MCHE 3920 Week 4: Sheet Metal Skeleton

1/58

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

59 Terms

Bending and matched die forming

Sheet metal forming methods fall btw 2 extremes:

matched die forming

complex, expensive, double curved parts, high volumes

Bending

simple, cheap, single curved parts, small volumes

blanking

precedes processed, cuts sheet metal to size

yield stress

want to keep stress below

exceed, bend the metal

in SMF, need to ________ yield stress in order to ________

anisotropy, isotropic

sheet metals have ________, but we assume ________

springs

interatomic bonds act like:

return to original shape

For no PERMANENT deformation, load removal makes material:

yield stress, crystal lattice

at the ________, dislocations begin to form in the ________

0.2% offset method

when hard to find yield stress from test, use ________

slip planes, slip

dislocations move along ________, where one part of lattice ________ relative to the other

strain/work hardening

slip planes hinder each s.t. it take more stress to keep deforming material

alpha (degree), R (radius); tension, compression; Neutral axis; thinner, thicker

Minimum Bending Radium (MBR) model assumptions: all deforms take place in zone defined by ________ and ________; metal deformation has same behavior in ________ as in ________ (anti-symmetric s-s curve); ________ does not change in length; metal outside NA becomes ________, inside becomes ________

original, actual, necking

Recall that stress is calculated using ______ area; if it was calculated using ______ (or instantaneous) area, stress would continue to increase in the _______ region.

true stress

calculating stress w time-varying area

unloading, parallel

If the load is reduced or removed, the material will follow a linear _____ curve that is ______ to the elastic portion of the curve.

fracture strain

The __________ is an indication of the amount of material elongation at failure.

smaller; yields; accommodated; uniform stress; more; bending; deformation

MBR caveats: can bend metal w/ ______ radius than predicted. There is a transition zone outside of the bend in which material ______ somewhat, meaning some deformation is ______ by this region. materials in bending DO NOT have ______, so can deform ______ than what tensile test suggest. in ______ tests, ______ concentrated in small volume

springback, removal

After bending the sheet metal, there will always be some amount of ______ associated with the ______ of the elastic strain.

beyond

If we can predict the amount of springback in a part, we can account for it by bending the part ______ the desired ending angle.

E, yield strenght, stress-strain

The amount of springback is proportional to the ratio of _____ to _______ (E + σ_y). Energy stored in the part is equal to the area under the _______ curve.

scaling laws

Hard to predict springback exactly, but if it is known in a reference case, we can use _________ to predict what it will be if we changed the thickness or the bending radius.

air bending

single curved parts: deforms part by predetermine bend angle w/o contacting die

Bottoming

sandwiches part btw punch and die

wipe bending

part is bent as a cantilever by a moving punch

roll bending

used to make cylinders

rollers, adjustable rolls

roll bending: Sheet metal is passed relatively slowly over turning _______ while ________ are moved with each pass to gradually deform the sheet part.

shape

In roll forming: A strip of metal is fed through a series of rollers that progressively _____ a cross-section.

good, high

in roll forming: _____ tolerance control, but initial investment is _______.

thin-walled sections, solid shapes

roll forming: Usually used with __________, but not __________ (typically extruded).

negative deformation (contraction)

Multi-axis bending: when tension is applied in one direction, positive deformation is accompanied by _______ in the other 2 directions

multi-axial deformations

poission’s ratio relates:

volume, plastic deformation

we assume ______ stays constant during ____________

v-0.5, e1+e2+… = 0 (true strains)

plastic Poission’s ratio:

e1, forming

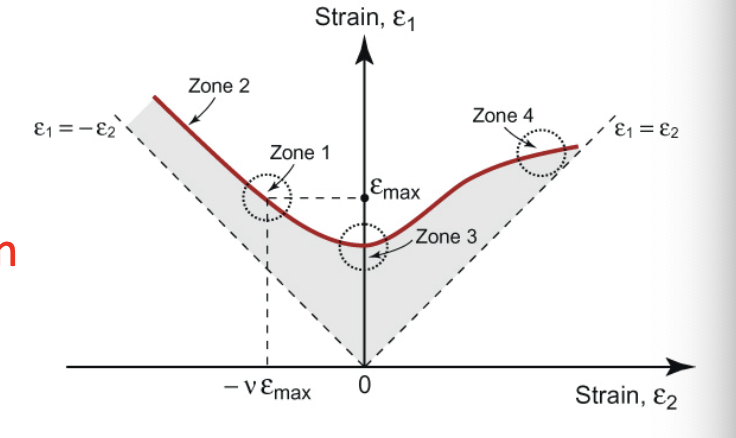

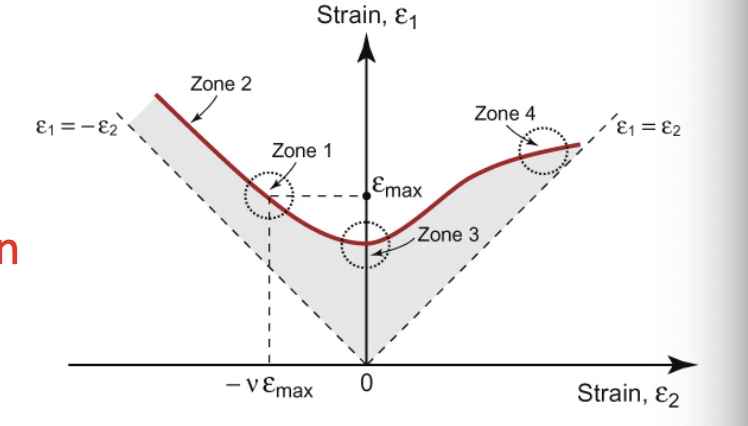

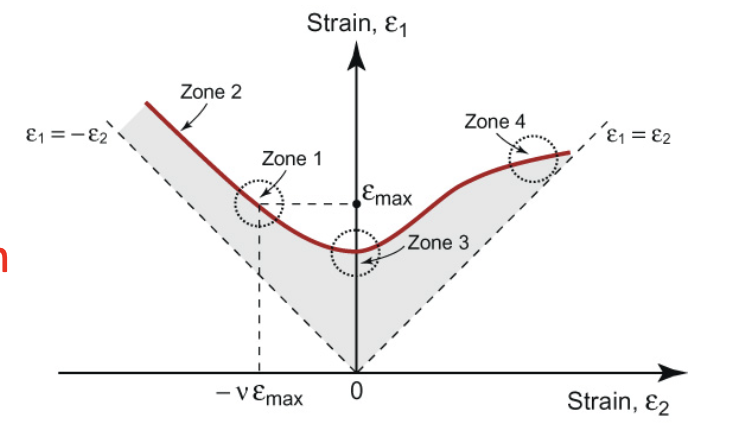

Forming Limit Diagram: applied stress is ________, so tensile test data can’t determine ______ limits

various

use FLD to show _______ combos of strain in two axes

true strains

plotted strains are what in an FLD?

e1; e2, perpindicular; not applicable, e1>e2; will fail

FLD: _____ is direction w/ largest tensile strain; _____ is _____ direction and can be in T or C; areas below dashed lines are _____ because _____; ABOVE THE FLD, THE MATERIAL _____

e1+e2+e3=0

how to solve for e3

-vplasticemax, Zone 1

for an FLD, if we only apply one load (e1=emax), e2=_____, which is denoted _____

transverse, higher, Zone 2

for an FLD, if greater compressive strain in _____ direction- there is now a _____ strain-to-failure in principle direction (_____)

transverse, reduced, Zone 3

for FLD, if we prevent deform. in _____ direction, then strain-to-failure is _____ (_____)

higher than emax

for an FLD, if tension applied in both directions, strain-to-failure is _______

out-of-plane and in-plane

2 directions for springback in double curved parts:

stiff, springback

highly double curved parts (hemispherical bowls eg) are usually _____ enough to resist ______

hammering/panel beating

process where a part is placed on leather sandbag and shaped with a rounded mallet

pressurized wheels

smooths out hammer marks from hammering

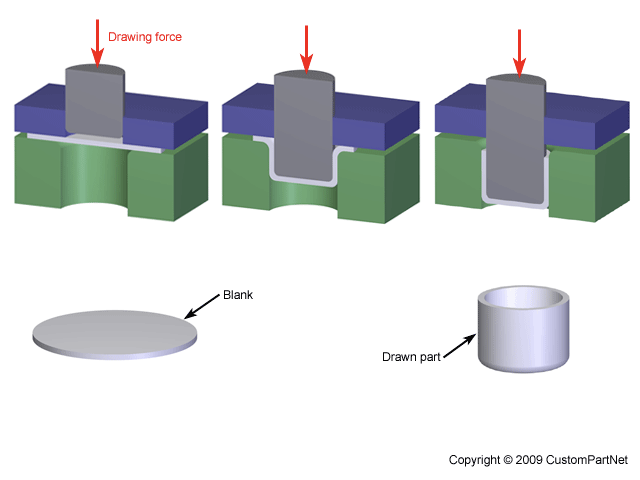

double curved parts (pans, cans, cooking pots)

deep drawing is used for

deep drawing

consists of die, blank holder, punch

plastic region

Deep drawing works best if material has a large _________

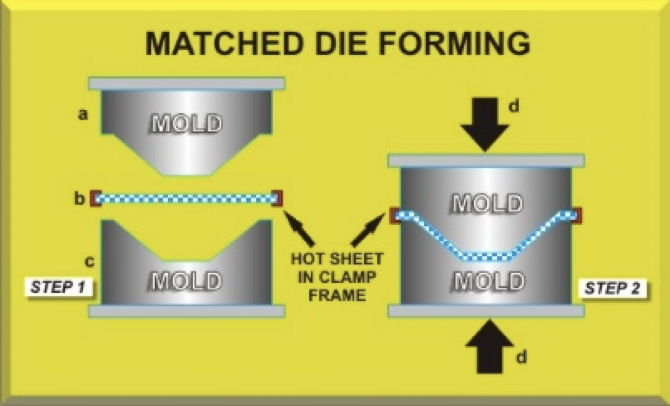

matched die forming

method for double-curved parts that is similar to deep drawing, except underside of the blank is fully supported by lower die

matched die forming

Method for double-curved parts used in automotive industry

sequential die forming

when done on a single line w/ each die doing a portion of forming

Rubber forming

method for double-curved parts similar to matched die forming, but lower die is a compliant material

lower die does not have to match upper die

what makes rubber forming easier to manufacture?

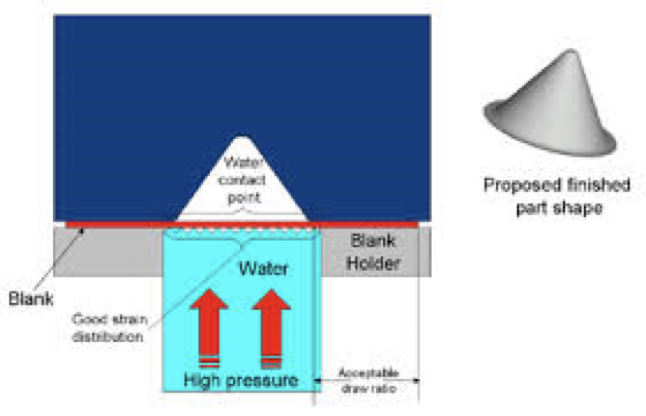

hydroforming

Method for double-curved parts where instead of a punch, high pressure water forces the sheet into the die

expand outward

what does hydroforming causes tubes to do?

fast, tight

hydroforming is ________ and allows ______ tolerances