production scheduling

Time sequencing of events required by the production subsystem to produce a meal.

for foodservice, what types of recipes should be used

standardized recipes

what are the 2 stages of scheduling

planning and action w

what is planning stage

forecasts are converted into the quantity of each menu item to be prepared and the distribution of food products to supervisors in each work center

what is action stage

preparing a production schedule

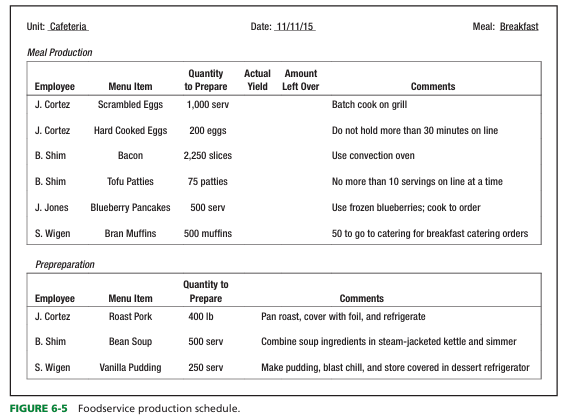

define production schedule

Written plan for production for a specific date and/or mea

what is a major control in the production subsystem

production schedule because it activates the menu and provides a test of forecasting accuracy

what must be included in the production menu (6)

The unit

Production date

Meal

Actual customer count

Weather

Special events

what in production schedule must be included to make specific action plan (10)

Employee assignments

Prep time schedule

Menu item

Over-and underproduction

Quantity to prepare

Substitutions

Actual yield

Additional assignments

Special instructions and comments

Preparation

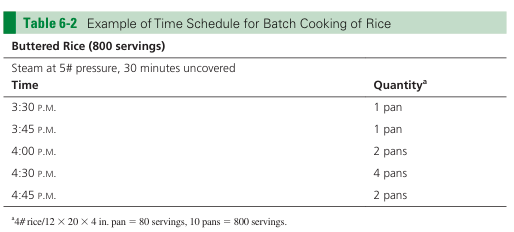

define batch cooking

Cooking smaller quantities of menu items as needed for service

INGREDIENT CONTROL

what is a major component of quality and quantity control in the production subsystem and a critical dimension of cost control throughout the foodservice system

ingredient control

how does process of ingredient begin and continues to what

the process of ingredient control begins with purchasing, receiving, and storage of foods and continues through forecasting and production

what are the 2 main aspects of ingredient control (2 main methods to control it)

Ingredient assembly

Use of standardized recipes

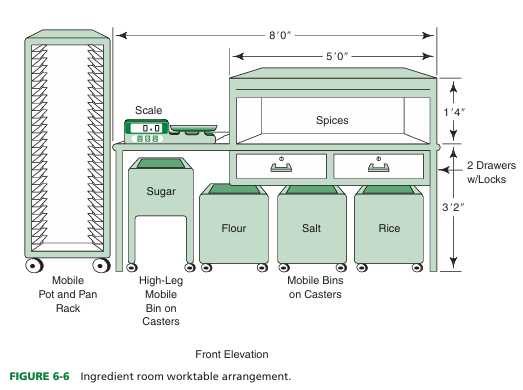

define ingredient room

ingredient assembly area designed for measuring ingredients to be transmitted to the various work centers.

define standardized recipe

Recipe that consistently delivers the same quantity and quality of a product when followed precisely

what components are important aspects of ingredient control (think chpt 5)

receiving, storage, and inventory control

advantages of using centralized assembly area (ingredient room)

The ingredient room contributes to cost reduction and quality improvement by stopping production employees from withdrawing large quantities of products from storage whether or not they are needed

can help eliminate over and underproduction

how does centralized ingredient control work (in terms for the cook)

the cook is issued only what is needed for the forecast production demands on the day of service - the excess is held in frozen storage in the ingredient room until the next time the ingredients are needed for a recipe

in centralized ingredient control how is control of unused portions facilitated

because storage is located centrally rather than in various work units throughout the kitchen.

what is the primary function of the ingredient room

to coordinate assembly, prepreparation, measuring, and weighing of the ingredients to meet both the daily production needs and the advance preparation needs of recipes for future meals

what should be in ingredient room (like organization)

fridge, water supply, carts, portable bins, worktable/counter, and scales

scales are MOST ESSENTIAL

what is the most essential piece of equipment in ingredient room

Scales

who should be in ingredient room

authorized personnel that are assigned to room and trained

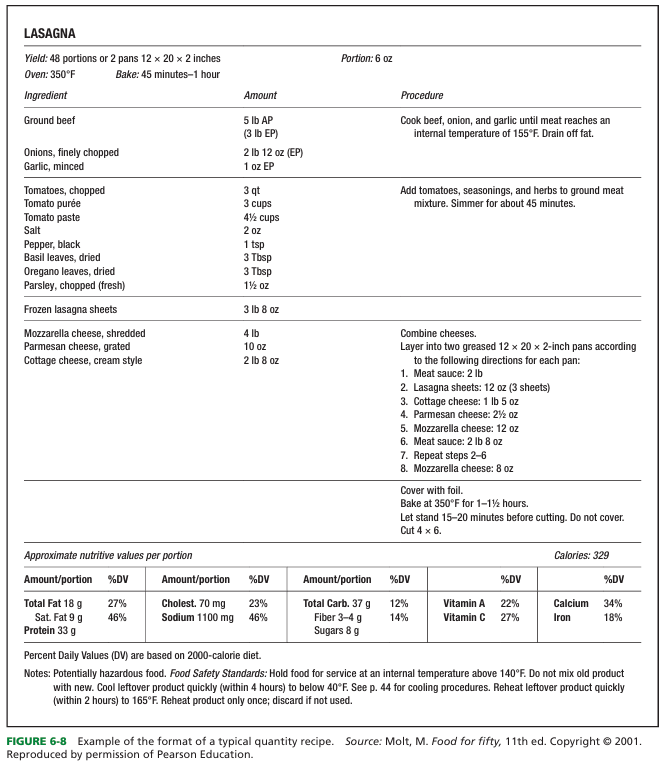

RECIPES

define recipe

Formula by which weighed and measured ingredients are combined in a specific procedure to meet predetermined standards

when is a recipe considered standardized

Once a recipe has been tested repeatedly to give same results and accepted by management and customers

format of recipes

for foodservice usually in BLOCK FORMAT

includes:

Name of item

Total yield

Portion size and # of portion

Cooking time and temp

List of ingredients in order of use

Amount of each ingredient by weight, measure, or count

Procedures

Plating info

Serving and garnishing suggestions

HACCP guidelines

Can also include nutrition info

define recipe standardization

Process of tailoring a recipe to suit a particular purpose in a specific foodservice operation

define quantity recipe

Recipe that produces 25 or more servings

are quantity recipes standardized recipes?

No, until they have been adapted to individual operation

advantages to recipe standardization (11)

Promote uniform quality of menu items

Promote uniform quantity of menu items.

Encourage uniformity of menu items.

Increase productivity of cooks.

Increase managerial productivity.

Save money by controlling overproduction.

Save money by controlling inventory levels

Simplify menu item costing.

Simplify training of cooks.

Introduce a feeling of job satisfaction

Reduce anxiety of customers with special dietary needs.

what is recipe verification

4 step process of:

reviewing components of recipe

make recipe

verify the yield

record changes on recipe

what is product evaluation

evaluation the result of the recipe

when does product evaluation occur

after recipe verification

what does product evaluation help with

determine the acceptability of the recipe by foodservice managers and staff and customers

define informal evaluation

General assessment of product or ser vice; no evaluation form or procedure used

Typically completed when the product is first prepared

define formal evaluation

Detailed assessment of product or service; evaluation form used and detailed evaluation procedure followed.

If foodservice staff members believe a recipe has potential for use in the operation, then a formal evaluation is conducted

QUANTITY ASSESSMENT

what are the 3 procedures that have been developed for quantity adjustment of recipe

factor method

percentage method

direct reading measurement table

what is the factor method (steps)

STEP 1 Convert all ingredients from measure to weight in pounds and ounces. Whenever possible, state liquid measures in weights; however, liquid measurements may be converted to decimal equivalents of a quart or gallon.

STEP 2 Convert ingredient quantity to whole numbers and decimal equivalents and round to one decimal place unless the original amount is less than one pound; that is, 2 lb 10 oz would be converted to 2.625 lb, but rounded to 2.6 lb for use. For amounts less than one pound, two places would be shown (e.g., 0.62 lb). Table 6-3 provides data for convert ing ounces into decimals of a pound and cups and quarts into decimal parts of a gallon.

STEP 3 Divide the desired yield by the base recipe yield to determine the conversion factor.

STEP 4 Multiply all recipe ingredients by the conversion factor.

STEP 5 Reconvert the new ingredient quantities back into pounds and ounces or quarts and cups.

STEP 6 Round off amounts to quantities simple to weigh or measure and within an acceptable margin of error

what is percentage method

measurements for ingredients are converted to weights and then the percentage of the total weight for each ingredient is computed

steps of percentage method (8)

STEP 1 Convert all ingredients from measure or pounds and ounces to tenths of a pound. Make desired equivalent ingredient substitutions, such as frozen whole eggs for fresh or powdered milk for liquid.

STEP 2 Total the weight of ingredients in a recipe after each ingredient has been converted to weight in the edible portion (EP). For example, the weight of carrots or celery should be the weight after cleaning and peeling. The recipe may show both AP (as purchased) and EP weights, but the edible portion is used in determining the total portion weight.

STEP 3 Calculate the percentage of each ingredient in the recipe in relation to the total weight. (Note: The sum of all percentages must equal 100.)

STEP 4 Check the ratio of ingredients. Standards of ingredient proportions have been established for many items. The ingredients should be in proper balance before going further.

STEP 5 Establish the weight needed to provide the desired number of servings, which will be in relation to pan size, portion weight, or equipment capacity.

STEP 6 Handling loss must be added to the weight needed and may vary from 1 to 10%, depending on the product. Similar items produce predictable losses that with some experimentation can be accurately assigned.)

STEP 7 Multiply each ingredient percentage number by the total weight to give the exact amount of each ingredient needed. After the percentages of each ingredient have been established, any number of servings can be calculated and the ratio of ingredients to the total will be the same. As in the factor method, one decimal place on a recipe is shown unless the quantity is less than 1 pound, in which case two places are shown.

STEP 8 Unless scales are calibrated to read in pounds and tenths of a pound, convert to pounds and ounces or to measure.

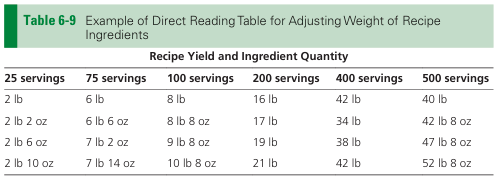

what is direct reading measurement tables

The third method of recipe adjustment uses direct reading measurement tables.

These tables have the advantage of being simple and quick to use and require no mathematical calculations.

he third method of recipe adjustment uses direct reading measurement tables.

These tables have the advantage of being simple and quick to use and require no mathematical calculations.