Conventional Machining (L4,5,6)

1/93

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

94 Terms

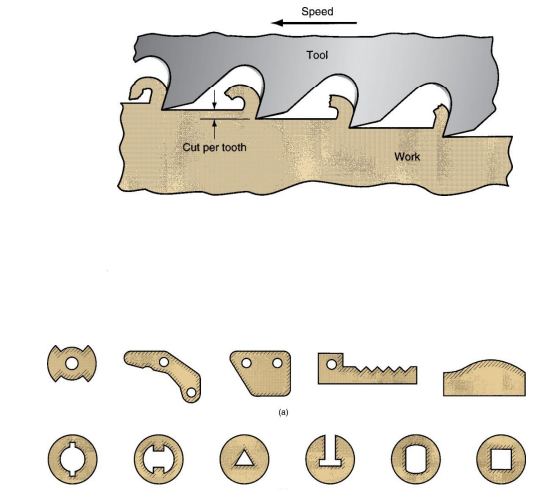

CONVENTIONAL MACHINING processes

Material is removed with a specifically shaped cutting tool in the form of small “chips”.

When machining, we want to…

Remove material as quickly as possible

Maintain acceptable geometric accuracy & surface finish

Not break or excessively deflect/wear tool

Cutting Forces/Taylor Tool Life calculations

Minimize non-cutting time (set-ups, stock load/part unload, tool changes)

jig

It has all the characteristics of a fixture, but also provides a means of guiding the tool during the operation

Fixture

work-holding device (usually custom designed) for a particular part

Advantages of machining

Can machine most solid materials

Can machine complex geometry parts

Tight tolerances (± 0.001”)

Good surface finish

Disadvantages of machining

Time consuming

Wasteful (chips)

Large energy use

Rotational Work Part

cylindrical or disk-like shape

This geometry involves a cutting tool removing material from a rotating work part.

Non-Rotational Work Parts (prismatic work part)

block-like and plate-like shape

Geometry is achieved by linear motions of the work part

generating

part geometry is determined by the feed trajectory of cutting tool

Types of generating processes

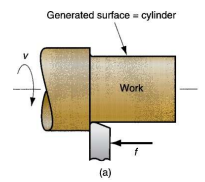

(a) Straight turning

(b) Taper turning

(c) Contour turning

(d) Plain milling

(e) Profile milling

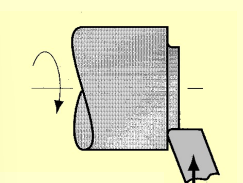

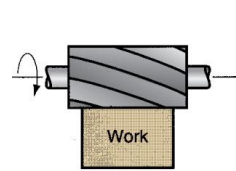

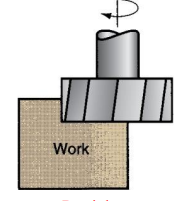

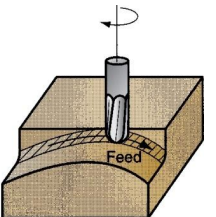

What generating process is shown?

straight turning

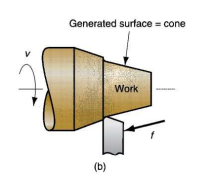

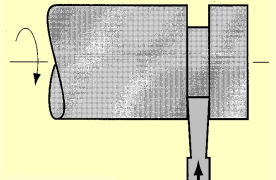

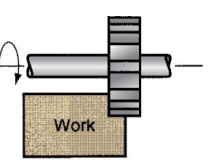

What generating process is shown?

taper turning

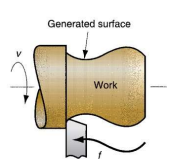

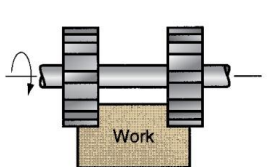

What generating process is shown?

contour turning

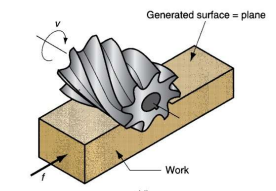

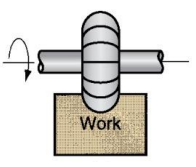

What generating process is shown?

plain milling

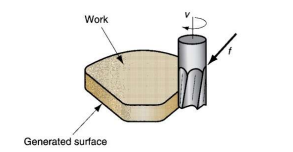

What generating process is shown?

Profile milling

Forming

part geometry is created by the shape of the cutting tool

Types of forming processes

(a) Form turning

(b) Drilling

(c) Broaching

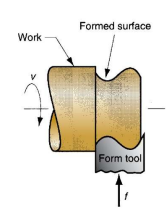

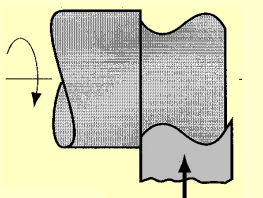

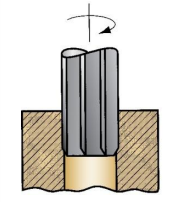

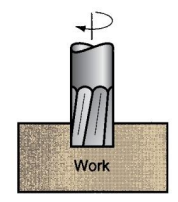

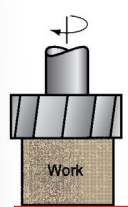

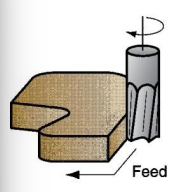

What forming process is shown?

Form turning

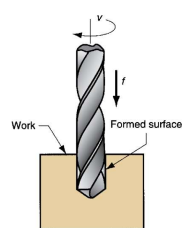

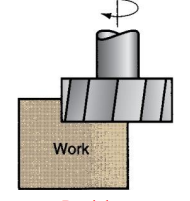

What forming process is shown?

Drilling

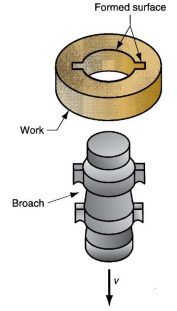

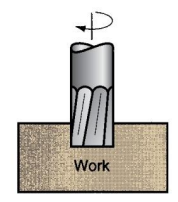

What forming process is shown?

Broaching

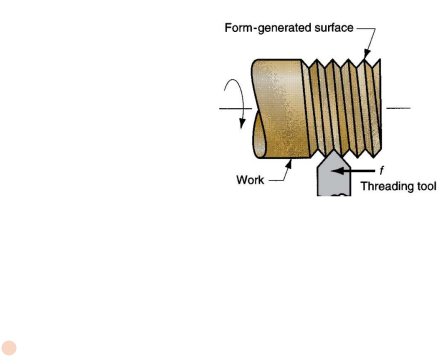

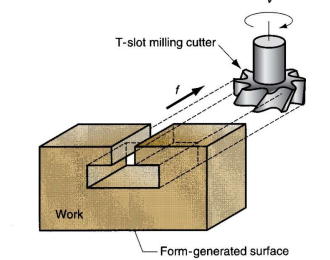

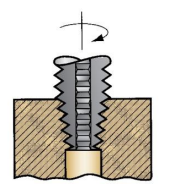

What are the processes that are a combination of forming and generating

thread cutting, slot milling

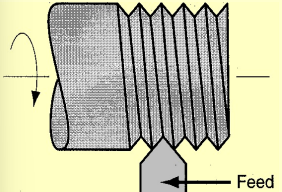

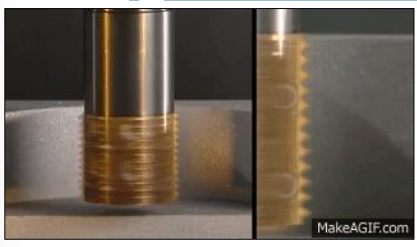

What process is shown?

Thread cutting

What process is shown?

slot milling

Three general common machining operations

turning, drilling, milling

Types of turning operations

facing, shaping, cut-off, threading, drilling, knurling, boring

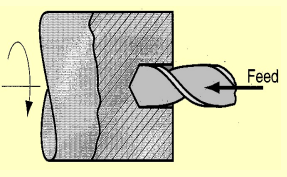

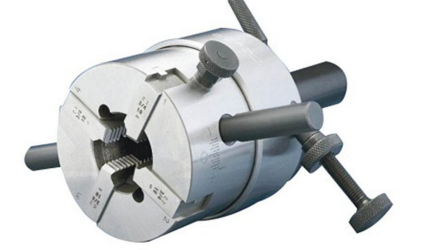

What turning process is shown?

facing

What turning process is shown?

shaping

What turning process is shown?

cut-off

What turning process is shown?

threading

What turning process is shown?

drilling

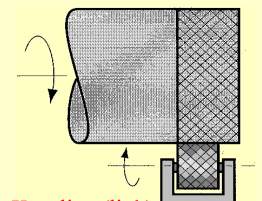

What turning process is shown?

knurling

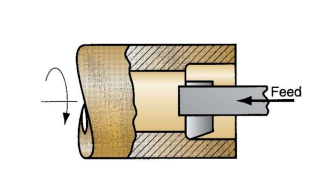

What turning process is shown?

boring

Drilling

Round rotating tool fed axially into workpiece

Turning is commonly accomplished on what type of machine?

lathe

Drilling is commonly accomplished on what type of machine?

drill press

Through hole

drill exits opposite side of work

Blind hole

drill does not exit opposite side of work

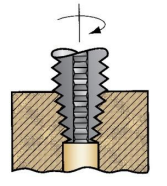

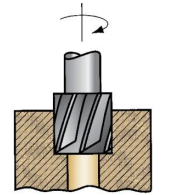

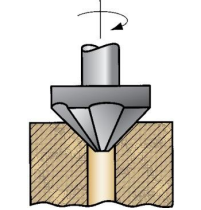

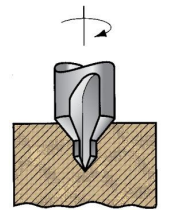

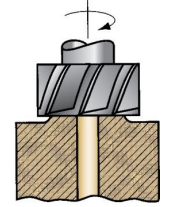

What drilling operation is shown?

Reaming

What drilling operation is shown?

Tapping

What drilling operation is shown?

Counterboring

What drilling operation is shown?

Countersinking

What drilling operation is shown?

Center Drilling

What drilling operation is shown?

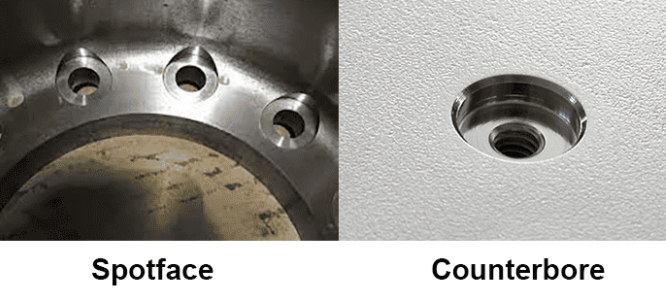

Spot facing

Reaming

Unlike drill bits, reamers are available in ANY size diameter. Used to remove very little material. Finishing operation.

Countersinking

Add chamfers to holes or creates geometry needed to house a flat head fastener

Center Drilling

used to create accurately located pilot holes for subsequent drilling or for a lathe’s tailstock center to support workpiece

Spot Facing

Used for producing a flat seat for a bolt head, washer, or nut

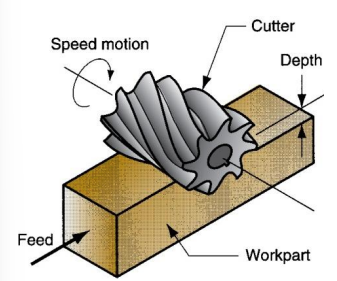

Peripheral Milling

Cutter axis parallel to surface being machined. Cutting edges on outside periphery of cutter. Use a horizontal milling machine

What type of peripheral milling is this?

slab milling

What type of peripheral milling is this?

slotting

What type of peripheral milling is this?

side milling

What type of peripheral milling is this?

Straddle milling

What type of peripheral milling is this?

Form Milling

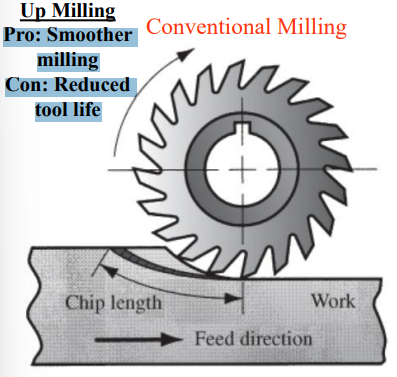

Up Milling (Conventional Milling)

Cutter teeth rotate opposite to feed direction

Pro: Smoother milling

Con: Reduced tool life

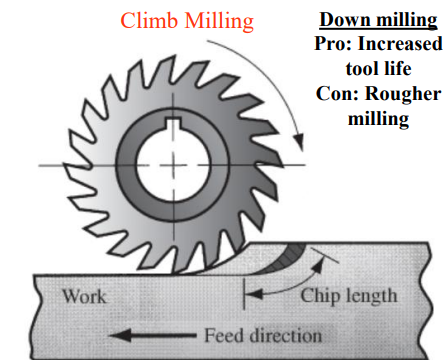

Down Milling (Climb Milling)

Cutter teeth rotate same as feed direction

Pro: Increased tool life

Con: Rougher milling

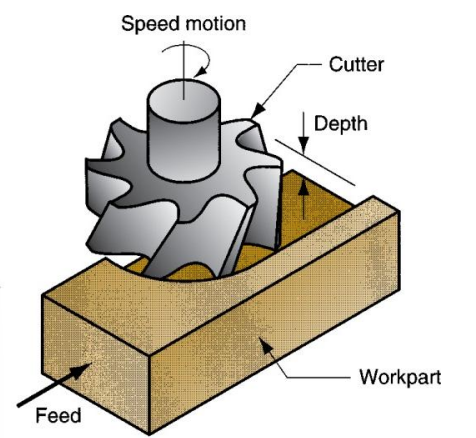

Face Milling

Cutter axis perpendicular to surface being milled. Cutting edges on both the end and outside periphery of the cutter. Uses Vertical milling machining`

What type of face milling is shown?

Conventional Face milling

What type of face milling is shown?

Partial Face Milling

What type of face milling is shown?

End Millling

What type of face milling is shown?

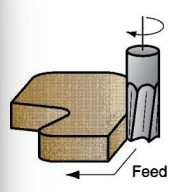

Profile Milling

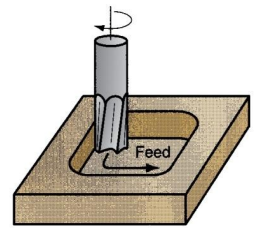

What type of face milling is shown?

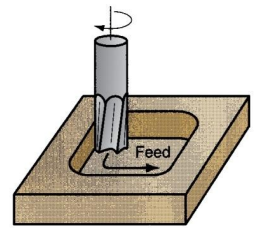

Pocket Milling

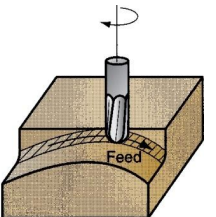

What type of face milling is shown?

Surface Contouring

Conventional Face Milling

Diameter of cutter is greater than the work part width

Partial Face Milling

Diameter of the cutter overhangs the work only on one side

End Milling

Diameter of cutter is less than the work width, so a slot is cut into the part

Profile Milling

A form of end milling in which the outside periphery of a flat part is cut

Pocket Milling

Another form of end milling to cut shallow pockets into parts

Surface Contouring

Creates 3D surface form. Typically using a ball-nose cutter rather than a square-end cutter

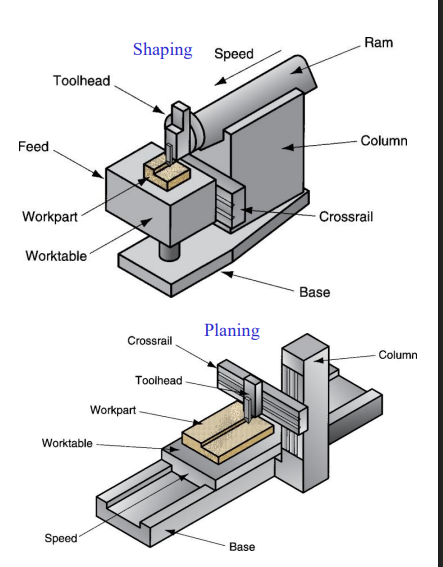

Shaping & Planing

A straight, flat surface is created in both operations. Similar operations, both use a single point cutting tool moved linearly relative to the work part

Planing: Part moves

Shaping: Tool Moves

Broaching

A multiple tooth cutting tool is moved linearly relative to work in direction of tool axis. Variety of work shapes possible

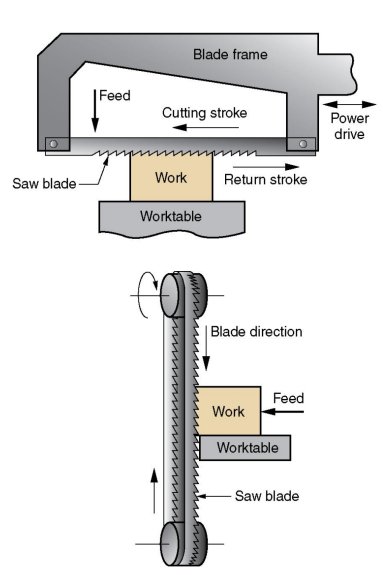

Sawing

Cuts narrow slit in work by a tool consisting of a series of narrowly spaced teeth

What are the types of special geometries

external screw threads, internal screw threads, gears

Methods of producing external screw threads

Single-point thread cutting

Threading die

Thread chasing using self-opening threading dies

Thread milling

Thread rolling

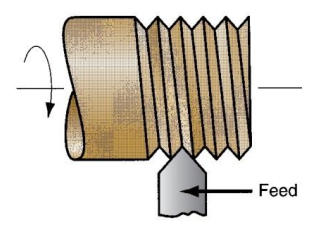

Single-point thread cutting

Simplest and most versatile method of cutting threads. Single point cutting tool on the lathe

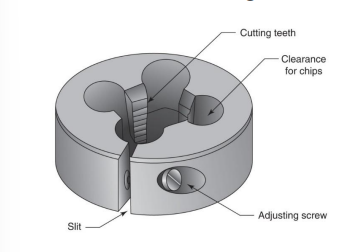

Thread die

Cut threads in a single pass rather than multiple passes, as in single-point threading

Thread chasing using self-opening threading dies

Similar to threading dies, but is equipped with an automatic device that opens the cutting teeth at the end of the cut

Thread milling

Use form-milling cutter to shape the threads of a screw. Can create internal and external threads

Thread rolling (“forming”)

Most common method for producing external threads. Process is not economical for low production quantities

Methods for producing internal screw threads

Tapping

Collapsible taps

Tapping

Cylindrical tool with cutting teeth arranged in spiral, whose pitch is equal to that of the desired screw threads

Collapsible taps

Similar to self-opening threading dies

Cutting teeth retract for quick removal from hole

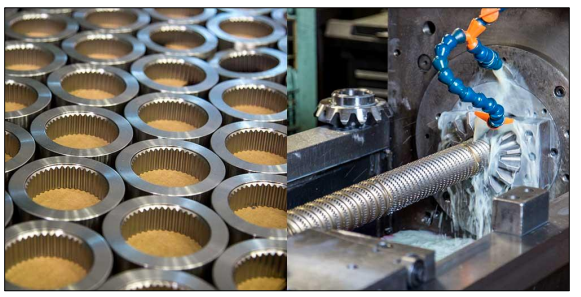

Methods for producing gears

Form milling

Gear hobbing

Gear shaping

Gear broaching - for internal and external gears

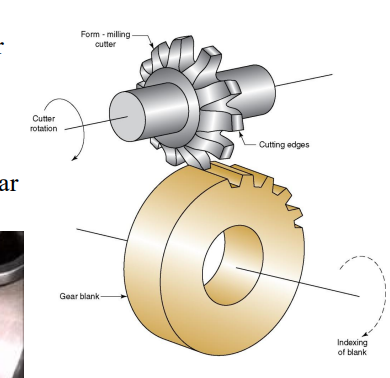

Form milling

Cutter has teeth with the shape of the spaces between teeth on the gear. Gear blank is indexed between each pass to establish correct size of the gear tooth

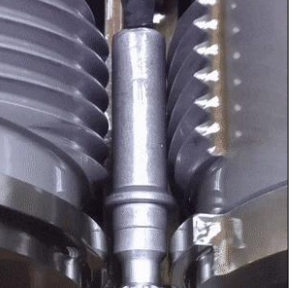

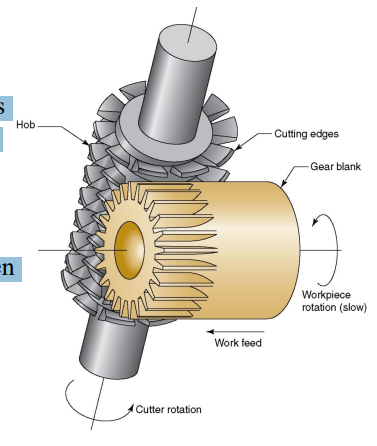

Gear hobbing

Hob has a slight helix and its rotation is coordinated with much slower rotation of the gear blank.

Special milling machines (called hobbing machines) accomplish the relative speed and feed motions between cutter and gear blank

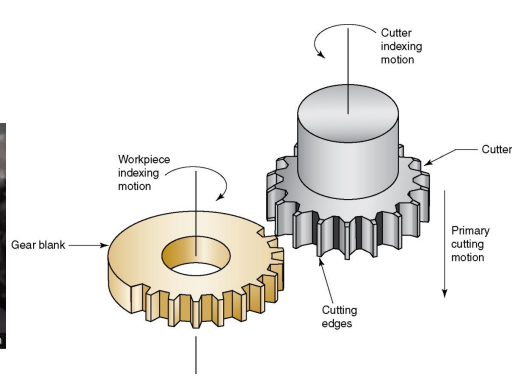

Gear shaping

To start the process, cutter is gradually fed into gear blank. Then, cutter and blank are slowly rotated after each stroke to maintain tooth spacing

Gear Broaching

For internal gears, broach consists of a series of gear-shaped cutting teeth of increasing size to form the gear teeth in successive steps as broach is drawn through starting hole.

For external gears, broach is tubular with inward-facing cutting teeth

What are the 3 possible modes by which a cutting tool can fail in machining

Fracture failure

Temperature failure

Gradual wear

Fracture Failure

Cutting forces at the tool point becomes excessive, causing it to fail suddenly by brittle fracture

Temperature failure

Cutting temperature is too high for the tool material, causing the material at the tool point to soften. Leads to plastic deformation and loss of the sharp edge

Gradual Wear

Gradual wearing of the cutting edge causes loss of tool shape, reduction in cutting efficiency, and acceleration of wearing as the tool becomes heavily worn.

What are the two location gradual wear occurs?

Crater wear

Flank wear

Crater Wear

occurs on top rake face

Flank Wear

Occurs on flank (side of tool)

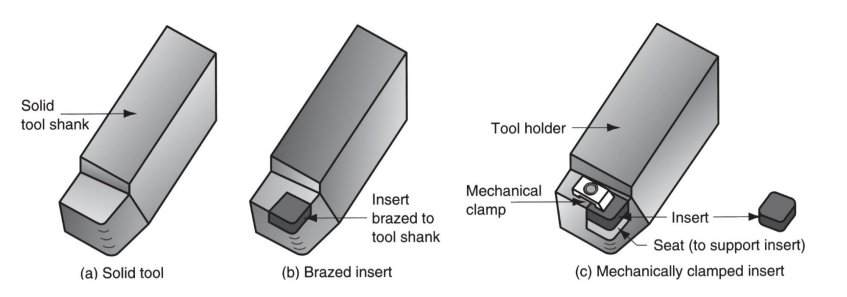

What are the 3 different cutting tools for turning?

Solid tool, brazed insert, mechanically clamped insert