MGMT CH 11

0.0(0)

Card Sorting

1/48

There's no tags or description

Looks like no tags are added yet.

Study Analytics

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

49 Terms

1

New cards

planning and organizing

•managers develop organizational strategy and create the structure to use resources most effectively to create value for customers and other stakeholders

2

New cards

controlling

managers monitor and evaluate whether strategy and structure are working as intended, how they could be improved, and how they might be changed if they are not working

3

New cards

steps in control process

1\.Establishing standards for performance

2\.Measuring performance

3\.Comparing actual performance with expected performance

4\.Correcting deviations if necessary

4

New cards

Establishing standards for performance

* criteria against which results are measured

* output standards: productivity, profitability, market share

* behavioural standards: customer responsiveness, absenteeism, punctuality

* output standards: productivity, profitability, market share

* behavioural standards: customer responsiveness, absenteeism, punctuality

5

New cards

Measuring performance

* actual rate of productivity?

* determine ROI

* measure market share

* monitor customer complaints, rates of absenteeism, and punctuality

* determine ROI

* measure market share

* monitor customer complaints, rates of absenteeism, and punctuality

6

New cards

compare actual performance with expected performance

* is performance higher than expected?

* is performance as expected?

* is performance lower than expected?

* evaluate the reasons for variances between the standard and actual performance

* is performance as expected?

* is performance lower than expected?

* evaluate the reasons for variances between the standard and actual performance

7

New cards

correct deviations

* corrective actions can focus on root of the problem when there is significant gap between actual and expected outputs/behaviours

\

* managers must determine the cause

* performance problems may occur because standard too high

* need to change the way in which resources are being used

* lack of training

* org needs restructuring

\

* managers must determine the cause

* performance problems may occur because standard too high

* need to change the way in which resources are being used

* lack of training

* org needs restructuring

8

New cards

types of standards

* output standards

* operating costs

* behavioural standards

* operating costs

* behavioural standards

9

New cards

output standards

refer to quantity of the service or product the employee is to produce

* may include operating costs, inventory levels, market share, ROI

* may include operating costs, inventory levels, market share, ROI

10

New cards

operating costs

measure the efficiency of production by monitoring and evaluating the actual costs associated with producing goods and services

11

New cards

behavioural standards

refer to quality of employees actions

* hours worked, dress code

* hours worked, dress code

12

New cards

operations management

process of managing the use of materials and other resources to produce goods and services

13

New cards

production system

system used to acquire inputs, convert inputs into outputs, and dispose of the outputs

14

New cards

5 Ps of org operations

* people

* plants

* parts

* processes

* planning and control systems

* plants

* parts

* processes

* planning and control systems

15

New cards

control systems

formal target setting, monitoring, evaluation, feedback systems that provide managers with info about org

16

New cards

3 effective control systems characteristics

* flecible so managers can respond to unexpected events

* provide accurate info about org performance

* provide info in timely manner

* provide accurate info about org performance

* provide info in timely manner

17

New cards

improving responsiveness

* managers must correctly identify customers and promote org strat that respond to their needs

* managers try to design production systems that produce the outputs that have the attributes customers desire

* ex: shift to online shopping due to COVID

* managers try to design production systems that produce the outputs that have the attributes customers desire

* ex: shift to online shopping due to COVID

18

New cards

impact of increased quality on org performance

leads to:

* increased reliability

* higher prices

* increased productivity

* lower costs

\

= higher profits

* increased reliability

* higher prices

* increased productivity

* lower costs

\

= higher profits

19

New cards

increasing efficiency

* total factor productivity

* partial productivity

* partial productivity

20

New cards

total factor productivity

* how well an org utilizes all of its resources

* labour, capital, materials, energy

* labour, capital, materials, energy

21

New cards

partial productivity

* specifics measures of efficiency that measures the efficiency of an individual unit

22

New cards

total factor productivity

outputs / all inputs

23

New cards

labour productivitu

outputs / direct labour

24

New cards

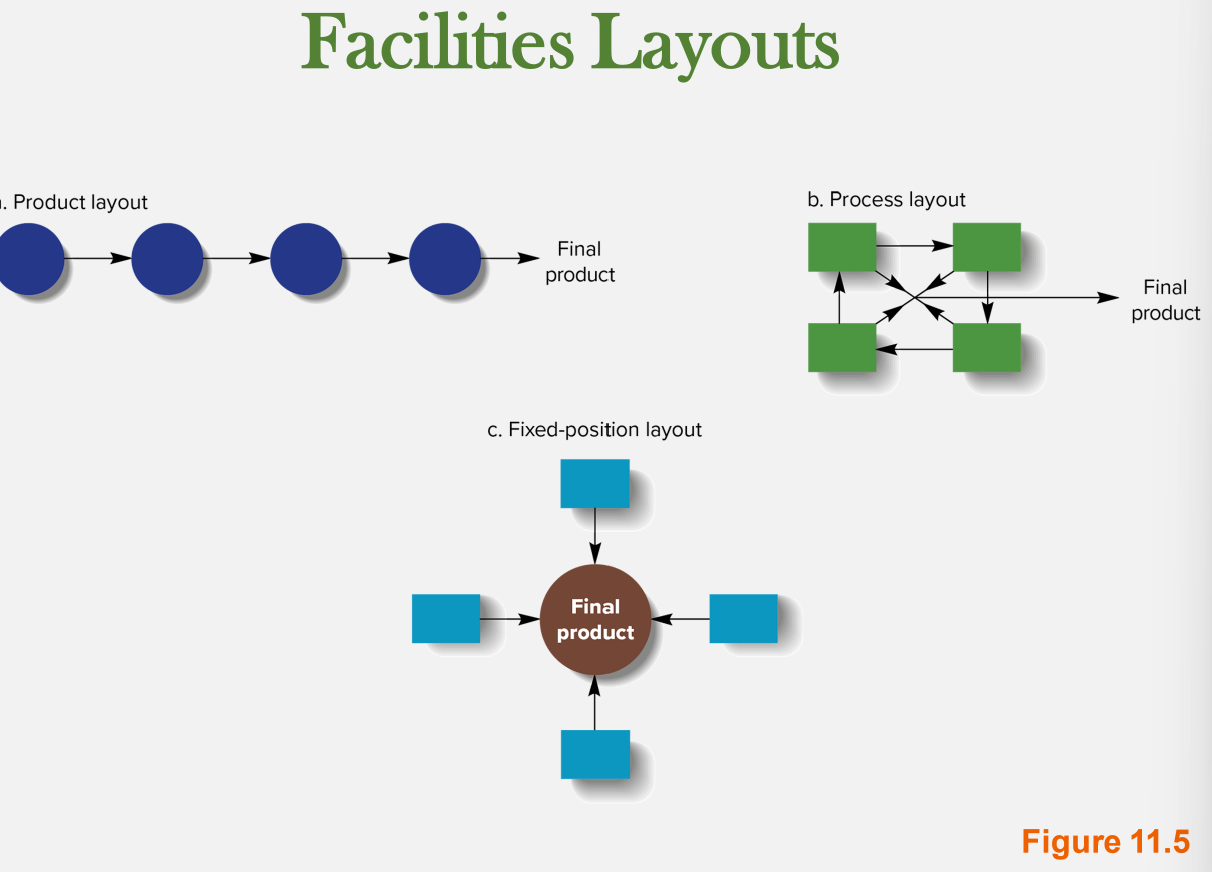

facility layout

* influences efficiency by way managers decide to lay out or design an org physical work facilities

* important because

* way in which machines and workers grouped together affects the efficiency of the production system

* major determinant of efficiency is the cost associated with setting up the equipment needed to make a particular product

* important because

* way in which machines and workers grouped together affects the efficiency of the production system

* major determinant of efficiency is the cost associated with setting up the equipment needed to make a particular product

25

New cards

product layout

* machiens organized so each operation eeded to manufacture a product is performed at workstations arranged in fixed sequence

* ex: car assembly lines

* ex: car assembly lines

26

New cards

process layout

* each workstation relatively self contained, and a product goes to whichever workstation is needed to perform the next operation to complete the product

* ex: custom made products

* ex: custom made products

27

New cards

fixed position layout

* the product stays in fixed position

* component parts are produced in remote workstations and brought to the production area for final assembly

* ex: airplanes

* component parts are produced in remote workstations and brought to the production area for final assembly

* ex: airplanes

28

New cards

inventory

* stock of raw materials, inputs, and component parts that an org has on hand at particular time

29

New cards

just in time inventory system

* parts or supplies arrive at the org when they are needed, not before

* leaves org without buffer stock of inventory needed if shortage

* inventory can be expensive to store

* sufficient inventory helps respond to increased customer demand

* leaves org without buffer stock of inventory needed if shortage

* inventory can be expensive to store

* sufficient inventory helps respond to increased customer demand

30

New cards

3 systems of control

* feedforward control

* concurrent control

* feedback control

* concurrent control

* feedback control

31

New cards

feedforward control

* anticipate and deal with potential problems before they occur

32

New cards

concurrent control

* immediate feedback on how efficiently inputs are being transformed into outputs

33

New cards

feedback control

* info about customers reactions so corrective action can be taken if necessary

34

New cards

output control

* main mechanisms managers use to assess output or performance

* financial measures

* organizational goals

* operating budgets

* financial measures

* organizational goals

* operating budgets

35

New cards

financial measures of performance

* financial measures of performance are objective and allow comparison to other firms

* profit ratios

* liquidity ratios

* leverage ratios

* activity ratios

* profit ratios

* liquidity ratios

* leverage ratios

* activity ratios

36

New cards

organizational goals

* once an org sets overall goals, they establish performance standards

* specify divisional and functional managers the level at which their unit must perform for orgs to reach overall goals

* managers evaluate how well performance matches up to goals set and determine if adjustments are needed

* provide framework for what is evaluated and assessed

* specify divisional and functional managers the level at which their unit must perform for orgs to reach overall goals

* managers evaluate how well performance matches up to goals set and determine if adjustments are needed

* provide framework for what is evaluated and assessed

37

New cards

operating budgets

* blueprint of how managers intend to use org resources to achieve org goals efficiently

* objective financial measures

* performance standards derived from goals

* appropriate operating budgets

* objective financial measures

* performance standards derived from goals

* appropriate operating budgets

38

New cards

pitfalls of output control

* extremely difficult goals may not motivate

* unachievable goals can lead to unethical behaviour

* inappropriate goals can lead to short term emphasis

* may not be responsive enough if conditions change

* unachievable goals can lead to unethical behaviour

* inappropriate goals can lead to short term emphasis

* may not be responsive enough if conditions change

39

New cards

behavioural controls

* mechanisms that managers can use to keep employee behaviour on track and make org structures work as they are designed to work

* ex:

* corporate governance

* direct supervision

* management by objectives

* bureaucratic rules and standard operating procedures

* clan control

* ex:

* corporate governance

* direct supervision

* management by objectives

* bureaucratic rules and standard operating procedures

* clan control

40

New cards

corporate governance and control

* processes companies use to be accountable to stakeholders, investors, employees, the environment, and communities

* include levels of executive pay, how they conduct audits, internal control systems, and shareholder rights

* transparent corp gov and sustainability strat

* help create comp advantage

* shareholders demand triple bottom line returns (economic, environmental, social impact)

* include levels of executive pay, how they conduct audits, internal control systems, and shareholder rights

* transparent corp gov and sustainability strat

* help create comp advantage

* shareholders demand triple bottom line returns (economic, environmental, social impact)

41

New cards

direct supervision

* managers actively monitor and observe behaviours of their subordinates

* problems with direct supervision

* very expensive

* can be demotivating to subordinates

* sometimes not feasible

* problems with direct supervision

* very expensive

* can be demotivating to subordinates

* sometimes not feasible

42

New cards

management by objectives

* provide framework within which to evaluate subordinates for their ability to achieve specific goals

* allow managers to monitor progress toward achieving goals

* reviews are held periodically looking at progress toward goals

* allow managers to monitor progress toward achieving goals

* reviews are held periodically looking at progress toward goals

43

New cards

bureaucratic roles and SOPs

* system of rules and standard operating prosedures (SOPs) that standardize the behaviour of divisions, functions and individuals

* SOPs

* written instructions describing the exact series of actions that should be followed in a specific situation

* rules and policies that standardize behaviours

* discipline: administering punishment when undesired behaviours are exhibited

* SOPs

* written instructions describing the exact series of actions that should be followed in a specific situation

* rules and policies that standardize behaviours

* discipline: administering punishment when undesired behaviours are exhibited

44

New cards

progressive discipline

* verbal reprimand

* ex: occasional tardiness/absenteeism

* written reprimand

* ex: booking off sick every friday

* discharge

* theft

* embezzlement

* ex: occasional tardiness/absenteeism

* written reprimand

* ex: booking off sick every friday

* discharge

* theft

* embezzlement

45

New cards

problems with bureaucratic control

* establishing rules easier than discarding them

* increases red tape

* firm can become too standardized and not flexible - people stop thinking for themselves

* incompatible with innovation

* best used for routine activities and programmed decisions

* increases red tape

* firm can become too standardized and not flexible - people stop thinking for themselves

* incompatible with innovation

* best used for routine activities and programmed decisions

46

New cards

clan control

* shared norms and values of org members

* relies on strong org culture

* employees internalize org values and norms and let these guide their decisions and actions

* important for 2 reasons

* provide control where output and behavioural controls do not work

* strong culture and clan control helps employees focus on what is best for org in the long run

* relies on strong org culture

* employees internalize org values and norms and let these guide their decisions and actions

* important for 2 reasons

* provide control where output and behavioural controls do not work

* strong culture and clan control helps employees focus on what is best for org in the long run

47

New cards

clan control and diversity

* values and norms embedded in the org culture may hinder diversity, equity, and inclusion goals

* inclusive cultures create opportunities for team building that are welcoming and respectful of differences

* managers must question assumptions that underpin clan control to dismantle systemic or unintended racism

* cultural norms upon which clan control relies must be inclusive of diversity

* inclusive cultures create opportunities for team building that are welcoming and respectful of differences

* managers must question assumptions that underpin clan control to dismantle systemic or unintended racism

* cultural norms upon which clan control relies must be inclusive of diversity

48

New cards

importance of control

* adapt to change and uncertainty

* discover irregularities and errors

* reduce costs, increase productivity, or add value

* detect opportunities

* deal with complexity

* decentralize decision making and facilitate teamwork

* discover irregularities and errors

* reduce costs, increase productivity, or add value

* detect opportunities

* deal with complexity

* decentralize decision making and facilitate teamwork

49

New cards

control and comp advantage

* control system: includes the measures to asses how efficiently the org is producing goods and services

* if any changes in production, measures tell managers how successful they have been

* without a control system managers have no idea how well their org is performing and how its performance can be improved

* if any changes in production, measures tell managers how successful they have been

* without a control system managers have no idea how well their org is performing and how its performance can be improved