Operations Management and Supply Chain Fundamentals

1/136

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

137 Terms

Operations management

science and art of ensuring that goods and services are created and delivered successfully to customers.

Supply chain management

a vital component of operations management, managing the flow and distribution of goods and services, information, and finances from their points of origin to their points of consumption.

Core of operations management

efficiency, cost, and quality.

Efficiency

measure of how well resources are used in the creation of outputs.

Cost

the cost of operations.

Quality

the quality of goods and services that create customer satisfaction.

Industry 4.0/4th Industrial Revolution

the information-intensive transformation of manufacturing in a connected environment of big data, people, processes, services, systems, and IoT enabled industrial assets.

Service 4.0

applying digitalisation to services that create higher productivity, innovation, and value chain advantages in service industries.

Good

a physical product that you can see, touch, or possibly consume.

Durable good

last longer than 3 years.

Non-durable good

no longer useful once it is used or lasts less than three years.

Service

any primary or complementary activity that does not directly produce a physical product.

Service encounter

an interaction between the customer and the service provider.

Moments of truth

any customer contact with any aspect of the delivery system and therefore has an opportunity to form an impression.

Service management

integrates marketing, human resources, and operations functions to plan, create and deliver goods and services and their associated service encounters.

Value

the perceived benefit associated with a good, service or bundle of goods and services in relation to what buyers are willing to pay for them.

Value formula

Value = perceived benefits/price to the customer.

Customer benefit package (CBP)

a clearly defined set of tangible and intangible features that the customer recognises, pays for, and uses or experiences.

Primary good or service

the 'core' offering that attracts the customers and responds to their basic needs.

Peripheral goods and services

offerings that are not essential to the primary good or service but enhance it.

Variant

a location or firm specific CBP attribute that departs from the standard CBP.

Value Chain

network of facilities and processes that describes the flow of materials, finished goods, services, information and financial transactions from suppliers, through to the facilities and process that create goods and services, and those that deliver them to the customer.

Supply chain

the portion of the value chain that focuses on the physical movement of goods and materials and supporting flows of information and financial transactions through the supply, production and distribution processes.

Process

a sequence of activities that is intended to create a certain result.

Value Creation Process

Focused on producing or delivering an organisations primary goods or services that create value for customers.

Value Chain Frameworks

Input-Output: begins with suppliers who provide inputs to a goods or service providing process, inputs are transformed into goods and services through core processes, the goods and services/outputs are provided to customers/market segments.

Pre- and Postproduction services framework

Complete the ownership cycle or the good or service.

Preproduction

Focused on gaining a customer.

Postproduction

Focused on keeping a customer.

Supply-Chain Structure

Hierarchical arrangement of suppliers, manufacturers, distributors, retailers, and customers.

Inventory

Refers to the raw materials, work in progress, or finished goods that are maintained to support production or satisfy customer demand.

Sustainability

Refers to an organisations ability to strategically address current business needs and successfully develop a long term strategy that embraces opportunities and manages risk for all products, systems, supply chains and processes to preserve resources for future generations.

Environmental sustainability

Commitment to the long term quality of our environment.

Social sustainability

Commitment to maintain healthy communities and a society that improves the quality of life.

Economic sustainability

Commitment to address current business needs and economic vitality and to have the agility and strategic management to prepare successfully for future business, markets and operating environments.

Triple bottom line

These three aspects of sustainability: environmental, social, and economic.

Analytics

Leveraging data to create competitive advantage.

Business analytics

Process of transforming data into actions through analysis and insights in the context of organisational decision making and problem solving.

Big Data

Massive amounts of business data from a wide variety of sources, much of which must be available in real time.

Measurement

The act of quantifying the performance of organizational units, goods and services, processes, people and other business activities.

Customer satisfaction measurement system

Provides customer ratings of specific goods and service features. Indicates the relationship between customer ratings and a consumer's likely future buying behaviour.

Quality

Measure the degree to which the output of a process meets customer requirements.

Goods quality

The physical performance and characteristics of a good.

Service quality

External focus: consistently meeting/exceeding customer expectations, internal focus, a service delivery system performance.

Service upsets/failures

Errors in service creation and delivery.

Processing time

Time it takes to perform a task.

Queue/wait time

The time spent waiting.

Variability

Variance around average time.

Flexibility

The ability to change easily.

Goods and service flexibility

The ability to develop a wide range of customised goods and services to meet different or changing customer needs.

Volume flexibility

The ability to respond to changes in volume and type of demand.

Process flexibility

The ability to manufacture different types of products in the same plant or production facility simultaneously.

Agility

The ability to change quickly.

Resilience

The ability to anticipate, prepare for, and recover from disruptions and to protect and enhance all aspects of operations.

Innovation

The ability to create new and unique goods and services that delight customers and create a competitive advantage.

Learning

Creating, acquiring, and transferring knowledge, and modifying behaviour of employees in response to internal and external changes.

Productivity

The ratio of the output of a process to the input.

Operational efficiency

The ability to provide goods and services to customers with minimum waste and maximum utilisation of resources.

Sustainability

The triple bottom line is a measurement of sustainability related to environmental, social, and economic factors.

Analytics

Help managers analyse data effectively and make better decisions.

Statistics

Can be used to gauge production and quality performance to determine process and design improvement.

Descriptive statistics

Refers to methods of describing and summarising data using tubular, visual, and quantitative techniques.

Interlinking

The quantitative modelling of cause-and-effect relationships between external and internal performance criteria, helps to quantify performance relationships between all parts of a value chain.

Value of a Loyal customer (VLC)

Quantifies the total revenue or profit each target market customer generates over a buyer's life cycle.

VLC formula

VLC=PxCMxRFxBLC, when P=revenue per unit, CM = contribution margin, RF = repurchase frequency per year and BLC = buyer life cycle (1/defection rate).

Total market value

Can be found by multiplying the VLC by the absolute number of customers gained or lost.

Good performance measures

Are actionable, providing the basis for decisions at the level at which they are applied.

Models of Organisational Performance

Provide a framework for thinking about, designing, monitoring, and evaluating performance in operations management.

Baldridge performance excellence framework

Helps understand an organisation's strengths and weaknesses through self-assessment of quality, productivity, and overall competitiveness and encourages developing high performance management practices.

Balanced Scorecard Model

Translates strategies into measures that uniquely communicate an organisation's vision.

Internal

Focuses on the performance of key internal processes.

Innovation and Learning

Emphasises people and infrastructure.

Value Chain Model

Evaluates performance throughout the value chain by identifying measures associated with suppliers, inputs, value creation process, goods and service outputs and outcomes, customer and market segments, supporting and general management processes.

Service-profit chain model

Based on a set of cause-and-effect linkages between internal and external performance, helps define key performance measurements on which service-based firms should focus.

Strategy

A pattern or plan that integrates an organisation's major goals, policies, and action sequences into a cohesive whole.

Competitive Advantage

A firm's ability to achieve market and financial superiority over its competitors, requires management to understand customer needs and expectations and build and leverage operational capabilities to support desired competitive priorities.

Order qualifiers

Basic customer expectations that are considered the minimum performance level required to stay in business.

Order winners

Goods and service features and performance characteristics that differentiate one CBP from another and help win the customers' business.

Evaluating goods and services

Customers use three types of attributes in evaluating the quality of goods and services.

Search attributes

What a customer can determine before purchasing the goods and/or services, e.g. colour, price, freshness, style, fit, feel, hardness and smell.

Experience attributes

After purchase or during consumption or use e.g. friendliness, taste, wearability, safety, fun and customer satisfaction.

Credence attributes

Aspects of a good or service that the customer believes but cannot personally evaluate even after purchase and consumption, e.g. expertise and knowledge of professionals.

Goods-services continuum model

Suggests that goods are easier to evaluate than services.

Competitive priorities

The strategic emphasis that a firm places on certain performance measures and operational capabilities within a value chain.

Flexibility

Mass customisation, being able to make whatever goods and services the customer wants, at any volume, at any time for anybody.

Innovation

The discovery and practical application or commercialisation of a device, method or idea that differs from the norm.

Strategic Planning

The process of determining long term goals, policies and plans for an organisation.

Core competencies

The strengths that are unique to an organisation.

Three levels of strategy

Corporate, Business and Functional strategy (operations strategy is included in this).

Operations strategy

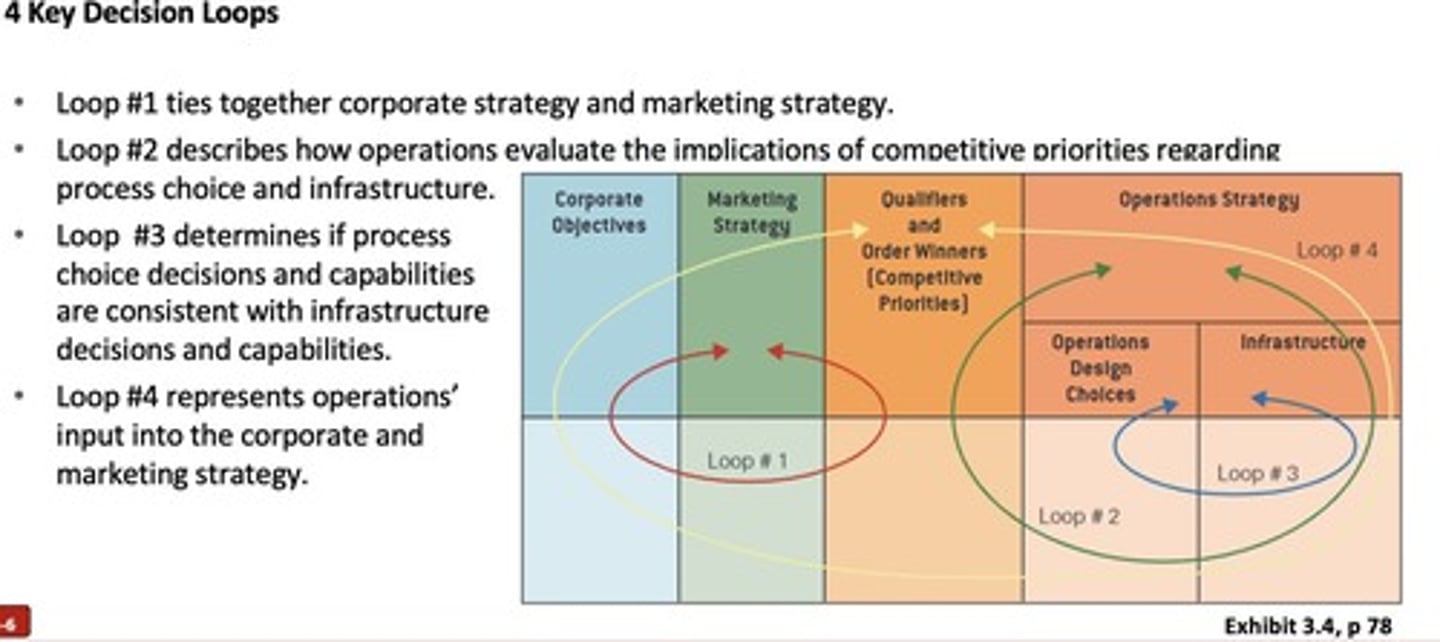

The set of business decisions across the value chain that supports the implementation of higher-level business strategies.

Operations design choices

Decisions made to determine the process structures that are best suited for producing goods or creating services, addressing six key areas.

Infrastructure

Focuses on non-process features and the capabilities of an organisation such as workforce, quality control, organisational structure, support services, compensation systems, operating plans and control systems, and learning and innovation systems.

IoT (Internet of Things)

Refers to physical products with embedded sensors that are connected to the internet, changing the way we live and business operates.

Implications of IoT

Need to select the right technology for the goods that are produced and the services that are offered; processes must be set up and configured in a logical fashion; labour must be trained to operate equipment.

Hard Technology

Equipment and devices that perform a variety of tasks in the creation and delivery of goods and services.

Soft Technology

Application of the internet, computer software, and information systems to provide data, information, analysis, and facilitate the accomplishment of creating and delivering goods and services.

CIMSs (Computer-integrated manufacturing systems)

Represent the union of hardware, software, database management, and communications to automate and control production activities.

CNC (Computer Numerical Control) machines

NC machines whose operations are driven by a computer.

CAD/CAE

Enables engineers to design, analyse, test, simulate, and 'manufacture' products before they physically exist, ensuring that a product can be manufactured to specifications when released to the shop floor.

CAM

Involves computer control of the manufacturing process.