material science 104

1/45

Earn XP

Description and Tags

quiz 1 material

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

46 Terms

why are the number of dislocations present greatest in metals

non-directional bonding:

Metallic bonds involve a "sea of electrons" shared among many atoms, which means the bonds aren’t rigidly fixed in a particular direction. This allows atoms to slide past one another more easily, which helps dislocations form and move.

closely packed

Many metals have close-packed crystal structures like FCC (face-centered cubic) and HCP (hexagonal close-packed).

These structures have high atomic packing density and many slip systems — combinations of slip planes and directions where dislocations can move easily.

The ionic ones if you are trying to shear the positive ions will want to repel.

how are strength and dislocation motion related

stronger material slippage is harder, harder to deform

why does heating alter strength and other properties

how does plastic deformation often occur

in metals by slip ( an edge dislocation slides over adjacent plane half-planes of atoms

how to find plane where easiest slippage occurs

slip plane → highest planar densities

slip directions

direction of movement → highest linear densities

strategies for strengthening

reduce grain size: grain boundaries are barriers to slip, smaller grain size more barriers, the strength of barriers increase with increasing angle of misorientation

form solid solutions: (mixture of atoms in solid, impurity atoms distort the original lattice and generate lattice strains which act as barriers to dislocation motion) (small or big impurity)

precipitation strengthening: space smaller yield strength higher. forming tiny particles (precipitates) inside the metal’s crystal structure. tiny precipitates block the motion of dislocations, making plastic deformation harder

cold work: forging, drawing (pull metal rod through narrow passage of dies) rolling, extrusion. All happen at room temperature.

dislocation density

total dislocation length / Unit volume (increases during cold working)

yield strength

strength before material plastic-ally deforms (0.002)

impact of cold working

increase yield strength, tensile strength but ductility decreases

annealing stages (heat treating after cold working)

recovery: reduction of dislocation density by annihilation

re-crystallization: more homogeneous/more uniform they consume and replace parent cold work grains until consumed

grain growth

recrystallization temperature

temperature at which recrystallization reaches completion in 1hr (Tr decreases with increasing %CW, decreases with increasing purity)

relationship between properties, structure, processing

Properties depend on structure

Processing can change structure

material selection process

Pick APPLICATION → determine required properties (mechanical, electrical, thermal, magnetic, optical, deteriorative)

Properties → identify candidate materials (materials: structure, composition)

material → identify required processing (processing: changes structure and overall shape

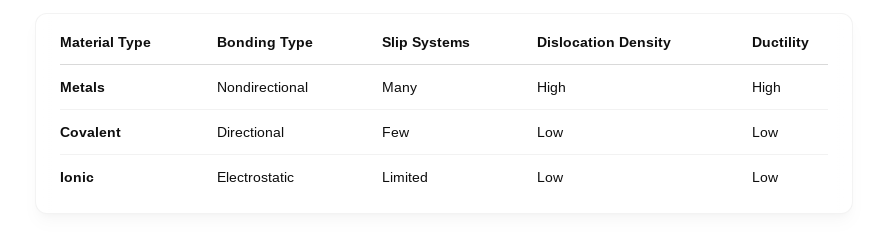

types of materials (metals, polymers, ceramics)

metals

strong, ductile

opaque, reflective

high thermal & electrical conductivity

metallic bonding

polymers

covalent bonding (sharing of electrons)

thermal & electrical insulators

optically translucent or transparent

ceramics

ionic bonding

compounds of metallic and non metallic elements

non-conducting (insulator)

brittle, glassing, eleastic

primary bonds

what promotes bonding ?

what types of bonds are there

what properties are inferred from bonding

why are most electron configurations not stable

because valence shell usually not filled completely

ionic bonds

metal (donates electrons) + nonmetal (accepts electrons)

electrostatic attractions between oppositely charged ions

large bond energy

nondirectional

covalent bonding

similar electronegativity (share electrons)

variable bond energy

directional

% ionic character MgO Xmg = 1.3 Xo =3.5

secondary bonding

arises from interactions between dipoles

fluctuating dipoles

permanent dipoles

small bond energy

properties from bonding: Tm (melting temperature) relation to bond energy (Eo)

Melting temperature is larger with larger bond energy which is dependent on bond length

properties from bonding: coefficient of thermal expansion

coefficient of thermal expansion is larger if bond energy is smaller. This value is the coefficient multiplied by heated temperature minus unheated temperature which is equal to change in length / initial length

polymorphism

some materials have more that one crystal structure

X-ray diffraction

used for crystal structure and interplanar spacing determinations

diffusion is faster for (structure, bonding, size of atoms, density)

open crystal structures

materials w/ secondary bonding

smaller diffusing atoms

lower density materials

how does diffusion occur

mass transport by atomic motion

interdiffusion

in an alloy, atoms tend to migrate from regions of high concentration to regions of low concentration

self-diffusion

in an elemental solid, atoms also migrate

vacancy diffusion

atoms exchange with vacancies

applies to substitutions impurities atoms

rate number depends on number of vacancies and activation energy to exchange

why is diffusion an important part of processing

how can the rate of diffusion be predicted for some simple cases

how does diffusion depend on structure and temperature

interdiffusion