CEPRCD30 INTRO TERMS

1/57

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

58 Terms

sand, gravel, crushed rocks, or other aggregates; paste

Concrete is a mixture of __________ held together in a rocklike mass with _________.

Concrete

has high compressive strength and a very low tensile strength.

REINFORCED CONCRETE

is a combination of concrete and steel wherein the steel reinforcement provides the tensile strength lacking in the concrete.

Reinforced concrete has a high compressive strength compared to other building materials.

Due to the provided reinforcement, reinforced concrete can also withstand a good amount tensile stress.

Reinforced concrete has a high fire and weather resistance.

The reinforced concrete building system is more durable than any other building system. It acts like a rigid member with minimum deflection.

A special feature of concrete is its ability to be cast into an extraordinary variety of shapes from simple slabs, beams, and columns to great arches and shells.

The maintenance cost of reinforced concrete is very low.

In the structure like footings, dams, piers etc. reinforced concrete is the most economical construction material.

Compared to the use of steel in structure, reinforced concrete requires less skilled labor for the erection of the structure.

ADVANTAGES OF R.C. AS A STRUCTURAL MATERIAL

Concrete has a very low tensile strength, requiring the use of tensile reinforcing. The tensile strength of concrete is about one-tenth of its compressive strength.

Forms are required to hold the concrete in place until it hardens sufficiently. In addition, shoring may be necessary to keep the forms in place for roof, walls, floors, and similar structures until the concrete members gain sufficient strength to support themselves. Formwork is very expensive.

The low strength per unit weight of concrete leads to heavy members. This becomes an increasingly important matter for long-span structures, where concrete’s large dead weight has a great effect on bending moments. Similarly, the low strength per unit volume of concrete means members will be relatively large, an important consideration for tall buildings and long-span structures.

The main steps of using reinforced concrete are mixing, casting, and curing. All of this affect the final strength.

DISADVANTAGES OF R.C. AS A STRUCTURAL MATERIAL

Compressive Strength of Concrete (f’c) for ordinary applications

3000 psi – 4000 psi (20.68 MPa – 27.58 MPa)

Compressive Strength of Concrete (f’c) for prestressed construction

5000 psi – 6000 psi (34.47 MPa – 41.37 MPa)

Compressive Strength of Concrete (f’c) for some applications such as for the columns of the lower stories of high rises buildings

<(9000 psi – 10,000 psi) (62.05 MPa – 68.95 MPa)

ASTM C39

________ has remained the industry standard for testing the compressive strength of cylindrical concrete specimens for more than 80 years.

ASTM C39

________ covers the determination of compressive strength of cylindrical concrete specimens such as molded cylinders and drilled cores.

Modulus of Elasticity of Steel (Es)

Es = 200,000 MPa

Es = 29,000 ksi

Ec

Modulus of Elasticity of Concrete

Poisson’s Ratio

Values ranges from 0.11 to 0.21 with average values of about 0.16

Surface shrinkage

On a very hot and windy day, the surface of the concrete may lose moisture faster than the concrete can tolerate and cause ______. This can occur throughout the initial setting to final setting phases of the concrete-curing process. The cracking is only on the surface and is not full depth.

plastic shrinkage cracking

Surface shrinkage due to lack of moisture is also known as?

Concrete Creep

deformation of structure under sustained load.

Concrete creep and shrinkage

_______ and ______ is caused partly by chemical volume changes, but mainly by self-desiccation due to loss of water consumed by the hydration reaction.

Tensile Strength

the maximum amount of tensile stress that a material can withstand before failure.

Shear Strength

the maximum shear stress a material can withstand without failure.

Compressive Strength of Concrete (f’c)

Modulus of Elasticity of Concrete (Ec) and Modulus of Elasticity of Steel (Es)

Poisson’s Ratio

Shrinkage

Creep

Tensile Strength

Shear Strength

PROPERTIES OF REINFORCED CONCRETE

Water Cement Ratio

Type of Cement

Supplementary Cementitious Materials / Pozzolans

Aggregates

Mixing water

Moisture and Temperature Conditions during Curing

Age of Concrete

FACTORS AFFECTING CONCRETE COMPRESSIVE STRENGTH

Water Cement Ratio

It is the most influencing factor affecting the compressive strength of concrete.

increases

When water is reduced in concrete, the compressive strength of the concrete ________.

0.30 - 0.35

Minimum water cement ratio.

*Beyond this the concrete becomes too stiff and impractical to handle.

Type I-V

Five basic types of cement recognized by ASTM

Type I

ordinary Portland cement (OPC), which is a general-use material.

Type II

has moderate sulfate resistance, and its MH variant is moderately resistant to heat of hydration. It’s used in structures that will come into contact with sulfate in water or soil.

Type III

cement is an extra rapid hardening cement. Most concrete takes about a month to get to its full strength after it is poured; this cement becomes harder more quickly.

Type IV

is a low heat cement that radiates less warmth as it sets and dries. It’s used for applications where too much heat is undesirable.

Type V

cement is highly sulfate resistant, used for contact with high alkaline soil and water.

Supplementary Cementitious Materials / Pozzolans

used to partially replace the Portland cement component in concrete.

fly ash, slag cement, silica fume, and metakaolin

examples of SCMs

Aggregates

make up 60-80% of the volume of concrete and 70-85% of the mass of concrete.

very important for strength, thermal and elastic properties of concrete, dimensional stability and volume stability.

Mixing water

Any water that is potable (drinkable). Some water that is not potable may also be suitable for concrete.

ASTM C94

Acceptance criteria for mixing water are given in ______.

Salt water

_____ should not be used as mixing water in steel-reinforced concrete.

ASTM C31

provides standardized requirements for making, curing, protecting, and transporting concrete test specimens under field conditions.

Age of Concrete

As per studies and researches, the compressive strength of the concrete will increase with age.

Age of Concrete

As per studies and researches, the compressive strength of the concrete will increase with age.

Appropriateness

Structural Adequacy/ Structural Safety

Economical

OBJECTIVES OF DESIGN

Appropriateness

Objective of design that is associated with arrangement of spaces, spans, ceiling heights, access and traffic to complement the intended use.

Structural Adequacy/ Structural Safety

Objectives of design that the structure must be strong enough to support anticipated loadings safely, must not deflect, tilt, vibrate, or crack in a manner that impairs its usefulness.

Economical

to build a specific building, bridge or other structure for the lowest possible cost, with fewer construction materials while providing a high level of functionality and safety based on design criteria and code requirements.

Ultimate Limit States

Serviceability Limit States

STRUCTURAL LIMIT STATES

limit state

When a structure or structural element becomes unfit for its intended use, it is said to have reached its _______.

Ultimate Limit States

involves a structural collapse of part or all of the structure.

Serviceability Limit States

are those conditions that are not strength based but still may make the structure unsuitable for its intended use.

durability, overall stability, fire resistance, deflection, cracking, and excessive vibration.

Serviceability limit state design of structures includes factors such as _______.

Variability in Strength

Variability in Loadings

Consequences of Failure

STRUCTURAL SAFETY

Three main reasons why safety factors, such as loads and resistance factors, are necessary in structural design:

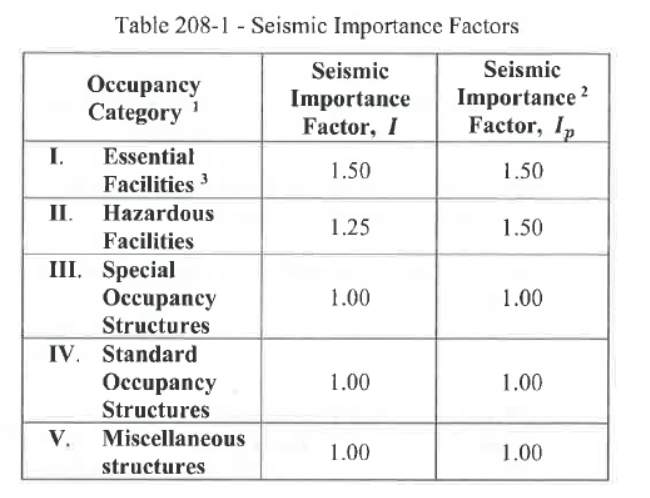

State the seismic importance factors of both I and Ip

Ans: SIF

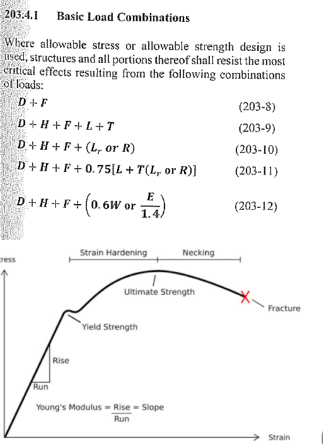

Allowable Stress Design (ASD)

Strength or Load and Resistance Factor Design

DESIGN PROCEDURES

Allowable Stress Design (ASD)

also known as Working Stress Design (WSD) method.

does not take into account the Plastic and Strain Hardening stages of material,

Strength or Load and Resistance Factor Design

based on the principle that strength (resistance) of various materials is scaled down by some factors while the applied loads are scaled up by some factors, and thereby the structural elements are designed using reduced strength and increased loads.

The strength of materials considered for design is the ultimate strength, which results in utilization of elastic, plastic and strain hardening stages of material thereby giving economical and safe design consistently.

Balanced Design

Under Reinforced Design

Over Reinforced Design

TYPES OF DESIGN IN REINFORCED CONCRETE

Balanced Design

A designed so proportioned that maximum stresses of concrete and steel are reached simultaneously.

both the materials will fail at the same time

Under Reinforced Design or Ductile Failure

A designed in which the amount of steel is lesser than what is needed in the balanced design. In this design the steel fails first but failure is gradual with the steel yielding.

Over Reinforced Design or Brittle Failure

A designed in which the amount of steel is more than what is required in the balanced design. In this design the concrete fails first in crushing and the steel will not yield before failure.