Timber Harvesting Techniques and Systems in the Philippines

1/120

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

121 Terms

Timber Harvesting

Process of extracting trees to processing mills.

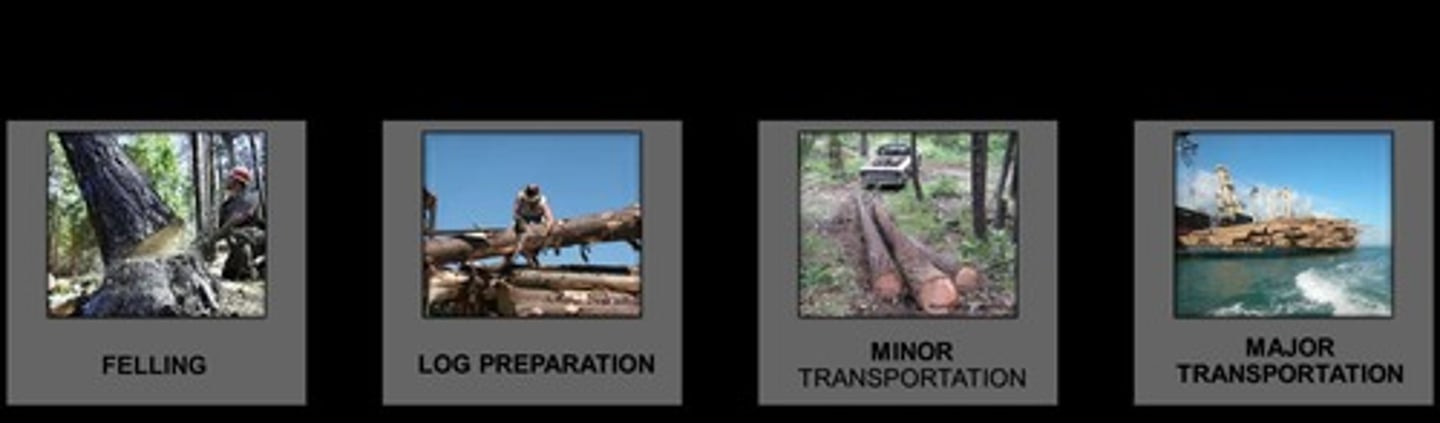

Felling

Cutting down trees for harvesting.

Delimbing

Removing branches from felled trees.

Debarking

Removing bark from logs.

Bucking

Cutting logs into specific lengths.

Chipping

Reducing wood into small chips.

timber harvesting

Transporting logs from forest to mill.

Piling

Stacking logs for transport or processing.

Loading

Placing logs onto transport vehicles.

Wood Transport

Moving logs to processing facilities.

Selective Logging

Harvesting specific trees while preserving others.

Shelterwood

Gradual removal of trees to establish new growth.

Clearcutting

Removing all trees in an area.

Highlead Logging

Using cables for log extraction.

Tractor Logging

Using tractors for log extraction.

Old Growth Forests

Forests with mature, untouched trees.

Second Growth Forests

Forests regrown after logging.

Philippine Selective Logging System

Guidelines for sustainable timber harvesting.

Annual Allowable Cut (AAC)

Volume of timber allowed for harvest yearly.

Cutting Cycle

Time interval between harvests.

Harvestable Volume

Amount of timber available for cutting.

Reduction Factor (f)

Compensation for logging inefficiencies.

Whole Tree Logging

Felling trees and processing elsewhere.

Full Length Logging

Felling and processing at stump site.

Assortment Logging

Logging method where all logging activities are done in the stumpsite.

Pre-harvest inventory

Assessment before timber harvesting begins.

Felling

Cutting down trees by severing the trunk.

Log Preparation

Preparing logs for transport and processing.

Minor transport

Initial movement of logs from stump site.

Hot decking

Transporting logs directly to mill or market.

Cold decking

Transporting logs to wait before final delivery.

Major transport

Transporting logs to their final destination.

Water transport

Moving logs using waterways.

Land transport

Moving logs over land routes.

Aerial transport

Using air methods for log transport.

Control and monitoring

Oversight of logging activities and roads.

Configuration of ground

Terrain layout affecting tree felling direction.

Undercut

Directional cut defining the tree's fall path.

Backcut

Final cut opposite the undercut for felling.

Wedging

Inserting wedges to assist tree falling.

Kickback

Saw blade reaction when hitting solid objects.

Barber Chair

Trunk splitting without hinge folding during felling.

Entanglement

Tree tangling with vines or other trees.

Setback

Tree falling back onto the saw during cutting.

Felling Tools

Equipment used for cutting down trees.

Felling considerations

Factors influencing safe and effective tree felling.

Lean

Tree's inclination affecting cutting direction.

Wedge

Inserted into tree to prevent setback.

Stump Jump

Tree detaches from stump due to hinge failure.

Open-faced Notch

Cut angle of 70-90° to prevent accidents.

Back Cut

Final cut made to fell the tree.

Escape Route

Cleared path for safety during felling.

Spring Pole

Tension release causing violent energy discharge.

Compression Side

Side of wood under compression during cutting.

Tension Side

Side of wood under tension; avoid cutting.

Accordion Cut

Small cuts on compression side to release tension.

Shave Cut

Layer-by-layer cutting to relieve wood tension.

Five-Step Felling Plan

Procedure for safe tree felling operations.

Debranching

Removing branches from a felled tree.

Detopping

Removing the top of a tree.

Bucking

Cutting logs into specified lengths.

Log Transportation

Moving logs from forest to processing facilities.

Operational Efficiency

Improved logistics reduce costs and delays.

Minimized Environmental Impact

Transportation planning minimizes ecological disturbances.

Yarding

Moving logs using stationary power sources.

Skidding

Moving logs using mobile power sources.

Manual Skidding

Short-distance log movement, suitable for steep slopes.

Animal Skidding

Log movement using animals for moderate distances.

Mechanical Skidding

Used for distances of 1km to 3km. Done in rolling terrain, For large logs, >20cm but <60cm DBH, Can be rubber-tired or tracked

Adverse Slopes

Rolling terrain with slopes of 20% to 35%.

DBH

Diameter at Breast Height

Rubber-tired Skidding

Skidding method using rubber-tired vehicles.

Tracked Skidding

Skidding method using tracked vehicles.

Habal-habal

Motorcycle transport in Southern Philippines.

Log Tong

Accessory for gripping logs during skidding.

Sled/Sledge

Accessory for transporting logs on the ground.

Log Hook

Tool for lifting and moving logs.

Log Grapple

Mechanical device for grasping logs.

Skidding Winch

Device for pulling logs during skidding.

Log Chain

Chain used to secure logs during transport.

Log Arch

Frame for lifting logs off the ground.

Log Pan

Platform for carrying logs during skidding.

Log Cone

Device for preventing logs from getting stuck in roots, stumps and other obstacles during skidding.

Skidding Safety Measures

Guidelines to ensure safe skidding operations.

Skidding Crew

Team structure: 1 operator, 2-3 setters, 1-2 chasers.

Skidding Cycle

Sequence: travel out, choker setting, travel in, chasing.

Groundlead Yarding

Logs dragged along ground using lines and blocks.

Highlead Yarding

Logs lifted above ground using high spar trees.

Rub Trees

Trees used to protect residuals during yarding.

Flying Dutchman

Logging block accommodating the mainline.

Bull Block

Logging block with extra throat for rigging.

Extended Choker

Method to increase yarding coverage area.

Yarding Safety Measures

Guidelines to protect residuals during yarding.

Skylining

Transporting logs using a suspended line system.

Swinging/ skylining

Moving logs from one landing to another.

Tight Skylining

Logs are transported with minimal slack in the line.

Slack Skylining

Logs are transported with more slack in the line.

Helicopter Logging

Using helicopters to transport logs from remote areas.

Balloon Logging

Transporting logs using balloons for aerial lift.

Rafting

Floating logs together on water for transport.