Quiz 1 (Lectures 1-4)

1/44

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

45 Terms

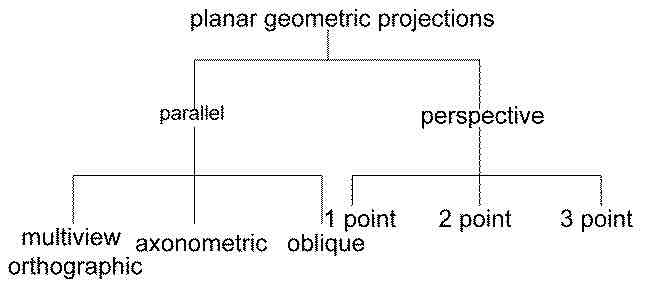

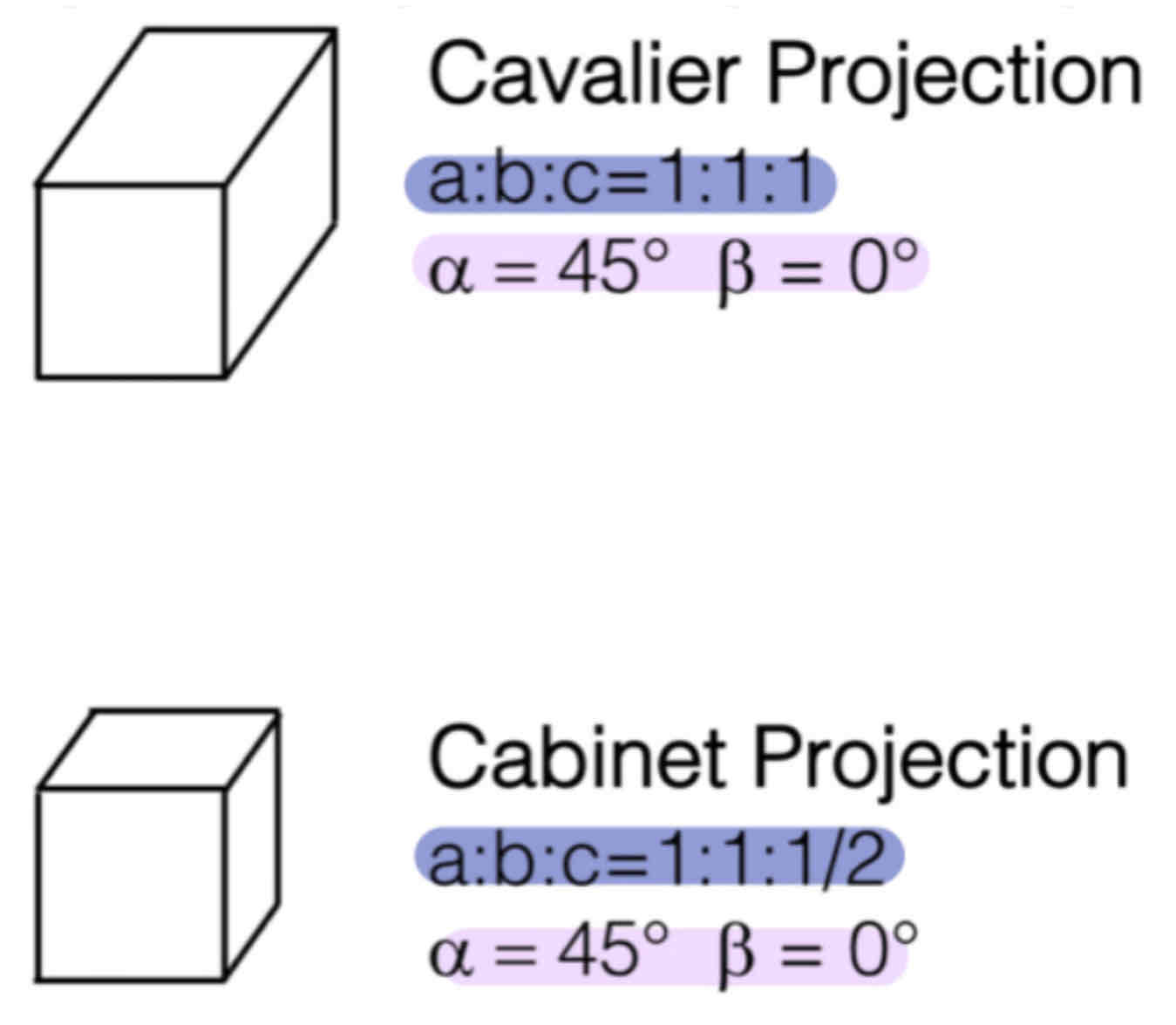

Name the two planar geometric projections and their subcategories:

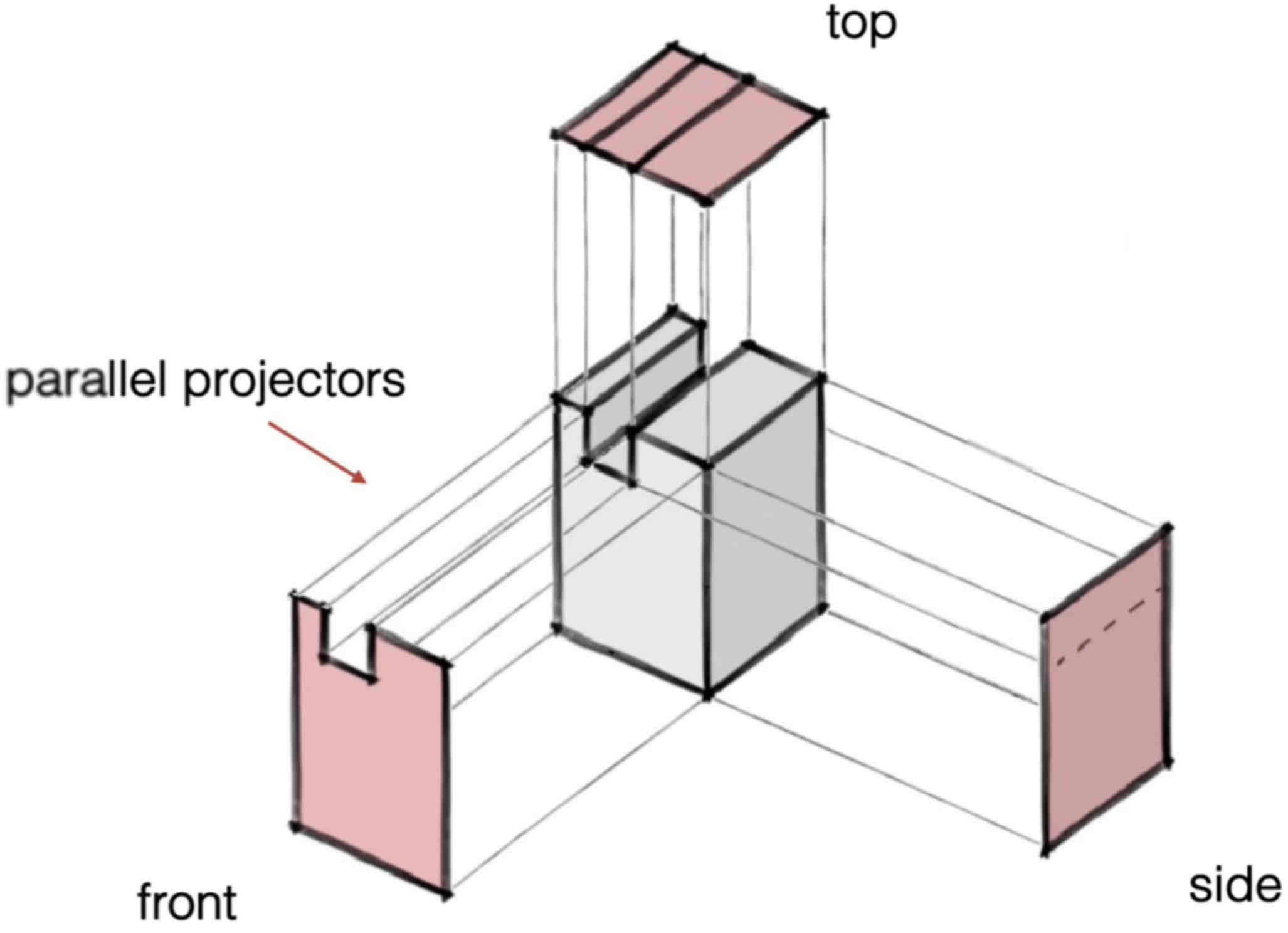

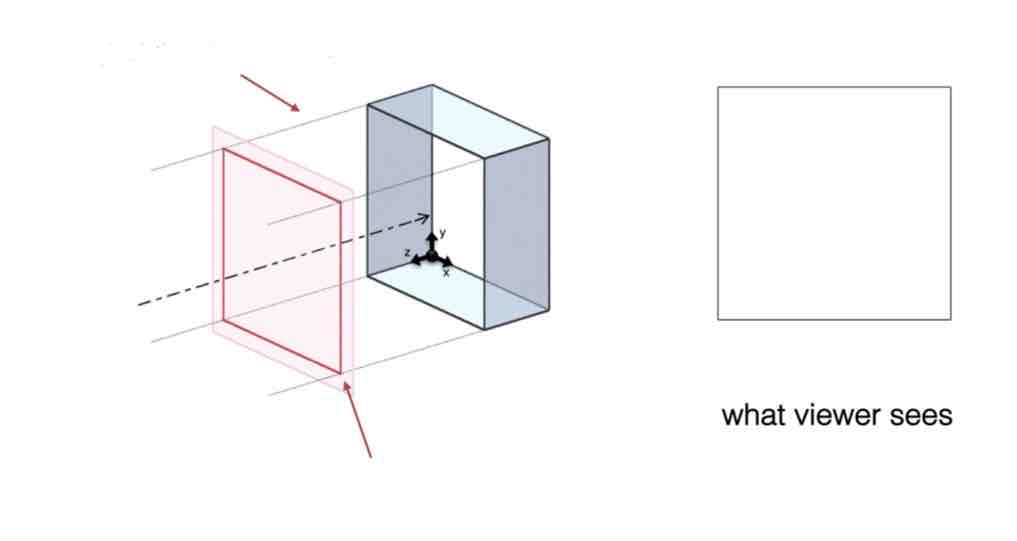

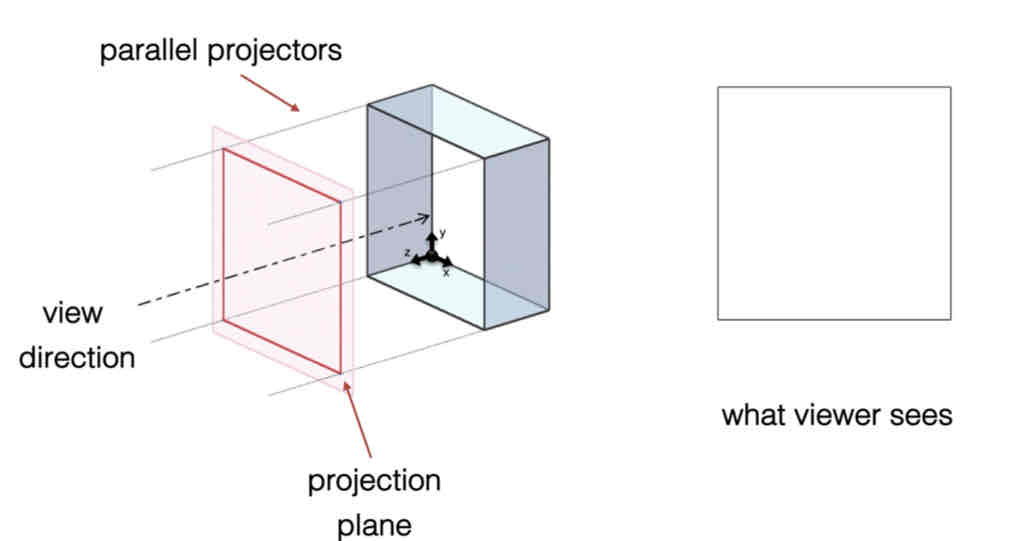

Parallel vs perspective projections:

Parallel:

used in technical drawings

Elements with equal length are equally dimensioned

Dimensions can be measured in drawings

Perspective:

Closer to the eyes’ perception

Elements with equal lengths can have different dimensions

Used in “Photorealistic: rendering (design, architecture)

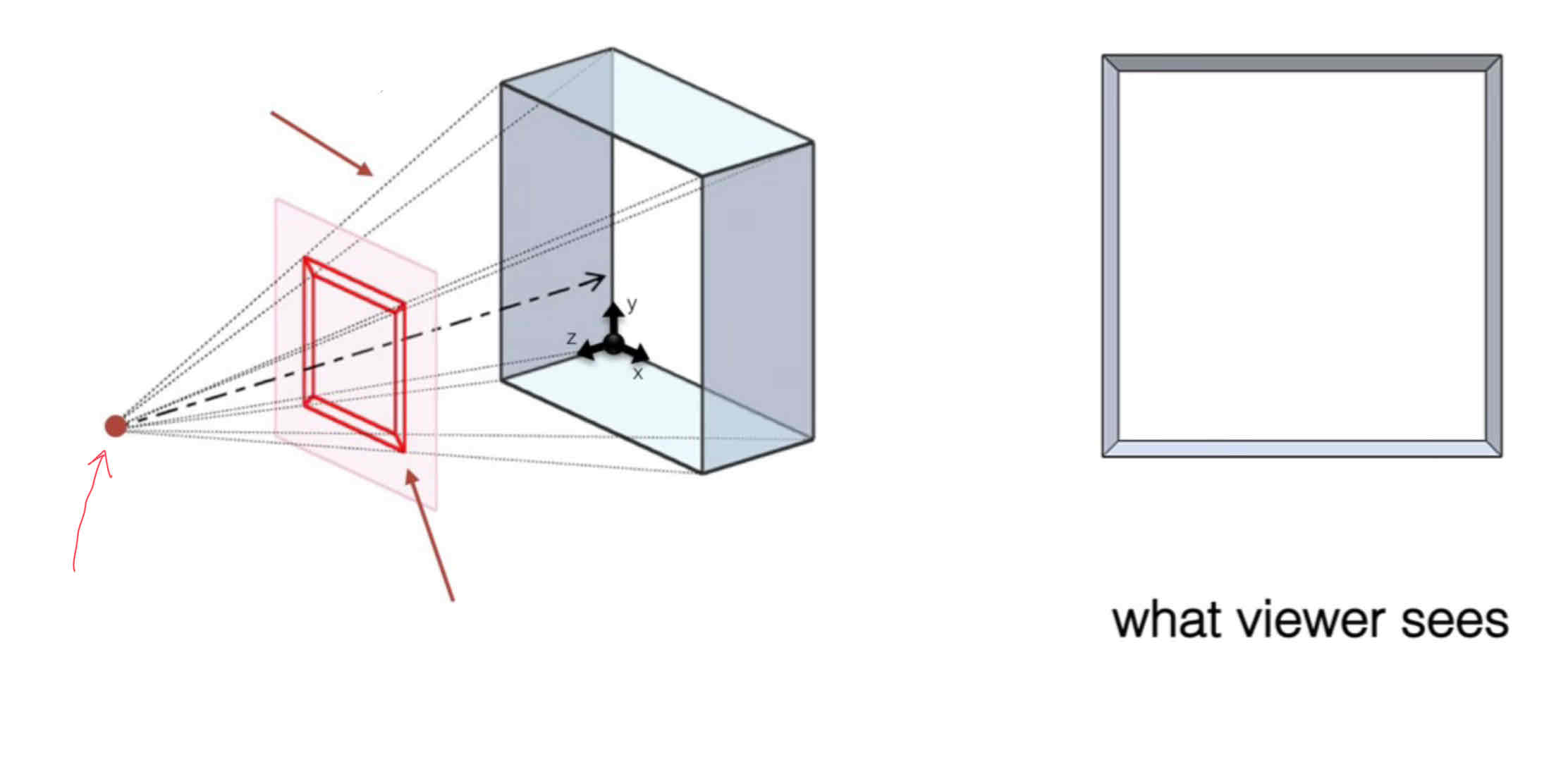

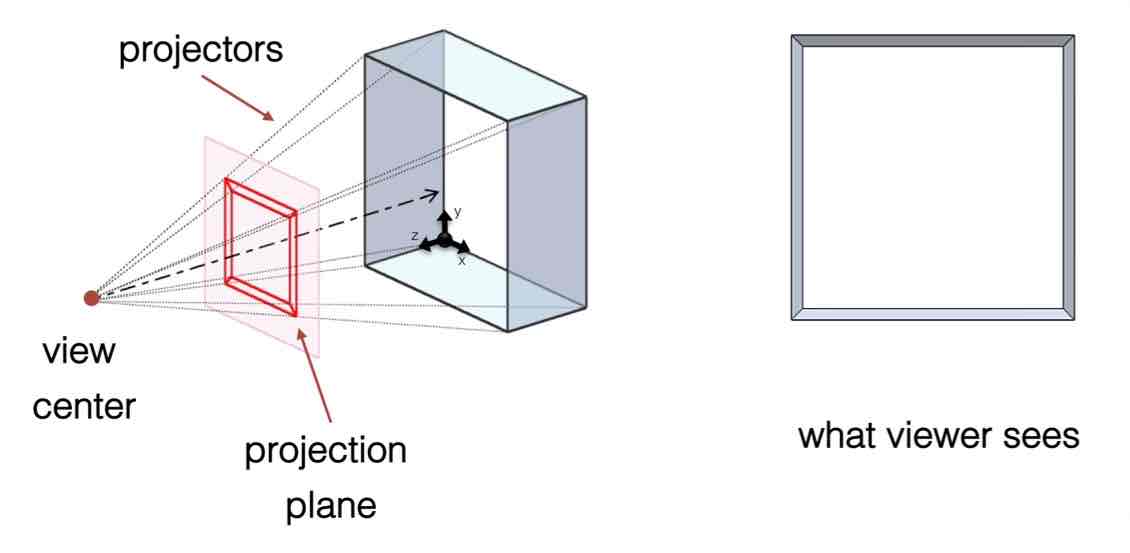

Name this projection method:

Perspective Projection

Name this projection method:

Perspective Projection - Orthogonal

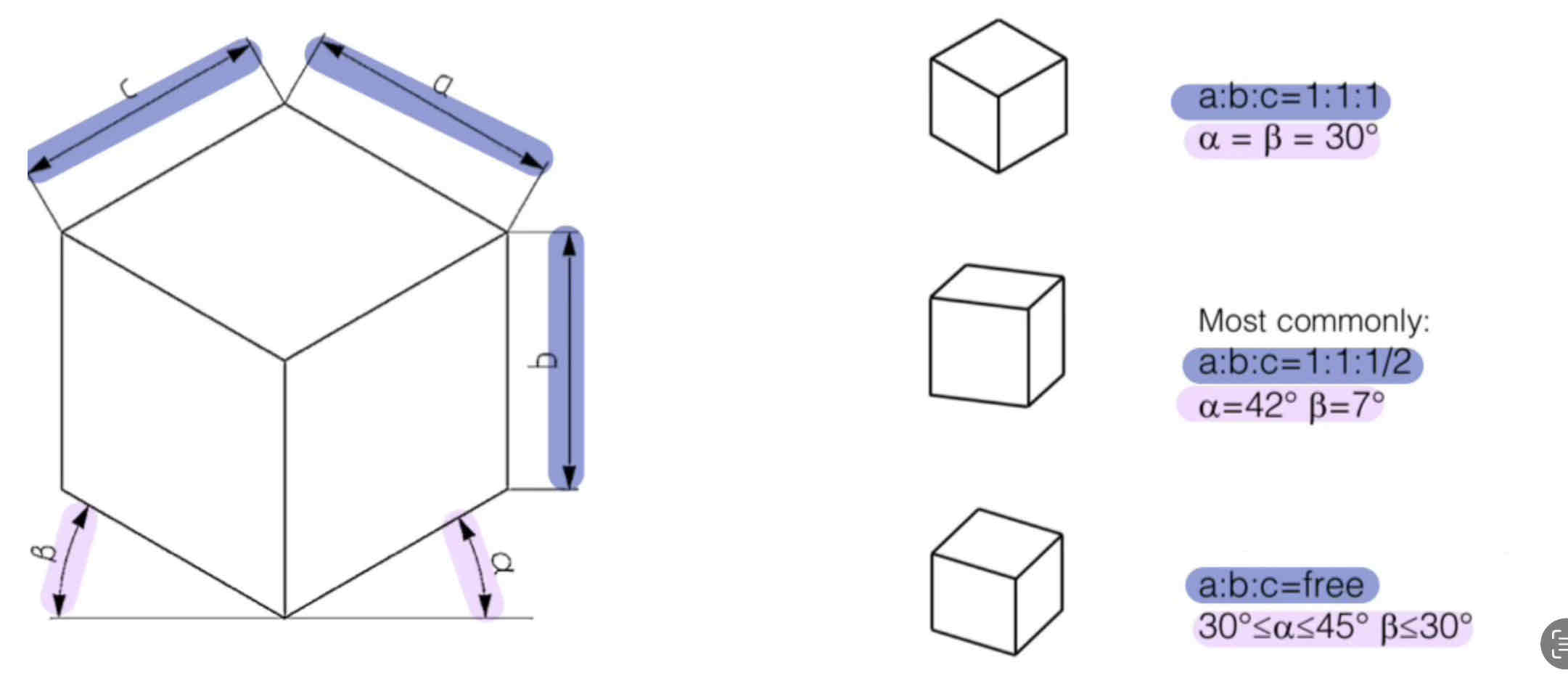

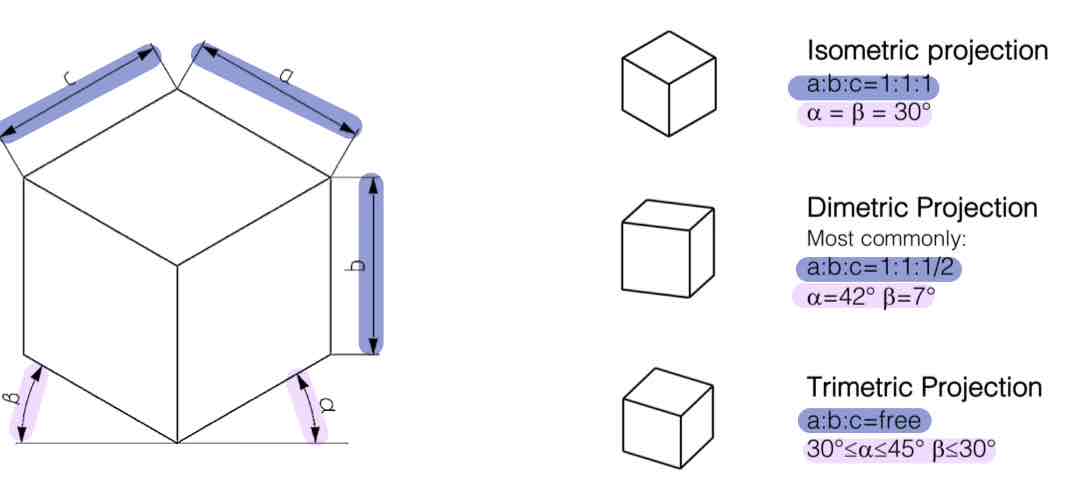

Name this projection method:

Perspective Projection - Axonometric

Name this projection method:

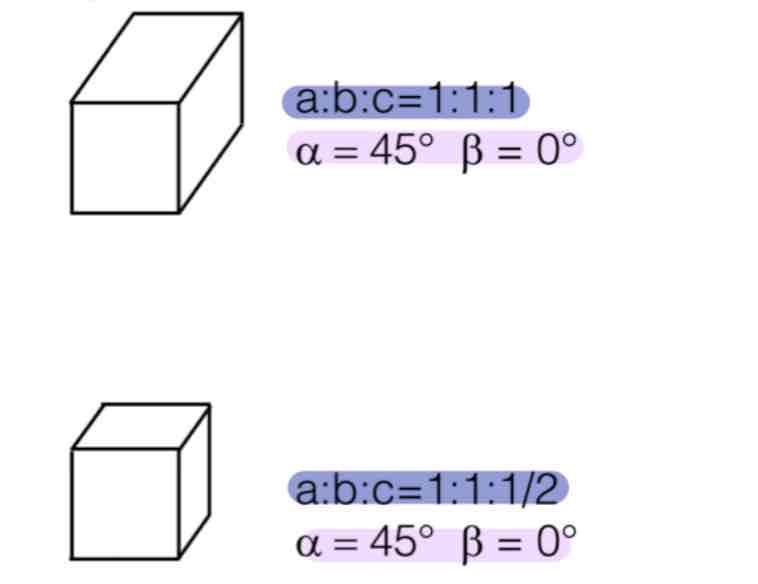

Perspective Projection - Oblique

Name this projection method:

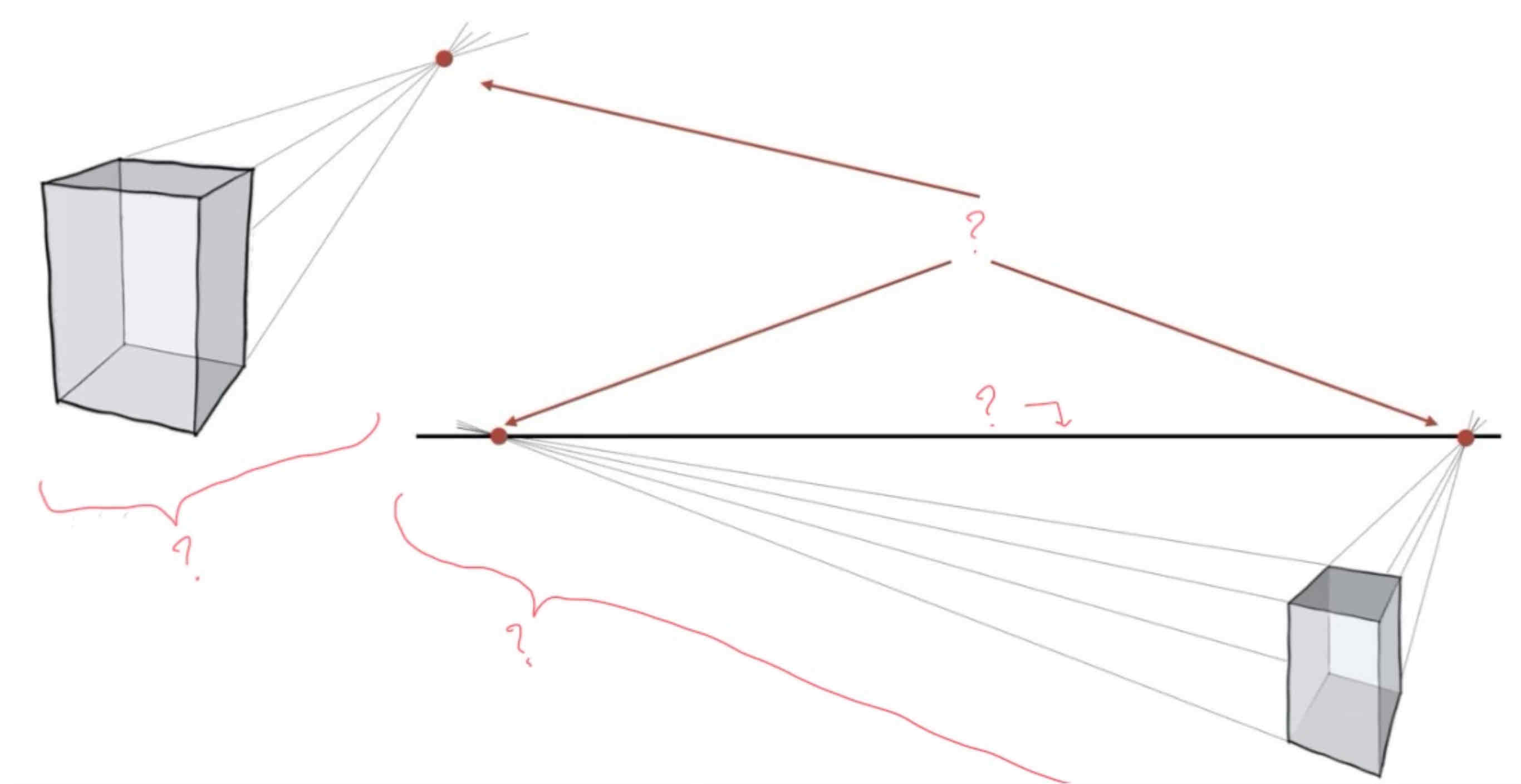

Parallel Projection

Name this projection method:

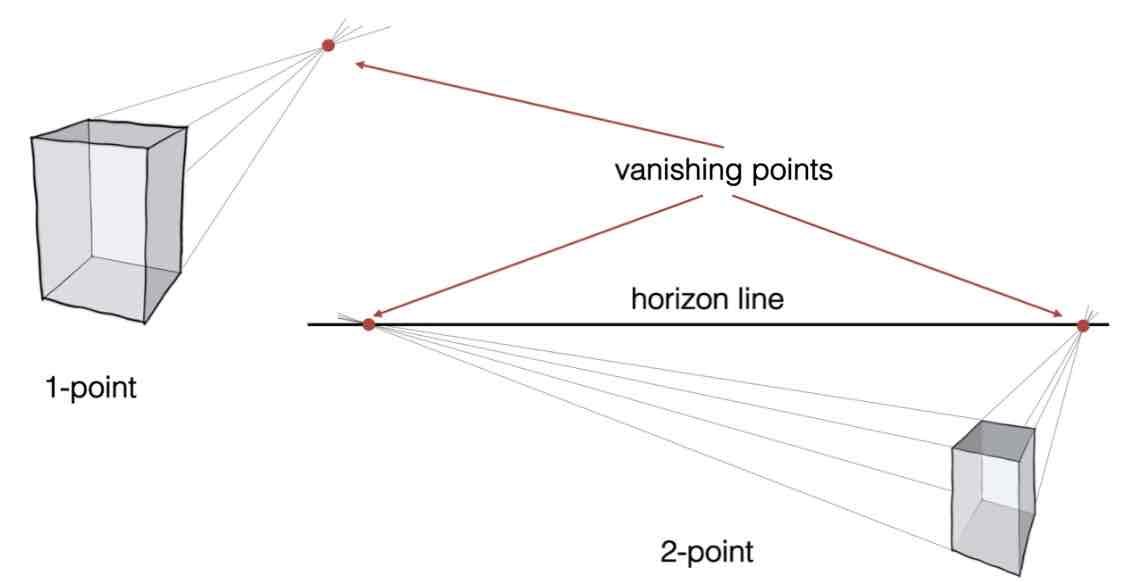

+ what happens if you were to move the vanishing points further / closer?

One- and two point perspective:

if you move vanishing points further: object becomes more orthogonal (rectangular, perpendicular, forming right angles…)

|| closer: object becomes more skewed, looks as if observed from a close distance.

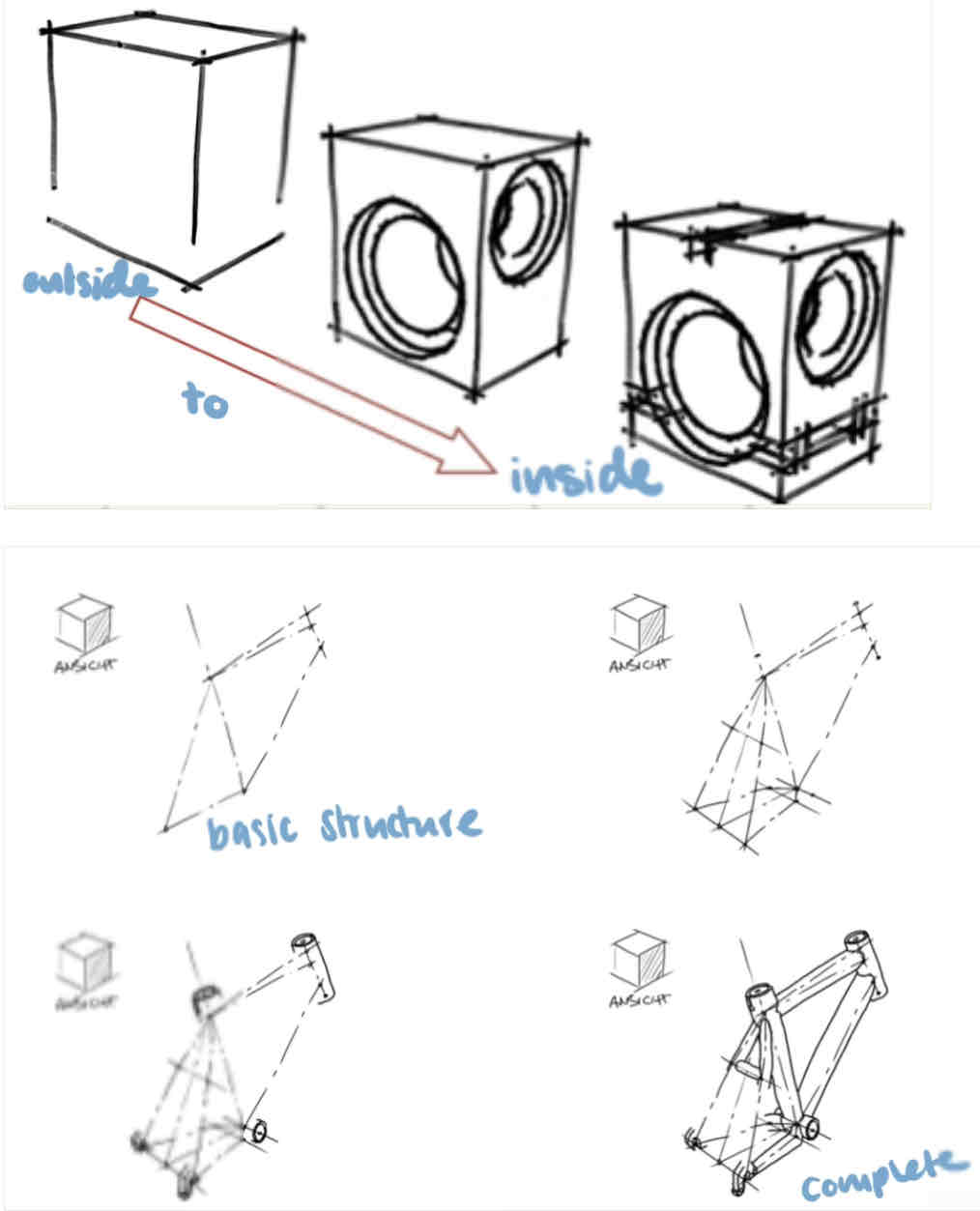

Name the two main sketching techniques:

outline and refine (outside to inside)

Reduce to basic structure and complete (inside to outside)

What are the most important sketching tips? (What to use / make / add / focus on)

Use outlines

Use meshing as an aid

Preserve proportions

Make cuts to show what is necessary

Focus on important aspects

Add comments and annotations

Checklist for sketching - important questions to ask yourself:

is the object / function sketched clearly?

Is the sketch aligned with the goals set?

Is it technically sound and clean?

Are the proportions and scale correct?

Is the perspective clear?

Are annotations needed to understand the sketch?

Sketching: Wrap-Up

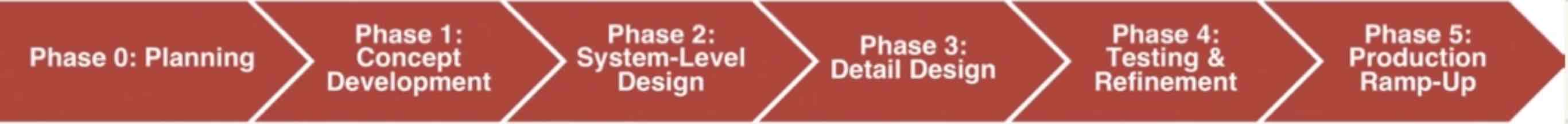

Product Development Process:

Name the 6 Phases, as well as the purpose and tasks of phase 1:

Phase 1: Concept Development:

Purpose

Define product requirements

Generalize promising concepts and select one for further development and testing

Tasks include:

Identify lead users and competitive products

Collect user needs

Define product requirements

Develop alternative design concepts and select one

Build and test concept prototypes

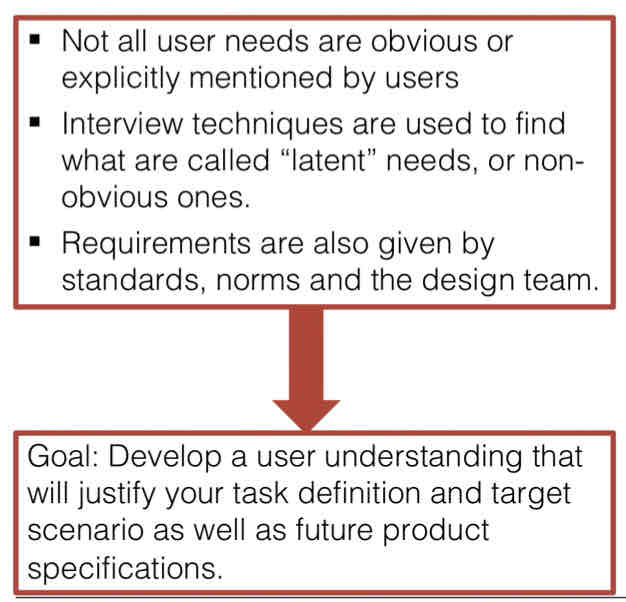

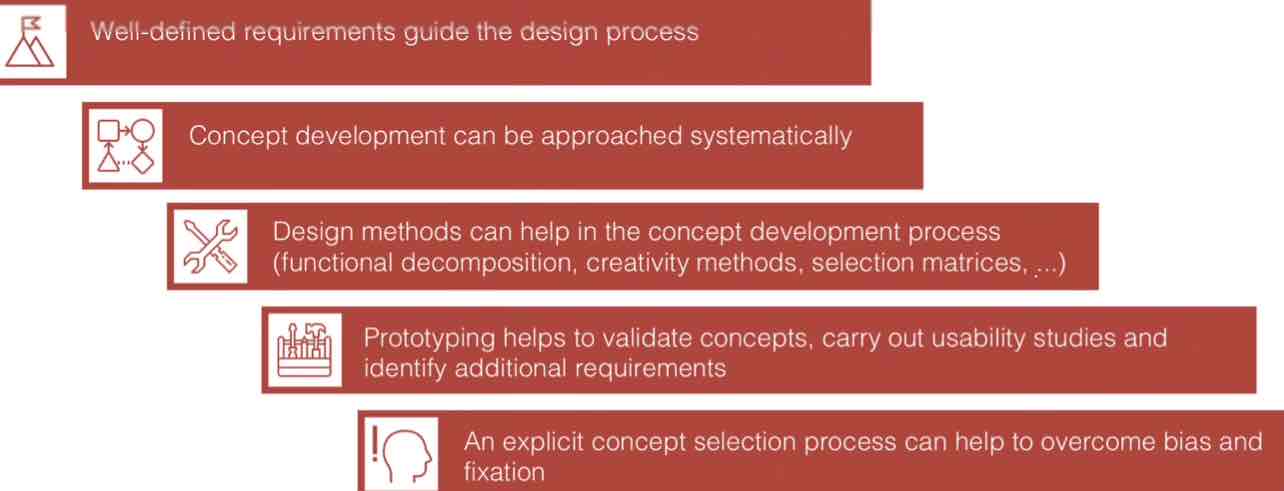

Requirement Definition: What are they exactly and why do we need them?

What are they exactly?

Needs product should fulfill

Explicit description of product’s desired form / functionality

Solution is independent

Define the WHAT not the how. Should be as specific as possible.

Why do we need them?

Effective communication, definition of goals / priorities / interface of product

To capture user expectation in binding contract

To ensure fitness of product for its intended use

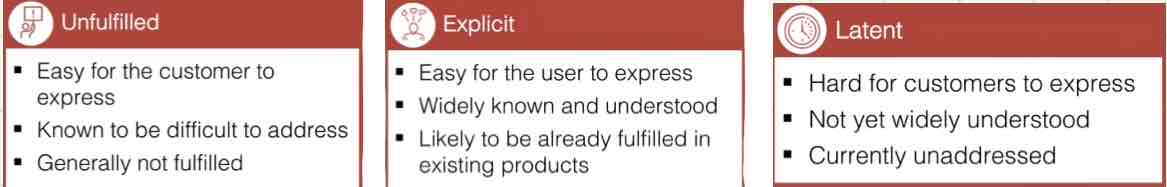

What are the challenges in understanding user needs?

What are the three types of user needs?

Key Requirements when producing:

Prototyping is very important, to also always go back and redefine initial requirements

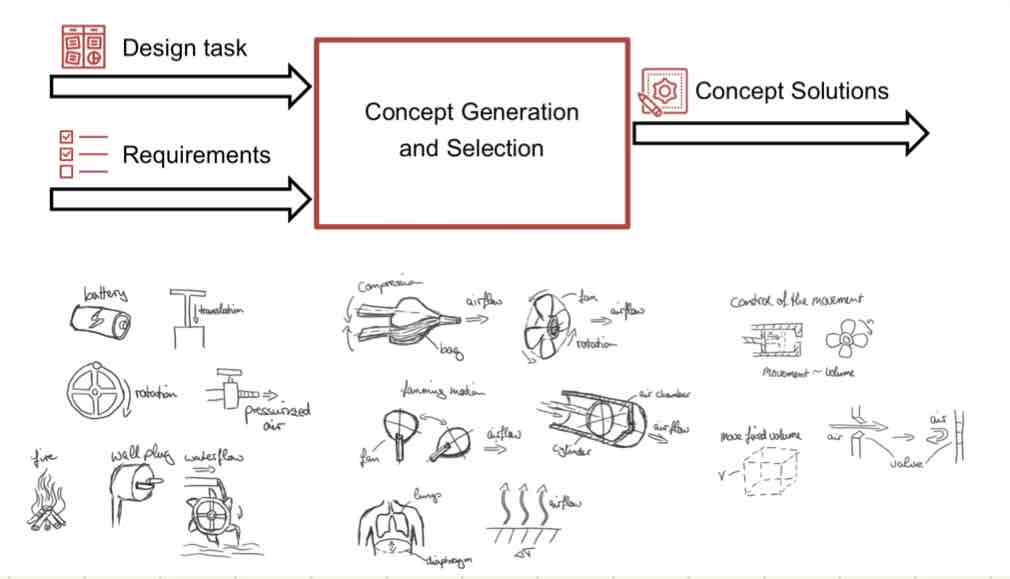

Concept generation and selection - design process and stages:

Design processes do not strictly move in one direction

Jumps between stages could be useful and necessary

Infinite loops should be avoided and a design decision should be considered to revise.

External Search - important steps for deigning and producing machinery / devices

search already existing patents

Determine the state-of-art (= state of newest technology)

Search published literature

Benchmark related products

Interview lead users > Evaluate reactions

Consult experts

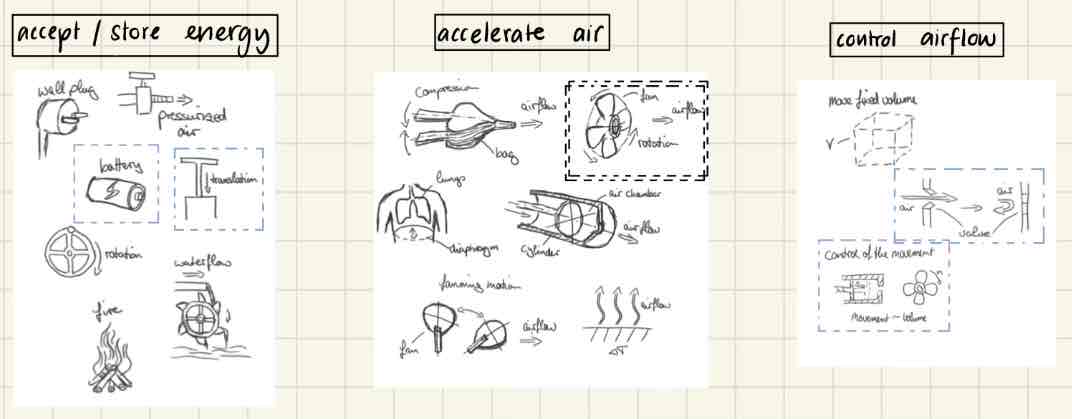

Internal Search (Creativity Methods / Creating a concept combination table)

Creativity Methods

Brainwriting, as many ideas as possible, plenty of sketches, no judgment (Generate ideas in groups)

Create a concept classification tree

Create a concept combination table

Combine different partial solutions to find best combination

Think about physical and geometric interfaces among partial solutions

Refine partial solutions to derive solution / final concept

e.g. in classification tree: Blue: Concept combination A / Purple: Concept combination B

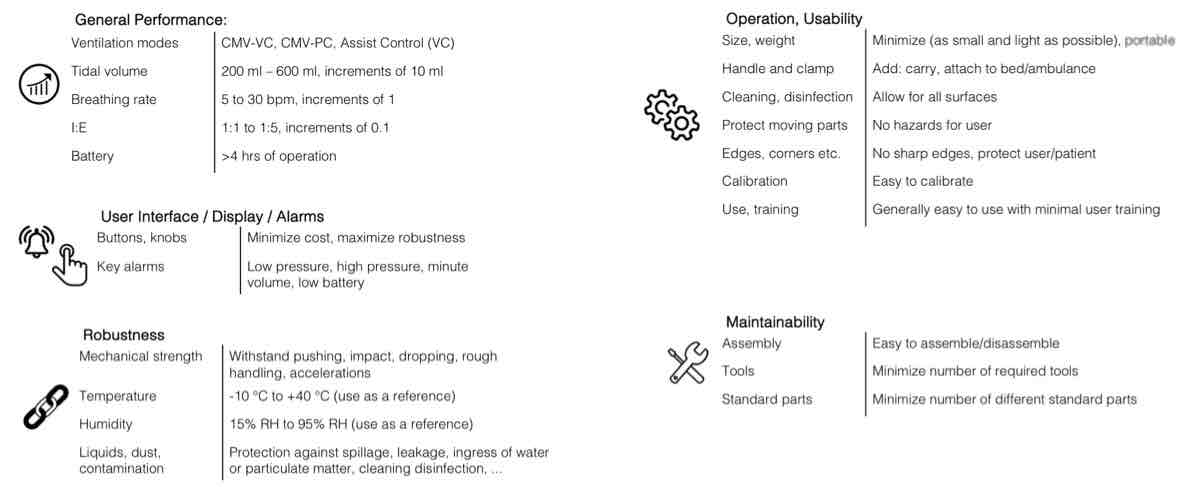

e.g. Ventilator (Picture)

Concept Selection - Explicit vs Implicit:

Explicit: Decision process, discussion

Implicit: Formulation of requirements, task description, favoring of established solutions, dominance of group members.

Concept Generation and Selection - Wrap-Up

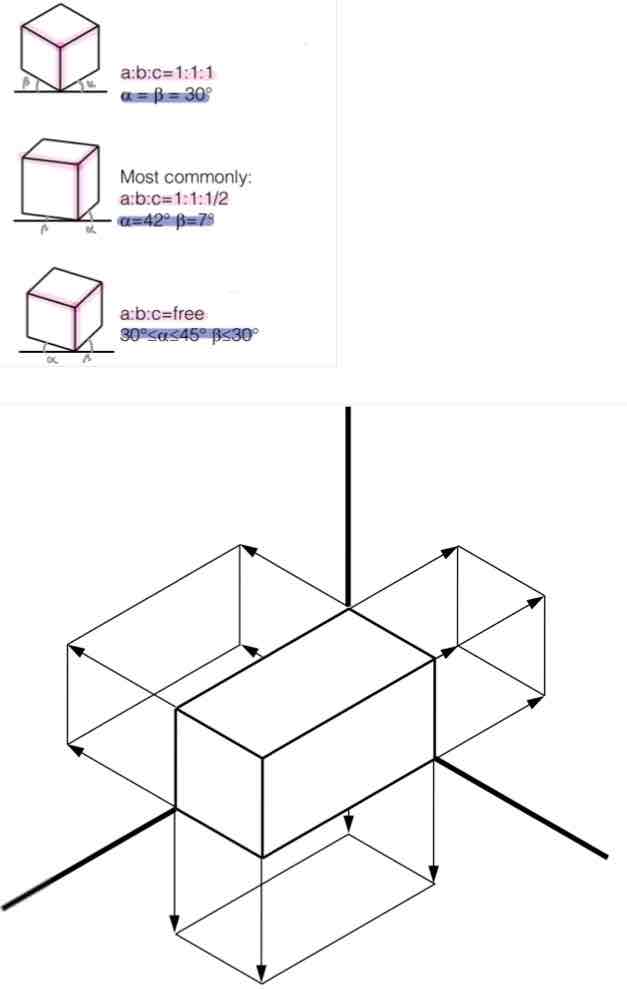

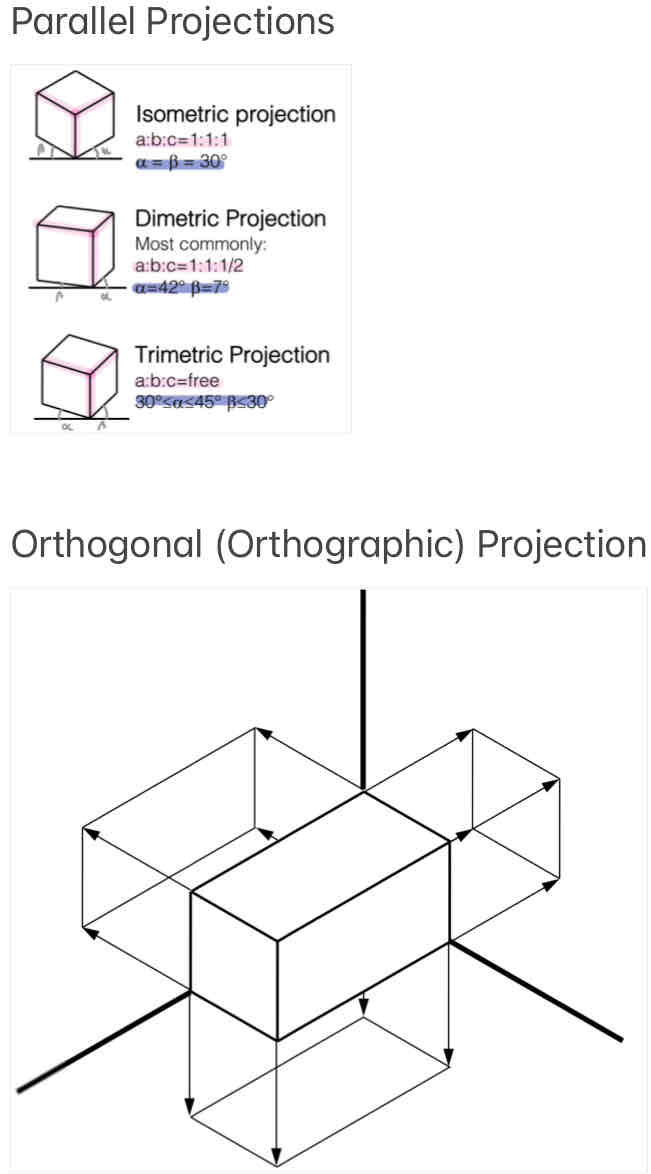

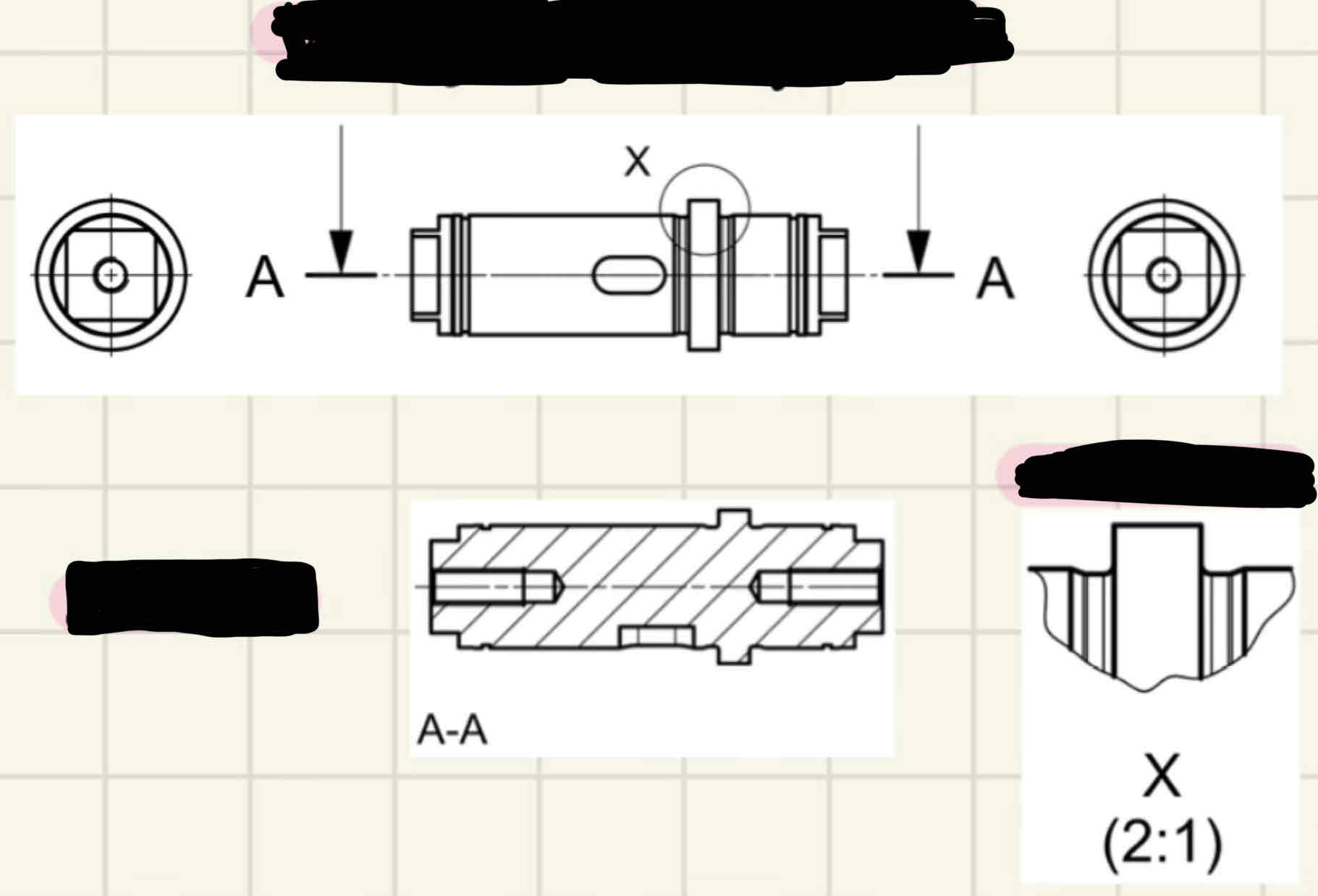

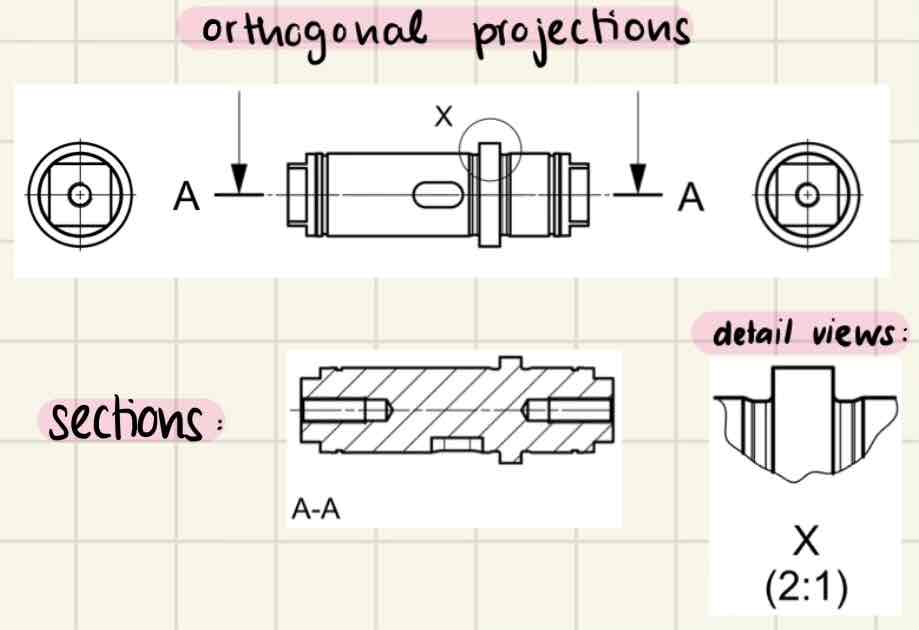

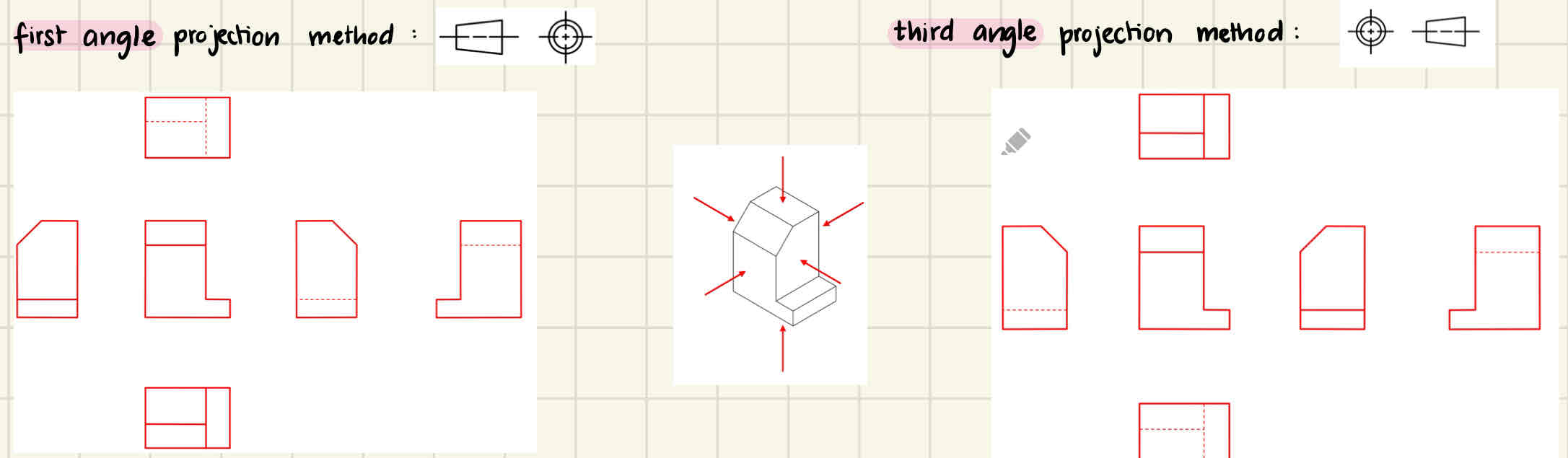

Views - Name these projections

Name the main types of views

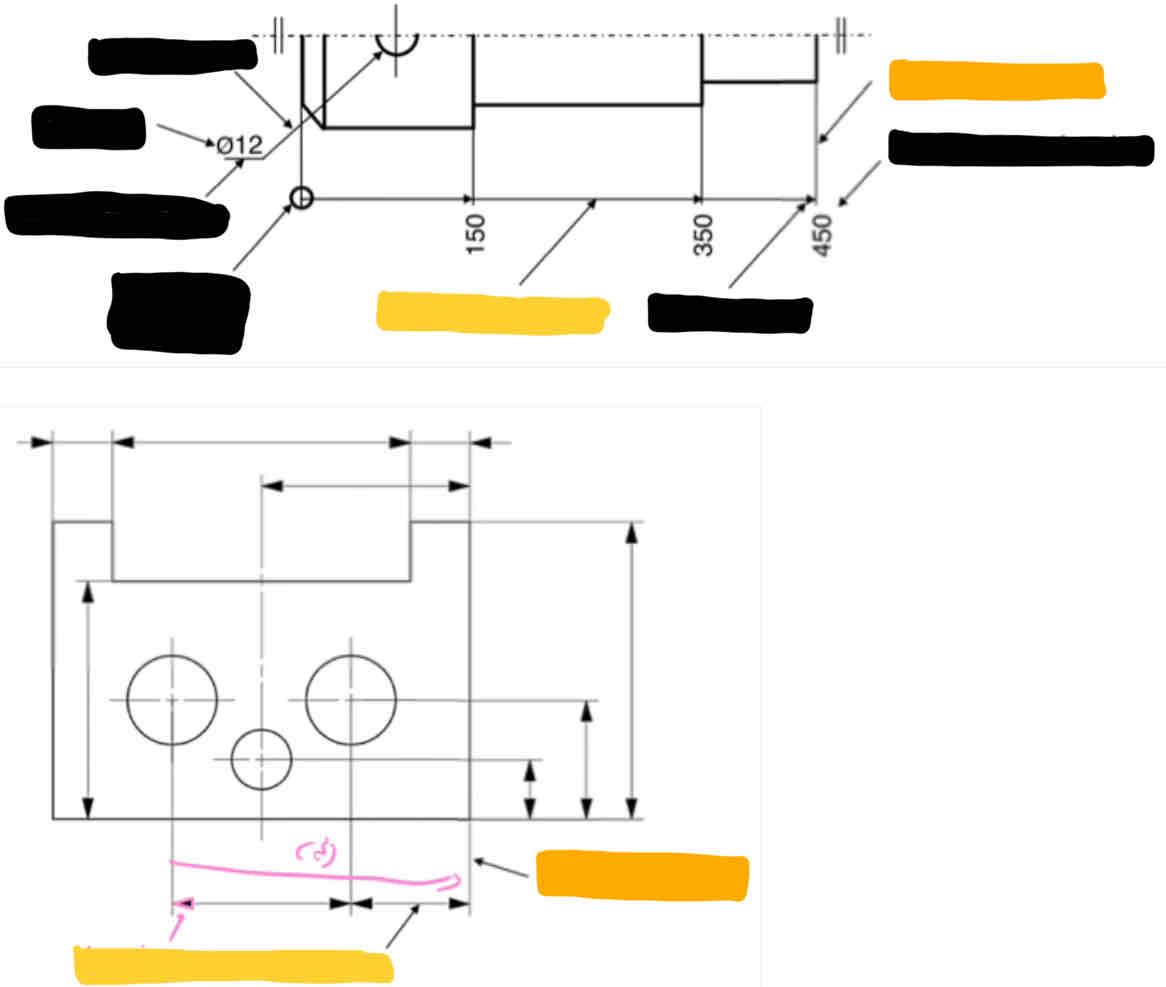

Over-/under-dimensioning

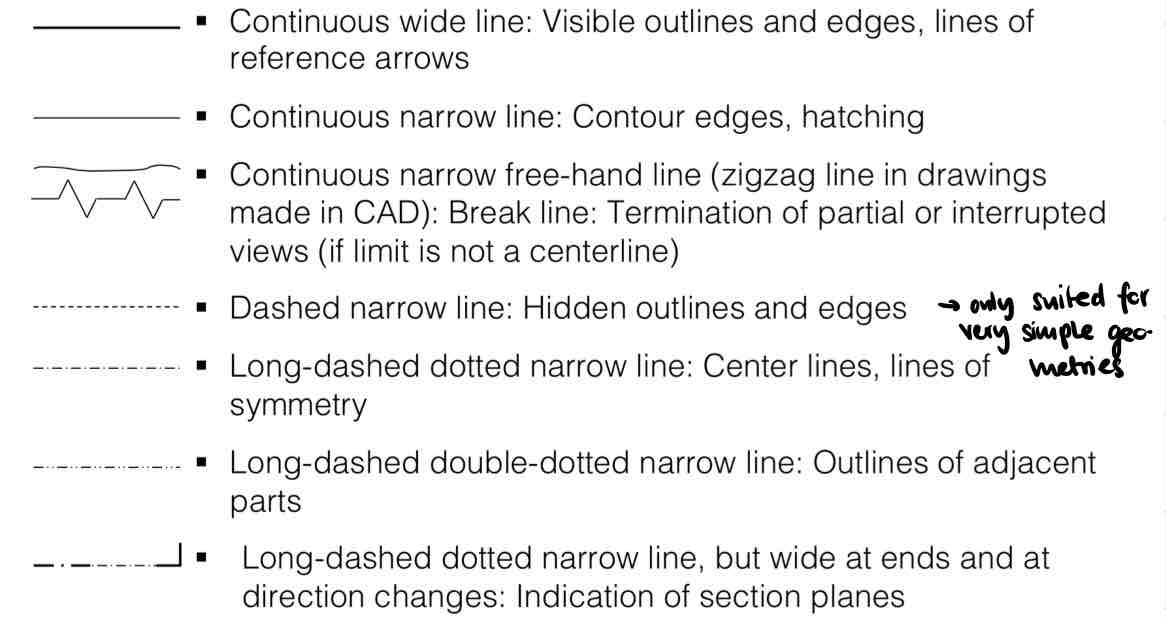

Name the line types:

Name the 5 steps in the technical drawing process:

Chose the principle view

Chose other required views and cuts

Draw views and cuts

Add dimensions

Verify

Arranging Views - first vs third angle projection method:

Important to look out for when choosing projected views

Most informative view is used as the principle view

All details have to be shown in a technical drawing

The object has to be presented without ambiguity

Number of views should be limited to the minimum necessary

By reasonable choice of views

By using partial and special views

Unnecessary repetition of details should be avoided

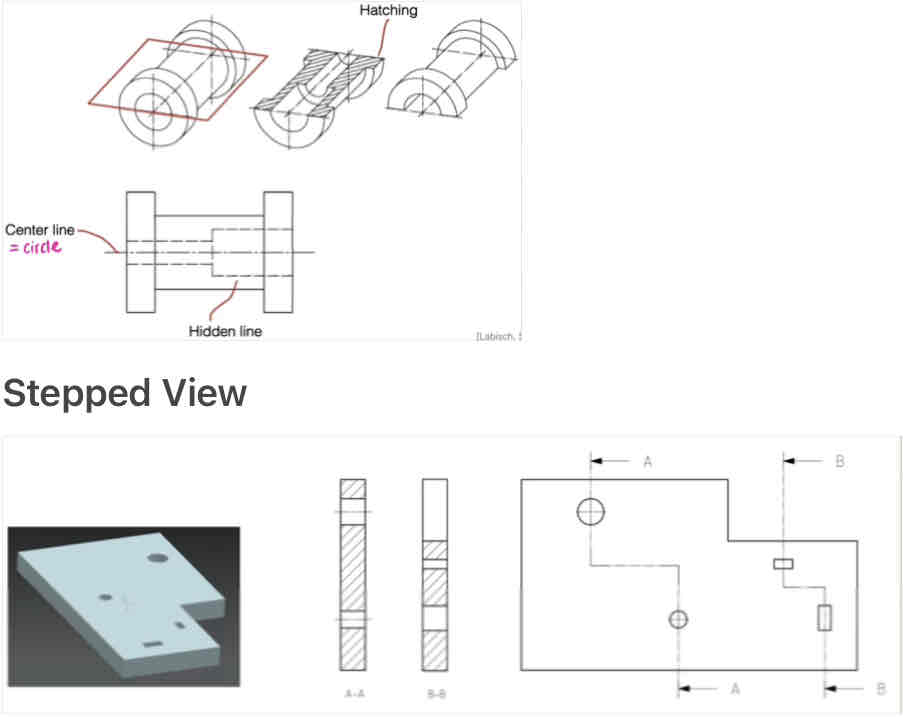

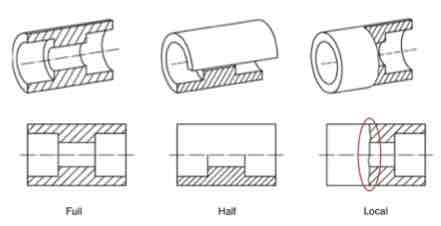

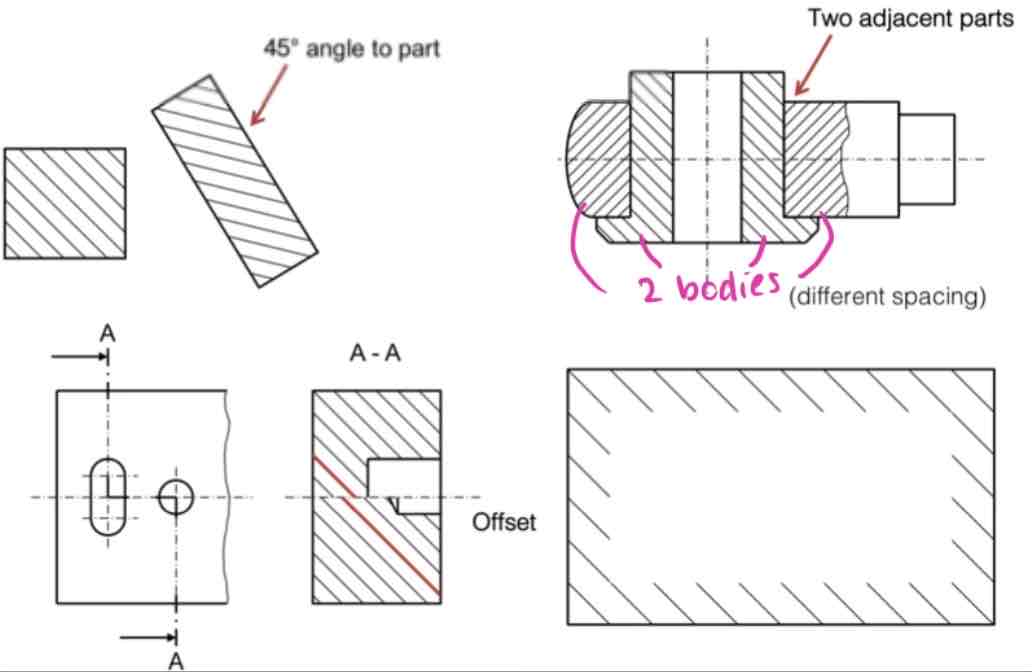

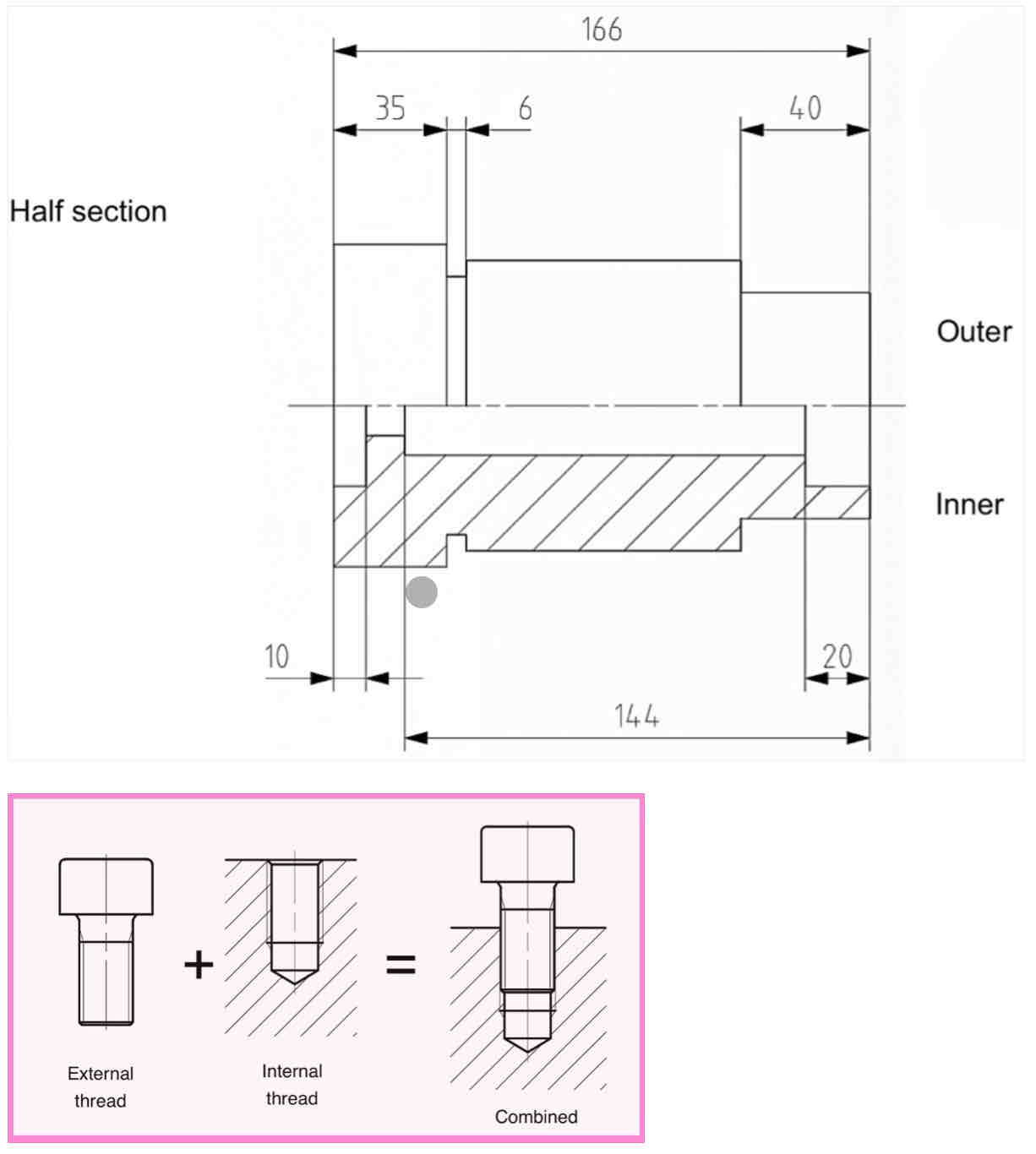

Cuts and sections including stepped view:

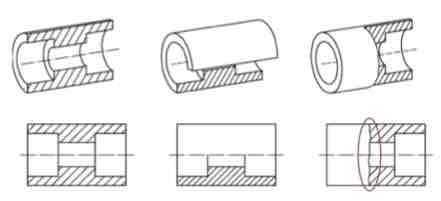

Name the three types of sections:

What are the three possible cut choices?

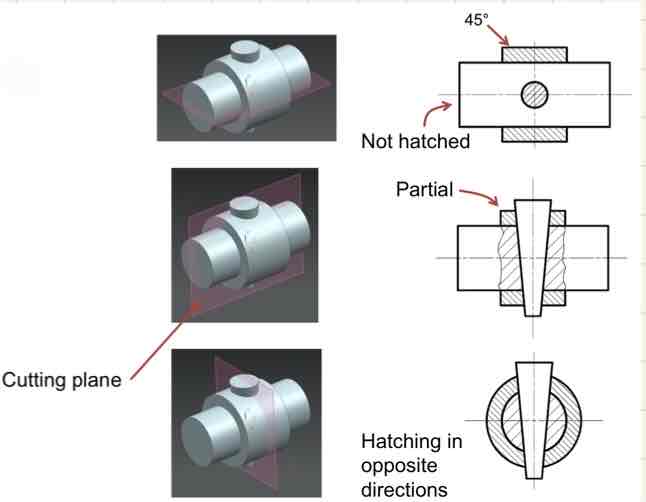

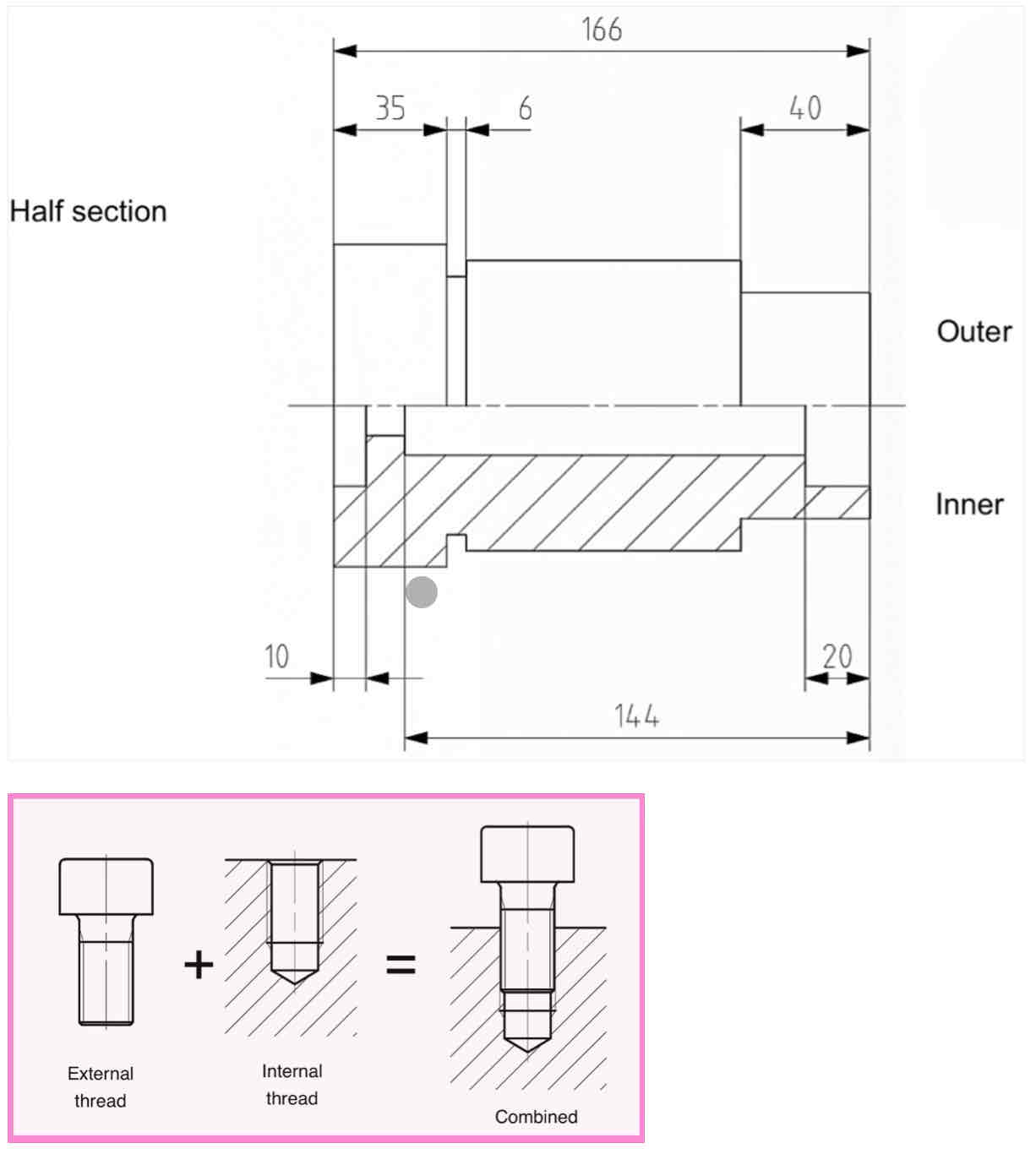

What is hatching? What does it look like?

Hatching: Using parallel lines to show the shape / direction / orientation of an object.

It can also help to differentiate different parts or materials of an object, as well as emphasize edges or contours.

Tips for cuts and sections:

Cuts and sections allow insights into parts and assemblies to illustrate hidden geometries

Cuts and sections have to be drawn and annoyed unambiguously

Cute are almost always needed when there are holes in parts

To avoid complex cuts, local sections can be used

Checklist to verify technical drawings: three questions:

Is principal view most informative view?

Are there sufficient views to fully define the geometry?

Are the smaller details clearly visible?

Projections and cuts - Wrap-Up:

What are elements of dimensioning? And what do we dimension for?

We dimension for:

Function

Manufacturing

Inspection

6 steps of the dimensioning process:

Define outside dimensions

Define functional dimensions

Add required manufacturing dimensions

Add any dimensions for inspection

Add auxiliary dimensions

Verify the dimensioning

What are functional dimensions?

Functional dimensions define the shape, size and location of features that are relevant for the function of a part when assembled (into a final product). Whether a dimension is functional or not depends on the engineering context of the part. If a part is used in a different way, different dimensions may become functional

What are non-functional dimensions?

Non-functional dimensions define the form, size and position of other features, which are not important for the function of a part (when assembled into a final product). They are to be selected and indicated as most suitable for manufacturing and inspection.

What are auxiliary dimensions?

Auxiliary dimensions are just for information and serve to avoid calculations. They supplement functional and non-functional dimensions. They are added in parenthesis. They cannot have tolerances associated to them.

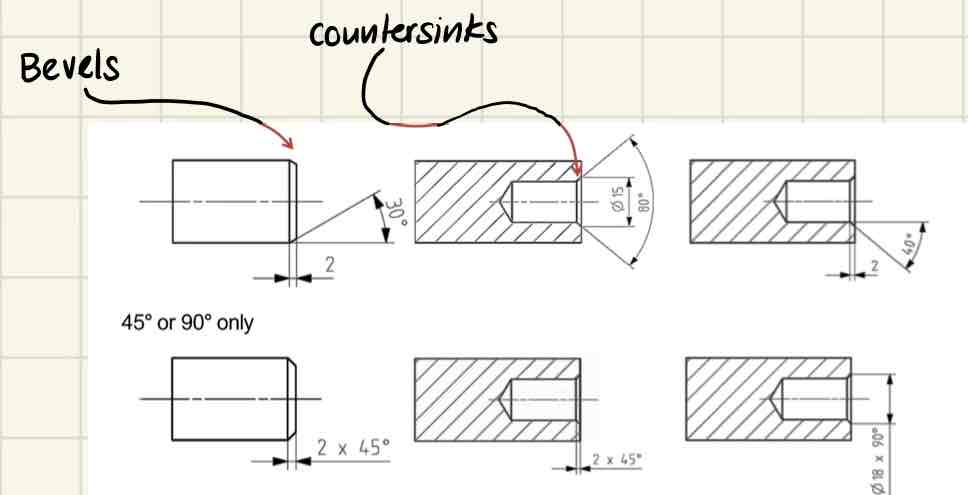

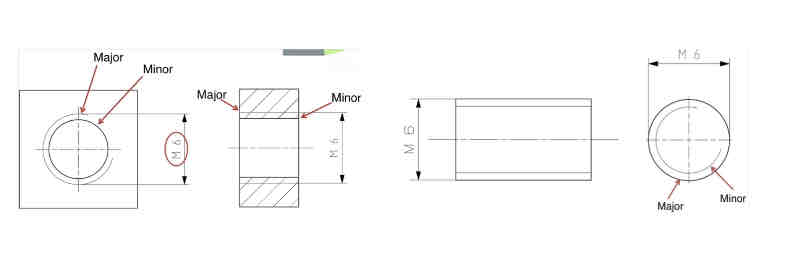

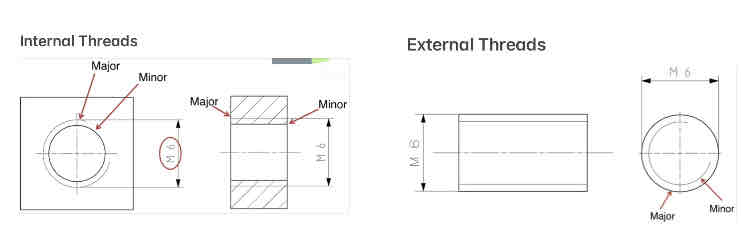

Dimensioning of special elements (Name two)

You have to put angle and linear dimensions for bevels / countersinks.

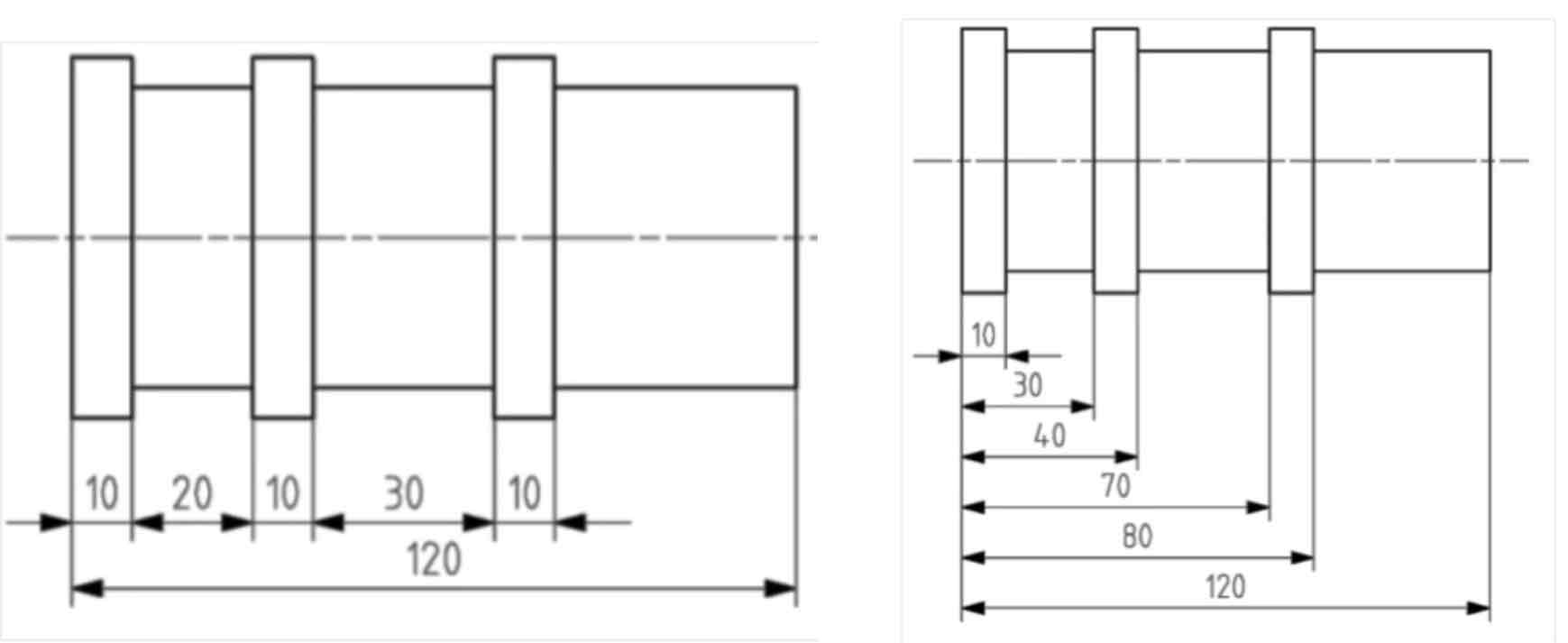

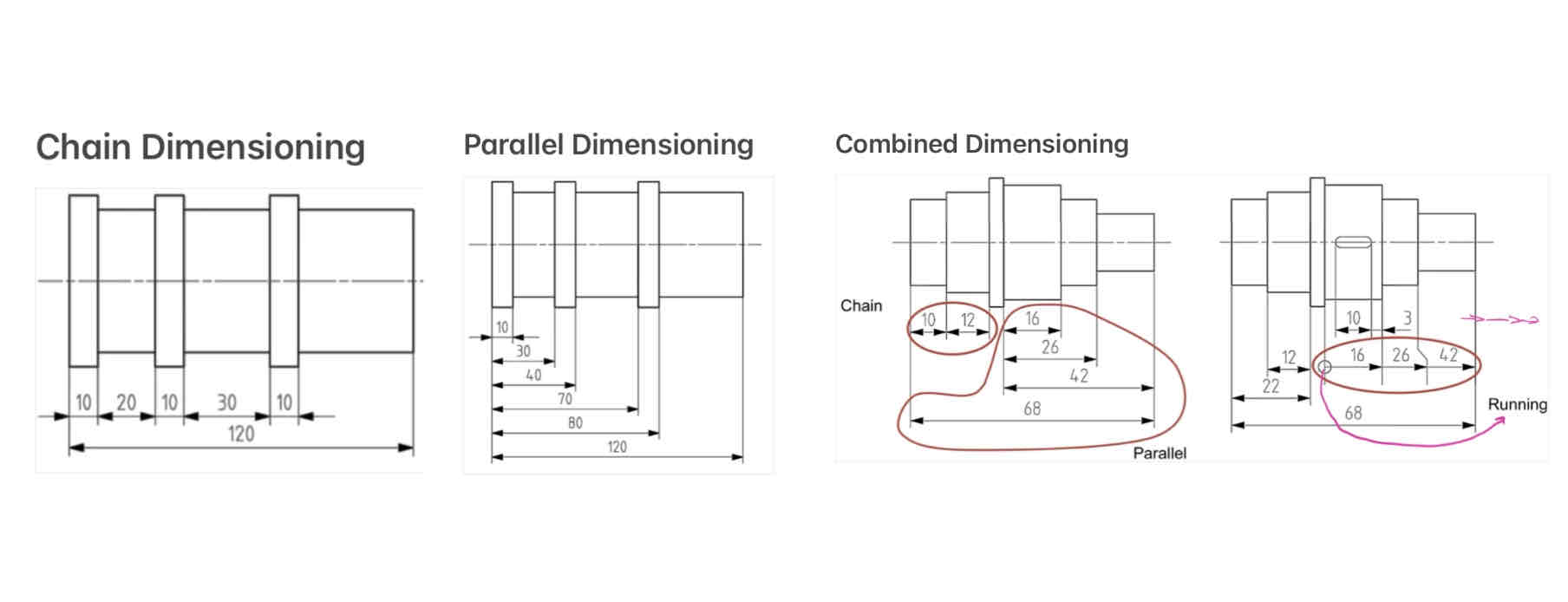

Name the two arrangements of dimensions:

Arrangement of dimensions - what is pictured here:

Arrangement of dimensions - what is pictured here:

Internal / External Dimensions:

Dimensioning - Wrap-Up: