Operations Management Midterms

1/83

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

84 Terms

capacity

upper limit or ceiling on the load that an operating unit can handle

upper limit on the rate of output

overcapacity

_____capacity causes operating costs that are too high

undercapacity

___capacity causes strained resources and a possible loss of customers

what kind, how much, when

the key questions in capacity planning

design capacity

maximum output rate or service capacity an operation, process, or facility is designed for

maximum rate of output under ideal conditions

effective capacity

design capacity minus allowances such as personal time, and preventive maintenance

less

effective capacity is always ___ than design capacity

actual output

_____ cannot exceed effective capacity

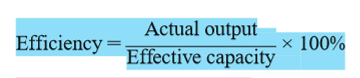

efficiency formula

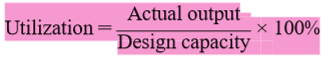

utilization formula

effective capacity

effective capacity acts as a lid to actual output, the real key to improving utilizationn is to increase __________

leading

a capacity strategy that builds capacity in anticipation of future demand increases

tracking

a capacity strategy that adds capacity in relatively small increments to keep pace with increasing demand

following

a capacity strategy that builds capacity when demand exceeds current capacity

capacity cushion

amount of capacity in excess of expected demand when there is some uncertainty about demand

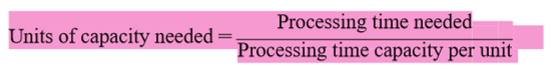

formula for units of capacity needed

process selection

refers to deciding on the way production of goods or services will be organized

job shop process

customized goods or services

batch process

semi-standardized goods or services

repetitive process

standardized goods or services

continuous process

highly standardized goods or services

True

True of False

increasing productivity and also quality will result in increased effective capacity

False

True of False

increasing capacity just before a bottleneck operation will improve the output

globalization

_________ has opened new markets, and it has meant increasing dispersion of manufacturing and service operations around the world

Product Plant Strategy

With this strategy, entire products or product lines are produced in separate plants, and each plant usually supplies the entire domestic market.

Market Area Plant Strategy

With this strategy, plants are designed to serve a particular geographic segment of a market (e.g., the West Coast, the Northeast).

Process Plant Strategy

With this strategy, different plants concentrate on different aspects of a process.

General-Purpose Plant Strategy

With this strategy, plants are flexible and capable of handling a range of products.

geographic information system (GIS)

___________ is a computer-based tool for collecting, storing, retrieving, and displaying demographic data on maps.

quality

______ refers to the ability of a product or service to consistently meet or exceed customer requirements or expectations.

Frederick Winslow Taylor

the “Father of Scientific Management”

True

True or False

Increasing productivity and also quality will result in increased effective capacity.

False

True or False

Increasing capacity just before a bottleneck operation will improve the output of the process.

60%

Calculate the efficiency given the following data:

48% = utilization

100 units per day = design capacity

80 units per day = effective capacity

I. number of passenger seats that can be filled per day on an airline route

Which of the following statements is the case where capacity is measured in terms of inputs?

I. number of passenger seats that can be filled per day on an airline route

II. kilowatt hours per day that can be generated by an electric power plant

Neither I nor II

Which of the following statements tends to reduce effective capacity?

I. Suppliers that provide more reliable delivery performance.

II. Improved production quality

True

True or False

Design capacity refers to the maximum output rate that can be achieved under ideal conditions.

Efficiency

It refers to the ratio of actual output to effective capacity.

True

True or False?

Capacity planning requires an analysis of needs by answering the following questions: what kind, how much, and when?

False

True or False

Having excess capacity tends to keep operating costs low.

effective capacity

It refers to the maximum possible output given a product mix, scheduling difficulties, personal time, etc.

Walter Shewhart

a genuine pioneer in the field of qual ity control, and he became known as the “father of statistical quality control.”

W. Edwards Deming

a statistics professor at New York University in the 1940s, went to Japan after World War II to assist the Japanese in improving quality and productivity. The Union of Japanese Scientists, who had invited Deming, were so impressed that in 1951, after a series of lectures presented by Deming, they established the Deming Prize

Deming Prize

Prize established by the Japanese and awarded annually to firms that distinguish themselves with quality management programs

Joseph M. Juran

he viewed quality as fitness-for-use.

Armand Feigenbaum

He recognized that quality was not simply a collection of tools and techniques, but a “total field.”

Philip B. Crosby

developed the concept of zero defects and popularized the phrase “Do it right the first time.”

Kaoru Ishikawa

Among his key contributions were the development of the cause-and-effect diagram (also known as a fishbone diagram) for problem solving and the implementation of quality circles, which involve workers in quality improvement.

Genichi Taguchi

known for the Taguchi loss function, which involves a formula for determining the cost of poor quality.

Taiichi Ohno and Shigeo Shingo

both developed the philosophy and methods of kaizen, a Japanese term for continuous improvement

Quality of design

refers to the intention of designers to include or exclude cer tain features in a product or service.

Quality of conformance

The degree to which goods or ser vices conform to the intent of the designers

Appraisal costs

Costs of activities designed to ensure quality or uncover defects.

Prevention costs

Costs of preventing defects from occurring.

Failure costs

Costs caused by defective parts or products or by faulty services.

Internal failures

Failures discovered during production.

External failures

Failures discovered after delivery to the customer

Return on quality

An approach that evaluates the financial return of investments in quality.

Baldrige Award

Annual award given by the U.S. government to recognize quality achievements of U.S. companies.

European Quality Award

European award for organizational excellence

The Deming Prize

Japan’s highly coveted award recognizing successful quality efforts.

quality control

evaluates output relative to a standard and takes corrective action

total quality management

a philosophy that involves everyone in an organization in a continual effort to improve quality

Regional factors

With reference to location planning, the location of raw materials, the location of markets, and labor factors are:

True

True or False

For service organizations, the dominant factors in location analysis usually are market-related.

True

True or False

For service and retail stores, a prime factor in location analysis is customer access.

False

True or False

The first step in developing location alternatives is identifying important factors.

A contract

Location options do not usually include:

Identify acceptable locations

Which statement best characterizes a typical search for location alternatives?

False

True or False

A strategy that emphasizes convenience for the customers would probably select a single very large facility.

False

True or False

Location decisions are one-time decisions usually made by new organizations.

Foreign locations

Cultural differences, customer preferences, labor and resources are factors relating to:

Cradle-to-cradle

It refers to the lean approach to waste management that involves design and manufacturing that is sustainable and waste-free. All material inputs can be recycled or reused, or are consumable or compostable.

Quality standards

It refers to national and international benchmarks that enable certification of quality assurance, certifying that the product has met certain minimum standards to meet the needs of customers.

To ensure products meet the quality standards set by the firm

What is the objective of quality control?

Choices:

To ensure products meet the quality standards set by the firm

To replace products returned by dissatisfied customers

To compare the firm's products against those of competitors

To reduce the need for investment in research and development

Quality assurance

Which term describes the approach of meeting quality standards at all stages of the production process?

Choices:

Quality control

Continuous improvements

Quality assurance

Lean production

Quality standards

It refers to national and international benchmarks that enable certification of quality assurance, certifying that the product has met certain minimum standards to meet the needs of customers.

Choices:

Kaizen

Quality standards

Total quality management

Quality circles

Cost of dealing with defective products

Quality management helps to reduce which of the following costs?

Choices:

Cost of dealing with defective products

Cost of improving the actual quality

Cost of monitoring the system

Cost of designing and setting up quality control systems

Kanban

Which method of lean production relies on using a card system to ensure that stock usage is based on actual demand from customers?

Choices:

Kaizen

Kanban

Just-in-time

Andon

Quality control

Which approach to quality management involves inspectors checking samples of the output of manufactured goods in the production process?

Choices:

Quality control

Benchmarking

Quality assurance

Kanban

Just-in-time

Which stock control system relies on inventories being delivered only when they are required in the production process?

Choices:

Just-in-time

Kanban

Andon

Kaizen

Cradle-to-cradle

What is the name given to the process of designing and producing goods that can be recycled to make the same product again?

Choices:

Andon

Cradle-to-grave

Cradle-to-cradle

Kaizen

Andon

It refers to a method of lean production that uses audio-visual controls and warning systems to indicate the status of particular aspects of the production process.

Choices:

Kanban

Kaizen

Andon

Just-in-time