DEFECTS IN CRYSTAL STRUCTURE - BME 296 EXAM 1

1/37

Earn XP

Description and Tags

lectures 3-5

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

38 Terms

defects in crystal structures:

near perfect crystal is difficult to achieve under normal conditions

can either be detrimental or beneficial to physical and mechanical properties of the material

defects often named according to number of dimensions affected by the imperfection

kinds of defects and the dimensions

point defect - 0D

line defect - 1D

planar defect - 2D

volume defect - 3D

why do point defects form

occur due to thermodynamics of crystal growth

during solidification process, vacancy could form due to vibrations

“shake off” atoms from position

creation of defects increases entropy of the system and is therefore favorable

what are the types of point defects: (3)

vacancies, self-interstitials, and impurities

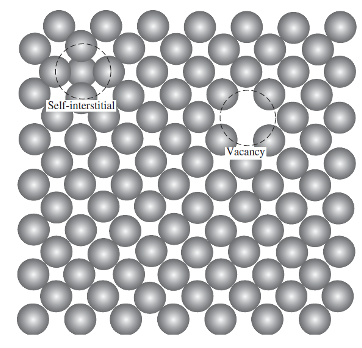

vacancy point defect:

a space where an atom would normally be present but is currently missing in a lattice

Defects are favorable yet produce strain on lattice

Higher temperature more vacancies

self-interstitial point defect:

occurs when an atom from the crystal is crowded into the interstitial space between two adjacent atoms, occupying a space that would otherwise be empty

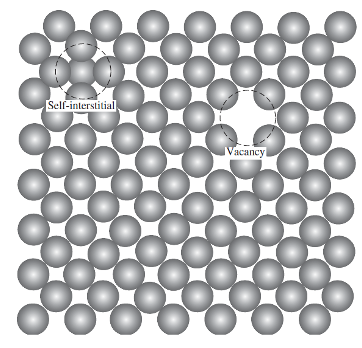

equation for number of vacancies:

Nv=number of vacancies

N= number of atomic sites

Q_v = Energy required to form vacancy (Activation energy)

k= Boltzmann's constant (1.38X10-23J/atom-K)

T= absolute temperature

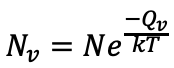

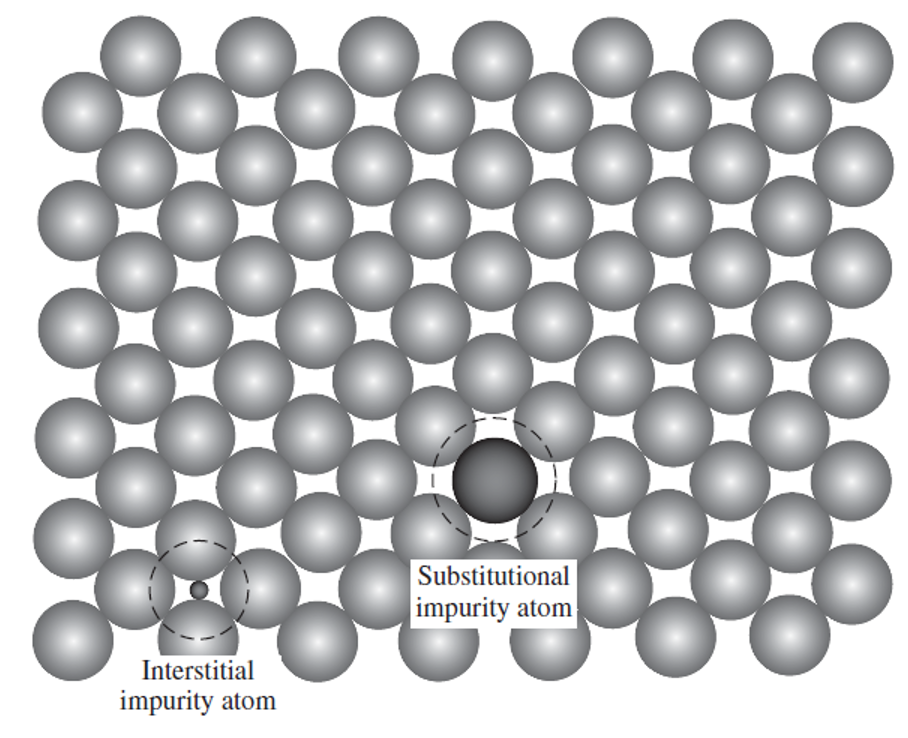

impurity

type of self interstitial defect

type of point defect since they affect the local lattice structure and induce a degree of lattice strain

could be an artifact of material processing or can be added deliberately to alter the final properties of the material

two types of impurities:

Host material =solvent, impurity =solute.

The solute atoms can either fill spaces between the solvent atoms (interstitial solution) or take the place of the solvent atoms (substitutional solution)

more on impurities:

Not always possible to predict when interstitial or substitutional solutions will be formed

Interstitial solutions occur when the solute atom is smaller than the solvent, placement in the interstitial spaces without extreme lattice strain.

In alloys, the impurity atom has been added in a particular concentration to improve properties of the host material.

Alloys used to increase strength, impart corrosion resistance ,or improve electrical properties of a pure metal.

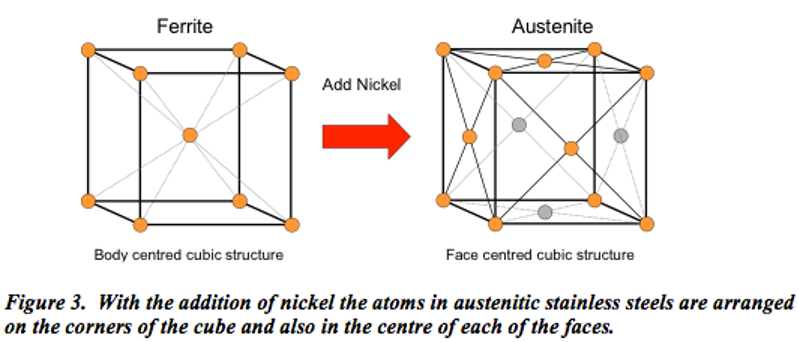

Common interstitial solid solution alloys include steels (alloys of carbon and iron), which form the basis of stainless-steel orthopedic implants.

how are metals manufactured?

molten metal is first cooled, followed by shaping or pouring into a mold for shaping

each of these steps matter as they determine mechanical properties of the material

formation of crystals occurs in all axes simultaneously when allowed to freely cool

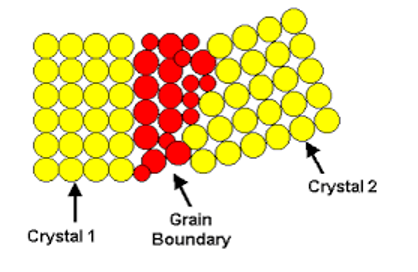

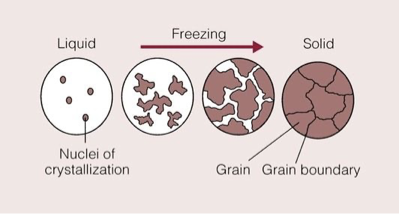

process of crystal formation and grain boundary:

First nucleation occurs where single unit cell is formed

New unit cells attach to existing unit cell in growth phase

As crystals meet grain boundaries are formed

As crystals are forming unit cells will usually align in patterns

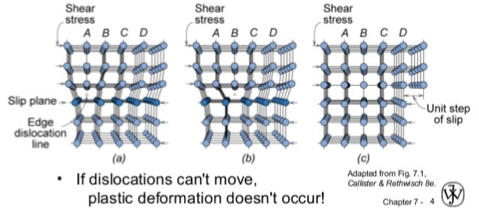

what is a line defect also known as

edge dislocation

why do line defects occur?

when an extra portion of a plane of atoms (half-plane) terminates in a crystal

the defect is the line that defines the end of the extra half-plane, called the dislocation line

occurs due to accidents in the crystal growth process, internal stresses from other defects in the crystal

Two important characteristics of dislocations are the magnitude and direction of atomic displacement

difference between point defect and line defect/edge dislocation?

point - at or around a single point of the crystal lattice

line - plane of an atom

how do line dislocations affect properties?

plastic deformation occurs by slip where an edge dislocation slides over adjacent plane of half-line atoms

line defects increase what?

PLASTICITY

energy around atoms

Atoms at the surface of a material are not bonded to the maximum possible number of nearest neighbors, so they possess higher energy than those atoms located inside a crystal

This extra energy is called the surface free energy or surface tension on and is expressed in units of energy per unit area

The existence of these sites with higher energy is thermodynamically unstable, and the need to minimize surface energy leads to chemical reactions at the surface

what do planar defects create?

grain boundaries

grain boundaries in planar defects

Most metals and ceramics are polycrystalline

The interface between these grains is called the grain boundary.

Grain boundary atoms are in a higher energy state than comparable atoms in the center of the grain.

This leads to higher chemical reactivity in these regions.

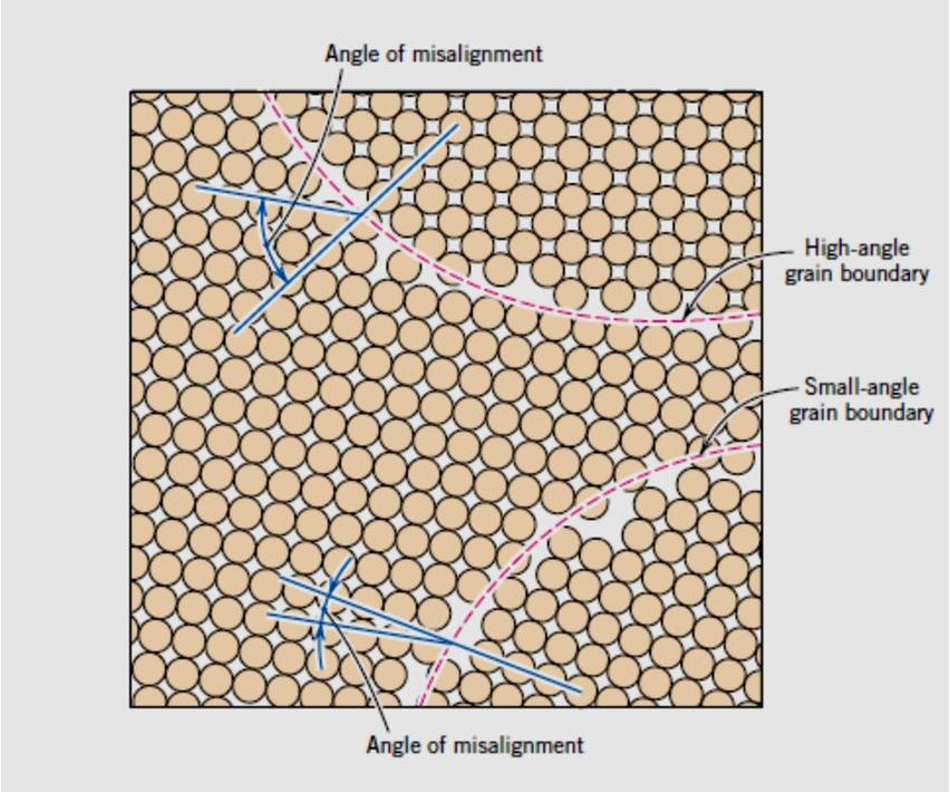

grain boundaries

There are two types of grain boundaries that can be distinguished via microscopic observation.

If the grains on either side of the boundary have similar orientations (only a few degrees different), this is a small-angle grain boundary

Grains with more severe misalignment form high-angle grain boundaries.

The greater the degree of misorientation, the higher the energy of the boundary.

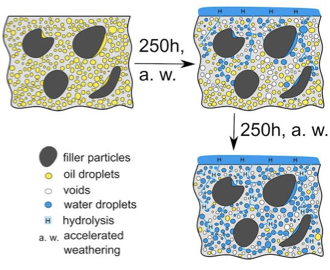

volume defects

Volume defects are three-dimensional regions in which the long-range order of the crystal is lost.

Examples of volume defects include precipitates and voids.

Precipitates are clusters of substitutional or interstitial impurities, while voids are three-dimensional aggregates of vacancies

Voids important in biomaterials, it is possible to create void space (pores) in a controlled manner to alter the biological response to the material.

diffusion

Solid state diffusion as it takes place in solid materials

High concentration to low concentration

Impurity diffusion

Self diffusion

Requirements for diffusion:

Vacant space

Energy to break bonds with neighboring atoms (from atomic vibrations when temperature of material is more than 1K; low temp.. low vibration.. may not break bonds)

Increase temp increase rate of diffusion

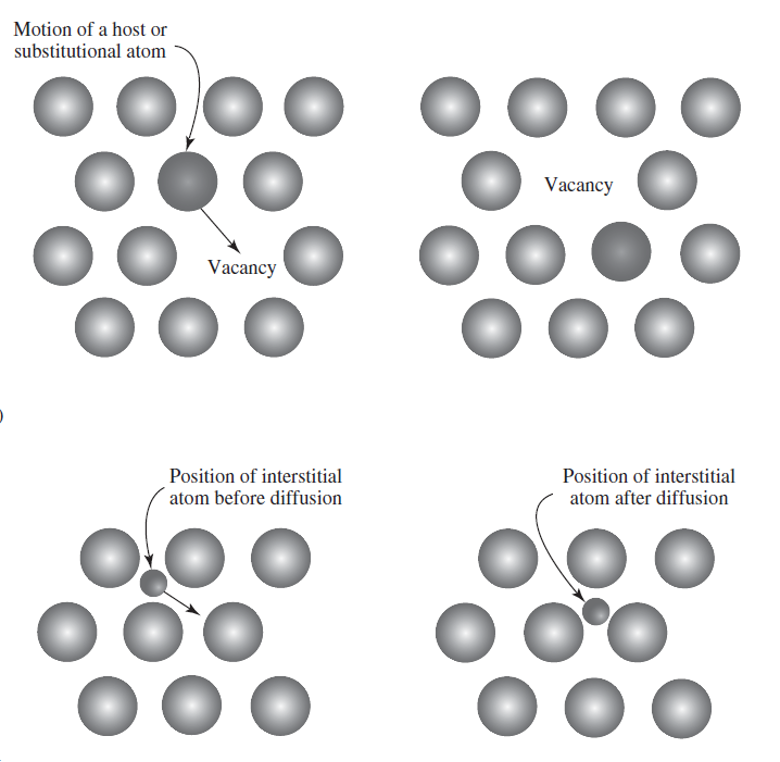

diffusion mechanisms

Two main types of diffusion occur in metals- vacancy and interstitial diffusion.

Vacancy: Atom jumps to an adjacent vacancy, thereby exchanging the location of the atom and the vacancy

the direction of atomic diffusion is opposite to that of vacancy diffusion.

Interstitial diffusion: an atom migrates from one interstitial position to a neighboring position

This usually occurs only with small atoms such as hydrogen, carbon, nitrogen and oxygen that can easily fit into the interstitial spaces.

Because of the small size of the diffusing species and their increased mobility, interstitial diffusion generally occurs more rapidly than vacancy diffusion.

how can we make metals stronger despite dislocations?

strain hardening and annealing

strain hardening

Ductile materials are deformed below their melting point causing an increase in number of dislocations (increased density)

distance between dislocations is reduced and this blocks motion

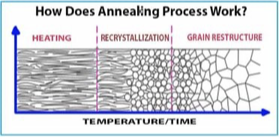

annealing

Increase temperature causing increased diffusion which causes dislocations to start moving

relieves strain energy thereby reducing dislocations

ceramics

two or more elements

can have ionic or covalent bonds (mainly ionic i think)

more ions than atoms

properties of ions

cations must be next to anions; maximize number of nearest neighbors that are anions

anions and cations must contact each other for a stable structure

what are cations and anions?

cation has positive charge, anion has negative charge

what are the sizes of cations and anions and why are they different?

cations are smaller because loss of electron will cause the positively charged nucleus to have greater attraction to remaining electrons.

anions have large electron cloud which will repel each other and less attractive force between positively charged nucleus and electron cloud.

crystal structure in ceramics

affected by two parameters:

The magnitude of the electrical charge on the constituent ions (important to keep crystal electrically neutral)

The physical size of these ions (need to know radii of both anion and cation) (Rc/Ra must be <1)

Crystal structures in ceramics exist in such a way that they satisfy charges (neutral) and size where (Rc/Ra<1)

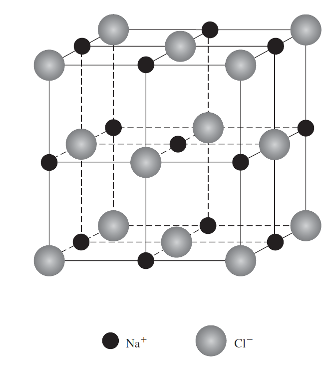

AX crystal structures

Both the cation and anion have the same charge, an equal number of each is required for a stable crystal structure.

A representing the cation and X representing the anion.

Example: Sodium chloride

AmXp crystal structures

Cations and anions that do not have equal charges, leading to compounds with the formula AmXp where m and/or p≠1

Example: Zirconia, ZrO2

Ceramics can also have more than one type of cation leading to AmBnXp

Such combinations are mostly found in materials for biomedical applications since we add several different elements to improve properties.

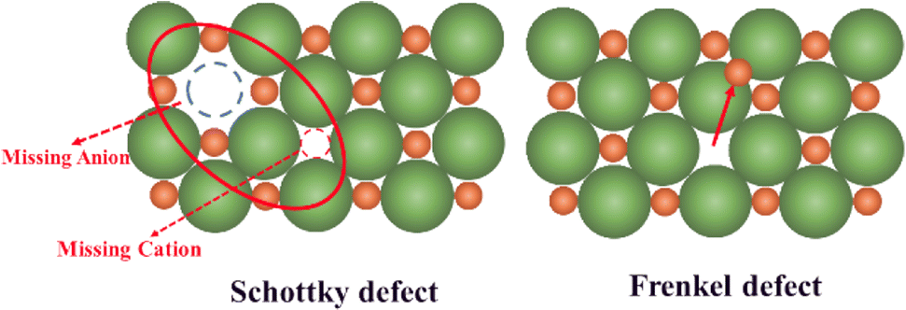

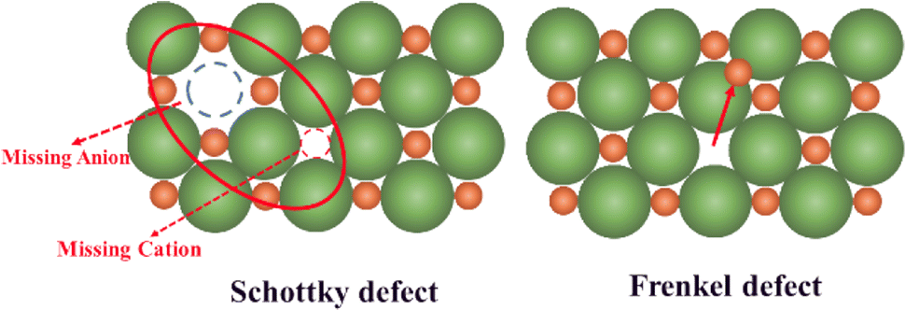

point defects is crystal structures - ceramics

Both interstitial and vacancy point defects can occur for either the cation or anion.

Defect should not affect the electroneutrality of the material.

individual point defects do not occur since that would leave the crystal with a net charge

Group defects occur so neutrality can be maintained.

Example of a group defect is Schottky defect and Frenkel defect.

Schottky defect

vacancies in both cations and anions in the correct ratio to maintain neutrality

Frenkel defect

a vacancy/interstitial pair is created to maintain electroneutrality

only occurs with cations, since anions are too large to reside in the interstitial space of the crystal without a significant amount of lattice strain.

REVIEW SLIDE

Metals

Metallic bonds

APF, miller indices

Line deformation- plasticity

Small angle, large angle grain boundary

Usually orthopedic implants

Ceramics

Ionic bonds, electroneutrality most important

Brittle- no plasticity due to ionic bonds

Dentistry, coating for orthopedic implants