structures and properties of materials finals

1/51

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

52 Terms

What is specific strength?

Strength divided by density (strength-to-weight efficiency)

What is specific stiffness?

Elastic modulus divided by density (stiffness-to-weight efficiency)

Compare carbon fiber composites vs metals in specific properties

Carbon fiber = much higher specific strength and stiffness than steel or aluminum

Role of the matrix in fiber composites?

Holds fibers, transfers load, protects fibers, provides shape, adds toughness

Common matrix materials

Epoxy, polyester, vinyl ester, thermoplastics (PP, PEEK), metals and ceramics

Role of fibers in composites?

Carry load, provide strength and stiffness, control directional properties

Common composite fivers?

Carbon fiber, glass fiber, Kevlar, natural fibers

Example of particulate composite in automotive use

Brake Pads, tires (carbon black), SiC-reinforced engine parts

Advantages of particulate composites over carbon fiber

Cheaper, easier to manufacture, good wear resistance, isotropic, durable

Composite desnity formula

ρc = Vfρf + Vmρm

Maximum stiffness condition?

Iso-Strain (parallel loading):

Emax = VfEf + VmEm

Minimum stiffness condition?

Iso-stress (series) loading): 1/Em in = Vf/Ef + Vm/Em

What is a hybrid composite?

Composite containing 2+ fiber types (e.g., carbon + Kevlar).

What is a laminar composite?

Composite made of stacked bonded layers (plywood, laminated CFRP)

Thermoset structure

Highly cross-linked 3D network. Strong permanent covalent bonds between polymer chains. (Epoxy resin)

Thermoset recyclability?

No—cannot be remelted

Thermoplastic structure?

Linear or branched chains, lightly engtangled. Weak IMF between polymer chains. No cross-links between chains. Softens when heated.

Thermoplastic recyclability?

Yes—can be reheated and reshaped

What is an elastomer?

Lightly cross-linkled polymer with large elastic deformation

How are elastomers strengthened?

Vulcanzation + fillers (carbon black, silica)

What is Tg (glass transition temperature?

Temperature where polymer changes from brittle to rubbery

Why is Tg important

Determines safe operating temperature of polymers

Repeat unit of polyethylene (PE)

–(CH₂–CH₂)–

Repeat unit of PVC

–(CH₂–CHCl)–

Repeat unit of polypropylene PP

–(CH₂–CH(CH₃))–

Repeat unit of polystyrene PS

–(CH₂–CH(Ph))–

Repeat unit of PTFE (teflon)

–(CF₂–CF₂)–

Why plastics replace metals in cars

Lighter, corrosion-resistant, cheaper, impact damping, easier to mold, fuel efficient

What is the purpose of heat treatment?

To change microstructure —alter strength, hardness, ductility and toughness

What microstructure forms when steel is slow cooled?

pearlite (coarse or fine depending on cooling rate

What microstructure forms when steel is rapidly cooled?

Martensite: very hard, very brittle

What does tempering do?

Converts martensite to tempered martensite: decreases hardness, increases toughness

Why do fine grains increase strength?

grain boundaries block dislocation motion

Where do cracks and corrosion often initiate?

At grain boundaries

What is a composite?

A material made from 2+ phases that reamin distinct, working together for improved properties

What is the role of the matrix?

Holds fibers, transfers load, protects reinforcement, adds toughness

What is the role of the reinforcement?

Provides strength and stiffness

Main composite types?

Fibrous, particulate, laminar, hybrid.

Why use composites in vehicles?

High strength-to-weight, hgih stiffness-to-weight, corrosion resistance, fuel efficiency

Stiffness and lower bounds formulas

Parallel loading: E=VfEf+VmEmE = V_fE_f + V_mE_mE=VfEf+VmEm

Series loading: 1/E=Vf/Ef+Vm/Em1/E = V_f/E_f + V_m/E_m1/E=Vf/Ef+Vm/Em

What are thermoplastics?

Linear/branched chains, no permanent crosslinks, recyclable, soften when heated

What are thermosets?

Cross-linked polymers with large elastic deformation

What strengthens elastomers?

Vulcanization and fillers (carbon black, silica)

Below Tg

Too brittle

Above Tg

Rubbery/ductile

Why use Mohr’s Circle?

To find principal stresses and maximum shear stress when under plane stress

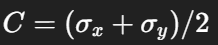

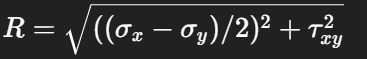

Center of Mohr’s Circle?

Radius of Mohr’s Circle

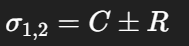

Principal stresses

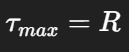

Maximum shear stress?

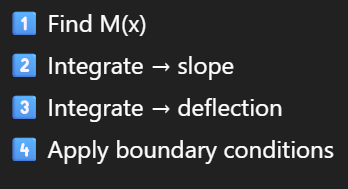

Steps to solve deflection by integration

How do material classes compare in stiffness?

Ceramics > Metals > Composites (varies) > Polymers