Materials Part C - Aluminium Alloys

1/26

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

27 Terms

What classifies a light metal?

Light metals are those with a specific gravity (density of metal compared with water) of less than 5.

Which are the main 4 base alloying metals?

Beryllium - Be

Magnesium - Mg

Aluminium - Al

Titanium - Ti

What are the specific strengths of these metals (Young’s modulus over density)?

Be - 170

Mg - 26

Al - 27

Ti - 24

What are the 6 alloying elements for aluminium?

Zinc

Magnesium

Copper

Manganese

Silicon

Lithium

What are the broad 3 uses of aluminium alloys?

Casting alloys

Precipitation hardening alloys

Cold working alloys

Aluminium alloys are sdandardised with 4 digit number with the first digit defining the group that the alloy is in, sometimes referred to as X - thousand series.

What are the different thousand series and what characterises each alloy?

1XXX - 99% Al

2XXX - Copper

3XXX - Manganese

4XXX - Silicon

5XXX - Magnesium

6XXX - Magnesium and Silicon

7XXX - Zinc

What are the negative effects on alloying aluminium?

Deformability / ductility is reduced

Corrosion resistance is worsened

Surface finish is worsened

Density is increased

Conductivity is decreased

What are positive effects of alloying aluminium?

Increased strength:

Pure Al has UTS 90 MPa

Strongest alloys have UTS of 700 MPa!!

Some Rapid Solidified Powder Metallurgy alloys have UTS of 1 GPa

What are the 4 main ways to increase the strength of a metal?

Grain refinement

Cold working

Precipitation hardening

Solid solution strengthening - Alloying

What are the families of Aluminium alloys?

Heat treatable alloys- Derive strength from precipitation hardening

Non-heat treatable alloys - Get strength from grain refinement, solid solution strengthening and cold working

What series of aluminium alloys are non-heat treatable?

1XXX: Copper

3XXX: Al-Mn

5XXX: Al-Mg

These cannot be hardened by precipitation methods.

In 1000 series alloy what impurities are present?

Iron and silicon however these impurities are actually beneficial from a strength point of view.

However 1000 series aluminium is mean to be 99 percent pure aluminium or higher so generally these impurities are not wanted.

How is strength improved for 3000 series alloys?

Manganese present (1%) forms dispersoids (interstitial grains)

What are the main benefits of 3000 series alloys and therefore what are the predominantly used for?

Very good recyclability and therefore used in drinks cans.

What are some advantages and disadvantages of 5000 series alloys (6% Mg)?

Advantages:

Light wieght

Disadvantages:

Weldability

Repairability

Yield point phenomena - serrated yield line

What aluminium alloys are heat treatable alloys?

2XXX: Al-Cu

6XXX: Al-Mg-Si

7XXX: Al-Zn

What are 2000 series alloys used for?

Aircraft wing skin lower wing skin due to its damage tolerance.

What are 6000 series alloys used for?

Extruded door and window frames.

However are being designed to replace 2000 series alloys for use in lower fuselage skin.

What are 7000 series alloys used for?

Used in upper wing structures, tank or or and bridges due to the high weldability.

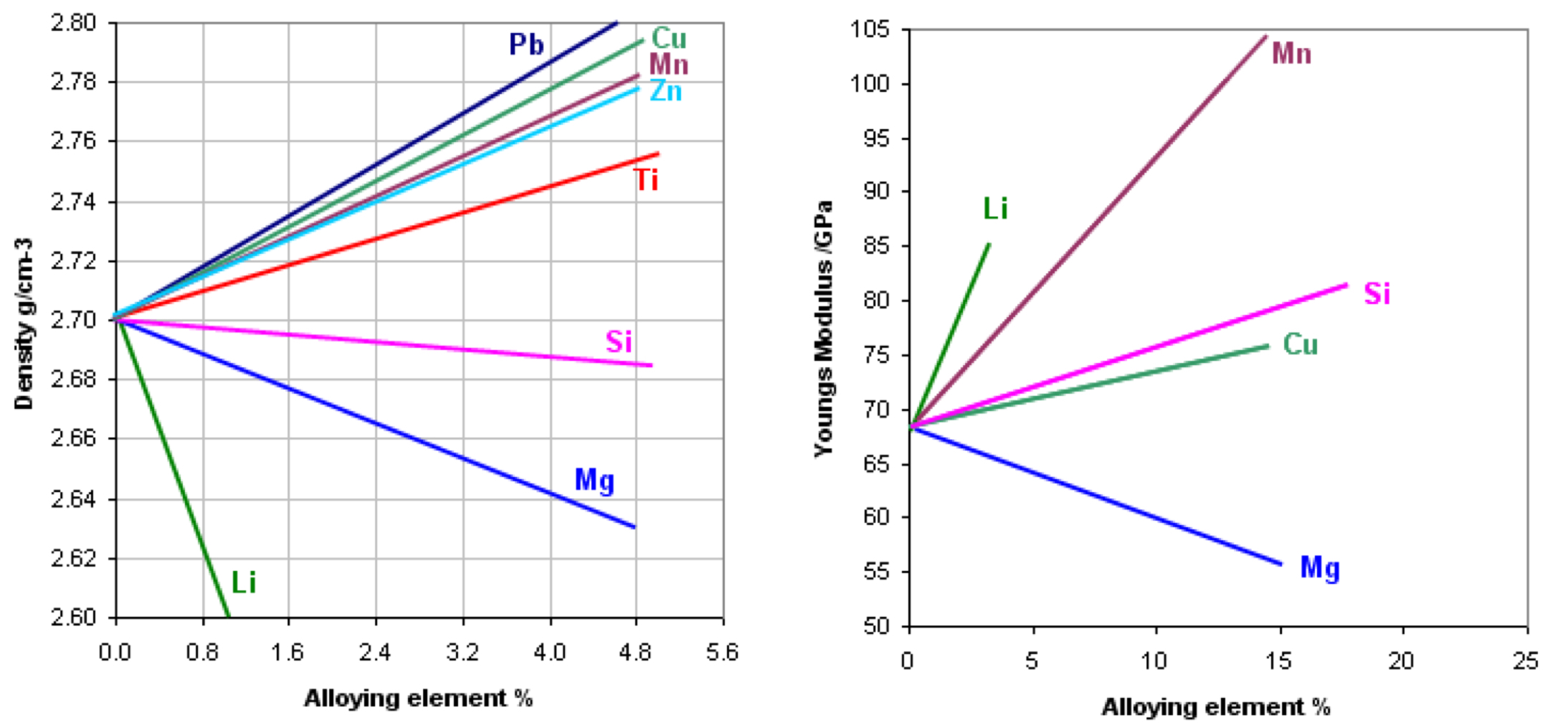

Here are some graphs of density and Young’s modulus against element concentration.

What is the new generation of Aluminium alloy designed to replace 2XXX and 7XXX series alloys?

Al-Li alloys (2% Li), offer excellent ductility and specific strength and match 2XXX and 7XXX series alloys for fracture toughness and fatigue crack growth performance.

What is the key alloy designation for this new series?

8090

What is a key super meta feature of this alloy?

This alloy can be superplastically formed alloying very complex geometry and thin sections.

What is the main drawback of this alloy?

It is prone to stress corrosion cracking.

As the name entails, under stress in corrosive environments, the alloy is prone to cracking.

What is the maximum operating temperature of aluminium alloys?

125 C

How can this be increased?

Draw metal into fibres and in case in matrix to form MMC (metal matrix composite).

What is an allotrope?

The bonding structure that an element can exhibit. Elements that can from multiple bonding structures are refereed to as having allotrophy.