PAES - Materials

1/98

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

99 Terms

Additives.

plastics and rubbers almost invariably contain, in addition to the polymer or polymers, other materials, i.e., additives. These are added to modify the properties and cost of the material.

Ageing

This term is used to describe a change in properties that occurs with certain metals at ambient or moderately elevated temperatures after hot working, a heat treatment process or cold working. The change is generally due to precipitation occurring, there being no change in chemical composition.

Alloy

This is a metallic material composed of two or more elements of which at least one is a metal.

Amorphous

an - material is a non-crystalline material, i.e. it has a structure which is not orderly

Annealing

this involves heating to, and holding at, a temperature which is high enough to result in a softened state for a material after a suitable rate of cooling, generally slowly. In the case of ferrous alloys the required temperature is the upper critical temperature. The purpose of - can be to facilitate cold working, improve machinability, improve mechanical properties, etc.

Anodizing

this term is used to describe the process, generally with aluminum, whereby acoating is produced on the surface of the metal by converting it to an oxide

Atactic structure.

polymer structure in which side groups, such as CH3, are arranged randomly on either side of the molecular chain

Austempering

this is a heat treatment used with ferrous alloys. The material is heated to austenizing temperature and then quenched to the Ms temperature at such a rate that ferrite or pearlite is not formed. It is held at the Ms temperature until the transformation to bainite is complete

Austenite

this term describes the structure of a solid solution of one or more elements in a face-centered cubic iron crystalline structure. It usually refers to the solid solution of carbon in the face-centered iron

Austenizing.

this is when a ferrous alloy is heated to a temperature at which the transformation of its structure to austenite occurs.

Bainite

This describes a form of ferrite-cementite structure consisting if ferrite plates between which, or inside which, short cementite rods form, and occurs when ferrous alloys are cooled from the austenitic state at an appropriate rate of cooling. It is a harder structure than would be obtained by annealing but softer than martensite. The process used is called austempering.

Brinell number

number given to a material as a result of a Brinell Test and is a measure of the hardness of a material. The larger the number, the harder the material

Brittle failure

With — a crack is initiated and propagates prior to any significant plastic deformation. The fracture surface of a metal with a brittle fracture is bright and granular due to the reflection of light from individual crystal surfaces. With polymeric materials the fracture surface may be smooth and glassy or somewhat splintered and irregular

Brittle material

a - shows little plastic deformation before fracture. The material used for a China teacup is brittle. Thus, because there is little plastic deformation before breaking, a broken teacup can be stuck back together again to give a cup the same size and shape as the original.

Carburizing

This is a form of case hardening which results in a hard surface layer being produced with ferrous alloys. The treatment involves heating the alloy to the austenitic state in a carbon-rich atmosphere so that carbon diffuses into the surface layers, then quenching to convert the surface layers to martensite.

Casehardening

This term is used to describe processes in which by changing the composition of surface layers of ferrous alloys a hardened surface layer can be produced.

Cementite

This is a compound formed between iron and carbon, often referred to as iron carbide. It is a hard and brittle material.

Charpy test value.

— test is used to determine the response of a material to a high rate of loading and involves a test piece being struck a sudden blow. The results are expressed in terms of the amount of energy absorbed by the test piece when it breaks. The higher the test value the more ductile the material.

Cis structure.

A polymer structure in which a curved carbon backbone is produced by bulky side groups. E.g., CH3+ which are grouped all on the same side of the backbone.

Compressive strength.

the maximum compressive stress a material can withstand before fracture

Copolymer.

this is a polymeric material produced by combining two or more monomers in a single polymer chain

Corrosion resistance.

the ability of a material to resist deterioration by chemical or electrochemical reaction with its immediate environment. There are many forms of corrosion and so there is no unique way of specifying the corrosion resistance of a material

Creep

the continuing deformation of a material with the passage of time when it subject to a constant stress. For a particular material the — behavior depends on both the temperature and the initial stress, the behavior also depending on the material concerned.

Creep modulus.

initial results of a creep test are generally represented as a series of graphs of strain against time for different levels of stress. From these graphs’ values, for a particular time, of strains a different stresses can be obtained. The resulting stress-strain values can be used to give a stress-strain graph for a particular time, suc a graph being reffered to as an ishochronous stress-strain graph. The — is the stress divided by the strain for a particular time. The modulus is not the same as the tensile modulus.

Creep strength.

is the stress required to produce a given strain in a given time.

Damping capacity

is an indicator of the ability of a material to suppress vibrations

Density

mass per unit volume

Dielectric constant.

also referred to as permittivity, a property of material defined as the ratio of capacitance of a capacitor with the material between its plates compared with that of the same capacitor with a vacuum

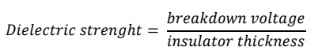

Dielectric strength.

measure of the highest potential difference an insulating material can withstand without electric breakdown.

Ductile failure.

there is a considerable amount of plastic deformation prior to failure. With metals the fracture shows a typical cone and cup formation and the fracture surfaces are rough and fibrous in appearance

Ductile materials.

show a considerable amount of plastic deformation before breaking.

Elastic limit.

the maximum force or stress at which, on its removal, the material returns to its original dimensions. For many materials the — and the limit if proportionality are the same, the limit of proportionality being the maximum force which the extension is proportional to the force or the maximum stress for which the strain is proportional to the stress.

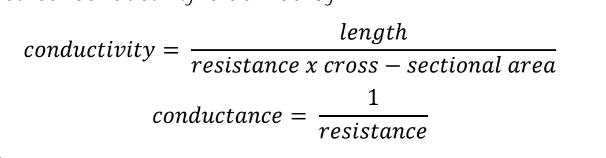

Electrical conductivity.

a measure of the electrical conductance of a material, the bigger the conductance the greater the current for a particular potential difference. The electrical conductivity is defined by

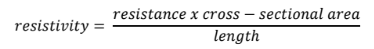

Electrical resistivity.

a measure of the electrical resistance of a material, being defined by

Endurance

number of stress cycles to cause failure

Endurance limit.

the value of the stress for which a test specimen has a fatigue life of N. cycles

Equilibrium diagram

The diagram, is, for metals, constructed from a large number of experiments, in which cooling curves are determined for the whole range of alloys in a group, and provides a forecast of the states that will be present when an alloy of a specific composition is heated or cooled to a specific temperature

Fatigue life.

he number of stress cycles to cause failure

Fatigue limit.

value of the stress below which the material will endure an infinite number of cycles

Fatigue strength.

— at N cycles is the value of the stress under which a test specimen has a life of N cycles

Ferrite

a solid solution of one or more elements in body-centered cubic iron. It is usually used for carbon in body-centered cubic iron; comparatively soft and ductile

Fracture toughnes

plane strain fracture toughness or opening-mode fracture toughness, Klc, represents a practical lower limit of fracture toughness and is an indicator of whether a crack will grow or not

Coefficient of friction.

maximum value of the frictional force divided by the normal force. In the situation where an object is to b started into motion, the maximum frictional force is the force needed to start the object sliding. Where an object is already in motion, the frictional force is that needed to keep in moving with a constant velocity. This is less than the frictional force needed to start sliding and so there are two coefficients of friction, a static coefficient and a dynamic coefficient, with the static coefficient larger than the dynamic coefficient

Full hard.

term is used to describe the temper of alloys. It corresponds to the cold-worked condition beyond which the material can no longer be worked.

Half hard

term is used to describe the temper of alloys. It corresponds to the cold-worked condition half-way between soft and full hard

Hardenability

the term — of a material is used as a measure of the depth of hardening introduced into a material by quenching

Hardening

heat treatment by which hardness is increased

Hardness

may be specified in terms of some standard test involving indentation, or scratching of the surface of the material.

Heat distortion/Deflection temperature.

the temperature at which a strip of polymeric material under a specified load shows a specified amount of deflection.

Heat-resisting alloy.

alloy developed for use at high temperature

Homopolymer

a polymer that has molecules made up of just one monomer

Impact properties.

property of material determined by Charpy and Izod test, and defined as a response of a material to a high sudden rate of load.

Izod test value.

used to determine the response of a material to a high rate of loading and involves a test piece being struck a sudden blow. The result are expressed in terms of the amount of energy absorbed by the test piece when it breaks. The higher the test value the more ductile the material (for brittle materials talaga to pero yung definition ay galing sa sinend ni sir k)

Jominy test.

test used to obtain information on the hardenability of alloys

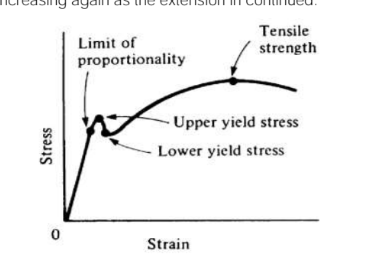

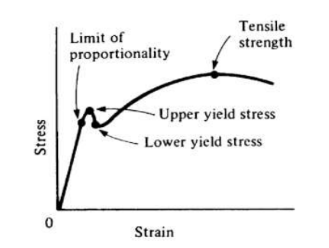

Limit of proportionality.

up to the —, the extension is directly proportional to the applied stretching forces, i.e. the strain is proportional to the applied stress

Machinability

There is no accepted standard test in —and so it is based on empirical test data and is hence subjective. — is a measure of the differences encountered in machining a material.

Maraging

precipitation hardening treatment used with some ferrous alloys

Martensite

general term used to describe a form of structure. In the case of ferrous alloys, it is a structure produced when the rate of cooling from the austenitic state is too rapid to allow carbon atoms to diffuse out of the face-centered cubic form of austenite and produce the body-centered form of ferrite. The result is a highly strained hard structure

Melting point.

the temperature at which a material change

Monomer

this is the unit, or mer, consisting of a relatively few atoms which are joined together in large numbers to form a polymer

Nitriding

treatment in which nitrogen diffuses into surface layers of a ferrous alloy and hard nitrides are produced, hence, a hard surface layer.

Normalizing

heat treatment process involves heating a ferrous alloy to a temperature which produces a fully austenitic structure, flowed by air cooling. The result is a softer material, but not as soft as would be produced by annealing.

Pearlite

lamellar structure of ferrite and cementite

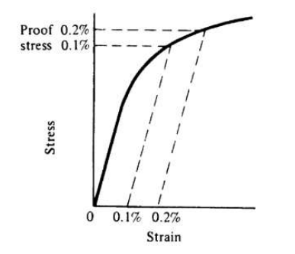

Permeability

used to describe the rate at which gases or vapors are transmitted through a material. The rate of transmission per unit surface area of the material is given by

Permittivity (relative permittivity or dielectric constant)

ratio of the capacitance of a capacitor with the material between its plates compared with that of the same capacitor with a vacuum

Poisson’s ratio

ratio of transverse strain and longitudinal strain

Precipitation hardening.

heat treatment process which results in a precipitate being produced in such a way that a harder material is produced.

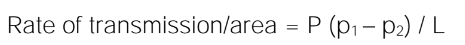

Proof stress.

The 0.2% — is defined as that stress which results in a 0.2% offset, i.e. the stress given by a line drawn on the stress-strain graph parallel to the linear part of the graph passing through 0.2% strain value. The 0.1% — is similarly defined. — are quoted when a material has no well-defined yield point.

Quenching

method used to produce rapid cooling

Fractional recovery.

defined as the strain recovered divided by the creep strain, when the load is removed

Recrystallization

generally used to describe the process whereby a new, strain free grain structure is produced from that existing in a cold-worked metal by heating.

Refractive index.

the ratio of speed of light in a vacuum / speed of light in the material. For some materials the speed of light depends on the direction through the material the light is traversing. For some materials the speed of light depends on the direction through the material the light is traversing and so the refractive index varies with direction

Resilience

used with elastomers to give a measure of elasticity of a material. A high resilience material will suffer elastic collisions, when a high percentage of the kinetic energy before the collision is returned to the object after the collision. A less resilient material would lose more kinetic energy in the collision

Modulus of rigidity.

slope of the shear stress/shear strain graph below the limit of proportionality

Rockwell test value.

used to give a value for the hardness of a material. There are number of Rockwell scales and thus the scales being used must be quoted with all test results

Rupture stress

to cause rupture in a given time at a given temperature and is widely used to describe the creep properties of materials

Secant modulus.

for many polymeric materials there is no linear part of the stress-strain graph and thus a tensile modulus cannot be quoted. In such cases the — is used. It is the stress at a value of 0.2% strain divided by that strain

Shear strength

the shear stress required to produce fracture

Shore durometer

method for measuring the hardness of polymers and rubbers. A number of scales are used.

Sintering

process by which powders are bonded by molecular or atomic attraction, as a result of heating to a temperature below the melting points of the constituent powders

S/N graph.

graph of the stress amplitude S plotted against the number of cycles N for the results from a fatigue test. The stress amplitude is half the algebraic difference between the maximum and minimum stresses to which the material is subject

Specific gravity.

the ratio of its density compared with that of water (density of material/density of water)

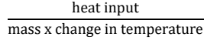

Specific heat capacity.

mount by which the temperature rises for a material, when there is a heat input depends on its —. The higher the — the smaller the rise in temperature per unit mass for a given heat input

Spheroidizing

treatment used to produce spherical or globular forms of carbide in steel

Strain

defined as a ratio of change in length/original length when a material is subject to tensile or compressive forces. Shear strain is the ratio of amount by which one-layer slides over another/separation of the layers. Because it is a ratio, strain has no units, though it is often expressed as a percentage. Shear strain is usually quoted as an angle in radians

Strain hardening.

an increase in hardness and strength produced as a result of plastic deformation at temperatures below the recrystallization temperature, i.e., cold working

Strength

Also referred to as shear and tensile strength

Stress

in engineering tensile and compressive stress is usually defined as force/initial cross-sectional area. The true stress is force/cross-sectional area at that force. Shear stress is the shear force/area resisting shear. Shear has the unit Pa or Nm-2 with 1 Pa = 1 Nm-2

Stress relieving

treatment to reduce residual stresses by heating the material to a suitable temperature, followed by slow cooling.

Stress-strain graph.

usually drawn using engineering stress and engineering strain.

Surface hardening.

eneral term used to describe a range of processes by which the surface of a ferrous alloy is made harder than its core.

Syndiatic structure.

polymer structure in which side molecular groups are arranged in a regular manner, alternating from one side to the other of the molecular chain

Temper

term is used with non-ferrous alloys as an indication of the degree of hardness or strength, with expressions such as hard, half-hard, three-quarters hard being used

Tempering

the heating of a previously quenched material to produce an increase in ductility

Tensile modulus

or young’s modulus; the slope of the stress-sstrain graph over its initial straight-line region.

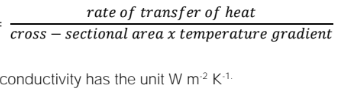

Thermal conductivity

rate at which energy is transmitted as heat through a material depends on a property called the —. The higher the —, the greater the rate at which heat is conducted. — id defined by

Wear resistance.

subjective comparison of the wear resistance of materials. There is no standard test

Weldability.

the - of a particular combination of metals indicated the ease with which sound welds can be made.

Yield point.

For many metals, when the stretching forces applied to a test piece are steadily increased, a point is reached when the extension is no longer proportional to the applied forces and the extension increases more rapidly than the force, until a maximum force is reached. This is called the upper —. The force then drops to a value called the lower — before increasing again as the extension in continued