IB DT: Topic 4.e: Textiles

1/24

Earn XP

Description and Tags

credits https://sites.google.com/view/designandinquiry/dp-sl-design/topic-4-final-production/4-2-materials/4-2e-textiles?authuser=0

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

25 Terms

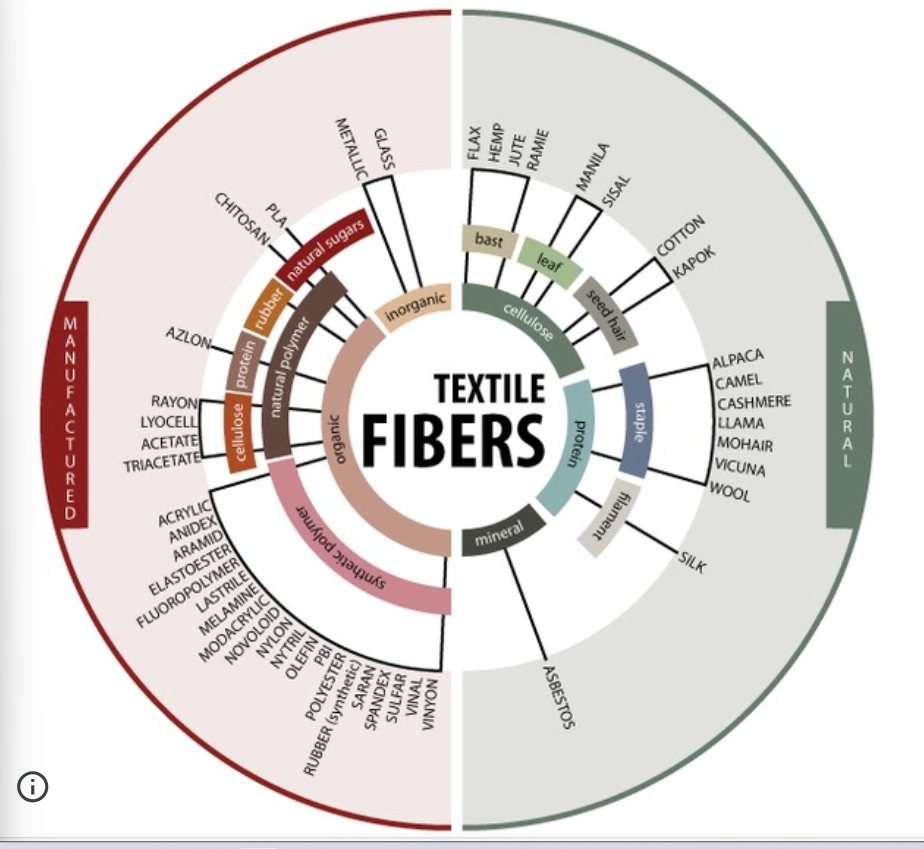

diagram of different textile origins

what is a fibre?

the raw form, used in the manufacture of other materials, called composites. can be processed into long forms called yarns.

what is a yarn?

a long, continuous fibre

what is a thread?

thin yarns used in sewing

what is fabric?

created by cloth produced by weaving, knitting or felting

what are the two types of textiles?

natural fibre or synthetic fibre

what are the properties of natural fibre textiles?

high absorbency

low tensile strength

low elasticity

burns but doesn’t melt

what are the properties of synthetic fibre textiles?

low absorbency

high tensile strength

high elasticity

burns and melts

what is wool and what are its properties?

originates from sheep

commonly used in clothing such as socks and suits

highly insulative

highly durable

highly absorbent

what is cotton and what are its properties?

the most common natural fibre, made from the cotton plant

highly absorbent

high tensile strength

durable

retains colour well

what is silk and what are its properties?

natural fibre made from silk cocoon

the strongest of all natural fibres

thermal properties make it cool in summer and warm in winter

very smooth and light to the touch

strength means it has medicinal uses such as stiches

what is nylon and what are its properties?

synthetic fibre derived from petrochemicals

good abrasion resistance

low absorbance

high elasticity

ideal for mass production

what is polyester and what are its properties?

versatile fabric that is strong, quick drying, resistant to scratching, resists mould and stains

synthetic and derived from petrochemicals

what is lycra and what are its properties?

synthetic fibre derived from petrochemicals

very highly elastic

what is a natural fibre?

materials produced by plants or animals that can be spun into a thread, rope or filament

what is a synthetic fibre?

materials made from man-made materials that are spun into thread - the joining of monomers and polymers through polymerisation

how are natural fibres converted from fibres to yarns?

yarn spinning

hand spinning: pre-industrial revolution, people made yarns by using a tool called a carder to align parallel the yarns before twisting

machine spinning

how are synthetic fibres converted to yarns?

most synthetic fibres are known as filament fibres - they are so long that they work as yarn themselves.

what is weaving?

the process of interlocking yarns at right angles to create a fabric

what is knitting?

the process of manipulating yarn in multiple lines to create a tube

what is lace making?

the weaving of yarns and threads into delicate, open patterns

what is felting?

the process of creating a fabric by compressing and matting fibres together. felted fabrics can be quite dense as the fibres are laid down in random, densely packed natures. (made from natural wool and synthetic fibres)

how are textiles recovered/disposed of? are they sustainable?

recyclable

donatable

however, the textile making process is energy and resource intensive.

what ethical considerations come with textile production?

labour intensive and poor working conditions: most raw material production and textile manufacturing takes place in developing countries, using low-skilled labour and under poor working conditions

treatment and genetic modification of plants and animals: the genome of goats has been modified by scientists to produce the same silk protein

what are the environmental considerations that come with textile production?

chemicals and pesticides used in production of natural fibres like cotton have a huge environmental impact

most synthetic fibres are oil based

cotton requires loads of water to grow

dying textiles relies on a range of chemicals and energy intensive processes - poor regulation means that toxic chemicals are released into the environment

large carbon footprint associated with transportation

regular cleaning of textiles requires lots of water, cleaning chemicals and energy